Professional Documents

Culture Documents

Case Study On Green Marketing by Coca Cola

Uploaded by

Singh ManpreetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study On Green Marketing by Coca Cola

Uploaded by

Singh ManpreetCopyright:

Available Formats

Case study on Green marketing by Coca Cola

Green marketing:

Green, environmental and eco-marketing are part of the new marketing approaches which do not

just refocus, adjust or enhance existing marketing thinking and practice, but seek to challenge

those approaches and provide a substantially different perspective.

In current scenario green marketing is a new marketing strategy which

provides a new space of competition for global business players. many companys are taking the

responsibility of protecting the environment by making eco-friendly products and changing the

manufacturing procedures and turning themselves as eco friendly.

Coca Cola has also adopted the eco-friendliness by making changes in

the manufacturing as well as the bottling procedures. It has taken the projects like

water stewardship program:

Inside every bottle of Coca-Cola is the story of a company that understands the priceless value of

water, respects it as the most precious of shared global resources and works vigorously to

conserve water worldwide. This was the program that was undertaken by the co mpany inorder

to conserve the water usage in the process of manufacturing. It has undertaken this project in

various stages.

First stage(Mitigating riskfor communities and for our system)

Goal: Assess the vulnerabilities of the quality and quantity of water sources for each of our

bottling plants and implement a locally relevant water resource sustainability program by the end

of 2012.

Progress: In progress. By the end of 2011, 612 of the 863 bottling plants in our system had

completed source vulnerability assessments, 582 had completed source water protection plans,

and 251 plants were scheduled to begin source vulnerability assessments in 2012.

Implementation:

Communities and ecosystems need plenty of clean, accessible water to thrive. So does our

business. Our bottling plants depend on local water sources. As demand for water increases and

stress on water sources intensifies, the communities that host our facilitiesand the local

consumers who buy our productsmay face serious health and economic challenges, and we

may face challenges to our growth.To mitigate water-related risks to our system and to the

communities we serve, we have required every one of our bottling plants to conduct a local

source vulnerability assessment. These assessments inventory risks to the water sources

supplying our facilities and the surrounding communities. Once the assessments are complete,

we and our bottling partners develop a locally relevant water resource sustainability

program detailing specific risk-mitigation actions that we can take to help with preserving the

sustainability of local water sources, along with deadlines for completing those actions. These

programs address water challenges at the watershed level, from hydrological vulnerabilities to

local government management. Often, the plans include partnerships and mitigation initiatives

with local governments and communities, water agencies and nongovernmental organizations

(NGOs). All of our bottling partners are required to be implementing their source water

protection plans by the end of 2012, a target we are on track to meet

Second stage(Meeting our goal for water efficiency)

Goal: By 2012, improve water efficiency in manufacturing by 20 percent compared with a 2004

baseline.

Progress: Achieved. By the end of 2011, we had reduced our water use ratio by 20 percent,

compared to 2004.

Implementation:

Greater efficiency in our water use does not mean making less product. To the contrary, we

intend to reduce our water use ratiothe amount of water we use per liter of product produced

while growing our business. Our goal, set in 2008, was to improve water efficiency systemwide

by 20 percent by 2012, compared with a 2004 baseline. Despite an expanding product portfolio

and increased production levels, we have achieved that goal. In 2011, we used 293.3 billion liters

of water to make 135 billion liters of product, giving us a water use ratio of 2.16

liters per liter of product.We are not stopping there. We are developing a new goal for further

improving our water efficiency between now and 2020.

Stage 3(Recycling wastewater):

Goal: By the end of 2010, return to the environmentat a level that supports aquatic lifethe

water we use in our system operations through comprehensive wastewater treatment.

Progress: In progress. We aspire to treat all wastewater from our manufacturing processes. As of

the end of 2011, we had achieved 96 percent alignment with our wastewater standards.

Implementation:

All facilities in our system are required to meet locally applicable legal requirements for

wastewater discharge. But we wanted to set our standards higher even though in some cases we

can legally discharge to the environment without or with little treatment. So, in 2006, we set

the goal that, by the end of 2010, all water used in our system operations would be discharged at

a level not only compliant with locally applicable law, but also one that supports aquatic life

even when not required to do so. Our internal wastewater treatment standards call for all water

we discharge to be treated to that level.

Stage 4(Replenishing the water we use)

Goal: By 2020, safely return to communities and nature an amount of water equal to what we

use in our finished beverages and their production.

Progress: In progress. We estimate we have balanced 35 percent of the water used in our

finished beverages (based on 2011 unit case volume).

Implementation:

We are on the road to achieving water balance through diverse, locally relevant community

water projectsprojects that support community and ecosystem needs for safe and sustainable

sources of water while protecting our ability to do business responsibly, safely and more

sustainably. Since 2005, we have engaged in 382* projects with such partners as World Wildlife

Fund (WWF), the United States Agency for International Development (USAID), The Nature

Conservancy, CARE and the United Nations Development Programme (UNDP).

