Professional Documents

Culture Documents

Equalization Tank

Uploaded by

nataliepoison8917Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equalization Tank

Uploaded by

nataliepoison8917Copyright:

Available Formats

Design Information

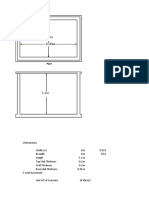

Length b 7 m 23.0 ft

Breadth c 7 m 23.0 ft

Depth a 5.5 m 18.0 ft

Volume 269.5 m3 9517.2 ft3

d 18.0 in

Weight of water 1000 kg/m3 62.4 lb/ft3

Weigth of moist soil 15.71 kN/m3 100.0 lb/ft3

fc 4000.0 psi

60000.0 psi

Wall thickness 18.0 in

Water pressure 624.3 lb/ft

Ratio

b/a 1.27 1.25

c/a 1.27 1.25

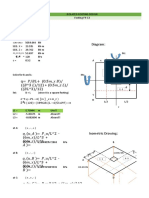

Design for shear forces

For b/a

Bottom edge - midpoint 0.36

Side Edge - maximum 0.25

Side edge - midpoint 0.25

For b/a = 1.25

Bottom edge - midpoint 0.36

Side Edge - maximum 0.25

Side edge - midpoint 0.25

Check shear at the bottom of the wall

Maximum shear coeffiecents, Cs 0.36 long wall

Maximum shear coeffiecents, Cs 0.36 short wall

1. Check shear at bottom of the wall

Shear force, V

V 4055.3 lbs

Vu 6894.1 lbs

d 15.7 in

Vc 23830.9 lbs

fVc 20256.3 lbs

If fVc > Vu OK

2. Check shear at side edge of long wall

V 2816.2 lbs

Vu 4787.6 lbs

Shear in short side wall:

V 2816.2 lbs

Nu -4787.6 lbs

Ag 216.0 in1

Vc 22774.5 lbs

fVc 19358.3 lbs

If fVc > Vu OK

Design for vertical bending moments(determine vertical steel

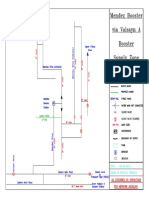

DESIGN OF EQUALIZATION BASIN

Exposure Conditions

BS 8110 Severe exposure

BS 8007 Design crack width 0.2 mm

Material

Concrete grade 35 A Concrete strength: 35.00 N/mm

2

Steel grade 460

Table 2.3 Characteristic yield proof stress, fy 460 N/mm

2

pg 18 Partial factor of safety

Materials

Concrete 1.5

Steel 1.15

Loads

Water 1.4

Soil 1.4

Calculations Reference Output

Calculations Reference Output

LIMIT STATE DESIGN

Cantilever Wall

Consider 1m length of wall

Design a cantilever wall to withstand water pressure

Height H 5.5 m

Normal Height of water 5 m

Water Wg 10 kN/m3

Partical safety factors:-

Table 21 Service limit state, g

f

1.4

Ultimate limit state, g

f

1

Service moment at roote of cantilever 208.3 kNm/m

Ultimate moment, M 388.2 kNm/m

From design charts the estimated root thickess

h 700 mm

Table 3.1 T 20 100 bar spacing (mm) 1625.00

Table A.2.12 Limiting moment Ms 396.1 kNm

Service steel stress fs 222 N/mm2

Ultimate shear capcity 363 kN/m

For Ms 388.2083 ,fs 217.6 N/m2

Ok

Using the values obtained from the design tables a check on the

accuracy of the orignal assumption must be now made.

cover 40

T

T 16

distribution steel

Calculations Reference Output

Cover, c 40 mm

R1 16 mm

R2 20 mm

Effective depth,d 650 mm

Table 2 M/bd2 0.92

BS 8110 -3 100As/bd 0.25

As 1625.00 mm2

Ultimate limit state

For ulitmate limit state, recall M 388.21 kNm/m

The Ultimate moment of resistance based on the steel is given by

Maximum, Mu 2321.638 kNm/m Satisfactory

If the Design Ultimate moment < Maximum Ultimate Moment

then it is satisfactory

The ultimate moment of resistance based on the steel is given by:

