Professional Documents

Culture Documents

E1844

Uploaded by

DannyChacon0 ratings0% found this document useful (0 votes)

247 views4 pagesThis specification covers the general requirements for a smooth-tread standard tire for measuring tire-pavement friction forces. It does not purport to address all of the safety concerns associated with its use. The individual standard tires shall conform to the design standards of Section 6.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis specification covers the general requirements for a smooth-tread standard tire for measuring tire-pavement friction forces. It does not purport to address all of the safety concerns associated with its use. The individual standard tires shall conform to the design standards of Section 6.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

247 views4 pagesE1844

Uploaded by

DannyChaconThis specification covers the general requirements for a smooth-tread standard tire for measuring tire-pavement friction forces. It does not purport to address all of the safety concerns associated with its use. The individual standard tires shall conform to the design standards of Section 6.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Designation: E 1844 96 (Reapproved 2004)

Standard Specication for

A Size 10 3 45 Smooth-Tread Friction Test Tire

1

This standard is issued under the xed designation E 1844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specication covers the general requirements for a

smooth-tread standard tire for measuring tire-pavement friction

forces.

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are provided for

information purposes only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

2

D 297 Methods for Rubber ProductsChemical Analysis

D 412 Test Methods for Vulcanized Rubber and Thermo-

plastic ElastomersTension

D 1054 Test Method for Rubber PropertyResilience Us-

ing a Goodyear-Healey Rebound Pendulum

D 1765 Classication System for Carbon Blacks Used in

Rubber Products

D 2240 Test Method for Rubber PropertyDurometer

Hardness

D 3182 Practice for RubberMaterials, Equipment, and

Procedures for Mixing Standard Compounds and Prepar-

ing Standard Vulcanized Sheets

E 867 Terminology Relating to Vehicle-Pavement Systems

2.2 Other Document:

GriptesterGTSV1 Descriptive Booklet

3

3. Terminology

3.1 Terminology used in this specication is in accordance

with Terminology E 867.

4. Materials and Manufacture

4.1 The individual standard tires shall conform to the design

standards of Section 6. Dimensions, weights, and permissible

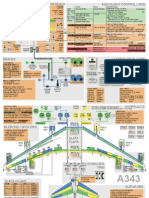

variations are also given in Section 6 and Fig. 1 and Fig. 2.

4.2 Tread compounding, fabric processing, and all tire

manufacturing shall be certied to ensure that the specica-

tions are met (see Section 8).

4.3 The markings on the tire, as shown in Fig. 1, shall be

molded on the sides of the tire.

4.4 Fig. 1 shows a view of the tread surface and a side view

of the tire. Fig. 2 is a typical tire cross-section with critical

dimensions identied.

5. Material Requirements

5.1 The compounding requirements for the tread compound

are given in Table 1.

5.2 The fabric shall be Nylon, 1260/2 Denier.

NOTE 1Certain proprietary products have been specied since exact

duplication of properties of the nished tire may not be achieved with

other similar products. This inclusion does not in any way comprise a

recommendation for these proprietary products nor against similar prod-

ucts of other manufacturers, nor does it imply any superiority over any

such similar products.

6. Physical Requirements

6.1 The physical and mechanical test requirements of the

tread compound are given in Table 2.

7. Construction, Dimensions and Permissible Variations

7.1 ConstructionThe tire shall be size 10 3 45, tube

type, two plies, nylon cord, and bias construction.

7.2 DimensionsTread width shall be 51 6 2.0 mm (2.0 6

0.08 in.), the tread radius shall be 165 625 mm (6.5 61.0 in.),

the cross-sectional width shall be 102 62 mm (4.0 60.08 in.),

and the outside diameter at the centerline shall be 258 6 2 mm

(10.15 6 0.08 in.) when measured on a 89 mm (3.5 in.) wide

rim at 138 63 kPa (20 60.5 PSI). See Fig. 2 which shows the

inated dimensions of the new tire.

7.3 TreadThe tread surface shall be smooth (blank) with-

out any ribs or grooves. The tread shall have a thickness of 5

mm (0.20 in.) and an undertread thickness of 2 60.5 mm (0.08

6 0.02 in.) at the tread centerline.

1

This specication is under the jurisdiction of ASTM Committee E17 on

Vehicle-Pavement Systems and is the direct responsibility of Subcommittee E17.24

on Tire and Slider Characteristics.

