Professional Documents

Culture Documents

CED 2 Final Presentation - Compile PDF

Uploaded by

Chan Keng ChunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CED 2 Final Presentation - Compile PDF

Uploaded by

Chan Keng ChunCopyright:

Available Formats

CONCEPTUAL

DESIGN

SUPERVISOR : DR TEO WEE

MUHAMMAD SYAFIE BIN MAZLAN 12050

ABDULLAH SOFIY BIN MANSOR 11848

ABDUL HALIM BIN ROSLY 11840

NORAZY SHAKILA BINTI MD. SALLIH 12124

NURUL NASYIHAH BINTI HAMBALI 12168

By Consultant :-

For Client :-

ORGANIZATION

CHART

PROJECT OVERVIEW

PROJECT DESCRIPTION

Office Building of 13-storey at Ara Damansara, Mukim Damansara,

Daerah Petaling, Selangor consists:-

Basement - 2 levels of car park,

Level 1 - Auditorium, Cafeteria, Childcare, Clinic, Multipurpose Shop,

Office Space, Prayer room

Level 2-12 Office spaces

SITE LOCATION

FOUNDATION AND

GEOTECHNICAL

ENGINEER PART

1. SOIL INVESTIGATION

2. FOUNDATION

3. BASEMENT WALL AND SYSTEM

4. PILE CAP

5. GROUND BEAM AND GROUND SLAB

6. OTHER CONSIDERATION

1. SITE INVESTIGATION

Soil constitutive properties

Design consideration for such soil

properties

Risk and integrity of the foundation

on such soil properties

Soil constitutive properties

Soil constitutive properties

SPT from

borelog

Standard SPT

Allowable

bearing capacity

Design consideration for such soil

properties

Platform level is 17-18m.

Average surface level is 53m, we have to cut the soil

up to the platform level.

The main constituent of soil is silty sand.

Major portion is silt.

Minor portion is sand.

The strength of sandy soil is represented with

friction angle (). Pure silts are frictional material

and for all practical purposes, it behaves as sands.

No clay present.

Ground water table is very high = 42m

Design consideration for such soil

properties

Assumptions

SPT value from the borelog are conducted using safety

hammer with 70% energy ratio.

Highest GWT after excavation is equal to platform level.

Based on Standard SPT:

Friction angle, = 38

Relative density = 0.85

Unit weight = 22kN/m

3

Since we decided to use concrete spun pile:

Lateral earth pressure coefficient, K = 1.0-1.5

Pile skin friction angle, =

Risk and integrity of the foundation on

such soil properties

Risk Risk assessment Propose mitigation

High ground water table Causes wet excavation, pile

driving and ground beam

construction.

Adoptions of water proof

reinforce concrete basement

wall, drainage culvert and

installation of sump pump.

Risk and integrity of the foundation on

such soil properties

Risk Risk assessment Propose mitigation

Absence of bed rock Cause excessive settlement

of pile.

Pile design based on both

skin friction and tip bearing

capacity.

Risk and integrity of the foundation on

such soil properties

Risk Risk assessment Propose mitigation

Main soil composition is silt Silt can get loose easily. Static compaction is done to

the soil before installation of

piles.

2. FOUNDATION

Type of foundation use

Design of the foundation and type

Risk assessment of the foundation

chosen

Type of foundation use

Silty sand load bearing capacity = 144kN/m

2

Maximum building load = 180kN/m

2

Shallow foundation is not sufficient, hence deep

foundation is needed.

Type = spun pile

Supplier = Industrial Concrete Product Berhad(ICP)

Pile shoes = open ended

Installation method = jacked in

Codes applied:

BS EN 1997-1:2004 Eurocode 7: Geotechnical design

solution Section 7.1 1(P)

BS EN 1997-1:2004 Section 7.4.2 Design Consideration 4(P)

Design of the foundation and types

Using Meyerhof equation correlated with SPT

value

Result:

Spun pile class B(effective prestress=5N/mm

2

)

Diameter = 500mm

Thickness = 90mm

Length = 18m (12m + 6m)

Spun pile individual capacity = 207ton

Design of the foundation and types

Design of the foundation and types

Cross section detail of the ICP piles

Design of the foundation and types

Bonding of ICP pile into pile caps

Design of the foundation and types

Risk assessment of the foundation

chosen

Risk Risk assessment Propose mitigation

Improper

welding of

pile during

splicing.

