Professional Documents

Culture Documents

Acid Gas Dewpoint and Hydrate Pred - Final3

Uploaded by

Rohit Kumar KushwahaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acid Gas Dewpoint and Hydrate Pred - Final3

Uploaded by

Rohit Kumar KushwahaCopyright:

Available Formats

The 83

rd

Annual Gas Processors Association Convention

Forum: Benefits of the GPA Research Program

Acid Gas ater !e" #oint$ %&drate

and Ph&sical Pro#ert& Predictions

Authors: Kindra Snow-McGregor

Process Engineer

Washington Group International

Johnny Johnson

Technology Manager

Washington Group International

AB'TRACT:

The accurate prediction o high-!"# acid gas water dew points is diicult$ !"# and %#S

ha&e unusual water holding capacity and hydrate or'ing characteristics( and predicting

these characteristics is urther co'plicated when there are e&en s'all concentrations o

'ethane( nitrogen and other co'pounds$ The data pro&ided ro' the GPA Section )

*esearch Progra' was instru'ental in deter'ining accurate water dew point conditions

or two recent pro+ects$

"ne re,uired accurate deter'ination o the eed gas water content o a high-

!"# content sour natural gas dehydration acility to acilitate e-panding its

capacity( while operating near the critical point o the gas 'i-ture$

*igorous co'parisons .etween the la.oratory data and co''ercially a&aila.le sotware

allowed Washington Group International to deter'ine the 'ost accurate 'odeling tool

a&aila.le or calculating water dew point in high-!"# gas 'i-tures$ A correction actor to

the 'odel was then deter'ined .ased on the co'parisons with the GPA data$

Preli'inary engineering was .ased on these 'odiied predicti&e nu'.ers$ Su.se,uent

dry and wet gas water sa'pling was conducted$ The results o the wet and dry gas

sa'ples were in-line with the correction actor applied predictions( and &eriied the

engineering design .asis$ This wor/ increased the acility0s capacity to appro-i'ately

123 4 o the original design capacity( with essentially the original e,uip'ent$

The other eort in&ol&ed design o an acid gas in+ection 5AGI6 acility that

includes operations near the critical point and at supercritical conditions$

Water content( hydrate or'ation and density o acid gas 'ust .e predicted accurately to

assure sae operation o high-!"# gas conditioning acilities and acid gas in+ection

pipelines$ Washington Group co'pleted rigorous co'parisons .etween the a&aila.le

GPA *esearch *eport data( other a&aila.le data( and co''ercially a&aila.le sotware to

deter'ine the 'ost accurate tools a&aila.le or high-!"# and acid gas hydrate

predictions$ The su.se,uent design wor/ has allowed design( construction and now

sae operation o an acid gas in+ection acility while i'pro&ing plant econo'ics$

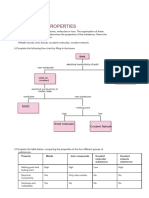

Acid Gas !e" #oint and %&drate Predictions

Introduction As design engineers approach pro+ects in&ol&ing high concentrations o

hydrogen sulide 5%#S6 and car.on dio-ide 5!"#6 they 'ust shit their

paradig': ro' the well-docu'ented and well-understood aspects o

handling natural gas strea's7 to the lesser-/nown and co'parati&ely less

well understood aspects o handling luids containing predo'inantly %#S

and !"#$

New

Paradigm

8Physical properties and ther'odyna'ic .eha&ior o %#S and !"#

de&iate signiicantly ro' natural gas strea's$

Water and hydrate e,uili.riu' or %#S and !"# diers signiicantly

ro' natural gas strea's$

)ield processing o high-%#S9!"# luids and AGI acilities 'ost oten

re,uires so'e portions o the process to operate at conditions that

are in or near the critical region o the acid gas 'i-tures phase

diagra'( and other portions e-tend into the supercritical regions$

Physical properties and ther'odyna'ic .eha&ior o acid gas

'i-tures e-hi.it so'e unusual patterns in their dependence on

te'perature and pressure( particularly in the critical and

supercritical regions$

!urrent process si'ulation 'odeling tools ha&e diering le&els o

accuracy in predicting the characteristics and .eha&ior o acid gas

'i-tures$

!urrent process si'ulation 'odeling tools ha&e esta.lished

'ethodology to deine whether a strea' is to .e treated as a

:li,uid; or as a :&apor;:

o depending on where the T-P point lies relati&e to the acid

gas 'i-tures critical point7

o or where the T-P point lies within the &arious portions o the

supercritical region

thus deter'ining the calculation 'ethod used to predict the strea's

properties$ So'e o these :deault; decisions are inaccurate$

In so'e cases( the process si'ulation 'odeling tools are una.le to

co'e to a solution$

In other cases( a solution is achie&ed that is signiicantly in error$

GPA

Research

Efforts

The Gas Processors Association 5GPA6 and Gas Processors Suppliers

Association 5GPSA6 ha&e recogni<ed the need or and .eneits o

unda'ental research to deter'ine solutions to recogni<ed natural gas

industry operating pro.le's$ Their eorts ha&e supported de&elop'ent o

data and process si'ulation 'odeling tools that ha&e allowed signiicant

ad&ance'ent in the design o 'ore opti'u'( econo'ical and sae

acilities$ The Section ) *esearch !o''ittee has .een the pri'ary .ody

responsi.le or deining research progra's( selecting ,ualiied

researchers( 'onitoring and criti,uing the research wor/ and results( and

pu.lishing ,uality data that supports the GPA9GPSA 'e'.ership$ The

GPSA has sponsored the Engineering =ata >oo/ that contains so'e o the

'ost rele&ant data and correlations( and is recogni<ed world-wide as a

&alua.le source o this inor'ation$

Summary of

Current Acid

The GPA and other industry data ha&e allowed process si'ulation

'odeling indi&iduals( uni&ersities and co''ercial ir's to i'pro&e on

Gas Database predicti&e techni,ues and progra's to assist designers and operators in

