Professional Documents

Culture Documents

Cement

Uploaded by

anshuldoc9Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement

Uploaded by

anshuldoc9Copyright:

Available Formats

THE CEMENT MANUFACTURING

PROCESS

Prof. Dr Elshafie Ahmed Gad

Faculty of Applied Science

Chemistry Dept.

Portland Cement

Portland cement is made by mixing substances

containing CaCO

3

with substances containing

SiO

2

, Al

2

O

3

, Fe

2

O

3

and heating them to a clinker

which is subsequently ground to powder and

mixed with 2-6 % gypsum

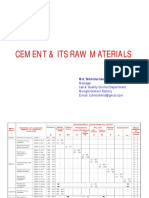

Raw Materials Necessary for

Portland Cement Manufacture

Must Provide the Following

Calcium

Silica

Alumina

Iron

Calcium Iron Silica Alumina Sulfate

Alkali waste

Aragonite

Calcite

Cement-kiln

dust

Cement rock

Chalk

Clay

Fullers earth

Limestone

Marble

Marl

Seashells

Shale

Slag

Blast-furnace

flue dust

Clay

Iron ore

Mill scale

Ore washings

Pyrite cinders

Shale

Calcium silicate

Cement rock

Clay

Fly ash

Fullers earth

Limestone

Loess

Marl

Ore washings

Quartzite

Rice-hull ash

Sand

Sandstone

Shale

Slag

Traprock

Aluminum-ore

refuse

Bauxite

Cement rock

Clay

Copper slag

Fly ash

Fullers earth

Granodiorite

Limestone

Loess

Ore washings

Shale

Slag

Staurolite

Anhydrite

Calcium

sulfate

Gypsum

PRODUCTION STEPS

1) Raw materials are crushed, screemed & stockpiled.

2) Raw materials are mixed with definite proportions to

obtain raw mix. They are mixed either dry (dry mixing)

or by water (wet mixing).

3) Prepared raw mix is fed into the rotary kiln.

4) As the materials pass through the kiln their temperature

is rised upto 1300-1600 C. The process of heating is

named as burning. The output is known as clinker

which is 0.15-5 cm in diameter.

5) Clinker is cooled & stored.

6) Clinker is ground with gypsum (3-6%) to adjust setting

time.

7) Packing & marketting.

Wet process

Dry process

Dry process with preheating tower

Quarry

Grinding

Burning

Grinding,

Storage,

Packing,

Dispatch

THE CEMENT

MANUFACTURING PROCESS

THE CEMENT MANUFACTURING PROCESS

1. BLASTING : The raw materials that are used to manufacture cement (mainly limestone

and clay) are blasted from the quarry.

Quarry face

1. BLASTING 2. TRANSPORT

3. CRUSHING AND TRANSPORTATION : The raw materials, after crushing, are

transported to the plant by conveyor. The plant stores the materials before they are

homogenized.

quarry

3. CRUSHING & TRANSPORTATION

2. TRANSPORT : The raw materials are loaded into a dumper.

crushing

conveyor

dumper

storage at

the plant

loader

THE CEMENT MANUFACTURING PROCESS

1. RAW GRINDING : The raw materials are very finely ground in order to produce the raw mix.

1. RAW GRINDING

Raw grinding and burning

2. BURNING

2. BURNING : The raw mix is preheated before it goes into the kiln, which is heated by a flame that

can be as hot as 2000 C. The raw mix burns at 1500 C producing clinker which, when it leaves the

kiln, is rapidly cooled with air fans. So, the raw mix is burnt to produce clinker : the basic material

needed to make cement.

conveyor

Raw mix

kiln

cooling

preheating

clinker

storage at

the plant

Raw mill

THE CEMENT MANUFACTURING PROCESS

1.GRINDING : The clinker and the gypsum are very finely ground giving a pure cement. Other

secondary additives and cementitious materials can also be added to make a blended cement.