Pile performance

will be affected and

load transfer will be

disturbed.

Site supervision must ensure that the welding

thickness must not be less than 6mm and after done

with the welding, it must be cooled at least 5 minutes

before applying the anti rust protection paint.

Risk assessment of the foundation

chosen

Risk Risk assessment Propose mitigation

Structural

damage to

the pile head

or pile toe.

This might be due to

overdriving of pile. The

existence of boulder can

cause spalling, cracking or

breaking of pile structure.

Pile capacity must always be checked and

ensure during pile driving, the driving force

does not exceed the pile capacity. It s useless

to force the pile into the soil while damaging it.

Practice good driving technique.

Risk assessment of the foundation

chosen

Risk Risk assessment Propose mitigation

Expose end of pile reinforcement

after pile trimming provide hazard

to the working personnel.

Potential to cause

injuries.

Use protection caps on the bars

after pile trimming and before

placing foundation concrete.

3. BASEMENT WALL

AND SYSTEM

Type of basement wall and system chosen

Design consideration of the basement wall

and system

Sequence of work and risk assessment of

the basement wall and system

Type of basement wall and system

chosen

Total area = 14, 030 m

2

.

Depth of excavation = 4.59m +3.425m = 8.015m

Excavation volume= 8.015m X 14, 030m

2

=

112,450 m

3

.

Code used:

BS 8004: 1986 Code of practice for foundations

BS 8002: 1994 Code of practice for earth retaining

structures

BS 8110: 1985 Structural use of concrete

DFCP 4: Drilling fluid material - bentonite

Type of basement wall and system

chosen

Based on BS8102, the function of basement

allowed us to design based on Type B.

Type of basement wall and system

chosen

Support system = braced

Why not anchored?

problem in maintenance in long term. (BS8081:1889 Code

of Practise for Ground Anchorages)

If the local authorities require to be removed, then it may

pose problems if the system has not been proven at site

to be fully removable.

Approval from the adjacent owners should be acquired if

there is encroachment of ground anchors into adjacent

properties.

Leakages and loss of fine through drill holes need

additional precautionary measures in the construction.

Design consideration of the basement

wall and system

Concrete compressive strength = 30N/mm

2

Reinforcement yield strength = 410N/mm

2

Soil equivalent fluid pressure = 60psf/f = 293kg/m

2

per

meter

Total service level vertical dead load on wall = 481 kN/m

Total service level vertical live load on wall = 286 kN/m

Design assumption

Design wall with fixed base

Ground water table is at platform level for conservative

design.

Use 2ft additional soil surcharge to account for compaction

pressure.

Design consideration of the basement

wall and system

Dimension of diaphragm wall

Basement depth = 8m

Depth of diaphragm wall = 14m

Thickness = 600mm

Vertical reinforcement = 20mm diameter at 200mm

c/c

Horizontal reinforcement = 14mm diameter at

300mm c/c

Length of interval for alternating diaphragm wall

excavation = 5m to 7m

Design consideration of the basement

wall and system

Method of

construction = top

down

Advantages:

reduces the time

Reduced

settlement.

saves the cost of

formwork.

Sequence of work

Earthwork

Diaphragm

wall

Bored, casing

and spun pile

Stanchions

Superstructure

and

substructure

Top down

construction

sequence

Sequence of work

Diaphragm wall sequence

Install guide wall at 1.5m

to 2m depth and 0.6m

wide.

Trench excavation and

deposit soil to a holding

tank

Install rebar cage

Checking verticality by

Coden Test.

Tremie concrete.

Disposal of excavated soil

from holding tank.

Risk assessment of the basement wall

and system

Risk Risk assessment Propose mitigation

Working

inside the

excavation

basement

area

Confine dark space give

minimum space for error.

Slight collision between

cranes with the stanchions

can cause disasters.

Implement systematic working condition with

extra precaution. Space opening must be

sufficient for safe mobilization of crane. Limited

access and number of workers inside the

basement for safety reason.

Risk assessment of the basement wall

and system

Risk Risk assessment Propose mitigation

Cold joint

due to the

interval

concreting.

Presence of small void

which can allow ground

water to pass thru the

basement wall.