the natural gas and other industries$ The 'ore than 23 current operating

acid gas in+ection acilities ha&e certainly .eneited ro' these eorts$

%owe&er( 'ost are relati&ely s'all- capacity installations with relati&ely low

operating pressure re,uire'ents or in+ection$ *ecently( 'uch larger( 'ore

co'ple- and 'ore costly installations are .eing considered and installed$

!ertain acilities re,uire operations near the critical point region and into

the supercritical region o the gas 'i-tures phase en&elope$ The speciic

GPA-sponsored pro+ects used or the wor/ reerenced in this paper are

listed .elow( in Ta.le 1$ In GPA pro+ects where 'ultiple gas co'positions

were studied( only the high acid gas co'positions were re&iewed or our

co'parisons$

Ta.le 1$ GPA *esearch *eports utili<ed or this wor/

Pro+ect ?o$

*esearch

*eport ?o$$ Title *esearcher

@#2-@A **-BB

E,uili.riu' Phase !o'position

and %ydrating !onditions in

Syste's !ontaining Me"%( Cight

%ydrocar.ons( !"# and %#S

=>**

@#2-@A **-DE

The Inluence o Methanol on

%ydrate )or'ation at Cow

Te'perature

=>**

@#2-@E **-@D

%ydrate )or'ation and

E,uili.riu' Phase !o'positions

in the Presence o Methanol

=>**

GPSA Eng$ =ata

>oo/

Fol$ II( 11

th

Edition

)igure #3-1#

!o'parison o E-peri'ental and

!alculated Water !ontents or

Acid Gases

=etails ?ot

Pro&ided

DD2-@G **-1#3

Water !ontent Falues o a !"# H

2$A1 Mol Percent Methane

Mi-ture

*ice

Ini&ersity

GE2 **-1DE

Water !ontent o ?atural Gas

Syste's !ontaining Acid Gas

5including so'e density data6

=>**

!ertain other pu.lic and pri&ate data sources were identiied and analy<ed

during the course o Washington Group0s eorts or the pro+ects discussed

in this paper$ %owe&er( it was the GPA data that pro&ed to .e 'ost relia.le

and dee'ed 'ost accurate$

Additional Acid

Gas Data

Requirements

The capital and operating costs o new and e-isting high-acid gas content

processing acilities can .e considera.ly lowered( and the saety o their

operations and 'aintenance can .e i'pro&ed( i additional data were

a&aila.le or water dew point( incipient hydrate or'ation te'perature( and

physical properties o acid gas 'i-tures at pressures a.o&e a.out 233

psig$

GPA *esearch Pro+ects G@D( GGD( 3A# and 3AB are in progress to address

certain H >IT ?"T ACC - pertinent water content and hydrate issues$ The

proposed GPA *esearch Pro+ect 3E# will speciically address physical

properties o acid gas 'i-tures i appro&ed during the in-progress

'e'.ership .alloting$

%igh(C)

*

Gas Conditioning Plant

Background Pre&ious to de.ottlenec/ing o a sour gas dehydration acility( the inlet sour

gas water content was esti'ated ro' plant historical operating data( and

ro' co'puter si'ulation$ Inortunately( the plant historical water disposal

rates pro&ided signiicant e&idence that the inlet water content was either

'uch lower than what the co'puter si'ulations predicted( or the actual dry

gas product water content 'ust .e 'uch higher than what the si'ulations

predicted$

Analyzer

Problems

%istorically( the acility had diiculty with accurate dry gas 'oisture

analy<er 'easure'ents due to TEG entrain'ent ro' the TEG !ontactors$

=uring this phase o the pro+ect( there were no 'oisture analy<er

instru'ents a&aila.le that were considered to gi&e accurate responses$

The lac/ o accurate dry gas water content data pre&ented calculation o an

accurate water .alance around the acility$ This pre&ented direct resolution

.etween the operating data and si'ulation or other calculations$ We were

conident in how 'uch water was re'o&ed ro' the gas .ased on careul

plant 'easure'ent( .ut were not conident in the water content o the inlet

and outlet gas si'ulation predictions$

Equiment and

!EG "ouling

Problems

=ue to ouling pro.le's in the TEG syste'( and e,uip'ent peror'ance

issues( the TEG circulation rate to the !ontactor was e-tre'ely low$ The

circulation rates were o the chart or all TEG dehydration syste' design

guides( and in 'any cases the si'ulations or the TEG !ontactor would

not con&erge as a result o the &ery low TEG eed rate to the !ontactor$

The low TEG circulation rates( co'.ined with the high-%#S and !"#

content o the gas 'ade predicting the water content o the dry gas

e-tre'ely diicult$ E&en typical TEG !ontactor peror'ance was un/nown

at these conditions$ The acid gas solu.ility in the TEG was o&er-predicted

.y a actor o # in co'parison to the historical loading o the recycle gas

co'pressors at the acility( adding to the diiculty o setting up a si'ulation

that would 'odel actual plant peror'ance$

It was speculated that the dry gas water content could .e anywhere ro'