Current edition approved Dec. 1, 2004. Published December 2004. Originally

approved in 1996. Last previous edition approved in 1996 as E 1844 96.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

3

Available from Findlay-Irvine Ltd., Bog Road, Penicuik, Midlothian

EH269BU, Scotland.

1

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

7.4 Wear IndicatorsThere will be two holes molded into

the tire tread, 5.0 mm (0.20 in.) deep and 3.2 mm (0.125 in.) in

diameter. These two wear-indicators will be spaced 180 apart.

8. Workmanship

8.1 Tires shall be free of defects in workmanship and

material.

9. Test Methods

9.1 For information on the following, refer to the ASTM

standards listed.

9.1.1 Tensile Sheet CurePractice D 3182.

9.1.2 Modulus (300 %)Test Methods D 412.

9.1.3 Tensile Sheet DurometerTest Method D 2240, using

a Type A Shore Durometer.

9.1.4 Restored Energy (Rebound or Resilience)Test

Method D 1054.

9.1.5 Specic GravityTest Method D 297.

9.1.6 Tensile StrengthTest Methods D 412.

9.1.7 ElongationTest Methods D 412.

9.1.8 Tire Tread DurometerTest Method D 2240, in addi-

tion to the following specic procedures:

9.1.8.1 Use a Type A Durometer. A12.7 mm (0.5 in.)

diameter presser foot, a sure code XAHAF is recommended.

9.1.8.2 The Durometer shall be calibrated at a reading of 60

hardness.

9.1.8.3 Condition the tire and durometer to equilibrium at

23 6 2C (73.4 6 3.6F) before determining tread hardness.

9.1.8.4 Determine the tire tread hardness by averaging at

least one set of six readings. A set should consist of readings

taken at approximately equally spaced intervals around the

tread circumference.

9.1.8.5 Apply the presser foot to the tire tread as rapidly as

possible without shock, keeping the foot parallel to the tread

surface. Apply just sufficient pressure to obtain rm contact

between the presser foot and tire tread surface. Read the

durometer scale within 1 s after the presser foot is in contact

with the tread, but after initial maximum transient which may

occur immediately after contact is made.

10. Precision and Bias

10.1 Precision standards are currently under development.

11. Certication

11.1 Tires are to be inated and measured prior to shipment.

Upon request, the manufacturer shall furnish the purchaser

with certication that the test tire meets this specication.

11.2 The Annex to this specication suggests a test proce-

dure for determining the reliability, performance and consis-

tency of the tires.

11.3 All tires under certication shall be subject to the

manufacturers normal variation.

12. Packaging and Preservation

12.1 Tires should be stored in a dry area, at a temperature

not exceeding 32.2C (90F) and in subdued light. Tires must

not be stored near electric motors, welders, or other ozone

generating equipment.

FIG. 1 Molded on Tire: 10 3 45 Tread ASTM Batch No.

FIG. 2 Tire SectionInated Dimensions

TABLE 1 Compounding of Tread Rubber

A

Material Parts by Mass

SBR 1714

B

89.38

CB1252

C

48.12

N347

D

75.00

High-Aromatic Oil 9.00

Zinc Oxide 3.00

Stearic Acid 2.00

Santoex 13

E

2.00

Paraffin Wax 2.00

Santocure NS

F

1.10

DPG

G

0.10

Sulfur 1.80

A

See Practice D 3182.

B

Styrene-butadiene rubber (23.5 % styrene) 37.5 parts of high-aromatic oil.

C

Cis-polybutadiene with 37.5 parts of high-aromatic oil or equivalent.

D

N347 Carbon Black, see Classication D 1765.

E

Dimethyl butylphenyl phenylenediamine.

F

Butyl benzothiazole sulfenamide.

G

Diphenyl guanidine.

TABLE 2 Physical Properties of Tread Compound

Tensile Sheet Cure, min at 300F (149C) 30

300 % modulus, psi (MPa) (Test Methods D 412) 800 6 200

(5.5 6 1.4)

Tensile sheet durometer (Test Method D 2240) 58 6 2

Restored energy (rebound or resilience) (Test Method D 1054) 466 2

Specic gravity (Methods D 297) 1.13 6 0.02

Tensile strength, min psi (MPa) (Test Methods D 412) 2000 (13.8)

Elongation, min % (Test Methods D 412) 500

Tire tread durometer (Test Method D 2240) 58 6 2

E 1844 96 (2004)

2

13. Recommendations for Tire Use and Operational

Requirements

13.1 The tire was designed for measuring tire-pavement

friction forces only and was not designed for any other use or

service.