1. GRINDING

Grinding, storage, packing, dispatch

2. STORAGE, PACKING, DISPATCH

2. STORAGE, PACKING, DISPATCH :The cement is stored in silos before being dispatched either

in bulk or in bags to its final destination.

clinker

storage

Gypsum and the secondary additives are added

to the clinker.

silos

dispatch

bags

Finish grinding

Quarry

1. Stone is first reduced to 125 mm (5 in.)

size, then to 20 mm (3/4 in.), and stored.

4 materials 225tph

limestone 88%,

sandstone 5%,

kaolin/clay 5%,

mill scale 2%

Raw mill

2. Raw materials are ground to powder and blended.

Or 2. Raw materials are ground, mixed with water to form

slurry, and blended.

Kiln

3. Burning changes raw mix chemically into cement clinker.

REACTIONS IN THE KILN

~100C free water evaporates.

~150-350C loosely bound water is lost from clay.

~350-650Cdecomposition of claySiO

2

&Al

2

O

3

~600Cdecomposition of MgCO

3

MgO&CO

2

(evaporates)

~900Cdecomposition of CaCO

3

CaO&CO

2

(evaporates)

~1250-1280Cliquid formation & start of compound formation.

~1280Cclinkering begins.

~1400-1500Cclinkering

~100Cclinker leaves the kiln & falls into a cooler.

Sometimes the burning process of raw materials is performed in two stages:

preheating upto 900C & rotary kiln

4. Clinker is ground with gypsum into portland

cement and shipped.

Clinker

Gypsum

Portland cement is composed of four major

oxides (CaO, SiO

2

, Al

2

O

3

, Fe

2

O

3

90%) &

some minor oxides. Minor refers to the

quantity not importance.

Chemical composition of

Ordinary Portland cement

CHEMICAL COMPOSITION OF OP.C.

Oxide Common Name Abbreviation Approx. Amount (%)

CaO Lime C 60-67

SiO

2

Silica S 17-25

Al

2

O

3

Alumina A 3-8

Fe

2

O

3

Iron-oxide F 0.5-6

MgO Magnesia M 0.1-4

Na

2

O Soda N

0.2-1.3

K

2

O Potassa K

SO

3

Sulfuric Anhydride 1-3

CaOlimestone

SiO

2

-Al

2

O

3

Clay

Fe

2

O

3

Impurity in Clays

SO

3

from gypsumnot from the clinker

S

COMPOUND COMPOSITION OF

O.P.C. (OR CLINKER)

Oxides interact with each other in the kiln to

form more complex products (compounds).

Basically, the major compounds of O. P.C. can

be listed as:

Name Chemical Formula Abbreviations

Tri Calcium Silicate 3CaO.SiO

2

C

3

S

Di Calcium Silicate 2CaO.SiO

2

C

2

S

Tri Calcium Aluminate 3CaO.Al

2

O

3

C

3

A

Tetra Calcium Alumino

Ferrite

4CaO.Al

2

O

3

.Fe

2

O

3

C

4

AF

Microscopic Images of Clinker

Alite

Belite

Aluminate

Ferrite

Types of Portland Cement

I Normal

II Moderate sulfate resistance

III High early strength

IV Low heat of hydration

V High sulfate resistance

ASTM C 150 (AASHTO M 85)

ASTM Type & Name

of P.C.

Average Compound

Composition

C

3

S C

2

S C

3

A C

4

AF

Type I - O.P.C. 49 25 12 8 General Purpose

Type II - Modified 46 29 6 12

For Moderate Heat of

Hydration

Type III - High Early

Strength 56 15 12 8

C

3

S&C

3

A increased, C

2

S

decreased

Type IV - Low Heat

P.C. 30 46 5 13 C

2

S increased

Type V - Sulfate

Resistant P.C. 43 36 4 12

Limit on C

3

A5%,

2C

3

A+C

4

AF25%

You might also like

- Design Criteria For Petcoke CalcinersDocument6 pagesDesign Criteria For Petcoke CalcinersAnonymous 1XHScfCINo ratings yet

- Hydration of CementDocument39 pagesHydration of Cementatul_kolhe100% (2)

- WHRB SopDocument13 pagesWHRB SopShambhu Mehta100% (2)

