Professional Documents

Culture Documents

The Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2)

Uploaded by

K Scott Wyatt86%(7)86% found this document useful (7 votes)

6K views21 pagestitle speaks for itself

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttitle speaks for itself

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

86%(7)86% found this document useful (7 votes)

6K views21 pagesThe Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2)

Uploaded by

K Scott Wyatttitle speaks for itself

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 21

The Box Tube MAC-11

The Ultimate DIY Machine Pistol

Practical Scrap Metal Small Arms Vol.II

By Professor Parabellum

Plans on paes 1! to "#

Intro$uction

The machine pistol described here is perhaps the most compact of any homebuilt design publicized. In it's

outward appearance it is an almost 1:1 clone of the M11-9 probably one of the most desired submachine guns

in e!istence due to it's highly compact size and mainstream notoriety. It uses minimal parts and is as simple to

construct as any typical homebuilt design yet matches an original commercially made gun in loo"s function and

#uality.

$ith the original weapon already ha%ing a highly refined recei%er layout the de%elopment stage focused solely

on simplifying both the bolt and fire control mechanism to negate the use of a well e#uipped wor"shop for

production as cloning the original would re#uire. The resulting weapon is e!ternally identical in size to the

original with the main differences being the method of constructing the bolt and it's fire control group consisting

of two easily constructed components. &onstruction has also been simplified by using measurements in-line with

the upper recei%er as is present on most open bolt submachine guns such as the 'T() and 'terling. This

negates ha%ing to offset the position of the breech face and barrel trunnion as replicating the original M11 would

re#uire. *y altering the design in this manor e%ery component housed in it's upper recei%er can be made by

simply laminating two sizes of tubing and steel bar stoc" together.

+nother 'get around' incorporated into this design is the simple two part assembly of it's wrap-around type bolt.

This component is constructed by combining a section of 1,mm steel bar stoc" fitted with a length of -.mm !

/mm steel bo! tube. *y laminating in this %ery simple manor the need for a milling machine to mill the bolt from a

single bloc" of steel is eliminated.

For legal purposes, the demonstration prototype shown in this publication was built as a legal non-firing dummy

replica. It's dummy barrel is completely destroyed, blocked and permanently welded in place as well as it's bolt

being built out of specification and having no provisions for a firing pin. Built In this manor It is not legally

considered a firearm in most places. This document is for academic study purposes only.

Tools % construction techni&ues

An angle grinder !he "oor #an's #illing #achine

)o e!pensi%e machine-shop tools are needed to construct the *o! Tube M+&-11. Instead a number of %ery

affordable tools can be used to the same effect. (#uipped with a cheap angle grinder the a%erage hobbyist has

the ability to perform machining actions usually reser%ed for an e!pensi%e milling machine. 0ather than tediously

using a hac"saw to cut steel sheet an angle grinder fitted with a 1mm slitting disc will accurately cut a straight

line through steel of any thic"ness in mere seconds. 1itted with a /mm disc it can be used to easily 'sculpt' thic"

steel into any shape in a fraction of the time it ta"es to manually use a hand file. Importantly for this pro2ect it is

used to grind the magazine cuts in the bolt piece after which a hand file can be used to neaten the newly created

9. degree channels. This techni#ue wor"s surprisingly well and it's not unusual to get %ery neat right-angle cuts

which loo" as though they were produced using a milling machine. 3ne can manufacture almost any component

of any weapon using this techni#ue in %ery short order with %ery pleasing end results.

$mall arc welders like the one above are available cheaply for purchase over the Internet

+ rotary tool or dremel is highly useful for delicate grinding and cutting operations. 1itted with a 'reinforced

cutting disc' it becomes a mini angle grinder ideal for cutting out and grinding openings in pieces of tube #uic"ly

and neatly without ha%ing to manually use a hand file. These can be purchased cheaply online with a large

%ariety of cutting grinding and sanding bits a%ailable for wor"ing with metal.

$ith enough patience it is possible to construct e%ery component described using only a drill hac"saw and a

few hand files. 4owe%er for under 51.. you can purchase all the budget tools necessary to complete the pro2ect

in only a couple of afternoons. It is well worth %enturing to any 'swap meet' 'car boot sale' or 'flea mar"et' as all

tools mentioned can be found practically being gi%en away in used condition.

