Professional Documents

Culture Documents

Natural Fruit Juice

Uploaded by

ShakeelAkramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Natural Fruit Juice

Uploaded by

ShakeelAkramCopyright:

Available Formats

Natural Fruit

Juice Company

Ltd

A Project feasibility report

Feasibility report encompasses

of different type of analysis,

ratios and projected financial

statements to enhance the

investors best utilization of

capital in Natural fruit Juice

Company Ltd.

1 | P a g e

PREFACE

Department of Commerce, the Islamia University of Bahawalpur has always

been admirable in its efforts to equip the future executives with arms of

creativity, flexibility and adaptability to meet the challenges offered by fast

changing business environment.

To achieve the above goals the department is providing both text and practical

knowledge to its students with its available resources. Text knowledge is very

well transferred to the students within the premises of the department;

Practical knowledge requires the kind co-operation of various business

organization of the country. Faculty members are always trying their best to

ask the students to explore the market by assigning different field activities

and to prepare a report.

This report has been written on the Natural fruit juice company ltd

Bahawalpur. We have done our best efforts to complete this report efficiently

and effectively with all abilities. We hope this report fulfills the criteria and

expectations of Department of Commerce. We have tried our best to make it

analytical as well as informative.

May Allah help us in this world.

2 | P a g e

ACKNOWLEDGEMENT

Up and above everything, we are thankful to ALMIGHTY ALLAH, the

most Beneficent and merciful, and His Holy Prophet (Peace be upon him)

who is forever a true torch of guidance for whole humanity. We are greatly

obliged to ALLAH by whom grace we have been able to complete this

Project Report successfully.

We also offer our thanks to Honorable Sir Hafiz Muhammad Adnan

for providing us a chance to work in such a Profitable Industrial Project.

We also offer our thanks to our Parents for being supporting us in all means

financially and mentally to complete our work. We would like to pay our

special regards to Mr.Qasim Bhati for reference and the owner Mr.sajid of

juice pack company shaikupora for providing all the relevant Information

necessary to complete this report.

3 | P a g e

Dedication

We dedicate this report to our parents and friends in recognition of

their worth and to our teachers who are the guiding force for us and it is

their efforts and hard work that showed us the path of success and

prosperity which would be there for us for the rest of our life.

Our thanks to all those who have generously contributed their

theoretical knowledge to this report including our teachers. Without their

understanding and support, completion of this work would not have

possible.

We hope people find this report useful and the subject matter adds

to their knowledge. Keep your dreams alive. Understand to achieve

anything requires faith and belief in yourself, vision, hard work,

determination, and dedication.

4 | P a g e

TABLE OF CONTENTS

Sr.NO Name Of Contents Page NO.

1 Name of Project 05

2 Location & Site Selection 05

3 Project Location 05

4 Availability of Labor 05

5 Transportation cost 06

6 Office location 06

7 Utilities 06

8 Sponsors 06

9 Market and Plant capacity 06

10 Products Range 09

11 Man Power 09

12 Installed Capacity Of project 10

13 Production flow chart 11

14 Name of Lenders

15 Name of Civil Contractors

16 Market Analysis

17 Economic Analysis

18 Personal Analysis

19 Technical Analysis

20 Financial Analysis

21 SWOT Analysis

22 Recommendation

23 conclusion

24 Reference

5 | P a g e

Name of Project

Natural fruit juice company Ltd

Location & Site Selection

Following factors are taken into account while selecting the location

for project.

Project Location:

The proposed locations for the Natural fruit juice company is Yazman

Road 12,B.c near Airport, Bahawalpur. The said project may be established in

industrial estate area or any other area of above said city.

Availability of Labor:

Adjacent with the area is the rural area that will provide cheaper and

hardworking raw man power for production.

Transportation cost:

The proposed location is a Yazman Road 12, B.c near Airport

Bahawalpur . The project will be situated over the Highway. The transportation

will be easy and the cost of transportation over the country will be less varying

with area to area.