If the crack is minute, it can be seal with thin

layer of concrete sealant. Sump pump need to be

installed inside the basement in case if the water

intrusion is unstoppable.

4. PILE CAP

Typical design of pile cap

Design of at least 50% of the total

types of pile cap

Risk assessment and integrity of the

pile cap

Typical design of pile cap

Code used:

BS 8110: 1997 Structural use of concrete

BS 5950 Structural steel design

Truss method

Check:

Shear capacity

Punching shear

Typical design of pile cap

Design criteria:

Concrete strength , f

cu

= 30N/mm

2

Reinforcement steel yield strength, f

y

= 460N/mm

2

Pile capacity = 2129 kN

Size aggregate = 20mm

Top and side cover = 50mm

Bottom cover = 75mm

Concrete

c

= 1.5

Steel

s

= 1.05

Concrete density = 24 kN/m

3

Typical design of pile cap

Typical design of pile cap

Design of pile cap methodology or

construction sequences

Formwork and

reinforcement bar are

placed

Ready mix concrete is transfer into the formwork. Various

method of transferring can be done which are by using

excavator bucket, specific concrete bucket or boom of pump

truck.

Then the concrete is

vibrated using vibrator to

reduce the air voids

The concrete is

allowed to harden.

Risk assessment and integrity of the

pile cap

Risk Risk assessment Propose mitigation

Shear failure and

punching failure

in pile cap.

This failure can be mitigate if the

pile cap have enough thickness

and reinforcement inside it.

Shear and punching failure should be

checked and provide sufficient

reinforcement bars.

Risk assessment and integrity of the

pile cap

Risk Risk assessment Propose mitigation

Eccentric loads

from axial column

Eccentricity induced

moment.

Column should be checked for verticality

during construction.

5. GROUND BEAM AND

GROUND SLAB

Typical design of ground tie beam

and ground slab

Design details and types of ground

beam and ground slab

Risk assessment of the designed

ground beam and ground slab

Typical design of ground tie beam and

ground slab

Code use:

BS 8110: 1997 Structural use of concrete

BS 5950 Structural steel design

Two way suspended slab 8.2m x 8.2m

Design details and types of ground

beam and ground slab

Concrete strength = 30N/mm

2

Reinforcement strength = 460 N/mm

2

Slab thickness = 300mm

Slab area = 8.2m x 8.2m = 67.24m

2

Beam width = 800mm

Beam thickness = 900mm

Beam length = 8200m

Design details and types of ground

beam and ground slab

Slab reinforcement details:

X direction = T12-150c/c

Y direction = T12-150c/c

Beam reinforcement details:

Top portion = 3T20

Bottom portion = 3T25

Link = 2T8 200c/c

Risk assessment of the designed

ground beam and ground slab

Risk Risk assessment Propose mitigation

The formwork at the

bottom of the slab is

difficult to remove.

Due to the weight of beam

and friction between soil

underneath and beam.

Provide extra thickness for bottom

concrete cover which is 75mm.

Eliminate the bottom formwork.

6. OTHER

CONSIDERATION

Waterproofing method

Cold joint treatment and waterstop

Risk mitigation of the chosen

method

Waterproofing method

High ground water table exert uplift

pressure to the basement slab and beam

Uplift forces = 433,000kN

Self weight of beam and slab = 154,000kN

Passive method = diaphragm wall

Active method = sump pump

Waterproofing method

Sump pump specification

Type: Submersible

Sump basin dimension: 0.6m

diameter x 1m depth

Individual capacity: 100 liters

Service life: 15 years

Head pressure: 10m

Suction capability: 0.5

horsepower (400W)

Periodic maintenance: annually

Daily operation using main

power supply but has backup

battery for power outage

Additional features:

- High water alarm

- Automatic operation

Waterproofing method

9 units of sump

pumps

Distance between

each sump pump is

between 30m to

70m.

Location of the sump pump

Waterproofing method

Installed along the

interior perimeter of

the basement wall.

Total length is 520m.

The drainage pipe

used is WaterGuard.

It includes a wall

flange that extends

up slightly from the

drainage system.

French drain system

Cold joint treatment using waterstop

Hydrophilic waterstop.

Exposure to water makes the material expand

dramatically

Enough to create a compression seal

Material = chloroprene rubber.

