Professional Documents

Culture Documents

Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase Output

Uploaded by

shyhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase Output

Uploaded by

shyhuCopyright:

Available Formats

435

Resistive

Position

Sensors

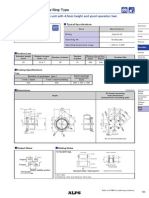

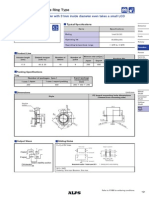

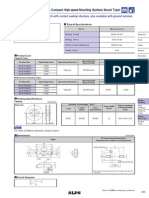

Circuit Diagram

$

Product line

Mounting

method

Linearity

guarantee range

Minimum order unitpcs.)

Japan Export

Model No. Linearity

Hollow shaft

variation

3 g4.05 1,600 1,600 RDC803001A Reow type

3301-phase)

3602-phase)

Refer to P.441 for product specications.

Refer to P.442 for soldering conditions.

OIher varieIies are also available. Please inquire.

Note

Packing Specications

Taping

Reel size

lnside Z5.4

Outside J0.5 nax.

1

J

h

o

le

Unit:mm

800 1,600 1,600

Number of packagespcs.)

24 401 401 110

Tape

width

mm)

Export package

measurements

mm)

1 reel

1 case /

Japan

1 case /

export packing

3

4 2

1

Shaded areas are solder lands.

hole hole

3

2

.

5

16.2

1

6

PC board mounting hole dimensions

Viewed from mounting side)

Style

2T 4T

3T 1T

4

.

2

2

-

1

.

3

12.5

3

.

0

5

1.2 3 1.2 4-2

16

1

5

13.2

Mounting face

4.05

Dimensions Unit:mm

QTypical Specifications

Items Specifications

Rated Voltage 5V DC

Operating life 100,000cycles

Total resistance 10kO

Operating temperature range 40T to 120T

RDC80

Rotary Type360Rotation)

Ho||ow-shaft type that enab|es output covering the who|e 360-degree

ang|e due to adoption of 2-phase output.

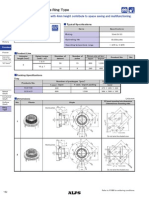

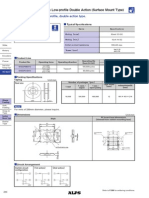

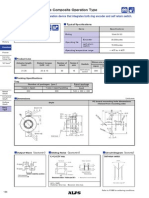

RDC40 / RDC50 / RDC90 Rotary Type

431

Resistive

Position

Sensors

Resistive Position Sensors

Q List of Varieties

Type Rotary Type Linear Type

Series RDC40 RDC50 RDC90 RDC80 RD6R1A RDC10 zRD7

Photo

Direction of lever Horizontal

Vertical

Horizontal

Vertical Vertical Horizontal

Effective electrical angle)

5,400

15 rotations)

333.3

80

(260 max.)

3401-phase)

3602-phase)

320 - -

Linearity guarantee range)

4,680

13 rotations)

320

60

(244 max.)

3301-phase)

3602-phase)

310 max. - -

Travel - - - - -

14mm

22mm

32mm

47mm

8mm

12mm

8mm

9mm

12mm

Operating temperature

range

30T to

80T

40T to 120T

-40T to

85T

30T to

85T

40T to

105T

Operating life

100,000

cycles

1,000,000

cycles

10,000,000

cycles

100,000

cycles

500,000

cycles

200,000

cycles

100,000

cycles

Available for automotive

use

Life cycle (availability)

Mechanical

performance

Operating

force

- - - - - 0.25N max. 2N max.

