Professional Documents

Culture Documents

Taylor Power Systems

Uploaded by

Teresa CarterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Taylor Power Systems

Uploaded by

Teresa CarterCopyright:

Available Formats

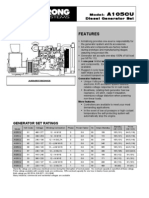

Standby: kW 20

kVA 25

Prime: kW 18

kVA 22.5

TMC20

Ratings Range 60 Hertz Operation

Genset

Model Number

Alternator

Voltage

L-N / L-L

Phase Hertz

130 Rise

Standby Rating

105 Rise

Prime Rating

kW / kVA Amps Amps

TMC20 277/480 3 60 20/25 30 18/22.5 27 PI144E311

139/240 3 60 20/25 60 18/22.5 54

254/440 3 60 20/25 33 18/22.5 30

127/220 3 60 20/25 66 18/22.5 59

240/416 3 60 20/25 35 18/22.5 31

120/208 3 60 20/25 69 18/22.5 62

120/240 3 60 20/25 60 18/22.5 54

219/380 3 60 20/25 42 18/22.5 34

120/240 1 60 17/17 75 16/16 67

Genset Ratings

RATINGS: All three-phase units are rated at 0.8 power factor. All single-phase units are rated at 1.0 power factor.

STANDBY RATINGS: Standby ratings apply to installations served by a reliable utility source. The standby rating is applicable to varying loads for the duration of a

power outage. There is no overload capability for this rating. Ratings are in accordance with ISO-3046/1, BS 5514, AS 2789, and DIN 6271.

PRIME POWER RATINGS: Prime power ratings apply to installations where utility power in unavailable or unreliable. At varying load the number of generator set oper-

ating hours is unlimited. A 10% overload capacity is available for one hour in twelve. Ratings are in accordance with ISO-8528/1, overload power in accordance with ISO

-3046/1, BS5514, AS2789, and DIN 6271. For limited running time and base load ratings consult the factory. The generator set manufacturer reserves the right to

change the design or specifications without notice and without any obligation or liability whatsoever.

GENERAL GUIDELINES FOR DERATION: Altitude: Derate 0.5% per 100m (328 ft.) elevation above 1000m (3279 ft.)Temperature: Derate 1.0% per 10C (18F) tem-

perature above 40C (104F).

Single source responsibility for the generator set

and accessories.

Prototype and production tested to insure one

step load acceptance per NFPA 110.

Two year limited warranty on generator sets and

accessories. Extended warranties also available.

Unit conforms to CSA, NEMA, EGSA, ANSI and

other standards.

Heavy duty 4 cycle industrial engine for reliability

and fuel efficiency.

Brushless rotating field generator with class H

insulation.

Heavy duty steel base with integral vibration

isolators.

EPA Tier 4i Certified Engine.

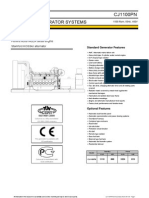

Throughout its 80 year history, Taylor Machine Works, which

manufactures heavy machinery for industries worldwide, has

maintained a reputation of having unparalleled products with

service to match. Taylor Power Systems is no different!

In the early 1980s Taylor Machine Works created Taylor Pow-

er Systems to distribute industrial engines and manufacture

generator sets offering diesel powered 9 kW to 2000 kW and

gaseous powered 30 kW to 400 kW. Taylor Power Systems

provides quality standby and prime generator sets in stationary

or mobile configurations for a wide variety of applications for

example the Healthcare and Telecommunications Industries,

Public Utilities, Federal, State and Local Government agencies,

Educational and Financial Institutions as well as Agricultural.

Taylor Power Systems is your 21st Century Power Source!

kW / kVA

Application and Engineering Data

Basic Technical Data

Manufacturer Perkins

Model 404D-22G

Number of cylinders 4

Cylinder arrangement Vertical in-line

Cycle Four stroke

Induction system Naturally aspirated

Compression ratio 23.3:1

Bore 3.3 in (84 mm)

Stroke 3.9 in (100 mm)

Cubic capacity 135 cu in (2.216 L)

Direction of rotation Counter clockwise (from flywheel)

Firing order 1,3,4,2

Governor type Mechanical 3-5%

Gross engine power 32.6 hp

Electropak net engine power 32 hp

Brake mean effective

pressure

106 psi (731 kPa)

