Professional Documents

Culture Documents

TESTING FRESH CONCRETE - PART 3: Ball Penetration Test

Uploaded by

broker57leonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TESTING FRESH CONCRETE - PART 3: Ball Penetration Test

Uploaded by

broker57leonCopyright:

Available Formats

testing fresh concrete part

In our previous article, we looked into Flow test as another common test method to ensure that

fresh poured concrete has the right consistency and workability. As in all testing methods, always

keep in mind that some limitationsoften apply. Today we will focus on a third method called Ball

Penetration Test (ASTM C360) and better understand main causes of segregation and bleeding

in concrete.

Kelly Ball

THE BALL PENETRATION TEST (a.k.a Kelly Ball Test) can be conducted on site by measuring

the indentation made by a Kelly Ball into plastic concrete. The device consists of a 6 inches steel

cylinder (15cm) in diameter with a semi spherical shaped bottom and 4 5/8 inches in height. It

also comes with a frame that guides a vertical handle marked in " increments on one side and

half inches on the other.

Advantages: this test can be conducted directly on the concrete in site (in a form, a hopper,

wheelbarrow), there is no need for filling and rodding a container. This means that the test can be

completed faster than with a slump test and will yield more precise results.

California Case Study:

The California Division of Highways used to perform a slump cone method but in 1953, they

adopted the Kelly Ball Test. In addition to the ASTM and AASHO requirements, they looked for a

minimum depth of 6 inches on concrete and a minimum clearance of 9 inches. If the test fails to

show 1 inch of slump (1/2 inch of penetration), more reading must be taken until 3 successive

readings within 1 inch are obtained. They average the first three valid penetration readings. ASTM

and AASHO test methods are to the nearest inch while with the California method each inch of

penetration.is read as 2 inches on the ball shaft.

WORKABILITY

DEGREE

SLUMP/PENETRATION (mm)

USES

Very low

0-25

Roads with power operated machines

Low

25-50

Road with hand operated machines

Medium

50-100

Flat slabs with crushed aggregates

High

100-175

For congested reinforcement (not for vibration)

Limitations:

There are several known sources of variances of the Kelly Ball Test, namely: sampling, testing,

differences in moisture content, inadequate mixing of materials, variation in mixing time and types

of aggregates.

To better master concrete workability, one must study and understand what causes segregation

and bleeding in fresh concrete. Below is some useful information that should help concrete

operators on the job.

CONCRETE SEGREGATION

This phenomenon occurs when the elements of the cement paste separate creating an uneven

distribution. It can happen when the concrete is mixed, transported, placed or compacted.

Types of segregation

When coarse particles are mixed with finer particles they can settle more because they are

heavier. This is the first form of segregation also called coarse segregation. The mix will have a

low asphalt content, low density, lots of air voids. It is the main cause for segregation.

The second type of segregation can happen in wet mixes, when cement and water separate from

the mix. It is called Fine segregation and produces cement with high asphalt content with low

density, concrete deformation and more.

Factors causing segregation:

Too much coarse aggregate in the concrete mix (in coarse segregation)

Too much fine aggregate in the mix (in fine segregation)

Excessive vibration

Overworking and flowing of concrete along the form through a chute

Pouring concrete from considerable height

Sudden change of direction through a chute

CONCRETE BLEEDING

This happens when the solid elements of the mix do not properly hold to the water when they are

poured and some of the water rises to the surface of the fresh concrete. This being said, most

freshly placed concrete will result in some level of bleeding. The amount of bleeding is

proportional to the depth of concrete poured. Bleeding can create pores or "wormhole channels"

in the interior and weaken the concrete. Do not attempt to remix the bleeding water during the

finishing steps as this will result in a weak surface, non-durable concrete vulnerable to freezing

and thawing and rebar corrosion.

What can cause bleeding

Too much water in the mix. Whatever time you thing you may have saved during placement will

be lost waiting for the water to evaporate! Excessive compaction can also push up water to the

surface of the fresh concrete.

Solution:

Wait for the bleeding water to evaporate before completing the finishing of the top surface.

Never trowel concrete while bleedwater is still on the surface!

Use more finely ground cement.

Add calcium chloride to cement and increase the fineness of cement.

Add fly ash, pozzolans or aluminium powder in the concrete.

Select a proper finishing method to protect the slab surface.

For air-entrained concrete, use an air-entraining agent to lower the amount of water needed to

achieve the desired slump.

Having the right concrete pump for the job is also important to minimize risks of segregation or

bleeding. Not sure about which pump to buy? Why guess when you can just give us a call us at

(503)281-2105? We always love a challenge and are ready to help you save money on your next

job.