Depth of neutral axis,x

pg 43

Eq 7

x= = 0.06705 d 43.6 mm

Where the lever arm , 0.97 d

But maximum value is 0.95d 630 mm

z

max

617.5 mm Use

Mu (ultimate moment of resistance) 401.6 kNm/m Satisfactory

This section is therefore satisfactory as the applied ulitmate momment

is less than the moment of resistance of the section

Ultimate shear force at root of wall, V

V 211.75 kN/m

BS8110

3.4.5.2 Therefore design shear stress,v = V/b

v

d 0.33

= 0.157

= 0.87

z

= 1 1 0.7

/0.9

= 0.45

= 0.95

Calculations Reference Output

0.25

Table 3.8 Design concrete shear stress,Vc (see Table 3.8) by interpolation

Effective

depth

0.25 0.40

0.25 vc

0.50 0.50

Gradient 0.4

vc 0.4 Statisfactory

This is satisfactory and no shear stee is necessary.

Note: As shear stress is satisfactory at the root of wall, it is not

necessary to consider the critical secion of a height 2d above root.

Limit State of Cracking

Service moment, M

s

208.3 kNm

Section Depth of neutral axis (elastic no-tension theory)

3.4

Table 3.4 Modular ratio, a

e

= E

s

/E

c

15

pg 40 Where Es - modulus of elasticity of concrete, Es modulus of elasticity of steel

0.0025

Therefore 0.0375

Depth of neutral axis is given by x/d 0.238917

And x = 155.30 mm

Lever arm z = d-x/3 598.2 mm

Moment of resistance of section

Therefore fs 214.3 N/mm2

100

1 +

2

Calculations Reference Output

BS 8007 Check steel and concrete service stress

App B fs 214.3057 N/mm2

B2 0.8fy 368 N/mm2

Fcb 2Ms/zbx 4.484945 N/mm2 fcb<0.45fu Ok Ok

0.4fcu 15.75 N/mm2 fs<0.8fy Ok Ok

Elastic strain at surface

Es 200 kN/mm

2

e

1

0.00118

e

2

0.000615

Average surface strain e

m

=e

1

-e

2

0.000565

Crack width w

Recall bar spacing,s 100 mm

c 56 mm

bar size,f 20 mm

Ca = cmin+f/2 66 mm

a

cr

72.80097 mm

Threrfore surface crack width,w 0.116165 mm 0.116165

Allowable w 0.2 mm Satisfactory

0.4

0.55 Cantilever wall

0.6

0.7

0.85

A 1 2.5

3.5

1

=

2

=

( )( )

3

( )

=

3

1 +2(

)

Calculations Reference Output

Wall Footing

Water pressure 10.00 h

Soil pressure 0.50 h

Surage

Roof load 0

Dead Load only

24 kN/m3

Case 1

Tank full

Taking moments about A

Restoring forces/ Moments about A

water 99 311.85

wall 92.4 117.81

Base 71.4 124.95

0.36 0.216

Soil 12.6 6.3

275.76 kN/m 561.126 kNm/m

Overturning Moment, 561.126 kNm/m

277.2917 kNm/m

283.8343

Factor safety against over turning 2.023595 Safe

Case2

Tank empty

Factor safety against over turning 2.251023 Safe

Footing reinforcment

Soil pressure under base

Calculate moment about centre line of base

Case1

Mc -198.746

Soil pressure 78.78857 +/- -81.1207

Soil pressure 159.9093 kN/m2

2.332109 kN/m2

Footing Reinforcement 55

Moment at root of toe -65.315 kN/m/m 17

114.8872

=

1

6

3

Calculations Reference Output

Moment root of heel 63.95095 kN/m/m 83.37178

By inspection not critical

Heel reinforcement

M 63.95095 kN/m/m

Mu 1.4xM 89.53133 kN/m/m

h 800

d 736

x1 0.026542

z = 1-0.45x 0.988056

But maxiumum value z is 0.95

Ast 228.5433 mm2

Calculations Reference Output

Tank Floor Slab

Assuming uniform ground conditions, the floor slab is uniformly loaded and has

no tranverse bending stresses.