Office location:

Registered Office will be with in the boundary of the factory.

6 | P a g e

Utilities:

The area is now becoming industrial area. A lot of factories are situated in

the area. So, utilities are easily available there

Sponsors:

Abdullah Iqbal

Nazakat Hussain

Market and Plant capacity:-

Materials and inputs:

Water

Sugar

Pulp

Artificial flavor

Citric acid

Sodium benzoate

Project Engineering:-

Requirement of Plant and different Machinery for Juice.

Filler Machine

Packer Machine

Sealer Machine

Crowner Machine

palletize Machine

7 | P a g e

Products Range:-

Apple juice:

Mango juice

8 | P a g e

Peach juice

Grape juice

9 | P a g e

Man Power:

The composition of manpower will be 30 highly skilled persons

to supervise technical operations, 70 skilled people to directly work on

production process.

Installed Capacity Of project:

The Plant and Machinery which we use is relatively more efficient and

effective. The chosen Plant & Machinery is capable of producing units per month.

70% starting capacity is proposed.

Production flow chart:

FRUIT

Years 2011 2012 2013

Estimated

Capacity

70% 75% 80%

Preparation of the

fruit

Pulp extraction

Added ingredients

10 | P a g e

Name of Lenders:

The amount of loan will be taken from ALFALAH BANK. The amount of loan is

Rs. 63 million. The interest @ 16% per annum.

Name of Civil Contractors:

Mr. IQBAL HUSSAIN HASHMI

Civil contractor of Building department Bahawalpur. We met on 20.05.2010 at 1

p.m.

Name of Machinery Suppliers:

Filtration

Juice

Fill & Seal

Heat treatment

Cool

11 | P a g e

Am Industriepark 210 21514 Buchan Germany

Phone +49 4155 49-0 Fax +49 4155 49-2724.

Introduction

To setup a plant for the manufacture of fruit juice from fruit pulp on Yazman road

12 b.c near airport Bahawalpur. The initial produce planned is Apple, Mango,

Grapes, Peach fruit juices. Later on more juices of more fruits can be added.

The main raw materials required are fruit pulp, treated water, sugar, citric acid,

fruit flavors and preservatives all of which are readily available. The technology

and machinery for this investment opportunity are readily available at a very

reasonable cost. Besides having the comparative advantage of being the major

producers of fruit and ready availability of the major raw material, i.e. fruit pulp.

The proposed locations of Yazman road 12 b.c near airport Bahawalpur have the

necessary infrastructure such as roads, electricity and telecommunications

available for the project. These juices can be sold both locally in the adjoining

areas of Bahawalpur, regional and national markets.

PROJECT PROFILE:

Project Brief:

1. Selection, Purchase and the Registration of Land in 1 Month.

2. Construct the Building in 2 months.

3. Purchase and installation of machinery in 2 months.

4. We produce five products of juice.

5. Commercial production starts from 1

st

January.

12 | P a g e

Legal Status:

The legal status of business tends to play an important role in any

setup; the proposed Natural Fruit Juice manufacturing setup is assumed to

operate on partnership basis. The Reason being it is easy to setup and manage.

Name of Promoters:

Abdullah Iqbal

Nazakat Hussain

Market Analysis:

Target customers:

The target customers of the proposed project would be the upper, middle

and lower income groups of people.

Exports of Pakistan:

Countries Trade value $

World

152,920

United Arab Emirates

7,890

Saudi Arabia

6,695

13 | P a g e

Demand Supply Gap in Pakistan:

The Gap of demand and supply of Natural Fruit Juice in Pakistan is 35%

Growth Percentage of Factories in Pakistan:

Description prices (Rs.)

All type of juices(250 ml) 16

All type of juices(500 ml) 36

All type of juices(1 litter) 91

14 | P a g e

Retail Price:

Distribution Channel:

The excessive distribution of the product in local market will be

implemented for this purpose 5 sales person will be hired. The supply of product

is delivered to local distributor free of cost through companys own

transportation and it varies due to deals with other dealers through companys

own transportation or contract with Transportation Company depending on

supply quantity.