13.2 Anew tire break-in sufficient to only remove the glossy

tread surface is recommended before using the tire for testing.

This break-in time will vary with pavement surface condition,

speed, and test tire operating mode, but is normally 511 km

(37 miles).

13.3 The ination pressure used in the test tire shall be 138

6 3 kPa (20 6 0.5 PSI) measured at ambient temperature

(cold). The maximum permitted ination is 275 kPa (40 PSI).

13.4 The recommended static test load on the test tire shall

be 21 kg (46 lbs).

13.5 When any irregular wear or damage results from the

testing or when the wear indicators are no longer visible, the

use of the tire as a standard friction test tire shall be

discontinued.

NOTE 2Caution: The measured friction number may be inuenced

by tire age or tread hardness, or both. The magnitude of this dependence

has not been exactly determined, but aging which has increased tread

hardness to 65 will inuence the resultant friction forces on some types of

pavements.

14. Keywords

14.1 friction test tire; size 10 6, 45

ANNEX

(Mandatory Information)

A1. SUGGESTED PROCEDURE FOR TESTING AND DOCUMENTING MEASURING TIRES

A1.1 Introduction

A1.1.1 The purpose of this procedure is to ensure that all

measuring tires give friction readings which match the stan-

dard. This standard is dened in terms of a reference

measuring tire or calibration tire.

A1.1.2 For continuity, there shall be three calibration tires:

two in active use and one master calibration tire held in reserve

for calibration tire testing. These tires are selected from those

that have passed the standard procedure for testing with

particularly stringent conditions (see paragraph A1.4 below).

A1.1.3 The three current calibration tires must undergo the

monthly cross-check set out in section A1.5 below.

A1.1.4 All tires must be manufactured from the rubber

compound dened in Specications E 1551, E 501, and E 524.

A1.2 Incoming Goods Inspection

A1.2.1 On receipt of a batch of tires from the manufacturer,

every tire must be visually examined for a batch number,

rubber formulation stamp, and physical imperfections. Tires

failing visual inspection must be returned to the manufacturer.

A1.2.2 Tires which have passed visual inspection must be

marked in bright metallic paint with an individual serial

number showing the type of tire, batch number, and tire

number. For example, A-08-21. These numbers must be

entered in the tire log book which will subsequently show the

date of test, whether it passed or failed, and (when appropriate)

to where it was dispatched.

A1.3 Running in of New Tires

A1.3.1 The tires, together with their inner tubes, must be

mounted on rims and inated to 138 6 3 kPa (20 6 1 psi) and

then run-in on a friction tester. The mileage required depends

on the temperature and moisture on the road surface at the time

and varies from 5 to 11 km (3 to 7 miles), at 50 to 65 kmH

(3040 mph). The tire must be considered run-in when the

central molding ash is no longer visible.

A1.4 Test Procedure

A1.4.1 The mounted and run-in tires must be road-tested for

accuracy of their friction readings, according to the following

procedure:

A1.4.1.1 Test ConditionsThe test must be made according

to the following rules:

A1.4.1.1.1 Tires must be tested within nine months of

manufacture and hardness recorded.

A1.4.1.1.2 All tires must be inated to 138 6 3 kPa (20 6

1 psi).

A1.4.1.1.3 All tires must travel at least 1 km (0.6 mile)

before entering the test section, and for the last 200 metres (220

yds), the surface must be wetted so that the surface is covered

with at least 0.5 mm (.02 in.) of water.

A1.4.1.1.4 A properly calibrated friction tester must be

used. Comparisons must only be made between runs carried

out using the same friction tester.

A1.4.1.1.5 Comparisons must only be made between runs

carried out on the same day and under the same conditions of

road state, moisture and temperature. If the ambient tempera-

ture changes more than 5C (9F) or if precipitation conditions

change, the procedure must be restarted.

A1.4.1.1.6 Test runs must be made on a 1 km (0.6 mile)

length of straight road, surfaced with hot-rolled-asphalt. Each

one third of each side of this test length must be regarded as a

separate test section.

A1.4.2 Calculation of Calibration Friction Numbers

A1.4.2.1 Because testing is carried out on surfaces whose

friction characteristics are not constant, the rst stage of the

testing procedure must always be to obtain a current set of

friction numbers for the six test sections used.

A1.4.2.2 With a calibration tire mounted, a run covering all

six test sections (that is, an outward and return run) must be

made and the average friction number for each section calcu-

lated. This double run must be repeated, and the average

friction number for each section calculated again.