'seful tools

Anle rin$er

(ac)sa* + cobalt tippe$ bla$es

Cobalt or titanium tippe$ $rill bits

,rill press or han$ $rill combine$ *ith a stan$

-el$er

,remel . rotary tool + reinforce$ cuttin $iscs

(an$ files

Materials

1/ x "/ 0!#mm x "!mm x 1.!mm1 mil$ steel box section

1/ 0"!mm x "!mm x "mm1 mil$ steel box section

1 1.!/ x "/ 02#mm x !#mm x "mm1 mil$ steel box section

12.13/ 0"#mm x "#mm x "mm1 mil$ steel box section

2.4/ 01#mm1 thic) aluminum or steel plate

15 aue 0"mm1 mil$ steel plate

!.4/ 013mm1 roun$ or s&uare mil$ steel bar stoc)

m26 m56 m4 bolts

2.5/ 014mm . 17mm $iameter1 compression sprin

If excess tihtness is encountere$6 s&uare tubin can be re$uce$ in 8, slihtly on each si$e

by usin an anle rin$er fitte$ *ith a rin$in or san$in $isc.

89er9ie* of components an$ their construction

:o*er recei9er

The lower recei%er is cut out from an 11.,6 7 /98mm long length of -.mm ! 8.mm steel bo! section tube with a

wall thic"ness of /mm onto which the trigger group rear support bar magazine and front lug holes are made.

The rear closure is bent to the specified dimensions and is welded in place with the rear sight plate welded o%er

it. + '9' shaped strip of /mm sheet metal ser%es as a trigger guard and is welded in place. The rear support bar

holds the upper recei%er firmly in position with the rear closure portion of the lower recei%er while the front lug

holes allow it to be secured in place.

+ section of 17:6 ;,mm< thic" aluminum or steel plate is cut to shape and ser%es as a feed ramp. It is secured in

place by tapping it to accept two m- bolts.

'pper recei9er

The upper recei%er is constructed from a length of /8mm s#uare steel bo! section with a wall thic"ness of /mm

onto which the e2ection port coc"ing handle slot and lower opening sections are cut out. The best method to

achie%e this is to use a combination of drilling holes around the inside section to be cut out before cutting along

the holes using a dremel type rotary tool fitted with a 'reinforced cutting disc'. These are e!tremely durable and

can be used to neatly grind the edges to shape without ha%ing to use a hand file. If a dremel is una%ailable a

hammer and a screw dri%er can be used to chisel out the drill hole lines after which a hand file can be used to file

down the edges. + front lug made from a piece of the same /8mm bo! section is welded or bolted onto the lower

front end and holds the upper recei%er in place. This same material is also used for the construction of the front

sight.

Barrel

The demonstration model pictured was made with a non-functioning dummy barrel which is permanently

destroyed ;bloc"ed by a hardened steel insert and cut open< and is welded in place. In this configuration it is not

considered a firearm and can be legally owned and built freely as a display replica in most places.

The outer dimension of the barrel is 87=6 ;1,mm<. This fits tightly into a section of /.mm ! /mm round tube or

s#uare bo! section which ser%es as a collar to attach the barrel to the upper recei%er. The barrel is secured in

place either by welding or by means of a pin installed across the upper recei%er as is present on the original

M+& design.

Maa;ine-*ell

The magazine-well is made from a section of 16 ! /6 ;/8mm ! 8.mm< steel rectangle tube shortened to /8mm !

:-mm by remo%ing widening slightly then re-welding one /8mm side to allow snug contact with the magazine.

The magazine catch is cut out from 1.mm aluminium plate it's housing consisting of a small piece of bent steel

sheet or rectangle section welded in place. The bac" grip piece is cut out from either wood or plastic and is

drilled to accept an M8 bolt to attach it to the magazine well. 3nce completed the magazine-well is welded to the

lower recei%er. If a welder is una%ailable an alternati%e method would be to use an '>' shaped piece of metal to

secure the magazine-well to the bottom of the recei%er using two short bolts.

The e!ample shown uses a modified 'T() magazine which has had the stop lips ground off and a new stopper

attached. +lternati%ely a homemade magazine constructed from 18mm ! -8mm tube can be used. In this case a

length of /.mm ! :.mm steel tube with a wall thic"ness of /mm is all that is re#uired for it's magazine-well. +

magazine-catch can be as simple as a length of handsaw blade combined with a modified nut and bolt.