The water projects we engage in have at least one of four objectives:

improve access to water and sanitation

protect watersheds

provide water for productive use

educate and raise awareness about water issues, including engagement on water policy.

Conclusion:

Our system in India has achieved full balance between the groundwater used in beverage

production and the groundwater replenished to nature and communitiesahead of our global

target date. Bottlers throughout India have improved water use efficiency by 25 percent since

2005.

You might also like

- Positioning of Namaste India in Kanpur Market ResearchDocument19 pagesPositioning of Namaste India in Kanpur Market Researchavneesh chaudharyNo ratings yet

- Study on consumer perception of Coca-Cola soft drinks in ChennaiDocument105 pagesStudy on consumer perception of Coca-Cola soft drinks in ChennaiShilpa SomilaNo ratings yet

- A Study On Consumer Behavior On Surf Excel Detergent Powder in Muzaffarpur CityDocument31 pagesA Study On Consumer Behavior On Surf Excel Detergent Powder in Muzaffarpur CityabhaybittuNo ratings yet

- Studying The Impact of Marketing & Distribution Strategy of Bisleri (Akshay)Document83 pagesStudying The Impact of Marketing & Distribution Strategy of Bisleri (Akshay)Sid ChauhanNo ratings yet

- 213 ProjectDocument63 pages213 ProjectDivyeshNo ratings yet

- A Project ReportDocument14 pagesA Project Reportvc22032000100% (5)

- Customer's Perception Regarding Water PurifierDocument25 pagesCustomer's Perception Regarding Water Purifierhrishikesh_debnath67% (3)

- Anshul BISLERIDocument66 pagesAnshul BISLERIjain_ansh00100% (1)

- A Project Report On Pepsi Co.Document60 pagesA Project Report On Pepsi Co.Gaurav248667% (3)

- Elkos Pens LTD FinalDocument57 pagesElkos Pens LTD FinalVijay Singh Singh100% (2)

- Positioning of Namaste India Milk in Kanpur MarketDocument19 pagesPositioning of Namaste India Milk in Kanpur MarketShruti SaxenaNo ratings yet

- Sip ReportDocument72 pagesSip ReporthemanthreddyNo ratings yet

- A Study On Consumer Satisfaction Towards Vesta Ice-Cream of KSE LTD - With Special Reference To Chalakudy MunicipalityDocument45 pagesA Study On Consumer Satisfaction Towards Vesta Ice-Cream of KSE LTD - With Special Reference To Chalakudy MunicipalityVeena SubramanianNo ratings yet

- Project PDFDocument6 pagesProject PDFwasee mdNo ratings yet

- Distribution of Cadbury Products PDFDocument52 pagesDistribution of Cadbury Products PDFMarilyn Marine KhemaiNo ratings yet

- Study On LakmeDocument27 pagesStudy On LakmekunalNo ratings yet

- Prakriya - Operation Club - Supply Chain - FlipkartDocument4 pagesPrakriya - Operation Club - Supply Chain - Flipkartakshaysingh211No ratings yet

- Bisleri ProjectDocument63 pagesBisleri ProjectHimasmita DasNo ratings yet

- Summer Internship Project Report ON Analysis of Marketing and Sales at AqualiteDocument40 pagesSummer Internship Project Report ON Analysis of Marketing and Sales at AqualitechiragNo ratings yet

- Project Report On Verka Milk Plant, MohaliDocument55 pagesProject Report On Verka Milk Plant, MohaliDr.Jaspreet KaurNo ratings yet

- Summer Internship ReportDocument43 pagesSummer Internship Reportnikhil yadavNo ratings yet

- Cross Cultural Training Effectiveness on Employee PerformanceDocument18 pagesCross Cultural Training Effectiveness on Employee PerformanceanitikaNo ratings yet

- Comparing Sales of Parle Agro Products in Organized vs Unorganized RetailDocument40 pagesComparing Sales of Parle Agro Products in Organized vs Unorganized Retailsantyarnr100% (1)

- Jio Recruitment and Selection ProjectDocument101 pagesJio Recruitment and Selection ProjectShobhit GoswamiNo ratings yet

- Anand FDocument76 pagesAnand FSunil BharadwajNo ratings yet

- Questionnaire of Aquaguard V/s KentDocument1 pageQuestionnaire of Aquaguard V/s Kentsanjeet_saini0% (1)

- Attitude of People Towards Green ProductsDocument52 pagesAttitude of People Towards Green ProductsMessiNo ratings yet

- Working Capital Management of Bisleri Pvt LtdDocument82 pagesWorking Capital Management of Bisleri Pvt LtdVivek Haridas75% (4)

- Voltas 1Document85 pagesVoltas 1Kuldeep Batra100% (1)