Engine coolant flow (against

5 psi (35 kPa) restriction)

14.6 gpm (55.2 Lpm)

Cooling fan air flow (29 psi

(200 kPa) external

restriction)

Combustion air flow (at rat-

ed speed)

61.4 cfm (1.74 m^3/min)

Exhaust gas flow (max) 168.1 cfm (4.8 m^3/min)

Exhaust gas mass flow

(max)

Exhaust gas temperature in

manifold (max)

950 F (510 C)

Boost pressure ratio

Overall thermal efficiency

(net)

35 %

Cooling System

Coolant

Total System Capacity

With radiator 1.8 gal (7.0 L)

Without radiator 0.95 gal (3.6 L)

Coolant Pump Drive

Coolant pump drive ratio

Maximum top tank

temperature

233 F (112 C)

Temperature rise across

engine

TBA

(rating dependent)

Thermostat operation range 180-203 F (82-95 C)

Recommended coolant: 50/50

Exhaust System

Maximum back pressure 1.5 psi (10.2 kPa)

Exhaust outlet size 1.65 in (42 mm)

Lubrication System

Lubricating oil capacity total

system

2.8 gal (10.6 L)

Maximum sump capacity N/A

Minimum sump capacity 2.4 gal (8.9 L)

Maximum engine operating

angles (front up, front down,

right side or left side)

35

Lubricating Oil Pressure

Oil Temperature (continuous

operation)

257 F (125 C)

Oil Temperature (maximum

intermittent operation)

N/A

Electrical System

Type 12 V neg earth

Alternator type N/A

Alternator Voltage 12 V

Alternator Output 65 A

Starter motor type N/A

Starter motor voltage 12 V

Starter motor power 2.7 hp (2.0 kW)

Minimum cranking speed N/A

Induction System

Maximum air intake restriction

Clean filter 0.44 psi (3 kPa)

Dirty filter 0.93 psi (6.4 kPa)

Air filter type Dry element

Duct allowance with 50% glycol

1800 rev/min

127 F (53 C)

17.4 psi (120 kPa)

6,427 cfm (182 m/min)

Fuel System

Type of injection Indirect

Fuel injection pump Cassette type

Fuel atomizer Pintle nozzle

Fuel Lift Pump

Max flow through customer

filter

16.6 gph (63 Lph)

Maximum suction head 0.8m

Fuel Consumption

110% Load 1.3 gph (4.9 Lph)

100% Load 1.26 gph (4.8 Lph)

75% Load 1.26 gph (4.8 Lph)

50% Load 1.4 gph (5.2 Lph)

Digital Control Panel

Integrated engine-genset control, protection, and metering

Microprocessor allows for exact measurement, setpoint adjustment, and timing functions

Front panel 3 position controls and indicators enable quick and simple operation

Emergency stop push button and an Alarm Horn with silence button

A wide temperature-range liquid crystal display (LCD) with backlighting

SAE J1939 Engine ECU communications

Multilingual capability

Remote RS-485 communications for Optional RDP-110 Remote Annunciator

4 programmable contact inputs and 10 contact outputs (2 Adc rated)

Modbus Communications with RS-485, Battery Backup for Real Time Clock, UL

recognized, CSA certified, CE approved, HALT (Highly Accelerated Life Tests) tested,

IP 54 Front Panel rating with integrated gasket. and NFPA 110 Level 1 Compatible.

Generator Controller Options

Manufacturer NEMA MG1, IEEE, AND ANSI standards

compliance for temperature and motor starting. Type

Gen Frame

Stamford

Ext. Voltage Regulated, Brushless

PI144E

Sustained short-circuit current enabling downstream

circuit breakers to trip without collapsing the alternator

Insulation NEMA

Material Class H Self-ventilated and dripproof construction.