Bolt

1or legal purposes the bolt on the demonstration model was made without pro%isions for a firing pin and can

only feed dummy inert rounds. 0ather than milling a bolt from a single bloc" of steel it is constructed by inserting

a length of 1,mm round or s#uare steel bar into a length of /.mm steel s#uare bo! section with a wall thic"ness

of /mm the same material used for the barrel collar. The breech face of the bolt piece is first drilled -mm deep

using a 1.mm drill bit and then le%elled flat using the same size drill bit with it's tip remo%ed. The feeding cuts for

the magazine are formed using an angle grinder fitted with a /mm or -mm grinding disc after which it is hand

finished using a file. The e2ector slot is cut using a 1mm slitting disc until the e2ector itself slides in and out

without resistance. The finished 'dummy' bolt is retained in place using a number of steel rods grub screws or

beheaded bolts threaded in place. +dditional weight can be added by drilling out and inserting tungsten bars or

partially filling the bac" of the bolt with lead. To ensure positi%e engagement with the sear the contact point at

the front of the bolt carrier can be increased in width using a welder and then filed to shape.

Angle grinder milling%

<xtractor

This machine pistol uses a fi!ed spring-less e!tractor. +dding an e!tractor to a blowbac" design is usually

optional though the simplicity of this design hardly 2ustifies lea%ing it out. In this case it is simply a strip of /mm

sheet steel bent at a right-angle and filed into a simple claw profile after which it is then attached to the bolt %ia

two m- or m: grub screws. 3nce confirmed functioning of the finished e!tractor claw is established it can be

hardened by heating until red then #uenching in a solution of salt water. The e!tractor claw should be made fairly

undersized so as to allow a cartridge rim to easily slide into contact with it without interfering with feeding.

<=ector

The e2ector consists of a plate bolted onto the bottom of the upper recei%er it's contact arm slotting up 9.

degrees into line with the bolt's e2ector channel. It is fabricated from a single piece of /mm thic" sheet steel. The

plans pro%ided contain a smaller simplified %ersion.

Trier roup

The trigger group consists of two pieces of modified 1.mm thic" aluminum or steel plate. The trigger is cut to the

dimensions specified while the flat sear piece is cut out and fitted with a modified section of hardened7stainless

steel bolt ground to it's re#uired profile. This part ma"es contact with the front of the bolt carrier under spring

tension pre%enting it from mo%ing forward until the trigger is pulled. + suitable sear spring can be obtained from

a hand sanitizer or shampoo bottle.

&eft% 'ocked position ready to fire. (ight% 'losed position round chambered and fired

>ecoil sprin

?ue to the small inner dimensions of the upper recei%er suitable compression springs are readily a%ailable for

purchase online. + compression spring around 1/.mm ;: -7:6< in length 1=mm ;- -7:6< in outer diameter and

wound from 18 gauge wire is desired. +s long as a spring firmly holds the bolt closed and can be coc"ed bac"

with a smooth and consistent pull it will li"ely be suitable.

Maa;ine

The demonstration model uses 9mm 'T() magazines which ha%e been modified by remo%ing the original

stopper tabs and instead fabricating a new stopper and catch notch. The magazine-well can optionally be slotted

and the mag-catch increased in length to accept original unmodified 'T() magazines. @lans for a homebuilt

magazine ha%e also been pro%ided.

?inishin

3nce completed the pistol can be stripped down and spayed with two to three coats of matt blac" 4igh

Temperature (ngine (namel. This type of finish usually re#uires no priming or preparation and is many times

more durable than standard auto or **A paint.

Plans

+ll pages included should be printed out on =.8 ! 11 9' letter paper. (ach component template is drawn to scale

and can be cut out and glued to their respecti%e thic"ness of material. Ma"e sure the ruler at the bottom left of

each sheet is / inches in length. +lternati%ely enlarge the plans using a computer program until the ruler is the

correct length then trace the parts needed onto a sheet of paper taped o%er your computer's screen.