To proivide a reasonable thickness of concrete, and allowing for possible

construction tolerances (crack tolerances)

Use 200 mm thick

Critical steel ratio r

crit

= f

ct

/f

y

Where:

f

ct

=Tensile stress in concrete

To proivde a resaonable thickness of concret and allowing for possible construction tolerance use slab 200 mm thick

rcrit = fct/fy 1.6/460 0.003478

Provie top reinforcment only based on a surface zone 100 mm

that is (one half of slab depth)

As = 0.35% x 100 x1000 347.8261 mm2/m

Use a welded mesh fabric with 10 mm wires in each direction at 200 mm

spacings (393)

Bottom zone does not require reinforcment

You might also like

- Design Report For 300m3 Rectangular ReservoirsDocument37 pagesDesign Report For 300m3 Rectangular ReservoirsARSENo ratings yet

- ReportTank 12.0m DiaDocument17 pagesReportTank 12.0m DiasuheilbugsNo ratings yet

- Slab DesignDocument12 pagesSlab Designkunjita dashoreNo ratings yet

- Conical Water TankDocument64 pagesConical Water TankRiyaz Siddique100% (1)

- 00 UEG C 51 301 001 (Rev.X0)Document28 pages00 UEG C 51 301 001 (Rev.X0)Amr AbdeinNo ratings yet

- Foundation Design: Exhaust StackDocument4 pagesFoundation Design: Exhaust StackHugoNo ratings yet

- Design of Circular Water TankDocument27 pagesDesign of Circular Water TankAbhay Thakur100% (1)

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Design of Foundation for Arch Bridge TransportDocument1 pageDesign of Foundation for Arch Bridge TransportvibishnanNo ratings yet

- Column Wall DesignDocument42 pagesColumn Wall DesignCivilax.comNo ratings yet

- VMS Gantry DesignDocument14 pagesVMS Gantry DesignNIRMAN INFRASTRUCTURESNo ratings yet

- Isolated Footing DesignDocument15 pagesIsolated Footing DesignAzzirrenNo ratings yet

- One Way Slabs11Document12 pagesOne Way Slabs11Hemant SonawadekarNo ratings yet

- Oht Rough DraftDocument49 pagesOht Rough Draftepe civil1No ratings yet

- Design of Propped Cantilever Retaining WallDocument3 pagesDesign of Propped Cantilever Retaining WallkkgcNo ratings yet

- Burial Tank FoundationDocument90 pagesBurial Tank FoundationjatinNo ratings yet

- AnchorboltsDocument2 pagesAnchorboltsrammohanNo ratings yet

- Design of wall footing with axial load and bending momentDocument7 pagesDesign of wall footing with axial load and bending momentKramyer100% (1)

- Chequered Plate DesignDocument1 pageChequered Plate DesignAsif AliNo ratings yet

- 5.15 Swing Barrier v.1.0Document190 pages5.15 Swing Barrier v.1.0rfvz6sNo ratings yet

- 1 Design ដៃរណែងមុំ 35Document1 page1 Design ដៃរណែងមុំ 35Ce WinNo ratings yet

- Water Tank Wal Foundation EXTERNAL WALL - Equalisation TankDocument12 pagesWater Tank Wal Foundation EXTERNAL WALL - Equalisation TankDenishmakvanaNo ratings yet

- Water Tank Load CalculationDocument2 pagesWater Tank Load CalculationyarmeenaNo ratings yet