Temperature Rise 130 C, Standby

Superior voltage waveform from a two-thirds pitch

stator and skewed rotor. Hertz 60

Phase 3 Linkboards

RPM 1800 Optimized Electrical Design

Exciter Rotating

# Leads 12 Reconnectable or 4 Single Phase

Enhanced Ventilation

Fully Guarded

PF 0.8 Heavy Duty Bearings

Ambient 40C

Coupling Single Bearing Flexible

Amortisseur Windings Full

Cooling Air Volume

Peak Motor Starting

Voltage Regulation

no-load and full-load

251 CFM

30% Voltage Dip, 70 skVA

1 Phase Sensing 1%

Alternator Specifications

Analog Controller

Analog instruments to monitor AC voltage, AC frequency, oil pressure, water temper-

ature, battery voltage, fuel level, run time/hour meter and percent of load

Red LED indication for overspeed, overcrank, low oil pressure, and high coolant tem-

perature

Green LED indication of engine running

Control switch is provided for local and remote starting with 3 position run/off/remote

switch

Engine mounted emergency by-pass key switch

ENCLOSED UNIT

Standard Enclosure With Internal Silencer

Sound Attenuated Enclosure With Silencer

CONTROLLER

DGC2020 Control Panel

DGC2020 Control Panel with Modem

DGC2020 with Generator Protection

DGC2020 with Modem and Generator Protection

Flush or Surface Mount Remote Annunciator

Remote Mount Break Glass E-Stop Switch

Analog Control Panel

MISCELLANEOUS

Coolant Drain Kit

Water Jacket Heater

Oil Pan Heater

Generator Strip Heater

Battery Charger

Pad Type Battery Heater

Battery Heater Blanket with Thermostat

OVERALL SIZE, L x W x H, in.: 151 in. x 73 in. x 72 in.

WEIGHT (DRY): 2550 lbs.

Note: Dim and weights reflect standard open unit with no options

Note: This drawing is provided for reference only and

should not be used for planning installation. Contact

your local distributor for more detailed information.

Trailer with integral fuel tank

Vibration Isolators

Oil Drain Valve with Extension

Battery

Battery Rack

Battery Cables

Water jacket heater

Flexible Fuel Lines

High Ambient Unit Mounted Radiator

Battery Charging Alternator

Factory Paint

Factory Test Prior to Shipment

2 Year Warranty

Owners Manual

STANDARD FEATURES

AVAILABLE ACCESSORIES

WEIGHTS AND DIMENSIONS

DISTRIBUTED BY:

120 Interstate Drive

Richland, Mississippi 39218

Phone (601)-932-5674 Fax (601)-932-4028

www.taylorpower.com

Line Circuit Breaker

Output Power Cable

Y-YY-ZZ Multi-voltage selector switch

20 amp 120vac and GFI receptacle

20 amp 120vac GFI and 30 amp 120/240vac

twist lock receptacle

30 amp 120vac RV receptacle

Cam-Loks

Diesel Locomotive cable

Extenda-Lites

Hydraulic Brake Kit

Pintle ring hitch

Spare tire kit

Lug wrench

Hydraulic Jack

Single Point Lift

WARRANTY

3 Year Warranty

5 Year Warranty

H

L

You might also like

- Perkins Diesel Generator P400pub 360kwDocument4 pagesPerkins Diesel Generator P400pub 360kwTariq KoyrattyNo ratings yet

- Volvo Diesel Generator p150v Tad720geDocument4 pagesVolvo Diesel Generator p150v Tad720geEvany Ziñho QNo ratings yet

- Reozjc: Standard Features Ratings RangeDocument4 pagesReozjc: Standard Features Ratings RangePapi CruzNo ratings yet

- Perkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorDocument4 pagesPerkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorConstantyn_FrederikNo ratings yet

- Manual BF DW550Document5 pagesManual BF DW550Luis Panti EkNo ratings yet

- Diesel Generating Set 250 kVADocument2 pagesDiesel Generating Set 250 kVAherrtamm100% (1)

- Manual Kholer 2000reozddDocument4 pagesManual Kholer 2000reozddVictorNo ratings yet

- QSK60 Series 50hzDocument4 pagesQSK60 Series 50hzbacuoc.nguyen3560% (1)

- Catalogo Generador Cat 3512Document6 pagesCatalogo Generador Cat 3512pamg50% (1)

- Gerador A Gas PDFDocument4 pagesGerador A Gas PDFpaulo102030No ratings yet

- A105CU A105CU A105CU A105CU: FeaturesDocument4 pagesA105CU A105CU A105CU A105CU: FeaturesshahrilidzwanNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- C1100 D5Document2 pagesC1100 D5anon_568723957100% (1)

- KV90EDocument5 pagesKV90EZawmin TunNo ratings yet

- P40PB (1004G) GensetDocument4 pagesP40PB (1004G) GensetBudi WaskitoNo ratings yet

- 150RZGDocument4 pages150RZGJorge Andre Olivera Aranibar100% (1)