#3 l.9MMsc to B3 l.9MMsc gas( &ersus the inlet wet gas water content$ I

the dry gas water content was a.o&e A3 l.9MMsc( then corrosion o the dry

gas pipeline could .e occurring$

Engineering

#asis

$ndefined

This uncertainty posed a signiicant pro.le'$ The 'ain design

considerations or a dehydration acility are water content o the inlet gas(

and the design dry gas water content to .e 'et at the design inlet gas low

rate$ This inor'ation essentially sets the re,uired circulation rate o TEG(

and i'pacts the si<ing o all pu'ps( cross-e-changers( and 'ost

i'portantly( the re.oiler$

Path "orward To o&erco'e the lac/ o relia.le water content data ro' the plant

operation( it was decided to deter'ine the 'ost accurate tool a&aila.le to

predict the inlet water content o the gas$ In&estigation was done to o.tain

all a&aila.le and pu.lished sour gas water content data$ The data was

then co'pared to &arious si'ulation 'odels e,uili.riu' predictions$

#enefits of

GPA Research

Reorts

)ro' re&iew o the data 9 si'ulation co'parisons( a correction actor was

deter'ined to .e applied to si'ulations o our gas co'position and

conditions to pro&ide a 'ore accurate esti'ate o the inlet water content to

the acility$ The predicted JdryJ gas water content or any operating

condition was then o.tained using a Mc!a.e-Thiele analysis o the TEG

!ontactor$ A spreadsheet calculation has .een de&eloped to allow plug-in

o speciic para'eters and ,uic/ output o predicted peror'ance as shown

in )igure 1 .elow$ "perating data ro' the downstrea' acility allowed an

indirect 'ethod o .ac/ calculating the e-iting dry gas water content$

These results were ound to agree well with the descri.ed si'ulation 9

calculation 'ethod and &alidated the correction actor used or deter'ining

the inlet water content to the acility$

)igure 1 Mc!a.e-Thiele =iagra' E-a'ple

Post TAR Performance Testing ( Train + Fi,ed -alve Tra&s

.levated Rates ( 3/0 11scfd at +8 g#m lean T.G

+2$222 l34 Car3on Test Filters in )#eration !uring Test

y K BDE$GA- L 1B$1@B

*

#

K 1

y K -AD1$3E-

#

L BB@$AA- L 11$1B@

*

#

K 1

y K -@EE$@D-

#

L 2#@$#B-

*

#

K 3$GG@G

y K -11GB$G-

#

L B2A$BE-

*

#

K 3$GGGD

3

#3

E3

B3

@3

133

1#3

1E3

3 3$32 3$1 3$12 3$# 3$#2

l3%

*

)56l3%

*

)7l3T.G8

l

3

%

*

)

5

1

1

s

c

f

>*ME Tray Eiciency - 3$A1

"perating Cine E,n:

%NSNS E,uili.riu' Cine E,n:

>* M E

E,uili.riu' Cine

>*ME Pseudo-E,uili.riu' Cine

"perating Cine

O1#(N1A

O3( N1

Inlet Water !ontent: 1#E l.9MMsc

PAS*C Preli'inary *esultsQ

=ry Gas Water !ontent: #A l.9MMsc

PAS*C Preli'inary *esultsQ

Cean TEG !o'p: GG$3# wt 4 TEG

*ich TEG !o'p: @E$1 wt 4 TEG

Total TEG Coss: #$2 gal9MMsc

3$BE gal TEG circ$9l. %#" re'o&ed

Total Water *e'o&ed:

Measured: 1B@3 l.9hr %#"

!alculated: 12DE l.9hr %#"

Total Plant Processing *ate:

RBA3 Mscd

>*ME Pseudo-E,uili.riu' Cine E,n:

>* M E E,uili.riu' Cine E,n:

%NSNS

E,uili.riu' Cine

The TEG !ontactors ha&e 1# trays( or 1# actual stages$ The operating line

is deined ro' plant peror'ance data$ )ro' the operating line( the

pseudo-e,uili.riu' line is calculated using an esti'ated >ryan *esearch

and Engineering 5>*ME6 tray eiciency$ The >*ME tray eiciency is then

ad+usted until 1# actual stages are achie&ed$ "nce the >*ME tray

eiciency has .een deter'ined ro' operating data( the Mc!a.e-Thiele

diagra' can .e used to predict how the contactor will peror' under

dierent operating conditions assu'ing the tray eiciency does not

change$

Definition of

Alied !ray

Efficiency

This later assu'ption has pro&en to .e &alid o&er the range o conditions

considered or the pro+ect$ The %NSNS e,uili.riu' line 5using the Peng-

*o.inson e,uation o state6 is pro&ided to illustrate the dierence o the

e,uili.riu' predictions .etween %NSNS and >*ME$ The sa'e 'ethod

descri.ed a.o&e can .e used to de&elop a %NSNS pseudo-e,uili.riu' line$

A dierent %NSNS tray eiciency would result to 'atch actual

peror'ance$ The pseudo-e,uili.riu' line is deined .y the ollowing

e,uation:

N pseudo-e,uili.riu' K N operating line H ST5N operating line H N >*MEe,uili.riu'6

Where S K tray eiciency$

Ater the TEG !ontactor peror'ance has .een deter'ined at the chosen

operating conditions .ased on plant data( hand calculations are co'pleted

to calculate speciic heat e-changer duties( ter'inal te'peratures( and

lash gas and regenerator o-gas &olu'es$ The trial and error hand

calculations utili<ed actual heat e-changer peror'ance data( a&aila.le

TEG ther'ophysical property data( and actual plant operating data or the

acid gas solu.ility in the TEG$ Through the use o the GPA *esearch =ata(

Washington Group was a.le to or' a sound engineering design approach

to de.ottlenec/ing the acility$

"nly the GPA *esearch *eports that were used will .e re&iewed in this

report$ All selected data conditions and co'positions were si'ulated using

the ollowing un'odiied( pu.licly a&aila.le sotware:

%riginal

&odels $sed

AUIAli.iru'( Fersion #$3i( =r$ John J$ !arroll

P*"SIM( Fersion GD$3( >ryan *esearch and Engineering( Inc$

%NSNS( Fersion #$E$1( %yprotech

)or the purposes o this paper( all the GPA research report data was re-run

using the ollowing updated &ersions o the sotware$

&odels

Reorted

AUIAli.iru'( Fersion #$3i( =r$ John J$ !arroll

P*"SIM( Fersion G@$A( >ryan *esearch and Engineering( Inc$

ProMa-( >eta Fersion #$3( >ryan *esearch and Engineering( Inc$ 5>*E6

%NSNS( Fersion A$1( Aspentech

The data co'parison results or P*"SIM( ProMa-( and in so'e cases(

%NSNS were pro&ided directly .y technical specialists ro' >ryan

*esearch and Engineering( and Aspentech respecti&ely$ The data

co'parisons or AUIAli.riu' were co'pleted .y Washington Group

#RE &odified

'i( "iles

>ryan *esearch and Engineering( Inc$ 5>*E6 pro&ided 'odiied Ki+ data

iles that pro&ide si'ulation prediction i'pro&e'ents or acid gas water

content calculations$ The results o these 'odiied Ki+ iles are pro&ided in

the **-1DE section$ These iles are a&aila.le to the pu.lic( and are

reco''ended or high-acid gas co'positions$ !ontact >*E directly or

the i'pro&ed Ki+ data iles$

Research Re#ort +*2: Water Content Values of a CO2 5.31 Mol

Percent Methane Miture

Datum

Analyzed

The iso.ar datu' at G33( 1(133( and 1(233 psia were o the greatest

interest to us( particularly in the te'perature range o 1#3 - 1#2

o

)$ The

ollowing data co'parisons were helpul in our deter'ination o an

ade,uate correction actor to use$ It should .e noted that the results ro'

%NSNS were not used or our wor/$ %NSNS reported that the deault

.inary interaction para'eters 5>IP6 are 'ost li/ely itted or lower !"#

concentration syste's( and thereore are less suita.le or this syste'

where !"# content in the gas strea' is as high as G24$ To accurately

represent the phase .eha&ior o such a syste'( the .inary interaction

para'eters should .e re-regressed with ade,uate data$ The pro+ect

resources and schedule did not allow the ti'e to underta/e such an eort$

)igure #$ Sour Gas Water !ontent !o'parisons( **-1#3( G33 psia Iso.ar

)igure A$ Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1#3( G33 psia Iso.ar

)igure E$ Sour Gas Water !ontent !o'parisons( **-1#3( 1(133 psia Iso.ar

)igure 2$ Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1#3( 1(133 psia Iso.ar

)igure B$ Sour Gas Water !ontent !o'parisons( **-1#3( 1(233 psia Iso.ar

)igure D$ Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1#3( 1(233 psia Iso.ar

)igure @$ Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1#3( 1##

o

) Isother'

Summary of

Results

)ro' the si'ulation de&iation co'parisons( it is clear that additional wor/

is re,uired to produce 'ore accurate acid gas dew point predictions or

near pure !"#$ !urrently( it is up to the engineer to deter'ine the 'ost

accurate water content prediction correlation or a gi&en 'odel$ They 'ust

.e cogni<ant o particular 'odel short alls or high acid gas concentration

strea's to 'a/e an educated decision$ Through out this pro+ect( 'any

e,uip'ent &endors pro&ided the client with si'ulation 'odel results( and

concluded that all o the e,uip'ent was signiicantly undersi<ed to 'eet

the pro+ect de'ands$ These conclusions were .ased on their e-tre'ely

high 'odel predictions oro inlet gas water content to the acility( which

were in error$

Current

&odels

Deficiency

)or the conditions o our interest( the applica.le 'odels consistently ha&e

de&iations around #34( with plus or 'inus depending on the correlation

and 'odeling tool as illustrated a.o&e$

Research Re#ort +/9: Water Content of !atural "as #$ste%s

Containing &cid "as

Datum

Analyzed

The datu' pro&ided in Ta.les 2(B( 11( and 1# were o the 'ost interest to

us or the purposes o our wor/$ Ta.les 2 and B pro&ide two isother' data

sets 51#3

o

)( and #33

o

)6 o e,uili.riu' phase properties or syste's

containing 24 'ethane-propane 5G2:2 'ole ratio6 and G24 hydrogen

sulide-car.on dio-ide 51:A 'ole ratio6 in the presence o water$

Ta.les 11 and 1# pro&ide two isother' data sets 51#3

o

)( and #33

o

)6 o

e,uili.riu' phase properties or syste's containing 24 'ethane-propane

5G2:2 'ole ratio6 and G24 hydrogen sulide-car.on dio-ide 51:1 'ole ratio6

in the presence o water$

The results ro' %NSNS are not presented here .ecause the de&iations

using deault >IP &alues are so large it intereres with the graphical

analyses$ )or e-a'ple( the a&erage %NSNS de&iations using deault >IP

&alues or Ta.le 2 and B are #@34( and 1#34 respecti&ely$

%dd Phase

#eha)ior

)ro' )igure G( the diiculty in predicting water content o high !"#-acid

gas containing syste's is illustrated$ ?otice the signiicant drop in

e,uili.riu' water content at #33

o

)( ro' #33 psia 5RB 'ole 46 to 1(233

psia 5R1$2 'ole 46$ This .eha&ior is 'uch less pronounced at 1#3

o

)$

)igure G Water !ontent Predictions and =ata !o'parisons( **-1DE( Ta.le 2 and B

)igure 13 Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1DE( Ta.le 2( Isother' K 1#3

o

)

)igure 11 Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1DE( Ta.le B( Isother' K #33

o

)

)igure 1# Water !ontent Predictions and =ata !o'parisons( **-1DE( Ta.le 11

)igure 1A Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1DE( Ta.le 11( Isother' K 1#3

o

)

)igure 1E Water !ontent Predictions and =ata !o'parisons( **-1DE( Ta.le 1#

)igure 12 Si'ulation =e&iations or Sour Gas Water !ontent !o'parisons

**-1DE( Ta.le 1#( Isother' K #33

o

)

Current

&odels

Deficiency

)ro' the si'ulation de&iation co'parisons( it is clear that additional wor/

is re,uired to produce 'ore accurate high !"#-acid gas water dew point

predictions$ )ro' re&iewing this datu'( along with other sources( it was

decided that a correction actor o 3$@( applied to either P*"SIM

un'odiied Ki+ output( or AUIAli.riu' output( would pro&ide a 'ore

accurate prediction o the inlet water content to this acility and or

operation at the design pressure and te'perature conditions$

Acid Gas :n;ection 6AG:8 Facilit&

#ac*ground Washington Group recently co'pleted a successul AGI Pro+ect$

A&aila.ility o pertinent data de&eloped under the GPA Section ) *esearch

!o''ittee was unda'ental to success o this pro+ect in se&eral ways:

The econo'ic &ia.ility and proita.ility o this natural gas

processing acility was i'pro&ed7

The operating lie o the acility was e-tended .y a ew years7

The saety o operating personnel was ensured during nor'al

operation7

And 'ore i'portantly( the potential or unsae conditions during

startup( shutdown( and operating upsets could .e identiied and

'itigated during design H rather than learning ro' .ad

e-periences$

Acid Gas

+n(ection

Process Phase

Diagram

)igure 1B represents the process design o the acid gas in+ection syste'

superi'posed on the phase diagra' or one o the acid gas 'i-tures

considered in the design o the su.+ect acility$ The phase diagra' is

located generally in the lower let portion o the igure$ To the right o the

phase diagra' is the representation o the acid gas co'pression ro'

a.out 13 psig through 2 stages o co'pression( that includes inter-cooling

o the discharge gas ro' stages 1 through E$ The acid gas ro' the inal

2th stage o co'pression discharges into an a.o&e-ground trans'ission

pipeline that transers the acid gas at a.out 1#33-1A33 psig to the in+ection

wellhead$ A wellhead heater o&erco'es any e-cessi&e heat loss along the

pipeline due to the cold winter cli'ate$ The acid gas enters the wellhead

and gains additional pressure to #233 psig due to static head as it lows

down the wellstring and .ac/ into the reser&oir ro' which it originated$

)igure 1B Process =esign o Acid Gas In+ection Syste'

Phase .nvelo#e 'u#erim#osed "ith Com#ression$

Pi#eline and ell Conditionds

2

*22

922

<22

822

+222

+*22

+922

+<22

+822

*222

**22

*922

*<22

(92 (*2 2 *2 92 <2 82 +22 +*2 +92 +<2 +82 *22 **2 *92 *<2 *82 322

Tem#erature$ !eg F

P

r

e

s

s

u

r

e

$

#

s

i

a

Hydrate @ 135 LB/MMSCF

Hydrate @ Saturated

Conditions

Acid Gas Phase

Enveo!e

"eservoir Conditions

#n$ection %e Strin&

%esite

Heater

PC' Pressure (ro!

Pi!eine Pressure (ro!

5th Sta&e (ischar&e

Co)!ression/Cooin& Sta&es

%ater (e* Point @

Pi!eine %ater Content

,ater Carrying

Caacity of

Acid Gas

&i-tures at

Ele)ated

Pressures

An AGI design re,uires good /nowledge o the water carrying capacity o

acid gas 'i-tures to deter'ine under what operating conditions :ree

water; 'ight .e e-pected to e-ist$ This acility speciically needed the

a.ility to handle acid gas 'i-tures containing ro' a.out 24 %#S to a.out

234 %#S( the rest .eing !"# and a s'all a'ount o 'ethane$ )ree water

in car.on steel e,uip'ent handling acid gas could cause serious corrosion(

resulting in e,uip'ent ailure and potential e-posure o operating

personnel to to-ic acid gas$ Ise o corrosion resistant 'aterials would

increase the cost o AGI acilities( perhaps 'a/ing the' unecono'ical$

It is accepted that prediction o acid gas 'i-tures water content can .e

done with reasona.le accuracy at .elow a.out 233 psig( .ut prediction o

dew point conditions and water content at higher pressures presents a

'ore signiicant challenge$ The data generated under the &arious research

pro+ects reerenced earlier were unda'ental to Washington Group0s

analysis o the su.+ect AGI acility$ Ise o pu.licly a&aila.le process

si'ulation 'odels were cali.rated &ersus the data during de&elop'ent o

the process and detailed design o the acility$

&odeling

Differences

?ote that one 'odel was used to calculate :water dew point te'perature;

o a.out L2) or the calculated water content$ This predicted point at this

low te'perature would 'ore li/ely then .e an :ice; or :hydrate; point$

Another 'odeling tool( howe&er( predicts an incipient hydrate or'ation

te'perature o a.out -A3) or the sa'e calculated water content$

Acid Gas Can

#e Self.

Dehydrating

)igure 1D pro&ides the water content predictions 'ade or the one o the

acid gas co'positions and relects clearly the eect that co'pression o an

acid gas 'i-ture is :sel dehydrating; due to the uni,ue saturated water

content characteristic o %#S( !"#( and their 'i-tures$

)igure 1D Acid Gas Saturated Water !ontent

As the pressure is increasingly raised in the latter co'pression stages

a.o&e a.out 233-D33 psig( at a i-ed te'perature( the 'i-tures .eco'e

drier relati&e to the saturated water dew point$ In other words( at ele&ated

pressure acid gas 'i-tures can hold 'ore water at a gi&en te'perature

than they could at say 233 psig$ The interstage cooler and water /noc/out

dru'( operating at a.out 233 psig( thereore condense and re'o&e water

and the acid gas 'i-ture e-its at its 'ini'u' saturated water content 5in

this case a.out 1#2-1A2 l.s9MMS!)6$ The acid gas ro' the inal stage5s6

o co'pression to higher pressure is thereore under-saturated$ ?o ree

water will .e condensed in the higher pressure portions o the in+ection

syste' unless the acid gas is cooled 5e$g$ .y pipeline heat loss6 to 'uch

colder te'peratures 5perhaps in the range o -A3V) to LA#V)( depending on

the te'perature and resulting water content o the acid gas lea&ing the Eth

ater Content of .nriched Acid Gas

Average Annual Case

2

+22

*22

322

922

022

<22

2 +22 *22 322 922 022 <22 /22 822 =22 +222 ++22 +*22 +322 +922 +022

Pressure$ #sia

'

a

t

u

r

a

t

e

d

a

t

e

r

C

o

n

t

e

n

t

6

l

3

"

a

t

e

r

5

m

m

s

c

f

g

a

s

8

Mini'u' Water !ontent

achie&ed at Stage E outlet

=ew point W 1233 psia

53

o

)6

52

o

)6

5A#

o

)6

5@3

o

)6

5133

o

)6

Saturated Water !ontent W 1#3 )