- CEP pit wall designDocument382 pagesCEP pit wall designsoumi bhattacharyaNo ratings yet

- AISC360 composite member designDocument2 pagesAISC360 composite member designHattori HanzoNo ratings yet

- Torsional Irregularity Check (Swey+Drift+Drift - Ratio)Document30 pagesTorsional Irregularity Check (Swey+Drift+Drift - Ratio)Sujon AhmmedNo ratings yet

- Raw Water &fire Water Sump-R1Document4 pagesRaw Water &fire Water Sump-R1mohanNo ratings yet

- Mechanical design of open top fire water tankDocument30 pagesMechanical design of open top fire water tankkpsahuNo ratings yet

- Strip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNDocument13 pagesStrip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNkushaljp8989No ratings yet

- Chequred PlateDocument2 pagesChequred PlateKumar Prasanna HNNo ratings yet

- Structural Report On 400 KLD STPDocument16 pagesStructural Report On 400 KLD STPVipin SinghalNo ratings yet

- Ec9 Ex94 Beam Column HAZDocument5 pagesEc9 Ex94 Beam Column HAZimotalpNo ratings yet

- Design of underground water tankDocument4 pagesDesign of underground water tankDhayalan PalanisamyNo ratings yet

- Design of RCC Pier Supporting Deck SlabDocument8 pagesDesign of RCC Pier Supporting Deck SlabiploguNo ratings yet

- DN400Document32 pagesDN400ersivarajNo ratings yet

- Design of C 120x60x20x2.5 PurlinsDocument12 pagesDesign of C 120x60x20x2.5 PurlinscarsotNo ratings yet

- Cold Formed Steel Channel Section DesignDocument62 pagesCold Formed Steel Channel Section DesignNishan GajurelNo ratings yet

- Design of Water Tank On The Ground According To Bs 8007:1987Document77 pagesDesign of Water Tank On The Ground According To Bs 8007:1987juliyet strucNo ratings yet

- Chapter 11 - Section DesignDocument8 pagesChapter 11 - Section DesignDavid SinambelaNo ratings yet

- Design of pad footing for column 225Document12 pagesDesign of pad footing for column 225Govendan GopalakrishnanNo ratings yet

- Isoloated Footing DesignDocument7 pagesIsoloated Footing Designvijay moreNo ratings yet

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 pagesDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeNo ratings yet

- ACI Beam DesignDocument1 pageACI Beam DesigndantevariasNo ratings yet

- Slab DesignDocument3 pagesSlab DesignMagdy BakryNo ratings yet

- Counter Fort Retaining WallDocument26 pagesCounter Fort Retaining WallSheikh Mizanur RahmanNo ratings yet

- Dike WallDocument18 pagesDike WallManan MansoorNo ratings yet

- Wind Load Calculation NZS PDFDocument1 pageWind Load Calculation NZS PDFSantoshNo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- Stair CaseDocument19 pagesStair CaseVanu VamalaiNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- Design of isolated footing for column with dimensionsDocument5 pagesDesign of isolated footing for column with dimensionsSougata MondalNo ratings yet

- Vertical Equation Foundation-Spread Sheet PDFDocument6 pagesVertical Equation Foundation-Spread Sheet PDFmassive85No ratings yet

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDocument3 pagesAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoNo ratings yet

- STR 237Document144 pagesSTR 237kavin patel100% (1)

- RCC81 Foundation PadsDocument23 pagesRCC81 Foundation PadsahmadNo ratings yet

- 04 - Waste Water Tank Load Calc - R1Document118 pages04 - Waste Water Tank Load Calc - R1mdutta2kNo ratings yet

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- Ba Culvertf TestDocument16 pagesBa Culvertf TestsanjuktaacharyyaNo ratings yet

- Design of RCC retaining wall in ExcelDocument30 pagesDesign of RCC retaining wall in ExcelRenuga DeviNo ratings yet