- Blue Dart Logistic ProjectDocument27 pagesBlue Dart Logistic ProjectFarshan SulaimanNo ratings yet

- Direct Marketing Data AnalysisDocument15 pagesDirect Marketing Data AnalysisShruti MaindolaNo ratings yet

- A Comparative Study of Bisleri and Aquafina Mineral WaterDocument74 pagesA Comparative Study of Bisleri and Aquafina Mineral WaterDevender Kumar Minhas100% (2)

- Abhishek Tiwari Major Research Project Kotak Mahindra BankDocument98 pagesAbhishek Tiwari Major Research Project Kotak Mahindra BankNikhilesh Katare100% (1)

- Case Study of AMULDocument5 pagesCase Study of AMULru4angelNo ratings yet

- Aditya Birla Group: Prepared By: Vishnupriya Ramesh S SharanyaDocument38 pagesAditya Birla Group: Prepared By: Vishnupriya Ramesh S SharanyaSharanya Sasi100% (1)

- Project Report IDFC Mutual FundDocument64 pagesProject Report IDFC Mutual Fundjanaaab5068100% (6)

- Final Project of Black Book of Coca ColaDocument62 pagesFinal Project of Black Book of Coca Colavishal birajdarNo ratings yet

- A Study On Consumer Behaviour Towards Different Chocolates Brands in Kolkata CityDocument27 pagesA Study On Consumer Behaviour Towards Different Chocolates Brands in Kolkata CityadritamukherjeNo ratings yet

- Tata Motors RaipurDocument51 pagesTata Motors RaipurSHOAIB MEMONNo ratings yet

- Product Life Cycle ParleDocument4 pagesProduct Life Cycle Parlesaivinayak0% (1)

- Tata Motors Final ReportDocument107 pagesTata Motors Final ReportNishan ShettyNo ratings yet

- Project On Consumer PerceptionDocument46 pagesProject On Consumer PerceptionAnonymous OIafnL100% (1)

- RM-Comparative Study of Mineral Water Sunrich Aqua Vs BisleriDocument40 pagesRM-Comparative Study of Mineral Water Sunrich Aqua Vs BisleriAatishKoliNo ratings yet

- AMUL'S Efficient Supply Chain ManagementDocument9 pagesAMUL'S Efficient Supply Chain ManagementD_12No ratings yet

- Survey On MedimixDocument256 pagesSurvey On MedimixJeffrin Smile JNo ratings yet

- Report On ChocolatesDocument41 pagesReport On Chocolatesmanishmaan2250% (2)

- A Study On Material Control TechniqusDocument55 pagesA Study On Material Control Techniquskathirvelmba100% (1)

- Entrepreneurship Project: Tanuja Water'S ReportDocument16 pagesEntrepreneurship Project: Tanuja Water'S ReportPrabir Kumar PatiNo ratings yet

- A Study On Customer Satisfication in FMCG of Pathanjali ProductsDocument14 pagesA Study On Customer Satisfication in FMCG of Pathanjali Productseswari100% (1)

- Project Report 2018 by D.rayDocument66 pagesProject Report 2018 by D.rayNilobroto SarkarNo ratings yet

- ConclusionDocument2 pagesConclusionJithu ChandranNo ratings yet

- Effective Cash Management at KFDCDocument77 pagesEffective Cash Management at KFDCshravan suvarna-mangaloreNo ratings yet

- Report On RaymondDocument44 pagesReport On RaymondSujayNo ratings yet

- Review of LiteratureDocument6 pagesReview of LiteratureSherry HutNo ratings yet

- Green Products A Complete Guide - 2020 EditionFrom EverandGreen Products A Complete Guide - 2020 EditionRating: 5 out of 5 stars5/5 (1)

- Coca Cola Environment InitiativeDocument4 pagesCoca Cola Environment InitiativeDushyant KumarNo ratings yet

- Coca-Cola Enterprises: Working To Become A Water Sustainable OperationDocument4 pagesCoca-Cola Enterprises: Working To Become A Water Sustainable OperationShrey BudhirajaNo ratings yet

- 1 Coca-Cola SocialDocument20 pages1 Coca-Cola SocialAnne D'souzaNo ratings yet

- Coca Cola - Case.studyDocument9 pagesCoca Cola - Case.studyBinh Phe0% (1)

- Crayon India PDFDocument7 pagesCrayon India PDFSingh ManpreetNo ratings yet

- Biodata Format For MarriageDocument1 pageBiodata Format For Marriageva4av57% (326)

- Organ Is IngDocument13 pagesOrgan Is IngSingh ManpreetNo ratings yet

- Stev JobsDocument2 pagesStev JobsSingh ManpreetNo ratings yet

- GAAPDocument1 pageGAAPSingh ManpreetNo ratings yet

- The Proposed Navi Mumbai International AirportDocument5 pagesThe Proposed Navi Mumbai International AirportSingh ManpreetNo ratings yet