Find out more about kelly ball test at http://www.unitedequipmentsales.com/

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Gemstone and Crystal Reference Book EnglishDocument29 pagesGemstone and Crystal Reference Book Englishsandu_livia100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hempel Coating Reference Handbook GBDocument145 pagesHempel Coating Reference Handbook GBGeorgios PapakostasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- TRIBOLOGY & LUBRICATION TECHNOLOGY May 2016Document228 pagesTRIBOLOGY & LUBRICATION TECHNOLOGY May 2016Jorge Cuadros Blas100% (4)

- Strategic TechnologiesDocument556 pagesStrategic TechnologiesMajmaah_Univ_PublicNo ratings yet

- Section 05-05 Fiber Optic NetworkDocument24 pagesSection 05-05 Fiber Optic NetworkYusuf AbdinasirNo ratings yet

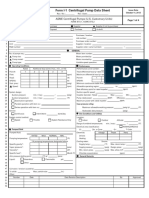

- Form I-1 Centrifugal Pump Data SheetDocument4 pagesForm I-1 Centrifugal Pump Data SheetJohnNo ratings yet

- Invalon: FL Equipment Cleaning AgentDocument5 pagesInvalon: FL Equipment Cleaning Agentsasko100% (1)

- Full download book Quantum Dots Fundamentals Synthesis And Applications Pdf pdfDocument41 pagesFull download book Quantum Dots Fundamentals Synthesis And Applications Pdf pdfhilda.pellowski343100% (19)

- Iso 8502 - 6Document1 pageIso 8502 - 6Ahmad BadriNo ratings yet

- CostingDocument5 pagesCostingJalindar BansodeNo ratings yet

- Development of Ghat River in Jaunpur City: 1-Anil BhartiDocument9 pagesDevelopment of Ghat River in Jaunpur City: 1-Anil BhartiA8304008005No ratings yet

- Detection of Porcine DNA in Gelatine and Gelatine-Containing Processed Food Products-Halal - Kosher AuthenticationDocument4 pagesDetection of Porcine DNA in Gelatine and Gelatine-Containing Processed Food Products-Halal - Kosher AuthenticationekosaputrobbppbatuNo ratings yet

- SPE 37084 Horizontal Well Length: Drill Short or Long Wells?Document9 pagesSPE 37084 Horizontal Well Length: Drill Short or Long Wells?Waleed Barakat MariaNo ratings yet

- UST Organic Chemistry Lab Separates Malunggay CompoundsDocument6 pagesUST Organic Chemistry Lab Separates Malunggay CompoundsAnonymouscatNo ratings yet

- Air Wipe ArgentinaDocument2 pagesAir Wipe ArgentinaalfdusNo ratings yet

- As Physics 2016Document21 pagesAs Physics 2016WongXinXinNo ratings yet

- Mid Term Presentation - Anish Kumar DakshDocument23 pagesMid Term Presentation - Anish Kumar DakshShubhadeep MajumdarNo ratings yet

- PC1Document11 pagesPC1Allen Low100% (1)

- Megtron 6Document3 pagesMegtron 6rfduh100% (1)

- Leader Test Series / Joint Package Course: Distance Learning ProgrammeDocument8 pagesLeader Test Series / Joint Package Course: Distance Learning ProgrammeReality of PoliticsNo ratings yet

- Chemigrams and CyanotypesDocument4 pagesChemigrams and Cyanotypesapi-481057728No ratings yet

- Artículo Toxic JuiceDocument6 pagesArtículo Toxic JuiceSonia Fernández PradosNo ratings yet

- The TBV AdvantageDocument24 pagesThe TBV AdvantageRaushNo ratings yet

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDocument38 pagesBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNo ratings yet

- Scaffold in Tissue EngDocument13 pagesScaffold in Tissue EngOluwasegun ModupeNo ratings yet

- TPO Product CatalogDocument210 pagesTPO Product CatalogMiguel BrionesNo ratings yet

- Soalan Kimia Pertengahan Tahun Form 4Document11 pagesSoalan Kimia Pertengahan Tahun Form 4Ridzuan Mohd AliNo ratings yet

- General Chemistry 1 Activity Sheet Quarter 2-MELC 12 Week 6Document9 pagesGeneral Chemistry 1 Activity Sheet Quarter 2-MELC 12 Week 6Joshua De La VegaNo ratings yet

- Mechanical Testing of Steel Products-Metric: Standard Test Methods ForDocument11 pagesMechanical Testing of Steel Products-Metric: Standard Test Methods ForCJPATAGANNo ratings yet

- Hydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesDocument26 pagesHydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesRahul AroraNo ratings yet