Factory

Wholesalers

Retailers

Consumer

Description Prices (Rs.)

250 ml juices

(24*15)360

500 ml juice bottles

(24*35)840

1 liter juice bottles (12*100)1200

15 | P a g e

Economic Analysis:

Economic evaluation is considered prominent yardstick to measure the viability of

a project. This analysis is directed towards determining whether the project is

likely to contribute significantly to the development of the economy as a whole

and the contribution of the project would be great enough to justify the use of

available resources. This aspect is reviewed under the following:-

Initial Impact

In order to pursue a theory of balanced growth of the economy the current

government is putting an emphasis on industrialization of our inherently agrarian

economy. Industrialization of substantial dynamic benefits is important for

changing the traditional structure of our less developed economy, while providing

employment for a rapidly increasing labor force, and saving scarce foreign

exchange by import substitution and creating export potentials.

A capital expenditure creates incomes for people engaged in the fabrication of

capital goods, who in turns spend their incomes on consumer goods. An initial

original capital investment creates a wave of income and spending which has

multiplied effect on the national income, increasing it by several times, the

original investment. The initial original capital investment of Rs. 62 million in local

currency would have a healthy impact on the GNP of the country, the extent of

which depends on the degree of multiplied effect.

16 | P a g e

It may have major contribution to the society benefits. There will be employment,

infrastructure improvements and that will be a factor to improve the living

standards of the peoples.

EMPLOYMENT OPPORTUNITIES:

The project would create employment opportunities for the following staff:

Detail Total Nos.

Skilled Labor 15

Factory Administrative Staff 14

Marketing Staff 02

BENEFIT COST ANALYSIS

The benefit/Cost ratio of the project is worked out in times which are considered

satisfactory. The NPV of the expected benefit and costs has been taken into

account for the calculation of this ratio.

Personal Analysis:

For the proposed project both skilled and unskilled labour is required which

is available at the selected area for the project. For the training of technical staff

the services of technical institution and experts are haired. A well mannered

process is adopt in hiring and retaining the efficient workers.

17 | P a g e

Requirement of staff:

50 people will be employed in manufacturing area, 15 will be

Employed as Administrative staff, 8 will be employed as security guards and 5 will

be as helper in Godown.

Technical Analysis:

The partners will be engaged interning management of factory a part

from over all management their will be skilled workers, Managing Director,

Production Manager, Finance Manager, Accountant, Technical Staff, etc, who will

carry out the policies and decision made for the business.

Electricity & Gas, Fuel, Water

Electricity requirement capacity for the running of machinery is 10,000

kw/Month and also for other inputs is required.

18 | P a g e

List of machinery:

Filler Machine:-

Packing Machine:-

19 | P a g e

Sealer and label Machine:-

20 | P a g e

Crowner Machine:-

21 | P a g e

palletize Machine:-

Financial Analysis:

Financial Analysis

Sr. No Cost of Project: Amount (Rs.)

1 Cost of Land 803000

2 Cost of Building 909650

3 Cost of Plant and Machinery 4270500

4 Cost of Furniture 722500

5 Cost of Vehicles 1955000

6 Legal Charges 7000

Total 8667650

1-Cost Of Land

Area Rate Legal charges Total

1Acer 8,00,000(par acar) 3,000 803,000

22 | P a g e

2-Cost of Building

Construction size(Area Sq ft ) rate( Sq ft) Total

Process Hall 300 120 36000

Storage Godown 626 115 71990

Storage Godown 3168 75 237600

Factory Office 1264 65 82160

Other Services 860 65 55900

Parking Area 1404 40 56160

Storage of Finished goods 3168 30 95040

Ground for Expansion 7240 20 144800

Air Conditioning and electricity (internal) 130000

Total 909650

3-Machinary Cost:

Sr.No Name of

Machinary

Cost Deprecation

rate

Accumulated

Depreciation

Book

Value

1 Machine for

Sachet

1000000 15% 150000 850000

2 Shrink Wrapping 669000 15% 100350 568650

3 Misc Fitting 550000 15% 82500 467500

4 Printing Machine 950000 15% 142500 807500

5 Tools &

Equipment

800000 15% 120000 680000

5 Installation

Charges

100000 15% 15000 85000

6 Packing

Machinery

96500 15% 14475 82025

7 Electric

Generator

300000 15% 45000 255000

Total 4465500 195000 4270500

23 | P a g e

5-Cost of furniture

Sr.No Cost Deprecation

rate

Book

Value

1 850000 15% 127500 722500

6-Cost of Vehicles

Sr.No Name of

Vehicles

Cost Deprecation

rate

Accumulated

Depreciation

Book

Value

1 Truck 1500000 15% 225000 1275000

2 Car 800000 15% 120000 680000

total 1955000

7-Legal charges

legal charges 7000

24 | P a g e

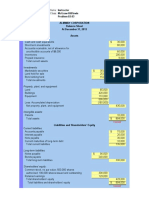

Natural Juice

Balance Sheet

As on December,2011

Assets: Amounts Liabilities Amounts

Current Assets : Current liabilities :

Cash 21985 Accounts Payable 3850

Accounts Receivable 15 % 31001 Accrued Expenses

Packaging Raw materials 8% 1753 short term Loans @ 75% 57395

inventory 7400 Current Maturity of Loan

Finish goods inventory 10 %

production

1634 Notes payable 2500

Stores & Spares 1107 tax payable

Marketable securities 14200 sub total 63745

sub total 79080 Owners Equity & Liabilities

Fixed Assets : Capital & reserves:

Fixed Assets 86877650 Capital 83431940

Less: Acc. Dep. - Retained earning -

Net Fixed Assets 6015 Sub Total 83431940

Pre-Production Exp. Long Term Liabilities

Less Amortized - loan from bank 40% of the

project cost

3467060

Net Pre-Production Exp. Sub Total 3467060

Sub total 86883665 Total Debt & Equity 86899000

Total Assets 86962745 Total Equity & Liabilities 86962745

25 | P a g e

Natural Juice

Balance Sheet

As on December,2012

Assets: Amounts Liabilities Amounts

Current Assets : Current liabilities :

Cash 31985 Accounts Payable 4850

Accounts Receivable 15 % 41001 Accrued Expenses

Packaging Raw materials 8% 2753 short term Loans @ 75% 67395

inventory 12800 Current Maturity of Loan

Finish goods inventory 10 %

production

1634 Notes payable 3500

Stores & Spares 4107 tax payable

Marketable securities 84200 sub total 75745

sub total 178480 Owners Equity & Liabilities

Fixed Assets : Capital & reserves:

Fixed Assets 96877650 Capital 93591940

Less: Acc. Dep. - Retained earning -

Net Fixed Assets 78615 Sub Total 93591940

Pre-Production Exp. Long Term Liabilities

Less Amortized - loan from bank 40% of project

cost

3467060

Net Pre-Production Exp. Sub Total 3467060

Sub total 96956265 Total Debt & Equity 97059000

Total Assets 97134745 Total Equity & Liabilities 97134745

26 | P a g e

Natural Juice

Income Statement

For the year

2010 2011 2012

Sales 219973 257683 277166

Cost of good Sold:

Raw material consumed 12478 13802 14896

Labour 6300 6750 7200

Manufacturing expense 2965 3176 3388

Depreciation 6497 6497 6497

Cost Of Goods Manufactured 28240 30225 31981

Cost of Goods Sold : 28239 30225 31981

Gross Profit 191734 227458 245185

Operating Expenses:

General and Admin. Expenses 2508 2759 3035

Total Operating Expenses 2508 2759 3035

Operating Profit 189226 224699 242150

Other Income - - -

Total Other Income - - -

Profit before Non-Operating Expenses 189226 224698 242150

Non-Operating Expenses:

Financial Exp. 16597 12661 8768

Amortization of preproduction exp. 1504 1504 1504

Total Non-operating Exp. 18101 14165 10272

Net Profit before Tax 171125 210533 231878

Tax 68450 84213 92751

Net Profit after Tax 102675 126320 139127

27 | P a g e

Calculate IRR

Cost of the Project -8667650

1 4666666

2 4227000

3 3676000

4 2234675

5 2457654

6 2454876

7 2679786

8 2875687

9 2986454

10 2875353

IRR 41%

Ratio Calculation:

Gross profit ratio

Gross Profit Ratio=Gross Profit/Sales

Year Gross Profit Sales Ratio

1 191734 219973 87.1625154

2 227458 257683 88.27047186

3 245185 277166 88.46142745

Operating Profit Ratio:

Operating Profit=Operating Profit/Sales

Year Operating Profit Sales Ratio

2010 189,226 219973 86.02237547

2011 224,699 257683 87.19977647

2012 242,150 277166 87.36641579

28 | P a g e

Net Profit Ratio:

Net profit ratio=Net Profit/Sales

Year Net profit Sales Ratio

2010 102,675 219973 46.67618299

2011 126,320 257683 49.02147212

2012 139,127 277166 50.19627227

SWOT Analysis

Strengths

Almost 10 manufacturing units of juice are present in Pakistan.

Raw material required for juice manufacturing is available.

Machinery used in juice production is Germany manufactured.

There is cooperation between foreign machinery supplier and local

machinery supplier.

Weaknesses

Local machinery is not of good quality and there is constant

breakdown in local made machinery.

Supply of electricity is not on a regular basis which is a hurdle in

production.

Labor used to operate the machinery is unskilled and not technical.

Demand from the consumer side is not high enough to uplift this

industry.

There is no research and development in this area therefore

technological knowhow in low.

29 | P a g e

Opportunities

Product range is not limited.

There is a possibility to export the product to your neighboring

countries.

Financial institution provides loans to small units to upgrade their

production technology.

The interest of local and foreign investors is increasing

Threats

High energy cost has always been a great concern for this industry.

The image of Pakistani products in international market is not on a

positive side because of its low quality.

Lack of training institutions in the country to put the industry on new

technological production basis.

Availability of international brand in local market is a threat for

local industry.

Recommendation:

Due to the customer complaint and the lack of guidelines to

prevent untrained sales staff from serving customers, the following

recommendations are made concerning compensating the customer, staff

training, monitoring new staff, and revising the guidelines

Compensation

Given that the customer has justifiably complained, we should give him his

money back

30 | P a g e

Staff Training

In the light of the customer's complaint that our salesperson recommended

the wrong product to him, we should ensure that all sales staff complete

their product training before serving customers. This guideline should be in

our staff manuals and procedures.

Monitoring New Staff

In order to reduce the possibility of new salespeople making incorrect

recommendations to customers, they should always be accompanied by an

experienced salesperson for the first month of their service. This guideline

should also be in our staff manuals and procedures

CONCLUSION:

To conclude, it is evident that nothing obtained as main product or by-product,

from the proposed unit goes waste or has no outlet. All the products serve

directly of indirectly human needs as well as they are involved in the

development of overall economic outlook. Hence the market viability of the

project being based on local raw material will result in substantial saving in

valuable foreign exchange

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Critical DiscussionDocument15 pagesCritical Discussionabeer fatimaNo ratings yet

- Soltion of Chemalite BDocument13 pagesSoltion of Chemalite BAITHARAJU SAI HEMANTHNo ratings yet

- The Environmental Impacts of Kopi Luwak Bean ProductionDocument11 pagesThe Environmental Impacts of Kopi Luwak Bean ProductionDina Rizkia RachmahNo ratings yet

- Chapter 3 - Excel SolutionsDocument8 pagesChapter 3 - Excel SolutionsHalt DougNo ratings yet

