Professional Documents

Culture Documents

20mm Metal Shaft Encoder & Potentiometer Guide

Uploaded by

shyhuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20mm Metal Shaft Encoder & Potentiometer Guide

Uploaded by

shyhuCopyright:

Available Formats

170

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

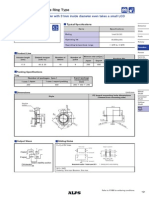

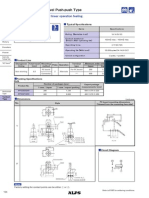

Only the encoder type can be supplied with a push-on switch.

Note

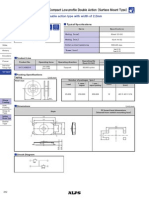

Product Line

Vertical Flat

Encoders

30 40 20

With 1.5

18 18

EC20A1824401

Without EC20A1820401

400 800

Product No.

1

2

Drawing

No.

Minimum order unitpcs.

Japan Export

Number

of

detent

Number

of

pulse

Shaft

conguration

Length of

the shaft

mm

Push-on

switch

Travel of

push-on switch

mm

Operating

direction

Detent

torque

mNm

Flat

Potentiometer

30 40 20 17 220 Vertical type

Single-

unit

10 1B RK203111000V 800 800

Product No.

3

Drawing

No.

Minimum order unitpcs.

Japan Export

Number

of

positions

Rotational

angle

Mounting

direction

Number of

resistor

elements

Total

resistance

k

Resistance

taper

Shaft

conguration

Length of

operating section

mm

Detent

torque

mNm

Tray

Packing Specications

800 400

Number of packagespcs.

374 508 272

Export package

measurements

mm 1 case / Japan 1 case / export packing

Refer to P.193 for soldering conditions.

EC20A

RK203

20mm Size Metal Shaft Type

Heavy torque and comfortable operation feel for encoder and potentiometer applications.

Typical Specifications

Items

Specifications

Encoder Potentiometer

Rating 1mA 5V DC 0.05W

Operating life 30,000cycles

Operating temperature range 30 to +80 40 to 85

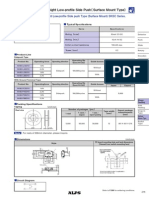

Dimensions

Photo No. Style

PC board mounting hole dimensions

Viewd from mounting side

Unit:mm

EC20A

with push-on switch

travel 1.5mm

Encoder Type

1

10

1.5

10

12

30

Switch travel

6

4

.

5

C1

2

.

5

3.5

Mounting

surface

3.5 1.5

1

.

5

9

20.2

1

9

.

2

8

.

3

15.5

3

31

M9G0.75

D E

NCNCNC

B

A

C

D E

(SW02) (SW01)

(17.8)

2-0.9

171

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

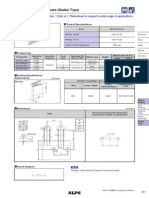

1.5

10

30

12

4

.

5

6

2

.

5

3.5

3.5 8

C1

M90.75

3-1

(17.8)

15.5

1

9

.

2

8

.

3

3 1

.

5

9

1

NC

NC NC

NC NC 3

2

20.2

Mounting

surface

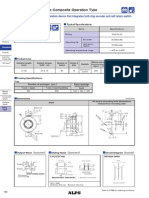

RK203

without switch type

Potentiometer Type

3

EC20A

without switch type

Encoder Type

2

1.5

10

30

12

2

.

5

3.5

3.5 8

M9G0.75

4

.

5

6

C1

3-1

(17.8)

20.2

15.5

1

9

.

2

8

.

3

3

1

.

5

9

NCNCNC

B

A

C

Mounting

surface

Dimensions

Photo No. Style

PC board mounting hole dimensions

Viewd from mounting side

Unit:mm

20mm Size Metal Shaft Type EC20A / RK203

Output WaveEC20A

Circuit DiagramRK203

Sliding NoiseEC20A

V

1

=V

2

=2.5V max.

At R 5k

Chattering : 8ms max. , Bounce : 5ms max.