- Simulation and Optimization of Air Pollutant Emissions from a Cement Calciner Using Aspen PlusDocument10 pagesSimulation and Optimization of Air Pollutant Emissions from a Cement Calciner Using Aspen PluscassindromeNo ratings yet

- CementDocument53 pagesCementAbuzar AliNo ratings yet

- Grinding & Milling Fineness RequirementsDocument6 pagesGrinding & Milling Fineness RequirementsJosé UrdayNo ratings yet

- Slide 1 - 25.01.2007: HR Activities & Outlook 2007 - Sid TuliDocument33 pagesSlide 1 - 25.01.2007: HR Activities & Outlook 2007 - Sid Tulishivam aggarwalNo ratings yet

- Production Process of CementDocument2 pagesProduction Process of CementMarwaNo ratings yet

- Building Materials & Construction LectureDocument32 pagesBuilding Materials & Construction LectureYash DhabaliaNo ratings yet

- Concrete TechnologyDocument23 pagesConcrete TechnologyM NANDITHA CIVIL STAFF100% (1)

- Cement Manufacturing ProcessDocument26 pagesCement Manufacturing ProcessZubair KhanNo ratings yet

- Cement PDFDocument70 pagesCement PDFhamza2k19No ratings yet

- Operation of The Kiln Line: TrainingDocument32 pagesOperation of The Kiln Line: TraininglafecapoNo ratings yet

- It's A Product of An Intimate Mixture of Correctly ProportionedDocument28 pagesIt's A Product of An Intimate Mixture of Correctly ProportionedshahriarNo ratings yet

- Training - Cga ApplicationDocument34 pagesTraining - Cga ApplicationSubhan MuhammadNo ratings yet

- 7 Most Common Problem in PyroProcessing For Kiln and CoolerDocument5 pages7 Most Common Problem in PyroProcessing For Kiln and CoolerbudiNo ratings yet

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiNo ratings yet

- A To ZDocument126 pagesA To ZMohamed Osama RagaaNo ratings yet

- Formulas of Chemical Analysis of CementDocument1 pageFormulas of Chemical Analysis of CementFahadullah Khan AfridiNo ratings yet

- Chemical AnalysisDocument8 pagesChemical Analysisصفاء رجبNo ratings yet

- Cement Manufacturing Process Explained in 40 CharactersDocument28 pagesCement Manufacturing Process Explained in 40 CharactersRish-ab KanwarNo ratings yet

- Kiln vt10 EnglishDocument153 pagesKiln vt10 EnglishRadu RusNo ratings yet

- Unit 2 - CementDocument55 pagesUnit 2 - CementSaharsha GadariNo ratings yet

- Department of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesDocument26 pagesDepartment of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesVijaya GosuNo ratings yet

- Cement PDFDocument38 pagesCement PDFmohamedtsalehNo ratings yet

- Cement Technology Cement Manufacturing: C E M E N T A D D I T I V E SDocument57 pagesCement Technology Cement Manufacturing: C E M E N T A D D I T I V E Sshani5573No ratings yet

- Test For Properties of Cement: Physical & ChemicalDocument4 pagesTest For Properties of Cement: Physical & ChemicalmuqeetNo ratings yet

- Cement Raw MaterialsDocument9 pagesCement Raw MaterialsTuhin TahmidNo ratings yet

- Grups Cement: Pend - Kimia A Industrial ChemistryDocument39 pagesGrups Cement: Pend - Kimia A Industrial ChemistryMaya Monica DwianggraeniNo ratings yet

- Typical Raw Minerals 202.1Document2 pagesTypical Raw Minerals 202.1Mohammed AbdoNo ratings yet

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Document14 pagesCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamNo ratings yet

- Chemical Technology Subject Code: CH2001Document13 pagesChemical Technology Subject Code: CH2001U SANKAR TEJONo ratings yet

- FLS Automation Control Systems OverviewDocument17 pagesFLS Automation Control Systems Overviewsilexsa100% (3)

- Interpreting Cement Science Since 2005: Understanding Cement Book/ebookDocument14 pagesInterpreting Cement Science Since 2005: Understanding Cement Book/ebookVirat ChintuNo ratings yet