Saturated Water !ontent W 133 )

Saturated Water !ontent W @3 )

51#3

o

)6

stage intercooler6$ >ased on this characteristic( the su.+ect design

e-tensi&ely used car.on steel downstrea' o the Eth stage o co'pression

and a gas dehydration unit was not re,uired$ The considera.le capital cost

sa&ings or this single acility was appro-i'ately e,ual to the cost o the

'entioned research progra's paid or .y the GPA9GPSA 'e'.ership$

Thereore( the 'ore than 23 acid gas in+ection acilities ha&e undou.tedly

.eneited ro' GPA data .y 'any ti'es its initial cost$

/ydrate

Pre)ention

There is a high potential or the or'ation o hydrates in three critical

co'ponents o AGI7 acid gas co'pression and intercooling( pipeline

trans'ission( and low into the in+ection well string itsel$ The hydrate

crystals could or' hydrate plugs that pre&ent acid gas in+ection$ The

saety concerns reported .y Sloan in another paper in this session are

e&en 'ore serious with the presence o %#S in AGI acilities$ Again the

unda'ental research and data a&aila.le ro' GPA-sponsored progra's

has played a leading role in the understanding o hydrate or'ation

conditions in acid gas operations$ Ising pu.licly a&aila.le process

si'ulation 'odeling tools( Washington Group was a.le to predict incipient

hydrate or'ation conditions or the acid gas 'i-tures at the nu'erous

conditions anticipated or the &arious operating cases and

startup9shutdown scenarios$ )igure 1@ consists o a set o incipient

hydrate or'ation cur&es or &arious le&els o water content as predicted

or dierent Eth stage intercooler outlet te'peratures$ =epending on the

acid gas co'position( Eth stage intercooling to 133V) results in achie&ing a

water content o 1#2-1A2 l.s9MMS!) 5)igure 1D6( and this water content is

low enough to pre&ent hydrate or'ation unless the acid gas is cooled

.elow a.out -A3V) 5)igure 1@6$

)igure 1@ Incipient %ydrate )or'ation !ur&es

Phase .nvelo#e > :nci#ient %&drate Curves

2422

*22422

922422

<22422

822422

+222422

+*22422

+922422

+<22422

(+2242 (82422 (<2422 (92422 (*2422 2422 *2422 92422 <2422 82422 +22422 +*2422 +92422

Tem#erature$ !eg F

P

r

e

s

s

u

r

e

$

#

s

i

a

Hydrate @ +,, -/MMsc.

Hydrate @ /15 -/MMsc.

Hydrate @ 1/5 -/MMsc.

Hydrate @ 5 -/MMsc.

Acid Gas

Phase Enveo!e

Hydrate @ Satd Conditions

ðanol

+n(ection for

/ydrate

Pre)ention

The su.+ect acid gas in+ection pro+ect design allows or in+ection o

'ethanol during startup( shutdown( and upset periods to a&oid water

condensation and hydrate or'ation$ This is a well pro&en concept .ut the

accuracy o acid gas 9 'ethanol 9water 9 hydrate e,uili.riu' data is o

concern to allow proper design$ Again( Washington Group reerenced data

a&aila.le ro' GPA *esearch *eports BB( DE and @D to deter'ine the

design para'eters and 'argins needed$

)igures 1G through #A present the co'parisons co'pleted using &arious

si'ulation 'odeling tools &ersus the reported data$ ?atural gas 'i-tures

5)igure 1G6 are accurately( i not slightly conser&ati&ely( predicted and allow

sae design$ Predictions o natural gas with addition o considera.le !"#

5)igure #16 are less accurate( especially at higher concentrations o

'ethanol( .ut are still generally conser&ati&e in prediction$ This 'ay .e

due to the un/nown ratio o 'ethanol9gas in the test cell$

)igure 1G %ydrate =ata and Si'ulation !o'parisons( **-BB( Ta.le G( Synthetic ?atural

Gas and Methanol Syste'

)igure #3 %ydrate =ata and Si'ulation !o'parisons( **-DE( Ta.le B( Synthetic ?atural

Gas and Methanol Syste'

)igure #1 %ydrate and Si'ulation !o'parisons( **-DE( Ta.le E( BG$D2 'ol 4 !%E(

A3$#2 'ol 4 !"#( and Methanol Syste'