2

3

1

5V DC

R R

Terminal B Terminal A

Terminal C

Encoder

Test circuit

t t

V1

V2

5

V

ON ON OFF

Output waveform

Sliding direction

t : Masking time to avoid chattering Measurement conditionRotation speed 360/s

Detent position cannot be specified for B signal.

Encoders Encoders Encoders

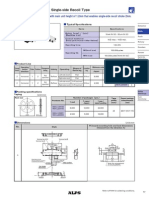

156

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

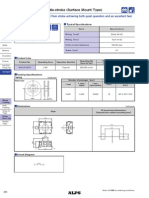

Type

Metal shaft

11mm size 20mm size

Series EC111 EC11EH EC11K EC11J EC20A / RK203 EM20B

Photo

Output Self-return switch

Incremental

Three phase A, B and C

IncrementalTwo phase A and B

Shaft types Single-shaft

Operating direction Vertical

Number of pulse /

Number of detent

-

6ABC / 18

10ABC / 30

9 / 18

15 / 30

18 / 18 40 / 40

Features - - -

Surface

Mount Type

-

Magnetic type;

LED indicator option

Dimensions

mm

W 11.7 20.2 20

D 13 12 14.2 19.2 22.25

H 5 4.5 10 13

Operating temperature range 40 to 85 30 to 80 10 to 70

Operating life 15,000 cycles 30,000 cycles 100,000 cycles 30,000 cycles 500,000 rotations

Automotive use -

Life cycle (availability)

Electrical

performance

Rating 10mA 5V DC 1mA 5V DC 10mA 5V5% DC

Max./min. operating current

Resistive load

10mA / 1mA - 15mA /

Insulation resistance 100M min. 250V DC 10M min. 50V DC 100M min. 250V DC

Voltage proof

300V AC for 1 minute

or 360V AC for 2s

300V AC for 1 minute

or 360V AC for 1s

50V AC for 1 minute

or 60V AC for 2s

300V AC for 1 minute

or 360V AC for 2s

Mechanical

performance

Rotational torque

Without detent

3 to 30mNm - 7mNm max.

Detent torque - 107mNm 12 5mNm 4020mNm 85mNm

Push-pull strength 100N

Shaft configuration Flat, Slotted, Serrated Flat

Terminal type Insertion Reflow Insertion

Switch

Specications

Switch type Push-on switch

Contact

arrangement

Single pole and single throwPush-on

Travel mm 0.5 0.3 1.5 0.5 0.5 0.3 1.5 0.5 0.5 0.3 1.5 0.5 0.5 0.3 1.50.5 0.5

Operating

force N

6 4 2 6 4 2 52 42 52 42 63

Rating

0.1A 5V DC

500A 5V DC min. ratings

0.1A 5V DC

0.1mA 5V DC min. ratings

0.5A 16V DC

1mA 16V DC min. ratings

0.1A 5V DC

Contact

resistance

100m max. for initial period; 200m max. after operating life.

Operating life 20,000 times min.

1,000,000

times min.

100,000

times min.

1,000,000

times min.

100,000

times min.

20,000

times min.

25,000

times min.

Page 161 170 172

Encoders Soldering Conditions 193

Encoders Cautions 194

Note

indicates applicability to all products in the series.

2.5

2

2.5

2

0.4

0.3

List of Varieties

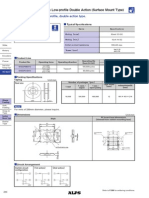

193

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

Encoders Soldering Conditions

Soldering surfacetemperature Soldering temperature Heating time Soldering time

No. of solders

3 s EC11J

EC10E, EC12D, EC12E

EC45A, EC60A

EC40A

EM20B

EC05E, EC09E, EC10E, EC111, EC11B,

EC11E, EC11G, EC11K, EC12D, EC12E,

EC18A, EC20A, EC21A, EC28A, EC35A,

EC35AH, EC35B, EC40A, EC45A, EC50A,

EC60A, EM20B

EC09E, EC11B, EC111, EC11E, EC11G,

EC11K, EC18A, EC20A, EC21A, EC28A,

EC35A, EC35AH, EC35B, EC50A

Series

Series

350 max. 3s max. 1 time

100 max. 2605 2 min. max. 51s 2 time max.