- Cement Chemistry Notation and Mineral NamesDocument2 pagesCement Chemistry Notation and Mineral NamesAfqan B-vNo ratings yet

- Rotary Kiln - Inst Manual English - Version 2015Document55 pagesRotary Kiln - Inst Manual English - Version 2015taghdirim100% (5)

- Cost of Capital ProjectDocument49 pagesCost of Capital ProjectfazalNo ratings yet

- False Set and Flash Set and CEMENTDocument31 pagesFalse Set and Flash Set and CEMENTk_981966368No ratings yet

- Kiln Heavy Build Ups detailsDocument12 pagesKiln Heavy Build Ups detailsIrfan AhmedNo ratings yet

- How To Control Kiln Shell CorrosionDocument72 pagesHow To Control Kiln Shell CorrosionNael100% (5)

- 4 Cement TechnologyDocument43 pages4 Cement TechnologySomu AdityaNo ratings yet

- Calcined ClayDocument4 pagesCalcined ClaynaikNo ratings yet

- Tyre PyrolysisDocument12 pagesTyre PyrolysisviswamNo ratings yet

- Lecture Cement IndustryDocument65 pagesLecture Cement IndustryUsman AliNo ratings yet

- Measuring The Composition of ClinkerDocument7 pagesMeasuring The Composition of ClinkerzementheadNo ratings yet

- Free Lime - Reasons Impacts and Corrective Actions R1Document17 pagesFree Lime - Reasons Impacts and Corrective Actions R1Gulam Dastgir100% (2)

- Grinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent GuillotDocument15 pagesGrinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent Guillotnathaniel villanuevaNo ratings yet

- Clinker Coolers: By: Oliver Christian D. DeyparineDocument26 pagesClinker Coolers: By: Oliver Christian D. Deyparinemoonbright27No ratings yet

- CementDocument52 pagesCementSugumar BalasubramaniamNo ratings yet

- Concrete Technology: 18CV44 Sem:IVDocument56 pagesConcrete Technology: 18CV44 Sem:IVsnehaNo ratings yet

- Cement and LimeDocument127 pagesCement and LimeEhab Anwer HassanNo ratings yet

- Quality Aspects of Cement Milling: Bob M QuillanDocument18 pagesQuality Aspects of Cement Milling: Bob M QuillanSamehibrahem100% (1)

- Influence of The Clinker SO3 On The Cement CharacteristicsDocument1 pageInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896No ratings yet

- Коротк Нотатки Про Хемiю ЦементiвDocument33 pagesКоротк Нотатки Про Хемiю ЦементiвCementarNo ratings yet

- 04 - Combustion and 10 Golden RulesDocument30 pages04 - Combustion and 10 Golden RulesAfqan B-vNo ratings yet

- Manufacture Process of Cement: 1. Mixing of Raw MaterialDocument11 pagesManufacture Process of Cement: 1. Mixing of Raw MaterialLhance BabacNo ratings yet

- Cement (Chapter 3)Document13 pagesCement (Chapter 3)teweleNo ratings yet

- Cement: N-W.F.P UET, Peshawar 1Document14 pagesCement: N-W.F.P UET, Peshawar 1Angelica Fontamillas SuicoNo ratings yet

- Burning The Mix 1Document11 pagesBurning The Mix 1John GiannakopoulosNo ratings yet

- Impact of calcium sulfates on cement properties and concrete workabilityDocument10 pagesImpact of calcium sulfates on cement properties and concrete workabilitycemsavantNo ratings yet

- Role of Gypsum in Cement and Its EffectsDocument3 pagesRole of Gypsum in Cement and Its Effectsvenkateswara rao pothinaNo ratings yet

- DBU CHEMICAL ENGINEERING DEPARTMENT INDIVIDUAL ASSIGNMENTDocument28 pagesDBU CHEMICAL ENGINEERING DEPARTMENT INDIVIDUAL ASSIGNMENTabrhshNo ratings yet

- Cement Industry: Handy ManualDocument44 pagesCement Industry: Handy ManualMahmoudRadiNo ratings yet