The co'parisons presented in )igure ## or pure %#S relect that the

'odeling tools predict incipient hydrate or'ation te'perature &ery well(

e&en at higher 'ethanol concentrations$ Pure !"#( and 'i-tures with high

!"# content appear to .e the 'ore diicult to predict with the current

'odeling tools$ )igure #A relects that ortunately the 'odels predict

hydrate or'ation at te'peratures war'er than the data indicate( so use o

the results or design should .e conser&ati&e$ Their accuracy does worsen

as 'ethanol concentration increases$

)igure ##( %ydrate =ata and Si'ulation !o'parisons( **-BB( Ta.le E

)igure #A %ydrate =ata and Si'ulation !o'parisons( **-DE( Ta.le #

Physical

Proerties of

Acid Gas

&i-tures

)igures #E through #@ represent inor'ation generated .y one o the

pro'inent process si'ulation 'odeling progra's or a 234 %#S 9 234

!"# acid gas 'i-ture$ )igure #E pro&ides the phase en&elope or the

'i-ture and indicates a critical point o a.out 1#33 psig and 1#3V)$ )igures

#2 through #@ pro&ide predicted physical properties &ersus pressure and

te'perature or density( heat capacity( &iscosity and ther'al conducti&ity$

These igures relect that there are so'e consistent discontinuities in the

predicted properties( particularly in the te'perature range o 1#2V) to

#D2V) and pressure range o 1333 psig to E333 psig$ This is a range o

te'peratures and pressures co''only encountered in the co'pression(

cooling( pipeline transport( and in+ection o acid gas 'i-tures$ )or the

generally s'all current acid gas in+ection acilities( the errors in prediction

o these properties and the i'pact on the e,uip'ent and pipeline design

are li/ely co&ered .y typical e,uip'ent design 'argins and rounding in

selection o pipe si<es$ %owe&er( the 'ore recent and proposed large and

'ore co'ple- acid gas in+ection acilities 'ay .e signiicantly i'pacted .y

the error in predicted physical properties$

)igure 1G#E Acid Gas Phase En&elope

)igure #32 Acid Gas =ensities as a unction o Pressure and Te'perature

)igure #B1 Acid Gas Fiscosity as a unction o Pressure and Te'perature

)igure #1D Acid Gas %eat !apacity as a )unction o Pressure and Te'perature

)igure ##@ Acid Gas Ther'al !onducti&ity as a )unction o Pressure and Te'perature

&odeling

Defaults

The reason or 'ost o the discontinuities in the predicted inor'ation in

)igures #32 through ##@ is that the progra's deault 'ethodology has

certain criteria to deter'ine whether the gi&en strea' is a li,uid or a &apor(

which then selects a dierent 'ethod o calculating the physical properties$

This 'ethodology needs i-ing or 'odeling such syste's$

Washington Group wor/ed to eli'inate these discontinuities .y ad+usting

correlation para'eters or /ey properties such as heat capacity and density

to produce calculation results that 'ight 'ore properly relect the state o

the 'i-tures in actual operation$ %owe&er( this still produced process and

e,uip'ent design results that had so'e degree o uncertainty$ See

)igures #GA and A3E$

)igure #GA Ad+usted Acid Gas %eat !apacity as a )unction o Te'perature at 1(233 psia

)igure A3E Ad+usted Acid Gas =ensity as a )unction o Te'perature at 1(233 psia

Acid Gas

!ensit& vs Tem# ? +022 P':A

2

+2

*2

32

92

02

<2

/2

2 02 +22 +02 *22 *02 322

Tem#erature$ !eg F

!

e

n

s

i

t

&

$

@

B

5

F

T

3

The reerenced GPA **-1DE also reported so'e density data or the acid

gas 'i-tures$ The 'odeling progra' did a reasona.le +o. o accurately

predicting acid gas density( though in the critical and supercritical regions

the prediction could .e 13-#34 in error H generally predicting a higher

density than 'easured$ Since 'any acid gas in+ection acilities operate in

Acid Gas %eat Ca#cit& vs Tem#erature at +$022 P':A

2

24*

249

24<

248

+

+4*

+49

+4<

+48

*

2 *2 92 <2 82 +22 +*2 +92 +<2 +82 *22 **2 *92 *<2 *82 322

Tem#erature$ !eg F

C

#

$

B

T

A

5

@

B

(

F

Avera&e Annua

"ated Case

0urndo*n Case

these regions( proper prediction o wellstring static head and thereore

re,uired top hole in+ection pressure could .e in error H too low$ Thereore(

the in+ection co'pressor or pu'p head could .e speciied incorrectly H

.eing deicient$

The su.+ect acid gas in+ection pro+ect predictions were ortunately close to

the resulting actual operation$ %owe&er( there was so'e incre'ental

in&est'ent re,uired in the co'pressors and pipeline to pro&ide so'e

le-i.ility to produce a higher discharge pressure than calculated and

ensure the success o the pro+ect$

Recommendations for Future GPA Research Pro;ects

Proosed GPA

Research

Pro(ect to

+mro)e

Predictions

Actual 'easured data or certain the other physical properties or acid gas

'i-tures are not readily a&aila.le to co'pare to the predicti&e 'odels$ The

GPA Section ) *esearch !o''ittee has recogni<ed this deiciency and

has proposed a new Pro+ect 3E# to collect data or se&eral acid gas 'i-ture

co'positions in the near critical and supercritical regions$ =ata ro' this

progra' should pro&ide considera.le reerence data to chec/ predictions

and will aidd co''ercial ir's and indi&iduals in de&eloping i'pro&ed

'odeling 'ethods$

ðanol#oth

0aor and

1iquid Phase

Comosition

for. /ydrate

01E Data

The hydrate data pro&ided in the GPA *esearch *eports do not contain

any data on the 'ethanol concentration in the syste'$ The eects on the

hydrate predictions appear to increase at higher 'ethanol concentration

and pressure$ *esearchers should .e as/ed to report Tthe a'ount o

a,ueous phase .eing reportedto would aid in hydrate 'odel de&elop'ent$

01E data of

Acid Gas

Systems at

/igh Pressure

Additional data on &apor 9 li,uid e,uili.riu' o acid gas syste's at ele&ated

pressures would aid in urther de&elop'ent o si'ulation 'odels to 'ore

accurately predict the phase .eha&ior o these syste's$ This will .eis

.eco'ing 'ore i'portant as higher acid gas in+ection pressure operations

it is .eco'eing 'ore co''on in industry to either process or in+ect high

pressure acid gas$

AcBno"ledgements

Washington Group would li/e to ac/nowledge the ollowing indi&iduals who

donated their ti'e to assist us with the data analysis presented in this

paper$ It is i'portant to ac/nowledge that each o these ir's and

indi&iduals donated their ti'e and resources to de&elop the co'parisons

represented in this paper or contri.uted to the e-a'ple pro+ects eorts$

Their cooperation and support was oered to urther the /nowledge in the

industry to the accuracy o current 'odels( which or 'ost situations and

luid properties can allow sae and successul design$ Most i'portantly(

this was a cooperati&e eort to identiy additional data needs to the

industry to allow these and other parties to de&elop urther i'pro&ed

'odeling and design tools$

!hristina =aniels( >ryan *esearch and Engineering( Inc$

=r$ =an Xhang( "ilphase-=>*( Schlu'.erger !anada Ctd$

=r$ >eryl Ed'onds( Inoche' !o'puter Ser&ices Ctd$

>rian Wood( %yprotech !o'pany - a su.sidiary o Aspen

Technology

=r$ E$ =endy Sloan( !olorado School o Mines

=r$ Paul =a&is( Al.erta Sulphur *esearch Ctd$

Ste&e Mac)arland( Ste&e Mac)arland( Inc$

In addition( Washington Group would li/e to ac/nowledge the contri.utions

ro' Mr$ !hris *oot o =u/e Energy )ield Ser&ices in analy<ing the

physical properties predicted o .y a pu.lic 'odeling tool or &arious acid

gas 'i-tures$

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Aerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsDocument10 pagesAerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsVIJAY YADAVNo ratings yet