- Unit 8: Marketing: Case Study: Wincote International P.80 - P.81Document53 pagesUnit 8: Marketing: Case Study: Wincote International P.80 - P.81ANH LÊ ĐỨCNo ratings yet

- Agrifood Sector 2023Document17 pagesAgrifood Sector 2023RaissaIngridaNo ratings yet

- How Environmentalism Nationalism and Civil Rights Shape CorporaDocument73 pagesHow Environmentalism Nationalism and Civil Rights Shape CorporaTien PhamNo ratings yet

- MERE5001-Module 2 - System Life CycleDocument22 pagesMERE5001-Module 2 - System Life CycleCedric Dela CostaNo ratings yet

- PHD Thesis On Human Resource Management PDFDocument8 pagesPHD Thesis On Human Resource Management PDFsandygrassolowell100% (3)

- đề thi 20%Document13 pagesđề thi 20%16. Nguyễn Thị Thúy KiềuNo ratings yet

- Badac AuditDocument57 pagesBadac AuditAlyza Layson67% (3)

- Essence of A Strong Legal Brand LEKE ALDERDocument9 pagesEssence of A Strong Legal Brand LEKE ALDERAJAYI EMMANUELNo ratings yet

- SOP - Adhesives Labeling Policy Direct Contact With Product & Packaging - 11!11!2021 v.1Document4 pagesSOP - Adhesives Labeling Policy Direct Contact With Product & Packaging - 11!11!2021 v.1Irfan KhanNo ratings yet

- PURCHASE AND SALES TRANSACTIONSDocument13 pagesPURCHASE AND SALES TRANSACTIONSNora AlghanemNo ratings yet

- Introduction of Tool Box Talk Rev 01 Global EHS TBT 001Document13 pagesIntroduction of Tool Box Talk Rev 01 Global EHS TBT 001Global EHSNo ratings yet

- Non-Disclosure Agreement TemplateDocument3 pagesNon-Disclosure Agreement TemplategiehartonoNo ratings yet

- For BIR Use Only Annual Income Tax ReturnDocument7 pagesFor BIR Use Only Annual Income Tax ReturndignaNo ratings yet

- Capital Intensive Labor Intensive: Required: Determine The FollowingDocument2 pagesCapital Intensive Labor Intensive: Required: Determine The FollowingMahediNo ratings yet

- A Study On The Effectiveness of On & Off The Job Traning in Taj HotelDocument23 pagesA Study On The Effectiveness of On & Off The Job Traning in Taj HotelArka Rocker100% (1)

- July, 2022 3Document3 pagesJuly, 2022 3Kristine Joy Recopelacion TuanNo ratings yet

- How Do Business Model Tools Facilitate Business Model ExplorationDocument14 pagesHow Do Business Model Tools Facilitate Business Model ExplorationManuel Antonio YartoNo ratings yet

- Entrepreneurship (Week.5)Document55 pagesEntrepreneurship (Week.5)ameer.omar.200262No ratings yet

- Caddy 2000Document23 pagesCaddy 2000ZainNo ratings yet

- Part - 1. Procurement and ContractDocument71 pagesPart - 1. Procurement and ContractOhitai Micheal edwardNo ratings yet

- Jacobs Pellet Mill BrochureDocument6 pagesJacobs Pellet Mill BrochureFreddy FiallosNo ratings yet

- Resume 1Document1 pageResume 1api-511626826No ratings yet

- Econ QuestionsDocument2 pagesEcon QuestionsEsanka FernandoNo ratings yet

- 57132bos46280p4 Inter Q PDFDocument12 pages57132bos46280p4 Inter Q PDFAyush ChowdharyNo ratings yet

- Nike Customized 3D InsolesDocument10 pagesNike Customized 3D InsolesSandy K. AtchisonNo ratings yet

- Sally: Geoff: Sally: Geoff:: Text 2: Negotiation UpdatesDocument1 pageSally: Geoff: Sally: Geoff:: Text 2: Negotiation Updatestamuna janezashviliNo ratings yet