35010 2 time

100 max.

100 max.

110 max.

80 max.

2605

260 max.

260 max.

260 max.

1 min. max.

2 min. max.

1 min. max.

1 min. max.

31s

5s max.

10s max.

3s max.

2 time max.

2 time max.

1 time

2 time max.

Tip temperature Soldering time No. of solders

Preheating Dip soldering

Reference for Dip Soldering

Condition for Refow

Reference for Hand Soldering

EC05E

EC11J

Series

260 230 180 150 2 min.max. 3s 40s 4 min. max 2 time max.

250 min. 230 min. 180 150 60s to 120s 30s to 40s 2 time max.

A B C D E F G H No. of reows

Temperature profle

1

0

1.When using an infrared reow oven, solder may sometimes not be applied. Be sure to use a hot air reow oven or a

type that uses infrared rays in combination with hot air.

2.The temperatures given above are the maximum temperatures at the terminals of the potentiometer when

employing a hot air reow method. The temperature of the PC board and the surface temperature of the

potentiometer may vary greatly depending on the PC board material, its size and thickness. Ensure that the surface

temperature of the potentiometer does not rise to 250C or greater.

3.Conditions vary to some extent depending on the type of reow bath used. Be sure to give due consideration to this

prior to use.

Notes

300

200

100

A

B

C

Time (s)

G max.

F max.

H max.

E max.

Room

temperature

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Pre-heating

D

You might also like

- 20mm Size Metal Shaft Magnetic TypeDocument4 pages20mm Size Metal Shaft Magnetic TypeshyhuNo ratings yet

- SEO Rotary EncodersDocument4 pagesSEO Rotary EncodersshyhuNo ratings yet

- 21mm Ring Encoder Guide with Specs & Soldering TipsDocument4 pages21mm Ring Encoder Guide with Specs & Soldering TipsshyhuNo ratings yet

- 35mm Ring Encoder GuideDocument3 pages35mm Ring Encoder GuideshyhuNo ratings yet

- EC35AH: 35mm Size ABC Switch TypeDocument4 pagesEC35AH: 35mm Size ABC Switch TypeshyhuNo ratings yet

- 50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDDocument3 pages50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDshyhuNo ratings yet

- Insulated Shaft Rotary EncodersDocument3 pagesInsulated Shaft Rotary EncodersshyhuNo ratings yet

- 35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchDocument3 pages35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchshyhuNo ratings yet

- 9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceDocument3 pages9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceshyhuNo ratings yet

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocument3 pages45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNo ratings yet

- Rotary Encoder GuideDocument3 pagesRotary Encoder GuideshyhuNo ratings yet

- INSULATED SHAFT TYPEDocument5 pagesINSULATED SHAFT TYPEshyhuNo ratings yet

- 60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningDocument3 pages60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningshyhuNo ratings yet

- 1.2 (H) MM, Single-Side Recoil TypeDocument4 pages1.2 (H) MM, Single-Side Recoil TypeshyhuNo ratings yet

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pages10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNo ratings yet

- 12mm Size Insulated Shaft TypeDocument4 pages12mm Size Insulated Shaft TypeZoltán Halász100% (2)

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- Recoil Type For Single-Side and Both SidesDocument5 pagesRecoil Type For Single-Side and Both SidesshyhuNo ratings yet

- EC18A 18mm Insulated Shaft EncoderDocument4 pagesEC18A 18mm Insulated Shaft EncodershyhuNo ratings yet

- Low-Profile Tri-Directional Operation TypeDocument3 pagesLow-Profile Tri-Directional Operation TypeshyhuNo ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- AlpsDocument4 pagesAlpsciohaniNo ratings yet

- Spvqa: Water-Proof TypeDocument4 pagesSpvqa: Water-Proof Typeshyhu100% (1)

- 6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationDocument4 pages6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationshyhuNo ratings yet