Risk mitigation of the chosen method

Risk Risk assessment Propose mitigation

Small silt can clog

the WaterGuard

passage inside the

French drain.

This prevent sump pump

from pumping ground water

out from the basement.

Periodic maintenance must be done

annually to ensure the system works.

Clogged WaterGuard must be

replaced with the new one.

SUPERSTRUCTURE

BS 6399 : part 1 : 1984

Loading

Dead Load

concrete 2400 kg/m

Metal deck 13.6 kg/m

Column Variable depending on type

Beam Variable depending on type

Loading

Live Load(kn/m)

General area 2.5

Balconies 4

Store 4

Toilet 2

Electric Room(AHU) 2

Stair 4

Harvesting tank 29.43

Typical floor layout

STAIRS

AHU

SHEAR

CORE WALL

TOILET

AHU

BALCONY

STORE

STORE

STAIRS

BALCONY

Slab System(Bondeck)

Bondeck(properties)

Section properties per m width

Thickness

(mm)

Grade(mpa) Section

modulus area

(x10mm/m)

Cross

sectional

area

(mm/m)

Second

moment

(x10^4

mm^4/mm)

Weight

(kg/m)

1.00 550 16.69 1678 64.08 13.6

Continous

span

No prop Concrete

thickness

2960

Continuos span 1 prop 150mm

5930

Steel conform to BS EN

10147

Fire resistance up to 120

minutes

BONDECK(reinforcement bar)

Help in

supporrting

load

(longitudinal)

Shrinkage

and

temperature

effect

(transverse)

Bondeck(piping)

Bondeck(electrical wiring)

BEAM

(Based on BS 5950)

Universal beam

1)UB 533 x 210 x 92

2)UB 610 x 229 x 125

3)UB 610 x 305 x 149

4)UB 914 x 305 x 224

5)UB 1016 x 305 x 314

Beam layout

UB 533 x 210 x 92

UB 610 x 229 x 125

UB 610 x 305 x 149

UB 914 x 305 x 224

(Floor 9)

UB 1016 x 305 x 314

(floor 13)

Column

(based on BS 5950)

Universal column

Column

(core)

Column

(critical)

Column

(External)

Column

GROUP

COLUMN

FLOOR

1-5 6-10 11-13

Core Column 356 X 406 X 467 305 X 305 X 118 254 x 254 x 89

External Column 356 X 406 X 467 356 X 368 X 177 356 X 368 X 129

Critical Column 356 X 406 X 467 356 X 406 X 467 356 x 368 x 177

Lift shear core

0.98 kn/m

Wind load

calculated

based on

MS 1553

2002

Assumption

that the wind

load will all be

taken by the

shear core

wall

Lift motor

room load

of

7.5kn/m

Lift Shear Core dimension

Lift shear core

Length(m) 2.4

Thickness/

width(m)

0.4

Lift Shear Core Rebar

4x1T25(corner) x 2x13T25(internal) x 2x6T25(side)

Staircase

Type 1

Type 2

Type 2

Staircase

G

R

T

Riser(R) = 166.67 mm

Tread(T) = 255 mm

Going(G) = 250 mm

Staircase

MAIN REBAR SIZE

TYPE 1 T12-300 T8-150 SC 1 & 2

TYPE 2 T12-250 T8-125 SC 6 & 7

CONNECTION

Base plate to column

UC 356 x 406 x 467

Dimension

= 58 cm x

57 cm

Thickness

= 7 cm

Bolt grade

of 4.6 with

20mm

diameter

Beam to column

One example dimension for UB 533 x 210

x 92

9 bolts M22 grade 4.6

o 6 bolts at column

o 3 bolts at beam

Splice

Splicing UC 356 x 406 x 467 to same

size

Plate connector length = 450 mm

Width connector length = 450 mm

Thickness plate = 35mm

Web cover plate width = 230 mm

4 no M20, 8.8 grade bolts

Splice

Splicing UC 356 x 406 x 467 to UC

305 x 305 x 118

Connector plate length of 320 mm

Width of connector plate of 125

mm

Thickness of connector plate of 15

mm

Web cover plate width of 165 mm

Use M20, 8.8 grade of bolt

Risk assesment

Risk Risk assesment Mitigation

Fire

Affect structural

ability

Danger to human

lives

Intumescent coating

that can upstand fire

up until 120 minutes

Corrosion

Affect structural

ability

Spread more into

the member

Coat with coating such

as paint

Lintel

Lintel

Height(mm) 60 110 210

Thickness

(mm)

3.0 3.0 3.0

UDL can

sustained

(kn/m)

4 8 10

INFRASTRUCTURE

Source: Perbadanan Urus Air Selangor

(PUAS) BHD.