E 1844 96 (2004)

3

A1.4.2.3 By this means, two average friction numbers will

have been obtained for each of the six sections. These two

average friction numbers should differ by no more than 0.03.

A1.4.2.4 If this condition is met, a calibration friction

number for each section must be formed by averaging the two

averages for that section.

A1.4.2.5 If this condition is not met, the double run must

again be carried out until two double runs are obtained which

do satisfy the condition.

A1.4.3 Acceptance Criteria for Production Tires

A1.4.3.1 With the new tire mounted, a run covering three of

the test sections must be made and the average friction number

for each section calculated. If the friction number for each of

the three sections is within 0.02 of the calibration average, the

tire is passed.

A1.4.3.2 If at least one of the average friction numbers is

not within 0.02 of the calibration average but each of the

average friction numbers is within 0.03 of the calibration

average, then a return run must be made; if the friction number

for each section is again within 0.03 of the calibration average,

the tire is passed.

A1.4.3.3 If the reading for one section has to be discarded

(because of obstruction or contamination) a return run is made;

ve readings which are within 0.03 of the calibration average

allow the tire to be passed.

A1.4.4 Acceptance criteria for calibration tires:

A1.4.4.1 The calculation of the six calibration friction

numbers described in A1.4.2 must be carried out using the

master calibration tire.

A1.4.4.2 With the new tire mounted, a run covering three of

the test sections must be made and the average friction number

for each section calculated. If the friction number for each of

the three sections is within 0.01 of the calibration average, the

tire is passed.

A1.4.4.3 If the friction number for each of the three sections

is only within 0.02 of the calibration average, a return run is

made; if the friction number for each section is again within

0.02 of the calibration average, the tire is passed.

A1.5 Checks on the Calibration Tires

A1.5.1 The life of a master calibration tire in that role must

not exceed six months, or if hardness exceeds 62.

A1.5.2 The life of an active calibration tire in that role must

not exceed eighteen months, or if the hardness exceeds 62.

A1.5.3 At least bi-monthly, each of the two active calibra-

tion tires must be tested against the master calibration tire as

dened in paragraphs A1.4.4.1-A1.4.4.3.

A1.5.4 A calibration tire which fails this cross check, is too

old for its role or exceeds 62 hardness, must be replaced.

A1.5.5 Areplacement for a master calibration tire must be a

new tire.

A1.6 Recording of Results

A1.6.1 Details of all tests are to be recorded in the Friction

Tester Log book in the same detail as tests for Friction Testers,

under the following headings:

A1.6.1.1 Date

A1.6.1.2 Location

A1.6.1.3 Friction Tester No.

A1.6.1.4 Tire No.

A1.6.1.5 Speed

A1.6.1.6 Distance

A1.6.1.7 Friction Numbers

A1.6.1.8 Remarks

A1.6.1.9 Pass/Fail

A1.6.1.10 Testers signature

A1.6.2 The results of the test are to be entered in the Tire

Log book (see A1.2.2).

A1.6.3 A green TESTED sticker initialed and dated is to be

applied to all tires which have met the requirements of this

annex. A tire which has passed as a calibration tire and is to be

adopted as such must be given an additional marking in

metallic paint CAL-A-n, where n is a serial number.

A1.6.4 Production tires which have passed these tests, are to

be stored in the bin kept solely for this category of material.

Calibration tires mounted, are to be stored in the bin kept solely

for this class of material.

A1.6.5 Production tires which have passed these tests shall

be supplied to customers accompanied by a release certicate.

A1.6.6 A red REJECTED sticker initialed and dated is to be

applied to all tires which have failed to meet the requirements

of these tests and on both sides of the tire the word FAILED

must be written in metallic paint, without obscuring the tire

number.

A1.6.7 Failed tires must be returned to the stores failed

inspection area.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

E 1844 96 (2004)

4

You might also like

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocument8 pagesPreparation of Asphalt Mixture Specimens Using Marshall Apparatussumukh swaroopNo ratings yet

- Percent Air Voids in Compacted Dense and Open Asphalt MixturesDocument4 pagesPercent Air Voids in Compacted Dense and Open Asphalt MixturesAhmad KhreisatNo ratings yet

- D 692 - 00 Rdy5mi0wmaDocument2 pagesD 692 - 00 Rdy5mi0wmaRufo Casco0% (1)

- Classifying Hot-Mix Recycling Agents: Standard Practice ForDocument2 pagesClassifying Hot-Mix Recycling Agents: Standard Practice ForRed Red100% (1)