- Cement ProcessDocument14 pagesCement ProcessChristian RuedaNo ratings yet

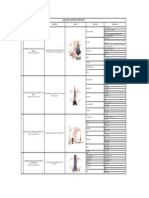

- Practicality Lab. Equipment Name Pictures List Details Specification NoDocument1 pagePracticality Lab. Equipment Name Pictures List Details Specification NoDede NurcahyadiNo ratings yet

- Cement Properties and Uses GuideDocument42 pagesCement Properties and Uses GuideMatheus Souza100% (1)

- The - 10 Basic Facts On ClinkerDocument1 pageThe - 10 Basic Facts On ClinkerParesh GohelNo ratings yet

- Installation and Mortar Types for Refractory LiningsDocument18 pagesInstallation and Mortar Types for Refractory Liningsvũ minh tâmNo ratings yet

- Cement Industry: Submitted To: Mr. Waqas Iqbal Submitted By: Mr. Ubaid Mehmood Mr. Hamza Sohail Mr. Iftikhar SaleemDocument22 pagesCement Industry: Submitted To: Mr. Waqas Iqbal Submitted By: Mr. Ubaid Mehmood Mr. Hamza Sohail Mr. Iftikhar SaleemAtif MehfoozNo ratings yet

- Cement Refractory Manufacturing ProcessDocument36 pagesCement Refractory Manufacturing ProcessJunaid MushtaqNo ratings yet

- Cement: Under The Guidance of Dr. Bahurudeen SirDocument64 pagesCement: Under The Guidance of Dr. Bahurudeen SirAjinkya IngaleNo ratings yet

- Cement Industry_MRUDocument50 pagesCement Industry_MRUeasyway187139No ratings yet

- Portland Cement ManufacturingDocument7 pagesPortland Cement ManufacturingCynric Leonardo100% (2)

- Iv Report Malabar CementsDocument12 pagesIv Report Malabar CementsSafanaNo ratings yet

- Global Cement October 2020Document70 pagesGlobal Cement October 2020s_prasy6540No ratings yet

- Waste Heat Recovery in Cement Plants: A Case Study of Lafarge Volos PlantDocument81 pagesWaste Heat Recovery in Cement Plants: A Case Study of Lafarge Volos PlantKuldeep RupareliaNo ratings yet

- Kiln Solution: Technical Design ConditionsDocument4 pagesKiln Solution: Technical Design ConditionsRenz Benhar Ocon BobadillaNo ratings yet

- Cleaner Environmental Systems 3 (2021) 100047Document11 pagesCleaner Environmental Systems 3 (2021) 100047ziaNo ratings yet

- Training Development Poject Report BkproductionsDocument72 pagesTraining Development Poject Report BkproductionsAbhijeet PurohitNo ratings yet

- Rotary Kiln Plant: Operating Manual en-D000091-4C-4VDocument129 pagesRotary Kiln Plant: Operating Manual en-D000091-4C-4Vnima mazaheriNo ratings yet

- ABC Cooler InletDocument4 pagesABC Cooler Inletjmpbarros100% (1)

- Cement ProductionDocument22 pagesCement Productionsudhir_921995600No ratings yet

- Recruitment and selection guideDocument73 pagesRecruitment and selection guidekum124267% (3)

- Green Energy from Sewage SludgeDocument11 pagesGreen Energy from Sewage SludgePopovac NetNo ratings yet

- Vidal CemexDocument3 pagesVidal CemexErven BascoNo ratings yet

- Ucky Ement: Production and Operations ManagementDocument21 pagesUcky Ement: Production and Operations ManagementUmer Arif100% (1)

- Topic: Gujarat Ambuja Cost Leader in The Indian Cement Industry'Document27 pagesTopic: Gujarat Ambuja Cost Leader in The Indian Cement Industry'surabhi vyasNo ratings yet

- Ambuja CementDocument113 pagesAmbuja Cementrohit_cmpn0% (1)

- Process CostingDocument108 pagesProcess CostingAnjali rajbharNo ratings yet

- Birla Cements MarketingDocument45 pagesBirla Cements MarketingDeependra Singh90% (10)