Bou might also want to ta"e a loo" at C

You might also like

- The Table Leg Typewriter (Practical Scrap Metal Small Arms Vol.10)Document37 pagesThe Table Leg Typewriter (Practical Scrap Metal Small Arms Vol.10)xan94% (17)

- The Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2) PDFDocument22 pagesThe Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2) PDFBangBoomBang90% (124)

- DIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)Document21 pagesDIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)fritzthecat5295% (21)

- The MAC-10 Construction Guide - Practical Scrap Metal Small Arms Vol.6Document23 pagesThe MAC-10 Construction Guide - Practical Scrap Metal Small Arms Vol.6Fisherman35787% (253)

- BSP SMG BookDocument29 pagesBSP SMG Bookbovine splendor90% (30)

- 9mm Bullet Hose (Practical Scrap Metal Small Arms Vol.8)Document24 pages9mm Bullet Hose (Practical Scrap Metal Small Arms Vol.8)gunpdfs95% (210)

- Metralleta Casera Sin Torno TRADUCIDO AL FINALDocument12 pagesMetralleta Casera Sin Torno TRADUCIDO AL FINALMiguel Omar Pieszko100% (5)

- The DIY STEN Gun (Practical Scrap Metal Small Arms Vol.3) PDFDocument23 pagesThe DIY STEN Gun (Practical Scrap Metal Small Arms Vol.3) PDFBangBoomBang86% (167)

- 9mm Bullet Hose (Practical Scrap Metal Small Arms Vol.8)Document24 pages9mm Bullet Hose (Practical Scrap Metal Small Arms Vol.8)jkruise81% (16)

- Build-A-Borz (Practical Scrap Metal Small Arms Vol.9) PDFDocument23 pagesBuild-A-Borz (Practical Scrap Metal Small Arms Vol.9) PDFknockelflies85% (20)

- The Box Tube MAC-11 Part 2 (Practical Scrap Metal Small Arms Vol.5)Document16 pagesThe Box Tube MAC-11 Part 2 (Practical Scrap Metal Small Arms Vol.5)BangBoomBang91% (67)

- Expedient Homemade Firearms - BSP 9mm SMG - P.A LutyDocument46 pagesExpedient Homemade Firearms - BSP 9mm SMG - P.A Lutybanjovy100% (4)

- Building a Home Defense Remington 870 ShotgunFrom EverandBuilding a Home Defense Remington 870 ShotgunRating: 3.5 out of 5 stars3.5/5 (5)

- Elementary Gunsmithing - A Manual of Instruction for Amateurs in the Alteration and Repair of FirearmsFrom EverandElementary Gunsmithing - A Manual of Instruction for Amateurs in the Alteration and Repair of FirearmsNo ratings yet

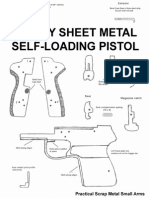

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- Professor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor ParabellumDocument23 pagesProfessor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor Parabellumzaid hashem100% (2)

- 9mm PistolDocument24 pages9mm PistolJall Desenvolvedor Web50% (4)

- The Box Tube MAC-11: The Ultimate DIY Machine PistolDocument24 pagesThe Box Tube MAC-11: The Ultimate DIY Machine PistolPatrick Peres100% (1)

- Professor Parabellum - The DIY Sheet Metal Self Loading Pistol - Practical Scrap Metal Small Arms Volume 1. 1-Professor ParabellumDocument15 pagesProfessor Parabellum - The DIY Sheet Metal Self Loading Pistol - Practical Scrap Metal Small Arms Volume 1. 1-Professor ParabellumKobi Zada100% (1)

- 3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsFrom Everand3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- A Guide to Making Your Own Fishing-Rod and TackleFrom EverandA Guide to Making Your Own Fishing-Rod and TackleRating: 5 out of 5 stars5/5 (1)

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverFrom EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverNo ratings yet

- Metalworking for Home Machinists: 53 Practical Projects to Build YourselfFrom EverandMetalworking for Home Machinists: 53 Practical Projects to Build YourselfNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Modelling the late Panzerkampfwagen IV Ausf. J, 5.Panzer-Division, East Prussia, 1944From EverandModelling the late Panzerkampfwagen IV Ausf. J, 5.Panzer-Division, East Prussia, 1944Rating: 5 out of 5 stars5/5 (1)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Modelling the late Panzerkampfwagen IV Ausf. H 'Frühe' version, 4.Panzer-Division, Russia 1944From EverandModelling the late Panzerkampfwagen IV Ausf. H 'Frühe' version, 4.Panzer-Division, Russia 1944No ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopFrom EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Paper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperFrom EverandPaper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyFrom EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyRating: 5 out of 5 stars5/5 (4)