- ASTM - E2157 Test Method For Measuring Pavement Macrotexture Properties Using The Circular Track Meter.Document5 pagesASTM - E2157 Test Method For Measuring Pavement Macrotexture Properties Using The Circular Track Meter.Theeraruk ManeenartNo ratings yet

- Astm Ac20Document3 pagesAstm Ac20Juan QuiñonesNo ratings yet

- D 2041 - 00Document4 pagesD 2041 - 00harisahamedNo ratings yet

- Astm D 4318Document16 pagesAstm D 4318Camilo OrozcoNo ratings yet

- Standard Method of Test For Resistance of Compacted Asphalt Mixtures To Moisture-Induced DamageDocument8 pagesStandard Method of Test For Resistance of Compacted Asphalt Mixtures To Moisture-Induced Damagemehdi zalnezhadNo ratings yet

- As 2341.2-1993 Methods of Testing Bitumen and Related Roadmaking Products Determination of Dynamic (CoefficieDocument2 pagesAs 2341.2-1993 Methods of Testing Bitumen and Related Roadmaking Products Determination of Dynamic (CoefficieSAI Global - APACNo ratings yet

- C1688C1688M 2285Document4 pagesC1688C1688M 2285Barnali DebnathNo ratings yet

- The Multiple-Stress Creep-Recovery (MSCR) Test and SpecificationDocument42 pagesThe Multiple-Stress Creep-Recovery (MSCR) Test and SpecificationVinayaka RamNo ratings yet

- Aashto t305Document3 pagesAashto t305SyahrulRamadhanNo ratings yet

- Astm D 2170 - 07Document10 pagesAstm D 2170 - 07m_seyedNo ratings yet

- D7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesDocument5 pagesD7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesSatya kaliprasad vangaraNo ratings yet

- D 4867 - D 4867M - 04Document5 pagesD 4867 - D 4867M - 04Luisinho Alvarez ChávezNo ratings yet

- Aashto T 391Document9 pagesAashto T 391Ramy Hussein100% (1)

- Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) TestDocument8 pagesPerformance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Testmohammed karasnehNo ratings yet

- Amount of Water Required For Normal Consistency of Hydraulic Cement PasteDocument3 pagesAmount of Water Required For Normal Consistency of Hydraulic Cement PasteThurain Aung KyawNo ratings yet

- Sampling Bituminous Paving Mixtures: Standard Practice ForDocument4 pagesSampling Bituminous Paving Mixtures: Standard Practice ForAnonymous x7VY8VF7No ratings yet

- Softening Point of Bitumen (Ring-and-Ball Apparatus) : Standard Test Method ForDocument5 pagesSoftening Point of Bitumen (Ring-and-Ball Apparatus) : Standard Test Method ForPyone Ei ZinNo ratings yet

- Effect of Water On Compressive Strength of Compacted Bituminous MixturesDocument3 pagesEffect of Water On Compressive Strength of Compacted Bituminous MixturesDEBOJIT NANDINo ratings yet

- Astm C330 C330M 23Document3 pagesAstm C330 C330M 23rsoasadigmoniem2023100% (1)

- C943Document4 pagesC943Jorge Luis Arevalo Lopez100% (1)

- Astm D6084 D6084M-21Document5 pagesAstm D6084 D6084M-21bestoon RamadhanNo ratings yet

- Methods For Testing Tar and Bituminous Materials - Determination of Specific GravityDocument10 pagesMethods For Testing Tar and Bituminous Materials - Determination of Specific Gravityturutriveni reddyNo ratings yet

- Portland Cement: Standard Specification ForDocument9 pagesPortland Cement: Standard Specification ForPedroNo ratings yet

- Performance Graded Asphalt Binder: Standard Specification ForDocument5 pagesPerformance Graded Asphalt Binder: Standard Specification ForJesús Luis Arce GuillermoNo ratings yet

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50 MM) Cube Specimens)Document12 pagesCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50 MM) Cube Specimens)Huzaifa U Farooq100% (1)

- ASSHTODocument3 pagesASSHTOmiguelangelNo ratings yet

- Astm C 618 02 1Document4 pagesAstm C 618 02 1Ciro Arnold Gonzales PauccarNo ratings yet

- Determining The Rheological Properties of Asphalt Binder Using A Dynamic Shear RheometerDocument16 pagesDetermining The Rheological Properties of Asphalt Binder Using A Dynamic Shear RheometerRahul HnkNo ratings yet

- Standard Specification For Aggregate For Masonry MortarDocument3 pagesStandard Specification For Aggregate For Masonry MortarAlbertto GuardadoNo ratings yet