- 80 KW John DeereDocument4 pages80 KW John DeereReynaldo VillarrealNo ratings yet

- 100 RDDocument4 pages100 RDMahmoud EldabahNo ratings yet

- C440 D5Document2 pagesC440 D5Thao Nguyen XuanNo ratings yet

- Perkins P200Document4 pagesPerkins P200PaulusIwanNo ratings yet

- Kohler Marine 500KW 500EOZCDocument4 pagesKohler Marine 500KW 500EOZCnathandemNo ratings yet

- Prime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsDocument4 pagesPrime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsLeonardusHSijabatNo ratings yet

- MTU10V1600DS550 550kVA Standby FuelOptDocument4 pagesMTU10V1600DS550 550kVA Standby FuelOptlcsandovalr989No ratings yet

- MTU20V4000DS2800 2500kW DCCP PDFDocument4 pagesMTU20V4000DS2800 2500kW DCCP PDFNestor AlbarranNo ratings yet

- C150D5 - Data Sheet UKDocument2 pagesC150D5 - Data Sheet UKphonggensetNo ratings yet

- Diesel Engine MitsubishiDocument4 pagesDiesel Engine MitsubishiMarbun Benny100% (1)

- 350EOZC - Gerador KOHLER - Marítimo - Uso Comercial-ServiçosDocument4 pages350EOZC - Gerador KOHLER - Marítimo - Uso Comercial-Serviçosgeraldo gilNo ratings yet

- C450 50 eDocument5 pagesC450 50 eAlfian M AbdjanNo ratings yet

- Diesel Generator Set Specifications and FeaturesDocument4 pagesDiesel Generator Set Specifications and Featuressahat100% (1)

- Ks2300 t3 Specs Rev2Document2 pagesKs2300 t3 Specs Rev2Sunthron SomchaiNo ratings yet

- 3412C 725 kVA Prime LowBsfc EU 50HzDocument6 pages3412C 725 kVA Prime LowBsfc EU 50Hzrbmr1No ratings yet

- 3612Document6 pages3612Chandrashekar PatigeNo ratings yet

- Generator SetDocument4 pagesGenerator Setbiz2721No ratings yet

- G 4170Document4 pagesG 4170Orlando Yerén ValenciaNo ratings yet

- DFHD - Model Specification SheetDocument4 pagesDFHD - Model Specification SheetAlejandro Lagares100% (1)

- Rental: XQ2000 Sound Attenuated Power ModuleDocument8 pagesRental: XQ2000 Sound Attenuated Power ModuleAngel Javier NuñezNo ratings yet

- 1000 Kva 400v c32 Low BSFC PrimeDocument6 pages1000 Kva 400v c32 Low BSFC PrimeelipholebNo ratings yet

- CukurovapowerDocument6 pagesCukurovapowerAhmed GadNo ratings yet

- XQ1000 Lehx0532Document6 pagesXQ1000 Lehx0532Anonymous uZJfsg819LNo ratings yet

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PDocument4 pagesDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryNo ratings yet

- Comprehensive specifications and ratings for Kohler 10RY/RZ natural gas generator modelsDocument4 pagesComprehensive specifications and ratings for Kohler 10RY/RZ natural gas generator modelsBianka HernandezNo ratings yet

- 90kVA PDFDocument4 pages90kVA PDFXander DelinyaNo ratings yet

- Çukurova j1100pn Data SheetDocument6 pagesÇukurova j1100pn Data SheetibilgeNo ratings yet

- KohlerDocument5 pagesKohlerRajesh S BhattNo ratings yet

- MITSUBISHI MGS SERIES DIESEL GENERATORDocument4 pagesMITSUBISHI MGS SERIES DIESEL GENERATORAbelRamadhanNo ratings yet

- SS8 CPGKDocument4 pagesSS8 CPGKRoozbeh BahmanyarNo ratings yet

- Caterpillar 3606 2425kVA GensetDocument6 pagesCaterpillar 3606 2425kVA GensetMuhammad Irfan KhanNo ratings yet

- 2010.diesel Generating Set2.23 - 13.55.7 - 1169Document5 pages2010.diesel Generating Set2.23 - 13.55.7 - 1169Bechara Philip AssouadNo ratings yet

- Tier 2 EPA-Certified 2250 kW Diesel Generator Model SpecificationsDocument4 pagesTier 2 EPA-Certified 2250 kW Diesel Generator Model SpecificationsVictorNo ratings yet