- Teri and LeedDocument29 pagesTeri and LeedkaranNo ratings yet

- MSD STD DrawingsDocument140 pagesMSD STD Drawingsharicv019No ratings yet

- Perencanaan Tempat Pemrosesan Akhir Sampah DenganDocument8 pagesPerencanaan Tempat Pemrosesan Akhir Sampah DenganLukman Malik TCM AdongNo ratings yet

- Mississippi River Water Quality and The Clean Water Act, Report in BriefDocument4 pagesMississippi River Water Quality and The Clean Water Act, Report in BriefNational Academies of Science, Engineering, and MedicineNo ratings yet

- WaterSense Labeled Products 02142024Document2,848 pagesWaterSense Labeled Products 02142024leeleegarciaNo ratings yet

- Progress of Water Environment Governance in The PhilippinesDocument33 pagesProgress of Water Environment Governance in The PhilippinesNinaNo ratings yet

- 03-DG-Section 3 Sewerage System Design-Version 4Document52 pages03-DG-Section 3 Sewerage System Design-Version 4MOHAMMED RAZI100% (1)

- MLVSS / MLSS Ratio's Standard Value Obtained From Different Aeration Tank Samples of Different Capacity Sewage Treatment Plant - A Case StudyDocument5 pagesMLVSS / MLSS Ratio's Standard Value Obtained From Different Aeration Tank Samples of Different Capacity Sewage Treatment Plant - A Case StudyRanadive AnanthNo ratings yet

- Cross Drainage Works and Their FunctionsDocument27 pagesCross Drainage Works and Their FunctionsMuhammad Nadeem100% (6)

- UNIT 3 B Disinfection and Water Distribution SystemDocument29 pagesUNIT 3 B Disinfection and Water Distribution SystemDeepak Narayan PaithankarNo ratings yet

- Draft Inception NRW Jimma Final EditedDocument21 pagesDraft Inception NRW Jimma Final EditedAnonymous TvOpvX100% (1)

- QuestionnaireDocument4 pagesQuestionnaireAnonymous gJAiNqqe29No ratings yet

- INTRODUCTION (Slide 1)Document21 pagesINTRODUCTION (Slide 1)naryanan ramakrishnanNo ratings yet

- Water ConservationDocument29 pagesWater ConservationsurekhakcNo ratings yet

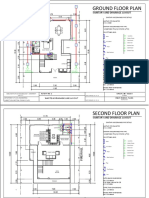

- Ground Floor Plan: Sanitary and Drainage LayoutDocument2 pagesGround Floor Plan: Sanitary and Drainage LayoutJessa VillaceranNo ratings yet

- Godavari PollutionDocument3 pagesGodavari PollutionPriya JohnsonNo ratings yet

- HWRA PermissionLetter-164Document2 pagesHWRA PermissionLetter-164Haryana Water AuthorityNo ratings yet

- Office Order PDFDocument2 pagesOffice Order PDFNageswara Rao GvdNo ratings yet

- Answer Key: Further 04: PhoneticsDocument5 pagesAnswer Key: Further 04: PhoneticsAbby NguyễnNo ratings yet

- CH-3 Water Resources Key PointsDocument3 pagesCH-3 Water Resources Key Pointssaksham2018 JainNo ratings yet

- Small Sewage Treatment Plant PDFDocument44 pagesSmall Sewage Treatment Plant PDFNGUYEN EthanNo ratings yet

- Water Quality Monitoring GuidelinesDocument34 pagesWater Quality Monitoring GuidelinesgustavoesanchezNo ratings yet

- Waste WaterDocument63 pagesWaste Waterashe zinabNo ratings yet

- Lot-01-WWTP-01 System PresentationDocument44 pagesLot-01-WWTP-01 System PresentationMesfinNo ratings yet

- Note Taking Water TreatmentDocument3 pagesNote Taking Water TreatmentHiro ExalionNo ratings yet

- Report On Manali PetroDocument2 pagesReport On Manali PetroV P GUPTANo ratings yet

- Seminar Course Report: TOPIC-Water Law & Policy in 21 CenturyDocument16 pagesSeminar Course Report: TOPIC-Water Law & Policy in 21 Centuryरायबली मिश्रNo ratings yet

- Oxidation Ditch ProcessDocument4 pagesOxidation Ditch Processsupriya2009100% (1)

- Grd. Flr. Wastewater Piping Layout 2Nd. Flr. Wastewater Piping LayoutDocument1 pageGrd. Flr. Wastewater Piping Layout 2Nd. Flr. Wastewater Piping LayoutBess Adrane JurolanNo ratings yet

- Second Major Term TestDocument3 pagesSecond Major Term TestLarbi NadiaNo ratings yet