- Astm D6373 - 23Document5 pagesAstm D6373 - 23rtiyer1970No ratings yet

- D139-12 Standard Test Method For Float Test For Bituminous MaterialsDocument3 pagesD139-12 Standard Test Method For Float Test For Bituminous MaterialsVag KatsikopoulosNo ratings yet

- ASTM Volume 04.03 Road and Paving MaterialsDocument7 pagesASTM Volume 04.03 Road and Paving MaterialsVenu GopalNo ratings yet

- Aashto t84 Specific Gravity and Absorption of Fine Gravity CompressDocument9 pagesAashto t84 Specific Gravity and Absorption of Fine Gravity Compressaisa syahNo ratings yet

- Astm D2726-17Document4 pagesAstm D2726-17Iranis E Lugo RodriguezNo ratings yet

- Resistance To Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 Inch-Diameter Specimen)Document5 pagesResistance To Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 Inch-Diameter Specimen)Phuc Nguyen QuangNo ratings yet

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Document11 pagesCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Yanina Rios ChavezNo ratings yet

- Astm D 217Document14 pagesAstm D 217Rosario BuonannoNo ratings yet

- Astm D2872-21Document6 pagesAstm D2872-21bestoon RamadhanNo ratings yet

- Lap Cement Used With Asphalt Roll Roofing, Non Fibered, Asbestos Fibered, and Non Abestos FiberedDocument2 pagesLap Cement Used With Asphalt Roll Roofing, Non Fibered, Asbestos Fibered, and Non Abestos FiberedMohammad YaseenNo ratings yet

- C535 12Document3 pagesC535 12Pedro VenturaNo ratings yet

- Standard Practice For Making and Curing Concrete Test Specimens in The FieldDocument7 pagesStandard Practice For Making and Curing Concrete Test Specimens in The FieldAlberto Robles CamposNo ratings yet

- Chemical Analysis of Hydraulic Cement: 1. ScopeDocument27 pagesChemical Analysis of Hydraulic Cement: 1. ScopeEvert RiveraNo ratings yet

- Is 8419 1 1977 PDFDocument12 pagesIs 8419 1 1977 PDFcodefinderNo ratings yet

- Astm C31-21Document7 pagesAstm C31-21Lázaro Henríquez sandovalNo ratings yet

- Effect of Aggregate Gradations on Porous Friction Course Mix PropertiesDocument13 pagesEffect of Aggregate Gradations on Porous Friction Course Mix PropertiesBen Mur MarNo ratings yet

- KEM Epoxy Grout ELV - 1Document2 pagesKEM Epoxy Grout ELV - 1BinodNo ratings yet

- Ready-Mixed Concrete: Standard Specification ForDocument15 pagesReady-Mixed Concrete: Standard Specification ForLogan PatrickNo ratings yet

- Uncompacted Void Content of Fine Aggregate Test ProcedureDocument4 pagesUncompacted Void Content of Fine Aggregate Test ProcedureRianSastikaNo ratings yet

- Sand Equivalent Test MethodDocument13 pagesSand Equivalent Test MethodRICARDO NOEL LEZAMA CHAVEZNo ratings yet

- AASHTO R-18 QA For Testing LabsDocument27 pagesAASHTO R-18 QA For Testing LabsMike FeistNo ratings yet

- D4552Document2 pagesD4552AnantNo ratings yet

- Mineral Filler For Asphalt MixturesDocument2 pagesMineral Filler For Asphalt MixturesAnonymous x7VY8VF7No ratings yet

- E1844 PDFDocument4 pagesE1844 PDFMo BlackNo ratings yet

- Conducting Wet Sand/Rubber Wheel Abrasion Tests: Standard Test Method ForDocument9 pagesConducting Wet Sand/Rubber Wheel Abrasion Tests: Standard Test Method ForMiguel Angel B. VazquezNo ratings yet

- ASTM D-4060 Abrasion Resistant of Organic CoatingsDocument5 pagesASTM D-4060 Abrasion Resistant of Organic CoatingsArieIndrawan100% (1)

- Standard Smooth Tire For Pavement Skid-Resistance TestsDocument3 pagesStandard Smooth Tire For Pavement Skid-Resistance TestsDannyChaconNo ratings yet

- Metadata To Support Archived Data Management Systems: Standard Practice ForDocument64 pagesMetadata To Support Archived Data Management Systems: Standard Practice Fordannychacon27No ratings yet