- SSSS7Document5 pagesSSSS7shyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- Low-Profile, 1.2mm Height, Long Travel TypeDocument3 pagesLow-Profile, 1.2mm Height, Long Travel TypeshyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- SKHH 6mm Square Tact Switch Product GuideDocument6 pagesSKHH 6mm Square Tact Switch Product GuideshyhuNo ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- Spvq9: Water-Proof TypeDocument3 pagesSpvq9: Water-Proof TypeshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 10mm Square Water-proof Tact Switch SpecificationsDocument5 pages10mm Square Water-proof Tact Switch SpecificationsshyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Snap-in Tact Switch Specs and Soldering GuideDocument3 pagesSnap-in Tact Switch Specs and Soldering GuideshyhuNo ratings yet

- SKEGDocument4 pagesSKEGshyhuNo ratings yet

- Spvq5: Micro Switch Type With Female Connector TerminalDocument3 pagesSpvq5: Micro Switch Type With Female Connector TerminalshyhuNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Power Detector Slide Push Rotary Encoders Dual-in-line Package Type TACT SwitchDocument4 pagesPower Detector Slide Push Rotary Encoders Dual-in-line Package Type TACT SwitchshyhuNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- Quiet Surface Mount Switch SpecificationsDocument3 pagesQuiet Surface Mount Switch SpecificationsshyhuNo ratings yet

- Resolver Smart SynDocument12 pagesResolver Smart SynLeon de RuijterNo ratings yet

- SPED2 Push Switch SpecsDocument3 pagesSPED2 Push Switch SpecsshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNo ratings yet

- Automotive Relays: Twin Relays EN2/EP2 Series Single Relays EP1/MR301 SeriesDocument13 pagesAutomotive Relays: Twin Relays EN2/EP2 Series Single Relays EP1/MR301 SeriesdziboNo ratings yet

- 40-character for detector switch documentDocument3 pages40-character for detector switch documentshyhuNo ratings yet

- Terazaki TZS-68 - Earth Leakage RelayDocument2 pagesTerazaki TZS-68 - Earth Leakage RelayJon Carlo DelmarNo ratings yet

- Snap-in switch documentDocument3 pagesSnap-in switch documentshyhuNo ratings yet

- SSC Frere Rre RerDocument4 pagesSSC Frere Rre RershyhuNo ratings yet

- 12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsDocument4 pages12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsshyhuNo ratings yet

- Resistive Position Sensors Linear Type Specifications and VarietiesDocument5 pagesResistive Position Sensors Linear Type Specifications and VarietiesshyhuNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Medijski linč Gorana JevtićaDocument64 pagesMedijski linč Gorana JevtićashyhuNo ratings yet

- WM 00013Document127 pagesWM 00013shyhuNo ratings yet

- List of Varieties: Resistive Position SensorsDocument1 pageList of Varieties: Resistive Position SensorsshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- RDC40 RDC50 RDC90: Rotary TypeDocument6 pagesRDC40 RDC50 RDC90: Rotary TypeshyhuNo ratings yet

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDocument4 pagesHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- Resistive Position Sensors Specifications and Testing MethodsDocument4 pagesResistive Position Sensors Specifications and Testing MethodsshyhuNo ratings yet

- Resistive Position Sensors Linear Type Specifications and VarietiesDocument5 pagesResistive Position Sensors Linear Type Specifications and VarietiesshyhuNo ratings yet

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocument5 pagesLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNo ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNo ratings yet

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDocument3 pagesSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 265 6.1×3.7mm Compact Switch SpecsDocument3 pages265 6.1×3.7mm Compact Switch SpecsshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Quiet Surface Mount Switch SpecificationsDocument3 pagesQuiet Surface Mount Switch SpecificationsshyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- Measuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsDocument1 pageMeasuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsshyhuNo ratings yet

- Case Study On Maruti 800Document4 pagesCase Study On Maruti 800Nizar MesaniNo ratings yet

- Product Differentiation and Market Segmentation As Alternative Marketing StrategiesDocument7 pagesProduct Differentiation and Market Segmentation As Alternative Marketing StrategiesCaertiMNo ratings yet