- Diesel Generator Set: Prime Model:LP90P Standby Model:LP100SDocument4 pagesDiesel Generator Set: Prime Model:LP90P Standby Model:LP100SLeonardusHSijabatNo ratings yet

- TAD1642GE: Volvo Penta Genset EngineDocument2 pagesTAD1642GE: Volvo Penta Genset EngineroozbehxoxNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- IM15204047Document1 pageIM15204047Teresa CarterNo ratings yet

- Moon River: H. Mancini Arr. Henry ObiDocument3 pagesMoon River: H. Mancini Arr. Henry ObiTeresa CarterNo ratings yet

- Summer Training DMRC ReportDocument34 pagesSummer Training DMRC ReportTeresa Carter100% (1)

- Moon River: H. Mancini Arr. Henry ObiDocument3 pagesMoon River: H. Mancini Arr. Henry ObiTeresa CarterNo ratings yet

- Summer Training DMRC ReportDocument34 pagesSummer Training DMRC ReportTeresa Carter100% (1)

- Baran Sweezy Monopoly Capital An Essay On The American Economic and Social Order OCRDocument212 pagesBaran Sweezy Monopoly Capital An Essay On The American Economic and Social Order OCRTeresa CarterNo ratings yet

- IM15204047Document1 pageIM15204047Teresa CarterNo ratings yet

- New King James Version 1982Document908 pagesNew King James Version 1982Teresa CarterNo ratings yet

- OneOS-Data User Guide V4 - 2R5 (Ed.5)Document484 pagesOneOS-Data User Guide V4 - 2R5 (Ed.5)Teresa CarterNo ratings yet

- Morgan Stanley Europe UpdateDocument25 pagesMorgan Stanley Europe UpdateTeresa CarterNo ratings yet

- Overflow FiltrationDocument3 pagesOverflow FiltrationTeresa CarterNo ratings yet

- Snapper 217019BV User GuideDocument32 pagesSnapper 217019BV User GuideTeresa CarterNo ratings yet

- Enzymes in The IndustryDocument76 pagesEnzymes in The Industrymarkfliance100% (1)

- Ubs Investment Banking PitchbookDocument19 pagesUbs Investment Banking PitchbookTeresa Carter100% (1)

- Coal Tar Solucion BP 98Document1 pageCoal Tar Solucion BP 98Teresa CarterNo ratings yet

- NASDAQOMXProposalfor NYSE04012011Document34 pagesNASDAQOMXProposalfor NYSE04012011Priyanshu BhattacharyaNo ratings yet

- SulfamethoxazoleDocument35 pagesSulfamethoxazoleTeresa CarterNo ratings yet

- Systemapproach 130101041650 Phpapp01Document12 pagesSystemapproach 130101041650 Phpapp01Teresa CarterNo ratings yet

- Bear Stearns NortelDocument79 pagesBear Stearns NortelTeresa Carter100% (1)

- Rubric Assessment of Student Responses To An Information Literacy TutorialDocument43 pagesRubric Assessment of Student Responses To An Information Literacy TutorialTeresa CarterNo ratings yet

- Bear Stearns NortelDocument79 pagesBear Stearns NortelTeresa Carter100% (1)

- John Lubieplacki EssayDocument1 pageJohn Lubieplacki EssayTeresa CarterNo ratings yet

- Sbi Mutual Fund Marketing Summer Training ReportDocument94 pagesSbi Mutual Fund Marketing Summer Training ReportAman Gupta97% (29)

- Sertindole MartindaleDocument4 pagesSertindole MartindaleTeresa CarterNo ratings yet

- Indian Oil CompanyDocument12 pagesIndian Oil CompanyTeresa CarterNo ratings yet

- S.M..PPTX PradeepDocument1 pageS.M..PPTX PradeepTeresa CarterNo ratings yet

- SF InstallDocument198 pagesSF InstallK Raghava ReddyNo ratings yet

- Public Service Announcement Rubric: CategoryDocument1 pagePublic Service Announcement Rubric: CategoryTeresa CarterNo ratings yet

- Public Service Announcement Rubric: CategoryDocument1 pagePublic Service Announcement Rubric: CategoryTeresa CarterNo ratings yet

- A New Method For Synchronous Generator Core EvaluationDocument7 pagesA New Method For Synchronous Generator Core EvaluationIndra JayaNo ratings yet