- Calculating The International Runway Friction Index: Standard Practice ForDocument5 pagesCalculating The International Runway Friction Index: Standard Practice ForDannyChaconNo ratings yet

- Measuring Pavement Macrotexture Properties Using The Circular Track MeterDocument5 pagesMeasuring Pavement Macrotexture Properties Using The Circular Track MeterDannyChaconNo ratings yet

- E2158 PDFDocument22 pagesE2158 PDFDannyChaconNo ratings yet

- Accelerated Polishing of Aggregates or Pavement Surfaces Using A Small-Wheel, Circular Track Polishing MachineDocument6 pagesAccelerated Polishing of Aggregates or Pavement Surfaces Using A Small-Wheel, Circular Track Polishing MachineDannyChaconNo ratings yet

- Computing Ride Number of Roads From Longitudinal Profile Measurements Made by An Inertial Profile Measuring DeviceDocument16 pagesComputing Ride Number of Roads From Longitudinal Profile Measurements Made by An Inertial Profile Measuring DeviceDannyChaconNo ratings yet

- E1448 PDFDocument8 pagesE1448 PDFAhmad Zubair RasulyNo ratings yet

- Developing Axle Count Adjustment Factors: Standard Practice ForDocument3 pagesDeveloping Axle Count Adjustment Factors: Standard Practice ForDannyChaconNo ratings yet

- Measuring The Frictional Properties of Winter Contaminated Pavement Surfaces Using An Averaging-Type Spot Measuring DecelerometerDocument4 pagesMeasuring The Frictional Properties of Winter Contaminated Pavement Surfaces Using An Averaging-Type Spot Measuring DecelerometerDannyChaconNo ratings yet

- Simulating Truck Response To Longitudinal Profiles of Vehicular Traveled SurfacesDocument5 pagesSimulating Truck Response To Longitudinal Profiles of Vehicular Traveled Surfacesdannychacon27No ratings yet

- Vehicle-Pavement Systems: Standard Terminology Relating ToDocument10 pagesVehicle-Pavement Systems: Standard Terminology Relating ToDannyChaconNo ratings yet

- E2415 PDFDocument4 pagesE2415 PDFdannychacon27No ratings yet

- Measuring Road Roughness by Static Level Method: Standard Test Method ForDocument6 pagesMeasuring Road Roughness by Static Level Method: Standard Test Method ForDannyChaconNo ratings yet

- E2133 PDFDocument4 pagesE2133 PDFJean Paul Tabera ColoradoNo ratings yet

- E2380Document4 pagesE2380DannyChaconNo ratings yet

- E2259Document21 pagesE2259DannyChaconNo ratings yet

- Conducting Subjective Pavement Ride Quality Ratings: Standard Guide ForDocument8 pagesConducting Subjective Pavement Ride Quality Ratings: Standard Guide ForAhmad Zubair RasulyNo ratings yet

- E2341E2341MDocument4 pagesE2341E2341MDannyChaconNo ratings yet

- E 2213 Â " 03 RTIYMTM - PDFDocument26 pagesE 2213 Â " 03 RTIYMTM - PDFJaime Edgardo Vasquez SanchezNo ratings yet

- Measuring Paved Surface Frictional Properties Using The Dynamic Friction TesterDocument8 pagesMeasuring Paved Surface Frictional Properties Using The Dynamic Friction TesterDannyChaconNo ratings yet

- ASTM Designation E 1926 - 98 Reapproved 2003Document18 pagesASTM Designation E 1926 - 98 Reapproved 2003rendyNo ratings yet

- E707Document5 pagesE707DannyChaconNo ratings yet

- ASTM E1845 - Standard Practice For Calculating Pavement Macrotexture Mean Profile Depth PDFDocument4 pagesASTM E1845 - Standard Practice For Calculating Pavement Macrotexture Mean Profile Depth PDFrendy100% (1)

- E1960 PDFDocument5 pagesE1960 PDFdannychacon27No ratings yet

- Measuring Pavement Roughness Using A Profilograph: Standard Test Method ForDocument4 pagesMeasuring Pavement Roughness Using A Profilograph: Standard Test Method Fordavid quinteroNo ratings yet

- Prioritization of Data Needs For Pavement ManagementDocument9 pagesPrioritization of Data Needs For Pavement ManagementDannyChaconNo ratings yet

- Friction Coefficient Measurements Between Tire and Pavement Using A Variable Slip TechniqueDocument8 pagesFriction Coefficient Measurements Between Tire and Pavement Using A Variable Slip TechniqueDannyChaconNo ratings yet