- Title Page Title: Carbamazepine Versus Levetiracetam in Epilepsy Due To Neurocysticercosis Authors: Akhil P SanthoshDocument16 pagesTitle Page Title: Carbamazepine Versus Levetiracetam in Epilepsy Due To Neurocysticercosis Authors: Akhil P SanthoshPrateek Kumar PandaNo ratings yet

- User Manual - Numrolgy SoftwareDocument14 pagesUser Manual - Numrolgy SoftwareComputershastriNoproblem0% (1)

- Differentiation SS2Document88 pagesDifferentiation SS2merezemenike272No ratings yet

- Lake Isle of Innisfree Lesson Plan BV ZGDocument4 pagesLake Isle of Innisfree Lesson Plan BV ZGapi-266111651100% (1)

- Ethics Book of TAMIL NADU HSC 11th Standard Tamil MediumDocument140 pagesEthics Book of TAMIL NADU HSC 11th Standard Tamil MediumkumardjayaNo ratings yet

- Internal auditing multiple choice questionsDocument4 pagesInternal auditing multiple choice questionsSantos Gigantoca Jr.No ratings yet

- Intro - S4HANA - Using - Global - Bike - Slides - MM - en - v3.3 MODDocument45 pagesIntro - S4HANA - Using - Global - Bike - Slides - MM - en - v3.3 MODMrThedjalexNo ratings yet

- EVS XT2+ Tech Ref Software Manual v10.03 PDFDocument80 pagesEVS XT2+ Tech Ref Software Manual v10.03 PDFgibonulNo ratings yet

- Frozen DessertDocument3 pagesFrozen DessertcsqueilNo ratings yet

- FD-BF-001 Foxboro FieldDevices 010715 LowRes PDFDocument24 pagesFD-BF-001 Foxboro FieldDevices 010715 LowRes PDFThiago FernandesNo ratings yet

- Color TheoryDocument28 pagesColor TheoryEka HaryantoNo ratings yet

- Hematology NotesDocument3 pagesHematology NotesFarisa Jane BanggoNo ratings yet

- Asian Games African Games: Beach VolleyballDocument5 pagesAsian Games African Games: Beach VolleyballJessan Ybañez JoreNo ratings yet

- Brochure HorticultureDocument46 pagesBrochure HorticulturezulfiqaralimalikNo ratings yet

- Polymer Science: Thermal Transitions in PolymersDocument20 pagesPolymer Science: Thermal Transitions in Polymerstanveer054No ratings yet

- EDUC 5 - QuestionairesDocument7 pagesEDUC 5 - QuestionairesWilliam RanaraNo ratings yet

- Literature Review Marketing StrategyDocument4 pagesLiterature Review Marketing Strategyc5td1cmc100% (1)

- Case Briefing and Case SynthesisDocument3 pagesCase Briefing and Case SynthesisKai RaguindinNo ratings yet

- Anki Very Useful ManualDocument5 pagesAnki Very Useful ManualSoundaryaNo ratings yet

- Informed Consent: Ghaiath M. A. HusseinDocument26 pagesInformed Consent: Ghaiath M. A. HusseinDocAxi Maximo Jr AxibalNo ratings yet

- Effectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting OperationDocument10 pagesEffectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting Operationchandan kumar100% (1)

- Uc 3525 ADocument17 pagesUc 3525 AespaguetesNo ratings yet

- Vsip - Info - Ga16de Ecu Pinout PDF FreeDocument4 pagesVsip - Info - Ga16de Ecu Pinout PDF FreeCameron VeldmanNo ratings yet

- Interview Question SalesforceDocument10 pagesInterview Question SalesforcesomNo ratings yet

- SID-2AF User Manual English V3.04Document39 pagesSID-2AF User Manual English V3.04om_zahidNo ratings yet

- Padmavati Gora BadalDocument63 pagesPadmavati Gora BadalLalit MishraNo ratings yet

- Quantitative Aptitude-More Exercise Questions Updated On Jul 2019Document4 pagesQuantitative Aptitude-More Exercise Questions Updated On Jul 2019SANAMGI BHAVYANo ratings yet

- Educating The PosthumanDocument50 pagesEducating The PosthumanCatherine BrugelNo ratings yet