Main Building (13 Storey Building) :

= 29125 m2

WATER DEMAND

Normal Usage (Drinking) : (PUAS)

= 291 250 L/day

= 291. 25 m3/day

For Hose Reel and Fire Hydrant Usage: (UBBL)

= 12133 L/day

= 12.133 m3/day

STORAGE TANK

STORAGE TANK

DIMENSION : 10000 mm x 8000 mm x 6000 mm

Designing storage tank for 3 days usage :

Normal usage = 873.75

3

Fire Hydrant and Hose Reel = 36. 4

3

TOTAL VOLUME OF WATER = 910.15

Volume of water per 1 tank = 456

3

No of tanks : 2

Using RC storage tank :

Concrete Plinth : 300 X 500 ( Gap = 1m)

STORAGE TANK

WATER RECTICULATION

Standard Code : MS 1058: Part 2: 2002

Dimensioning:

Source: Hazen-Williams Equation

Diameter : 110 mm

Flow velocity : 0.17 m/s

Length : 100 m

Pipe head loss : 0.35

Implement pumps to water tank

--> Hazen Williams Equation

Type of Pipe = HDPE PIPE

SEWERAGE CAPACITY

Source: Indah Water Konsortium)

PE calculated:

= 1446 person

Discharge Produced:

= 0.225m3/day.person * 1380

= 310.5m3/day

= 3.59

3

m3/s

STORAGE TANK

SEWERAGE PIPE

Standard Code : MS 1228 : 1991

: MS 1228 C1. 4. 3. 3 (Hydraulic Design)

Slope (%) 0.4 %

Sewer Line Diameter (mm) 100

Source: Indah Water Konsortium ( IWK)

Dimension Selection:

Diameter, Dia = 200 mm

Slope, S = 1: 100

Material used: HDPE Pipe

where

= 3.59

3

m3/s

Peak Factor = 1.164

= .

m3/s

Using V = 0.45 m/s :

From Q= AV A = .

STP

(1 km from

the site)

Project

Site

Manhole:

- At every change of direction (at 100m)

- No of manhole = 6

- Min diameter = 225 mm

Sewerage Tapping Point

STORAGE TANK

DRAINAGE SYSTEM

OUTER DRAIN

Minor System Design ARI : 10 years (

10

= 315.33 mm/ hr)

Major System Design ARI : 50 years (

50

= 385.25 mm/ hr)

ANNUAL RAINFALL INTENSITY (Source : MSMA)

INNER DRAIN

360

------------- Equation 14.7

Note: C= 0.09

Area = 1.4 ha

Q

10

= 1.1036 m

3

/s

= 38.998 ft

3

/s

Q

50

= 1.3484 m

3

/s

= 47.646 ft

3

/s

Area = 0.19 ha

Q

10

= 0.1498 m

3

/s

= 5.293 ft

3

/s

Q

50

= 0.1830 m

3

/s

= 6.466 ft

3

/s

Outer Drain Inner Drain

Width (m) 0.9 0.45

Height (m) 0.75 0.45

Freeboard (m) 0.05 0.05

Flow Capacity ,q (m

3

/s ) 1.45 0.19

Velocity (m

2

/s) 2.29 1.38

q = A R

2/3

S

1/2

n

Drain capacity > Q peak

OK

V = Q

A

Type of Drain : U- Drained Size

Material : Concrete

Supplier : OKA COOPERATION BHD.