- Gyrolok CatalogDocument58 pagesGyrolok CatalogmartinvandoornNo ratings yet

- Brochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionsDocument8 pagesBrochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionskmalNo ratings yet

- TFG A 020Document81 pagesTFG A 020Sergio FontechaNo ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFDocument42 pagesModule 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFshareyhou100% (1)

- Turbomachinery For Ammonia Plants: Man TurboDocument20 pagesTurbomachinery For Ammonia Plants: Man TurboavwnashNo ratings yet

- Rajasthan Power Sector Reforms Act 1999Document41 pagesRajasthan Power Sector Reforms Act 1999Latest Laws TeamNo ratings yet

- Aviation Paperbacks 2012Document4 pagesAviation Paperbacks 2012tomas.kujal8455No ratings yet

- Maruti SuzukiDocument33 pagesMaruti SuzukiNaman Arya100% (4)

- An Integrated Lean Approach To Process Failure ModDocument12 pagesAn Integrated Lean Approach To Process Failure ModLeoo Cotrina FranciaNo ratings yet

- Timber-framed homes guideDocument44 pagesTimber-framed homes guideMtkNo ratings yet

- Mechanical Engineer Resume For FresherDocument5 pagesMechanical Engineer Resume For FresherIrfan Sayeem SultanNo ratings yet

- SG 247777Document862 pagesSG 247777ieatbeesNo ratings yet

- Sudhakar ProjDocument71 pagesSudhakar ProjsureshexecutiveNo ratings yet

- Bartec Headed Bars Qualification File and References 2017.09.08Document35 pagesBartec Headed Bars Qualification File and References 2017.09.08Andres Hermoso MeijideNo ratings yet

- Continuous Improvement SWOT AnalysisDocument2 pagesContinuous Improvement SWOT AnalysisichintanNo ratings yet

- Bajaj PULSUR 220 DTS - OkokDocument75 pagesBajaj PULSUR 220 DTS - OkokSubramanya DgNo ratings yet

- Comsoal: Computer Method For Sequencing Operations For Assembly LinesDocument30 pagesComsoal: Computer Method For Sequencing Operations For Assembly LinesCarson HungNo ratings yet

- Creating The Lean Car DealerDocument52 pagesCreating The Lean Car DealerMahadiMohdDinNo ratings yet

- Industrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDDocument17 pagesIndustrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDAmiruddin HassanNo ratings yet

- The Critical Success Factors in Customer Relationship Management (CRM) (ERP) ImplementationDocument15 pagesThe Critical Success Factors in Customer Relationship Management (CRM) (ERP) ImplementationSatya Sai KiranNo ratings yet

- Catalog E EslonValve ManualOperationDocument72 pagesCatalog E EslonValve ManualOperationAnonymous ItzBhUGoiNo ratings yet

- RMA Process Complete Flow SampleDocument2 pagesRMA Process Complete Flow SampleBharathNo ratings yet

- Fidic Quality Based Consultant Selection GuideDocument20 pagesFidic Quality Based Consultant Selection GuideJuan McdanielNo ratings yet

- Support Dept Cost Allocation - 3 Allocation MethodsDocument6 pagesSupport Dept Cost Allocation - 3 Allocation MethodsSophie PearsonNo ratings yet

- Overview of Sabah and Labuan Grid Code 16 June 2014Document81 pagesOverview of Sabah and Labuan Grid Code 16 June 2014kiddjoe1470100% (1)

- Assam & Nagaland 1Document218 pagesAssam & Nagaland 1Ahmer KhanNo ratings yet

- Project Title: Simple Cafe Billing System: Rajokari Institute of TechnologyDocument8 pagesProject Title: Simple Cafe Billing System: Rajokari Institute of TechnologyVinodNo ratings yet

- CHRIST (Deemed to be University) School of Engineering and Technology Department of Mechanical and Automobile Engineering ME636OE4 – PROJECT MANAGEMENT ASSIGNMENT #1Document5 pagesCHRIST (Deemed to be University) School of Engineering and Technology Department of Mechanical and Automobile Engineering ME636OE4 – PROJECT MANAGEMENT ASSIGNMENT #1NIRMAL RAJESH 1860434No ratings yet

- Industrial Apron FeedersDocument5 pagesIndustrial Apron FeederstonyNo ratings yet