- B29Document3 pagesB29dasarisuryaNo ratings yet

- Aws D10.4Document43 pagesAws D10.4Riza Khan100% (1)

- Alkyl Halides & Aryl Halides-02 - Solved ProblemsDocument13 pagesAlkyl Halides & Aryl Halides-02 - Solved ProblemsRaju SinghNo ratings yet

- Liquid-Solid Leaching ProcessDocument49 pagesLiquid-Solid Leaching ProcessFikrie Muhd0% (1)

- Hach Nitrate Method 10206 Final 01102013Document10 pagesHach Nitrate Method 10206 Final 01102013dunavko1No ratings yet

- GRP Tank Calculator, Sands Civil Services Estimation To BS 4994Document2 pagesGRP Tank Calculator, Sands Civil Services Estimation To BS 4994Sung Woong Moon100% (1)

- The Flame Test I. Objectives:: Grade 9 - Science Activity SheetDocument3 pagesThe Flame Test I. Objectives:: Grade 9 - Science Activity SheetJoana Rose Fantonial100% (1)

- Co2 FreezingDocument10 pagesCo2 FreezingRohit Kumar KushwahaNo ratings yet

- 3-Phase SepDocument1 page3-Phase SepRohit Kumar KushwahaNo ratings yet

- CLASSIFICATION of AIR COMPRESSORS An Air Compressor May Be Classified According To PressureDocument2 pagesCLASSIFICATION of AIR COMPRESSORS An Air Compressor May Be Classified According To PressureRohit Kumar Kushwaha0% (1)

- Flame ArrestersDocument1 pageFlame ArrestersRohit Kumar KushwahaNo ratings yet

- 3-Phase SepDocument1 page3-Phase SepRohit Kumar KushwahaNo ratings yet

- Safety RequirementsDocument1 pageSafety RequirementsRohit Kumar KushwahaNo ratings yet

- PumpDocument2 pagesPumpRohit Kumar KushwahaNo ratings yet

- 3-Phase SepDocument1 page3-Phase SepRohit Kumar KushwahaNo ratings yet

- 3-Phase SepDocument1 page3-Phase SepRohit Kumar KushwahaNo ratings yet

- 3-Phase SepDocument1 page3-Phase SepRohit Kumar KushwahaNo ratings yet

- IFARS generic drugsDocument5 pagesIFARS generic drugsOky Spinola IdroosNo ratings yet

- Fibres PPT 1Document19 pagesFibres PPT 1rajesh duaNo ratings yet

- Importance of nucleic acidsDocument2 pagesImportance of nucleic acidsMyla Angelica AndresNo ratings yet

- WCH01 01 Que 20161013Document24 pagesWCH01 01 Que 20161013lolomg900% (1)

- Bonding & Properties WorksheetDocument4 pagesBonding & Properties WorksheetCraig KingNo ratings yet

- Gmaw WQTDocument23 pagesGmaw WQTDera LesmanaNo ratings yet

- Workshop 2 - Material ClassificationDocument7 pagesWorkshop 2 - Material ClassificationH2 MgZNo ratings yet

- ARL 3460 For Iron SteelDocument2 pagesARL 3460 For Iron SteelkmiqdNo ratings yet

- Science 7 Parallel Test 2021-2022Document6 pagesScience 7 Parallel Test 2021-2022malifi ciadoNo ratings yet

- High Performance Thin Layer ChromatographyDocument69 pagesHigh Performance Thin Layer ChromatographyAliefanugerahsani Attabe100% (1)

- Hydrogen Sensors - A ReviewDocument24 pagesHydrogen Sensors - A ReviewNaga RajuNo ratings yet

- A Novel and Cleaner Technological Process of Extracting L-Glutamic Acid From PDFDocument8 pagesA Novel and Cleaner Technological Process of Extracting L-Glutamic Acid From PDFGooi Ming YanNo ratings yet

- Comparison Between SA516 Gr. 70 and SA612Document2 pagesComparison Between SA516 Gr. 70 and SA612Jaison JoseNo ratings yet

- Dixit and Hering, 2003Document8 pagesDixit and Hering, 2003José Roberto Rivera HernándezNo ratings yet

- OringmatDocument39 pagesOringmatRoby MastreNo ratings yet

- CIE IGCSE Resistant Materials GuideDocument23 pagesCIE IGCSE Resistant Materials GuidekevinNo ratings yet

- Human Physiology An Integrated Approach 6th Edition Silverthorn Test BankDocument25 pagesHuman Physiology An Integrated Approach 6th Edition Silverthorn Test BankLauraMitchellfgie100% (56)

- Mock Engineering MaterialsDocument6 pagesMock Engineering MaterialsJohn AsokNo ratings yet

- Presentation On White RustDocument12 pagesPresentation On White RustapparaomsNo ratings yet

- Lipids ExperimentDocument3 pagesLipids ExperimentCyra LumibaoNo ratings yet

- A532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast IronsDocument4 pagesA532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast Ironsalexander zuritaNo ratings yet

- General Chemistry Course v5 PDFDocument448 pagesGeneral Chemistry Course v5 PDFStefan AdrianNo ratings yet