- The Tools and Materials of the Watchmaker - A Guide to the Amateur Watchmaker's Toolkit - Including How to make your own ToolsFrom EverandThe Tools and Materials of the Watchmaker - A Guide to the Amateur Watchmaker's Toolkit - Including How to make your own ToolsNo ratings yet

- The DIY STEN Gun (Practical Scrap Metal Small Arms Vol.3) PDFDocument23 pagesThe DIY STEN Gun (Practical Scrap Metal Small Arms Vol.3) PDFBangBoomBang86% (167)

- Trijicon RECOIL TargetDocument1 pageTrijicon RECOIL TargetK Scott WyattNo ratings yet

- NATO Ammo Clone InformationDocument6 pagesNATO Ammo Clone InformationK Scott Wyatt100% (1)

- Instructions For Colloidal Silver ProductionDocument6 pagesInstructions For Colloidal Silver ProductiondanmiclovanNo ratings yet

- Simple Homemade Pistol Pit-Bull-1Document22 pagesSimple Homemade Pistol Pit-Bull-1sjdarkman1930100% (1)

- Davids War DiaryDocument47 pagesDavids War DiaryK Scott WyattNo ratings yet

- WP LoadSpec 7-2-13Document54 pagesWP LoadSpec 7-2-13K Scott Wyatt100% (1)

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- HFDDocument55 pagesHFDK Scott Wyatt100% (1)

- Sigs IntafDocument12 pagesSigs IntafK Scott WyattNo ratings yet

- PM 01 CarbineDocument9 pagesPM 01 CarbineK Scott Wyatt100% (2)

- Ul FuqraDocument24 pagesUl FuqraK Scott WyattNo ratings yet

- Mormon Emergency PreperationDocument86 pagesMormon Emergency PreperationK Scott WyattNo ratings yet

- CfmotoV5 Owner's ManualDocument45 pagesCfmotoV5 Owner's ManualK Scott WyattNo ratings yet

- Low Maintenance Rifle 556mm Tech ManualDocument24 pagesLow Maintenance Rifle 556mm Tech ManualK Scott Wyatt100% (1)

- By Timj: PDF Version 1 - May 21, 2006Document158 pagesBy Timj: PDF Version 1 - May 21, 2006K Scott WyattNo ratings yet

- SF Recon ManualDocument127 pagesSF Recon ManualK Scott Wyatt100% (9)

- Atv PlansDocument90 pagesAtv PlansK Scott Wyatt100% (6)

- 5.7x28 Hand LoadsDocument4 pages5.7x28 Hand LoadsK Scott Wyatt100% (1)

- A Handbook For Light ArtilleryDocument555 pagesA Handbook For Light ArtilleryK Scott WyattNo ratings yet

- 1911 Frame TutorialDocument22 pages1911 Frame Tutorialblackta6100% (5)

- A Rough Guide To Bike MaintenanceDocument8 pagesA Rough Guide To Bike MaintenanceK Scott WyattNo ratings yet

- M16a2 25m ZeroDocument1 pageM16a2 25m ZeroAlan Warren SnyderNo ratings yet

- Becoming Riflemen BookletDocument28 pagesBecoming Riflemen BookletK Scott WyattNo ratings yet

- Assorted Recipes For Survival & Snack Food Bars RecipesDocument9 pagesAssorted Recipes For Survival & Snack Food Bars RecipesK Scott Wyatt100% (1)

- 37mm Firework ProjectDocument5 pages37mm Firework ProjectK Scott Wyatt100% (1)

- Build Bolt ActionDocument101 pagesBuild Bolt Actionknkl99% (68)

- RationsDocument6 pagesRationsK Scott Wyatt100% (1)

- Powder Loads With Pistols Rev.BDocument4 pagesPowder Loads With Pistols Rev.BK Scott WyattNo ratings yet

- (Gordon - L - Rottman Vietnam Riverine CraftDocument51 pages(Gordon - L - Rottman Vietnam Riverine CraftNdivhuwo Nepfumbada100% (4)