- Structural Design of RCC Clear Water Reservoir (C. W. R.)Document36 pagesStructural Design of RCC Clear Water Reservoir (C. W. R.)abhishek5810100% (1)

- Development of Model Equations2Document2 pagesDevelopment of Model Equations2nataliepoison8917No ratings yet

- Problem StateDocument4 pagesProblem Statenataliepoison8917No ratings yet

- Field Data For ImportDocument30 pagesField Data For Importnataliepoison8917No ratings yet

- NotesDocument5 pagesNotesnataliepoison8917No ratings yet

- Napierala AndrewDocument2 pagesNapierala AndrewJozef LademoraNo ratings yet

- Napierala AndrewDocument2 pagesNapierala AndrewJozef LademoraNo ratings yet

- Sampling Design Methods For Water Distribution Model CalibrationDocument12 pagesSampling Design Methods For Water Distribution Model Calibrationnataliepoison8917No ratings yet

- Research ProposalDocument1 pageResearch Proposalnataliepoison8917No ratings yet

- Problem StateDocument4 pagesProblem Statenataliepoison8917No ratings yet

- Cso97Pop Prjpo00: North Oropouche Waterworks in 1979 (Halcrow)Document3 pagesCso97Pop Prjpo00: North Oropouche Waterworks in 1979 (Halcrow)nataliepoison8917No ratings yet

- Session 2Document3 pagesSession 2nataliepoison8917No ratings yet

- Major ProjectDocument210 pagesMajor Projectnataliepoison8917No ratings yet

- Introduction CHDocument2 pagesIntroduction CHnataliepoison8917No ratings yet

- Research ProposalDocument1 pageResearch Proposalace1205No ratings yet

- Kalua RDocument18 pagesKalua Rnataliepoison8917No ratings yet

- Lec 19Document33 pagesLec 19mnry414No ratings yet

- Introduction To Wavelet A Tutorial - Qiao-22Document49 pagesIntroduction To Wavelet A Tutorial - Qiao-22gosstakeNo ratings yet

- Pearson Chi SquareDocument5 pagesPearson Chi Squarenataliepoison8917No ratings yet

- A Really Friendly Guide To WaveletsDocument19 pagesA Really Friendly Guide To Waveletsallanviento100% (2)

- Source Areas ServedDocument2 pagesSource Areas Servednataliepoison8917No ratings yet

- ACI Tanks 10Document1 pageACI Tanks 10nataliepoison8917No ratings yet

- Site LayoutDocument1 pageSite Layoutnataliepoison8917No ratings yet

- Business Victoria Design Brief TemplateDocument2 pagesBusiness Victoria Design Brief Templatenataliepoison8917No ratings yet

- Water Main Breaks Are A Problem of Concern To Many Water Supply AgenciesDocument1 pageWater Main Breaks Are A Problem of Concern To Many Water Supply Agenciesnataliepoison8917No ratings yet

- Cracking and DeflectionsDocument21 pagesCracking and DeflectionsDeepakRavindraPrasadNo ratings yet

- 4 AugustDocument13 pages4 Augustnataliepoison8917No ratings yet

- CDM codes and descriptions for healthcare servicesDocument299 pagesCDM codes and descriptions for healthcare servicesnataliepoison8917No ratings yet

- Structural Analysis and Design Tcm4-118204Document141 pagesStructural Analysis and Design Tcm4-118204nataliepoison8917No ratings yet

- Plaisance ParkDocument1 pagePlaisance Parknataliepoison8917No ratings yet

- Empire in Ruins EndpapersDocument2 pagesEmpire in Ruins EndpapersMagazyn BotNo ratings yet

- Manrose Brochure Issue 15Document116 pagesManrose Brochure Issue 15StephenNo ratings yet

- Wiremold/Legrand Guide SpecificationsDocument7 pagesWiremold/Legrand Guide Specificationssplaw9484No ratings yet