Slope of Drain

= 0.005

STORAGE TANK

HARVESTING TANK

2 harvesting tank

Dimension : 3000 x 3000 x 3000

Volume Capacity = 27

3

x 2 tanks

= 54

3

Maximum volume of rain water collected

= 32.19m

3

< 54

3

OK

PAVEMENT

PARKING LOT PAVEMENT

Pavement type: Asphalt Concrete Base Pavement

Subgrade class: moderate

4cm

9cm

DCA REQUIREMENT

AIRPORT REQUIREMENT

2.96km

3.5km

Inner horizontal surface

AIRPORT REQUIREMENT

Elevation of Inner Horizontal Surface: 27m MSL

Requirement for obstacles height: 45m

PL

Inner Horizontal

Surface

Height requirement

Height : 53.5m

MSL

27m

45m

17.8m

ASSESSMENT

TRAFFIC IMPACT ASSESSMENT (TIA)

Year Volume (veh/hr) LOS

2010 8 233 C

2012 9 283 D

2015 11 113 D

2020 15 000 E

Census Station :

Kuala Lumpur-

Subang Airport

(BR802)

Mitigation for year

2020:

Add one lane per

direction. AND

Increase lane width

LOS : D

ENVIRONMENTAL IMPACT

ASSESSMENT (EIA)

Environmental Quality (Prescribed Activities)

(Environmental Impact Assessment) Order 1987.

Required area: 500 000 squared-metre

Area of project: 14 030 squared-meter

No EIA is required

ENVIRONMENTAL IMPACT

ASSESSMENT (EIA)

MATERIALS USED

STEEL FRAME

Advantages

Shorter build times

Reduced site labour

Superior quality

Reduced

environment

disruption to site.

LYSAGHT BONDEK

Excellent spanning capacities for

greater strength and less deflection

Acts as permanent formwork with

minimal propping and no stripping

of formwork is required

Fast and easy to install with less

handling required

Works as composite slab saving on

concrete and reinforcement costs

Ribs at 200mm centres creating a

safe working platform with slip

resistant embossments

Advanced design for fire resistance

HOMOGENEOUS TILES

Tougher tile because

lower water absorption

rate & higher density.

Use in:-

Staircase

Balconies

Toilets

GRANITE TILES

Easily remove stains

Wide availability in

market

Use in:-

Staircase

Floor outside the lift

CEMENT RENDER

Solid plastering

Often textured,

colored, painted after

application.

Use in:-

AHU

Store

FLOOR SCREEDS/CARPET

Screed directly

bonded to base

Carpet offering

warmth

Use in:-

Office area

FLOOR DROPS

To avoid water flow out

to other area in

building.

Examples:

Toilets (50mm drop)

Balconies (100mm drop)

BUILDING SET-BACK

Required distance that a building must be

located away from the streets, easements,

and other structures.

3500mm setback

SCHEDULING

CED 1

CED 2

SUBMISSION SCHEDULE

CONSTRUCTION SCHEDULE

MINIMIZED

WASTAGES IN

CONSTRUCTION

PROJECT

Construction Waste

Construction Waste

A waste allowance is generally included

within the order to account for design waste

and construction process waste.

Construction waste categories:

Generated by design activities.

Generated by construction activities.

Typical Malaysian Contractors

Material Wastage Allowance

Material Wastage Allowance

Concrete 7%

Rebar up to 16mm 8%

Rebar more than 16mm 15%

Formwork 12%

Cement screed 30%

Red bricks wall 12%

Metal roofing 5%

Tiling 8%

MINIMIZE CONSTRUCTION WASTE

An effective effort in

minimizing wastage in

construction can:

Make significant savings

to the client, contractors

and the environment

Divert a high percentage

of all construction waste

materials from the landfill

and recycled into new

products.

BUILDING ECONOMICS

BUILDING COSTING (June 2012)

SECTIONS COST (RM)

Steel beam RM6,338,588.26

Steel Column RM 75,232,858.80

Lysaght Bondex RM 497,605.45

Spun Pile RM 824,100.00

Pile Cap RM 90,159.00

Water tank RM20,875.20

Harvesting Tank RM2,635.20

Water Reticulation Pipe RM 2,300.00

TOTAL RM83,009,121.91

MAIN TOWER ONLY:-

WHOLE PROJECT AREA MAIN TOWER AREA

SECTIONS COST (RM) COST (RM)

Basement walls RM3,763,327.71 -

Excavation RM11,245,045.00 RM1,697,152.21

TOTAL RM14,571,572.71 RM1,697,152.21

MAIN TOWER &

WHOLE AREA:-

BUILDING COSTING (June 2012)

ESTIMATION TOTAL COST OF MAIN BUILDING:-

RM140,000,000

THANK YOU

By Consultant :-

For Client :-

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Design of Lifting and Tailing LugsNetsc001Document30 pagesDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Coral20100304 DLDocument111 pagesCoral20100304 DLMohd HazrickNo ratings yet

- ASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedDocument68 pagesASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedAnthony Gravagne100% (5)

- Marine Bilge Water Treatment SystemDocument11 pagesMarine Bilge Water Treatment Systemrobjsimon100% (3)

- Drainage Impact Assessment Within The Environmental AreasDocument10 pagesDrainage Impact Assessment Within The Environmental AreasRonald Gomeseria y Valledor100% (1)

- Water Balance of Plants-1Document49 pagesWater Balance of Plants-1Desy Yusriyyah100% (1)

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDocument20 pagesTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- EN Folder Watersupply ILF PDFDocument12 pagesEN Folder Watersupply ILF PDFMishealNo ratings yet

- Plastic AnalysisDocument37 pagesPlastic AnalysisChan Keng ChunNo ratings yet

- Comparing wind load standards Eurocode and BSV 97Document10 pagesComparing wind load standards Eurocode and BSV 97andre_vicenteNo ratings yet

- Robusta Cupping ProtocolsDocument9 pagesRobusta Cupping Protocolswienda100% (1)

- AISC Errata ListDocument8 pagesAISC Errata ListLuis Gonzales Salazar67% (3)

- LiftingLugStress Rev 1.5Document20 pagesLiftingLugStress Rev 1.5ilijarskNo ratings yet

- Fair Geyer Okun PDFDocument2 pagesFair Geyer Okun PDFJustin0% (3)

- EIA of Petroleum Industry: Environmental Impacts & MitigationDocument18 pagesEIA of Petroleum Industry: Environmental Impacts & Mitigationanon_800166261100% (2)

- FBM KLCI up 8.64 points as DRB-HICOM to exit ProtonDocument33 pagesFBM KLCI up 8.64 points as DRB-HICOM to exit ProtonChan Keng ChunNo ratings yet

- Column To Steel Plate CalculationDocument1 pageColumn To Steel Plate CalculationChan Keng ChunNo ratings yet

- D3 - Buckling Analysis (Designer)Document18 pagesD3 - Buckling Analysis (Designer)Chan Keng ChunNo ratings yet

- Tutorial 2 - Axially Loaded Members-TensionDocument27 pagesTutorial 2 - Axially Loaded Members-TensionChan Keng ChunNo ratings yet

- Shabu Ten Dinner Buffet Voucher for 2 PeopleDocument1 pageShabu Ten Dinner Buffet Voucher for 2 PeopleChan Keng ChunNo ratings yet

- Lecture 2 Intro Continued - 2072Document46 pagesLecture 2 Intro Continued - 2072Chan Keng ChunNo ratings yet

- D3 - Buckling Analysis (Designer)Document18 pagesD3 - Buckling Analysis (Designer)Chan Keng ChunNo ratings yet

- Tutorial 4 - Flexural Members - Bending and ShearDocument42 pagesTutorial 4 - Flexural Members - Bending and ShearChan Keng ChunNo ratings yet

- Braced Beam DesignDocument32 pagesBraced Beam DesignChan Keng ChunNo ratings yet

- Lecture 1 Introduction - 2072Document48 pagesLecture 1 Introduction - 2072Chan Keng ChunNo ratings yet

- Stainless Steel Grade 316 Data Sheet (Aalco)Document3 pagesStainless Steel Grade 316 Data Sheet (Aalco)Chan Keng ChunNo ratings yet

- Summary - Flexural Members - Lateral Torsional BucklingDocument5 pagesSummary - Flexural Members - Lateral Torsional BucklingChan Keng ChunNo ratings yet

- Strength of Fillet and Full Penetration Butt Weld To BS 639Document1 pageStrength of Fillet and Full Penetration Butt Weld To BS 639Chan Keng ChunNo ratings yet

- Plastic AnalysisDocument37 pagesPlastic AnalysisChan Keng ChunNo ratings yet

- 304 Vs 316 PDFDocument2 pages304 Vs 316 PDFRiza KhanNo ratings yet

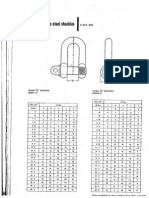

- Higher Tensile Steel 'D' and 'Bow' Shackles To BS 3032Document2 pagesHigher Tensile Steel 'D' and 'Bow' Shackles To BS 3032Chan Keng ChunNo ratings yet