- Highway Weigh-In-Motion (WIM) Systems With User Requirements and Test MethodsDocument16 pagesHighway Weigh-In-Motion (WIM) Systems With User Requirements and Test MethodsNada KhlifNo ratings yet

- E1844 PDFDocument4 pagesE1844 PDFMo BlackNo ratings yet

- Validating New Area Reference Skid Measurement Systems and EquipmentDocument5 pagesValidating New Area Reference Skid Measurement Systems and Equipmentdannychacon27No ratings yet

- CCPW QC 504 Concrete Inspection FormDocument2 pagesCCPW QC 504 Concrete Inspection FormsaharuiNo ratings yet

- Smart View User GuideDocument352 pagesSmart View User Guidemalik_sohaibNo ratings yet

- Information Systems: Definitions and ComponentsDocument20 pagesInformation Systems: Definitions and Componentssubhash221103No ratings yet

- Case Memo #3Document3 pagesCase Memo #3Iris WangNo ratings yet

- 5cdriveragrement PDFDocument1 page5cdriveragrement PDFMilcoDuliNo ratings yet

- Subjective and Objective Food Technology: February 2018Document8 pagesSubjective and Objective Food Technology: February 2018Khan JavedNo ratings yet

- Jet Pack: From Wikipedia, The Free EncyclopediaDocument13 pagesJet Pack: From Wikipedia, The Free EncyclopediaBhawani Singh RajawatNo ratings yet

- Process CostingDocument44 pagesProcess CostingMayla Lei Pablo100% (2)

- Data Processing For Big Data ReportDocument24 pagesData Processing For Big Data ReportVarun MathurNo ratings yet

- Royal Wolf Product CatalogueDocument24 pagesRoyal Wolf Product Cataloguelouza8No ratings yet

- EPDP Overview Training For TeamsDocument186 pagesEPDP Overview Training For Teamsp.c abhishek50% (2)

- UI API Is UnavailableDocument4 pagesUI API Is UnavailableMark Stephen CaleNo ratings yet

- VDA White Paper Harmonization Classification Levels FinalDocument9 pagesVDA White Paper Harmonization Classification Levels FinalR JNo ratings yet

- McKinsey - Unlocking The Potential of The IoT PDFDocument144 pagesMcKinsey - Unlocking The Potential of The IoT PDFWillianKenzoFujimotoNo ratings yet

- Landing Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Document1 pageLanding Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Elias IruelaNo ratings yet

- Ankur GuptaDocument2 pagesAnkur GuptaChandan MondalNo ratings yet

- Machinery ChecklistDocument2 pagesMachinery Checklistmike_day90% (31)

- Gas AbsorptionDocument121 pagesGas AbsorptionKrystel Monica ManaloNo ratings yet

- Telescopic CylinderDocument4 pagesTelescopic Cylindergapc210% (1)

- 3bc899b9-e56d-40c4-a304-1cc5edf4b6c7Document4 pages3bc899b9-e56d-40c4-a304-1cc5edf4b6c7Swamy Dhas DhasNo ratings yet

- Distribution Network Design and Transport OptimizationDocument5 pagesDistribution Network Design and Transport Optimizationdicky suryaNo ratings yet

- Funds ManagementDocument3 pagesFunds ManagementSowmyaNo ratings yet

- RIT Case Brief ALGO2 Algorithmic Market MakingDocument3 pagesRIT Case Brief ALGO2 Algorithmic Market MakingmarioNo ratings yet

- Turbocharger RetrofitingDocument2 pagesTurbocharger RetrofitingShoaib Arshad100% (1)

- Blog - Oscarliang - Net - Build A Quadcopter Beginners Tutorial 1Document23 pagesBlog - Oscarliang - Net - Build A Quadcopter Beginners Tutorial 1Number ButNo ratings yet

- FoxMeyer TempDocument9 pagesFoxMeyer TempGanesh Divekar100% (1)

- Digital Weighing Indicator XK3190-A12 (E) : User ManualDocument17 pagesDigital Weighing Indicator XK3190-A12 (E) : User Manualiyol1No ratings yet

- 2016 CPRA Log - Grand TerraceDocument3 pages2016 CPRA Log - Grand TerraceBeau YarbroughNo ratings yet

- Boeing C-137 StratolinerDocument3 pagesBoeing C-137 StratolinerMa RiaNo ratings yet

- IS 2062 Rev 2011Document10 pagesIS 2062 Rev 2011Ganesh LohakareNo ratings yet