- Black Powder II Quick ReferenceDocument2 pagesBlack Powder II Quick Referenceclive clivetablet100% (3)

- Tank Guns and AmmunitionDocument27 pagesTank Guns and Ammunitionhaftom gebrehiwot50% (2)

- 2004 AlliantPowderSMDocument64 pages2004 AlliantPowderSMscottperkinsusaNo ratings yet

- Quick Reference Sheet for Varmint and Hunting BulletsDocument5 pagesQuick Reference Sheet for Varmint and Hunting BulletsToxophilus TheLuckyNo ratings yet

- Mira Trijicon Acog PDFDocument52 pagesMira Trijicon Acog PDFjohn alex HoyosNo ratings yet

- Maverick Model 88Document21 pagesMaverick Model 88Serteco Coleccionista MilitariaNo ratings yet

- M88 ManualDocument16 pagesM88 Manualbalkanmonitor100% (1)

- Annual RIfle Training Data Book (M27)Document60 pagesAnnual RIfle Training Data Book (M27)harrisburrrg100% (1)

- French Guns Technical Data 1940Document4 pagesFrench Guns Technical Data 1940enrico100% (1)

- Sister of Battle 1250 Pre-RevisionDocument12 pagesSister of Battle 1250 Pre-RevisionEmy MobileNo ratings yet

- Grimdark Future - Human Defense Force v1.0Document3 pagesGrimdark Future - Human Defense Force v1.0joble02No ratings yet

- TM 9-290 Pyrotechnic ProjectorsDocument61 pagesTM 9-290 Pyrotechnic ProjectorsedrestNo ratings yet

- Apj Abdul KalamDocument11 pagesApj Abdul KalamBhavin LodhiyaNo ratings yet

- Technical SpecificationsDocument12 pagesTechnical SpecificationsgrenzoNo ratings yet

- Hellfire Assembly ManualDocument9 pagesHellfire Assembly ManualTimNo ratings yet

- Firearms Blueprint Sten MK V Ingram MAC10 Austin MK I Beretta 38-44 Madson Model 1950 Sub Machine GunsDocument9 pagesFirearms Blueprint Sten MK V Ingram MAC10 Austin MK I Beretta 38-44 Madson Model 1950 Sub Machine GunsFlavio Marçal100% (12)

- Computer Aided Design For EngineersDocument51 pagesComputer Aided Design For EngineersJeft TanNo ratings yet

- 2020-12-01 HandgunsDocument70 pages2020-12-01 Handgunsgabrielabarberio.aleNo ratings yet

- Defence Mission Shakti-7Document12 pagesDefence Mission Shakti-7sassasassNo ratings yet

- DCX ManualDocument58 pagesDCX ManualVinicius GalvãoNo ratings yet

- Diemaco M203A1Document2 pagesDiemaco M203A1Hunter_TothNo ratings yet

- Aor Errata v10Document4 pagesAor Errata v10Bruce Lee PowNo ratings yet

- Anthony J Whelan - Multiple Effects Warheads For Defeat of Urban Structures and ArmourDocument18 pagesAnthony J Whelan - Multiple Effects Warheads For Defeat of Urban Structures and ArmourDeez34PNo ratings yet

- Counter-Strike 1.1 ManualDocument13 pagesCounter-Strike 1.1 Manualanon-221758No ratings yet

- Freeman'S Glock 17: Project NotesDocument6 pagesFreeman'S Glock 17: Project NotesAdriano AndradeNo ratings yet

- Bullet-Proof: Bullet-Proof Vest Made From Anti-Ballistic Fiber Protects From Bullets, Schrapnel, Small Arms ProjectilesDocument3 pagesBullet-Proof: Bullet-Proof Vest Made From Anti-Ballistic Fiber Protects From Bullets, Schrapnel, Small Arms ProjectilesSudhir JainNo ratings yet

- Battlegroup DataCards SovietsDocument7 pagesBattlegroup DataCards SovietsFOWNo ratings yet

- PPM 2Document4 pagesPPM 2John Alejandro Rangel RetaviscaNo ratings yet

- The Colt .45 Automatic - A Shop Manual Vol.1 by KuhnhausenDocument208 pagesThe Colt .45 Automatic - A Shop Manual Vol.1 by Kuhnhausennaulamarad100% (34)