- CNPC No7 Chinese Steel Sections (2004)Document5 pagesCNPC No7 Chinese Steel Sections (2004)Chan Keng ChunNo ratings yet

- Kaolite Insulating CastablesDocument2 pagesKaolite Insulating CastablesChan Keng ChunNo ratings yet

- Astm A 216, Grade WCBDocument12 pagesAstm A 216, Grade WCBChan Keng ChunNo ratings yet

- Construction Costs Across Asia PacificDocument0 pagesConstruction Costs Across Asia PacificSudhakar GanjikuntaNo ratings yet

- Effect of PH On FlotationDocument10 pagesEffect of PH On FlotationInnocent Achaye100% (1)

- Scotch-Weld Epoxy Adhesive DP460, DP460NS-349252Document9 pagesScotch-Weld Epoxy Adhesive DP460, DP460NS-349252sinofreebirdNo ratings yet

- List of Environmental DisastersDocument7 pagesList of Environmental DisastersCerise FranciscoNo ratings yet

- CV - Kheav Kimleng - 14nov2021Document5 pagesCV - Kheav Kimleng - 14nov2021Duncan josefNo ratings yet

- Cooling Technology - Cooling TowersDocument2 pagesCooling Technology - Cooling TowerstaghdirimNo ratings yet

- Echnology Rief: Autoclaved Aerated Concrete Masonry UnitsDocument4 pagesEchnology Rief: Autoclaved Aerated Concrete Masonry UnitsJayakumar AnanthaNo ratings yet

- Toilet Specification Status Rev 2 2010Document4 pagesToilet Specification Status Rev 2 2010aprilmarieadeveraNo ratings yet

- Reducers Used in Piping Industry PDFDocument2 pagesReducers Used in Piping Industry PDFaap1100% (1)

- EC Safety Data Sheet: SulfolyserDocument9 pagesEC Safety Data Sheet: SulfolysernevilleborgNo ratings yet

- Career Episode 2 - Waste Water Treatment PlantDocument11 pagesCareer Episode 2 - Waste Water Treatment PlantMiyuranga W.H.D.D. en17081344No ratings yet

- Bahasa Inggeris k2 MPSM Pulau Pinang SPM 2019Document18 pagesBahasa Inggeris k2 MPSM Pulau Pinang SPM 2019Odah Tai100% (1)

- Compilación de Investigaciones y Análisis de Coyuntura Ambiental en GuatemalaDocument194 pagesCompilación de Investigaciones y Análisis de Coyuntura Ambiental en GuatemalaPrograma Regional para el Manejo de Recursos Acuáticos y Alternativas EconómicasNo ratings yet

- AWWA BookstoreCatalog 2007 PDFDocument168 pagesAWWA BookstoreCatalog 2007 PDFRita CaselliNo ratings yet

- Self Healing ConcreteDocument21 pagesSelf Healing ConcretethirumalNo ratings yet

- Lab Weir Exp 3Document15 pagesLab Weir Exp 3Amy FarhanaNo ratings yet

- Hydrodynamics in Cornell Dual-Drain Tank - SummerfeltDocument8 pagesHydrodynamics in Cornell Dual-Drain Tank - SummerfeltNtpbdrNo ratings yet

- Preschool IncidentDocument2 pagesPreschool IncidentHNNNo ratings yet

- Hho 2Document5 pagesHho 2Prittam Kumar JenaNo ratings yet

- How CCPPs Work to Generate Power EfficientlyDocument11 pagesHow CCPPs Work to Generate Power EfficientlyPGPalomaNo ratings yet

- What Are ZooplanktonDocument4 pagesWhat Are ZooplanktonMosdalifahNo ratings yet

- Ground Water Quality Monitoring in A Developing Area Using Water Quality Index and Principal Component Analysis: A Case Study of Visakhapatnam IndiaDocument8 pagesGround Water Quality Monitoring in A Developing Area Using Water Quality Index and Principal Component Analysis: A Case Study of Visakhapatnam IndiaMallikarjuna Rao DuvvadaNo ratings yet

- Superthrive Dosage Chart PDFDocument6 pagesSuperthrive Dosage Chart PDFELI AlavaradoNo ratings yet