- Panel Door vs Sliding Door Features ComparisonDocument17 pagesPanel Door vs Sliding Door Features ComparisonFaris AsriNo ratings yet

- American Girl Dollhouse - Fits 18 Dolls Ana WhiteDocument1 pageAmerican Girl Dollhouse - Fits 18 Dolls Ana WhiteSchindler JoanieNo ratings yet

- Molo MansionDocument1 pageMolo MansionKryla Anika JamerlanNo ratings yet

- Ibs AcademyDocument37 pagesIbs AcademyNasir ZakiNo ratings yet

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Technical Specification for Earthing and Lightning ProtectionDocument20 pagesTechnical Specification for Earthing and Lightning Protectionpatitay036817No ratings yet

- BFC 32102Document14 pagesBFC 32102Zuliyah ZakariaNo ratings yet

- Proposed construction cost estimate office shed working shed PalakkadDocument4 pagesProposed construction cost estimate office shed working shed PalakkadMahaManthraNo ratings yet

- Guruvayoor Sri SankaranilayamDocument4 pagesGuruvayoor Sri SankaranilayamAnonymous AMmNGgPNo ratings yet

- The Tower of London 64622Document3 pagesThe Tower of London 64622Maria AdamNo ratings yet

- Joist - Canam (05-2005)Document122 pagesJoist - Canam (05-2005)lostprophet1301No ratings yet

- Weight of Bitumen WaterproofingDocument5 pagesWeight of Bitumen WaterproofingJerusalemsNo ratings yet

- Calumet Coach MMT-530M Site Planning Guide - CZ-70 & UpDocument18 pagesCalumet Coach MMT-530M Site Planning Guide - CZ-70 & UpaaguilarmNo ratings yet

- Post Tensioned Sample PDFDocument13 pagesPost Tensioned Sample PDFอัชวิน เจริญสินNo ratings yet

- British housing preferencesDocument4 pagesBritish housing preferencesЖенька ВоронькоNo ratings yet

- Shaker FurnitureDocument25 pagesShaker Furniturevictor100% (1)

- B-Housing and Living - 1Document2 pagesB-Housing and Living - 1Štěpánka OndrůškováNo ratings yet

- PG&E 2012 Greenbook ManualDocument366 pagesPG&E 2012 Greenbook ManualVlade KljajinNo ratings yet

- Air ConditioningDocument5 pagesAir ConditioningDC1234No ratings yet

- Bead Room EstimateDocument6 pagesBead Room EstimatedanysubashNo ratings yet

- Mindanao's Badjao Sea Nomads and Their Driftwood HousesDocument7 pagesMindanao's Badjao Sea Nomads and Their Driftwood HousesCharles Dominic Reyes TapnioNo ratings yet

- Rangs Waterfront Apartment Complex ReportDocument8 pagesRangs Waterfront Apartment Complex ReportShezan NayemNo ratings yet

- V. Gallardo Elementary School Castillejos Accomplishment Report For The Month of JULY 2021Document2 pagesV. Gallardo Elementary School Castillejos Accomplishment Report For The Month of JULY 2021Renee Rose BaysaNo ratings yet

- INDUSTRIAL TRAINING REPORT ON CIVIL ENGINEERING WORKSDocument56 pagesINDUSTRIAL TRAINING REPORT ON CIVIL ENGINEERING WORKSsentaljohnNo ratings yet

- QDCMP 3.4 Swimming Pool BarriersDocument39 pagesQDCMP 3.4 Swimming Pool Barriersgoodspeed_phNo ratings yet

- Air conditioning design proposal for office blocksDocument9 pagesAir conditioning design proposal for office blocksSharif Mohd ZakiNo ratings yet

- Wyndham Garden Prototype Layout March 2020Document8 pagesWyndham Garden Prototype Layout March 2020Hammad AINo ratings yet