Rotational

torque

1.96 mNm max. 2mNm max. 10mNm max. 100mNm - -

Electrical

performance

Total resistance

tolerance

30% 20% 30% 20%

Linearity%) 1 2 3 2 (320) 0.5 1

Rated Voltage

VDC)

5 12

Environmental

test

Cold

303T

for 240h

403T for 168h

403T for

240h

402T for

96h

Dry heat

802T

for 240h

1203T for 168h

853T for

168h

902T for

240h

1052T for

96h

Damp heat

602T,

90 to 95%RH

for 240h

602T,

90 to 95%RH for 96h

80T,

90 to 95%RH

for 96h

602T,

90 to 95%RH

for 240h

402T,

90 to 95%RH

for 96h

Termimal style Connector

Insertion /

Reflow

Reflow Connector

Lead terminal /

Insertion

Insertion

Page 432 435 436 437 439

Resistive Position Sensors Measurement and Test Methods 441

Resistive Position Sensors So|dering Oonditions 442

Resistive Position Sensors Oautions 443

Note

1. zThe RD7 series are used to detect vehicle headlight angles.

2. indicates applicability to all products in the series.

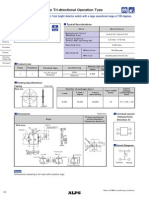

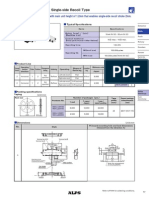

441

Resistive

Position

Sensors

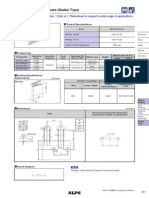

Method for Regulating the Linearity

With rated voltage applied between terminals 1 and 3, the straight

line which connects the measured output values VB and VA at

specied reference positions B and A is assumed to be an ideal

straight line, so that deviation against the ideal straight line when

the voltage applied between terminals 1 and 3 is assumed to be

100 can be expressed as a percentage.

Mecha stroke)

Position B Position A

VA

VB

A B

Model RDC80

4T output

2T output

3

%

3

%

165

165

180phase difference

O

u

t

p

u

t

v

o

l

t

a

g

e

r

a

t

i

o

2. The center is in the configuration diagram condition

1. Reference taper : 100%/ 340

100

0

50

0

center

Model RDC40

O

u

t

p

u

t

v

o

l

t

a

g

e

r

a

t

i

o

%

0

0

5

100

VA

13 rotations

1

%

1. Reference taper : 90%/13rotations

2. VA is measured output value

O

u

t

p

u

t

v

o

l

t

a

g

e

r

a

t

i

o

0

0

5

100

VA

13 rotations

1

%

1. Reference taper : 90%/13rotations

2. VA is measured output value

Model RDC10 / RD7

Resistive Position Sensors Product Specifications

Resistive Position Sensors Measurement and Test Methods

0

0

100

B

50

C

1. Reference taper100/A

2. Index point is 50% output point

O

u

t

p

u

t

v

o

l

t

a

g

e

r

a

t

i

o

The center is in the configuration diagram condition

Model RDC50 / RDC90 / RD6R1A

Series A B C

RDC50 333.3 160 2

RDC90 80 30 3

RD6R1A 320 155 2

Total Resistance

The total resistance, with the shaftlever)placed at the end of terminal 1 or 3, shall be determined by measuring the

resistance between the resistor terminals 1 and 3 unless otherwise specied.

Rating Voltage

The rating voltage corresponding to the rated power shall be determined by the following equation. When the resulting

rated voltage exceeds the maximum operating voltage of a specic resistor, the maximum operating voltage shall be

taken as the rated voltage.

E=

PR

ERated voltageV)

PRated power W)

RTotal nominal resistanceO)

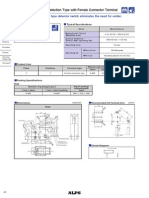

Analog Output Contact Type Sensor

(RDC60 / RDC90)

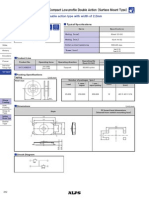

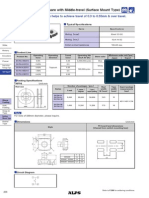

442

Resistive

Position

Sensors

Reference for Hand Soldering

Example of Reow Soldering Condition

Reference for Dip Soldering

I max.

H max.

300

200

100

Room

temperature

Pre-heating

E max.

Times

T

e

m

p

e

r

a

t

u

r

e

A

B

C

D

F max.

G max.

Series Tip temperature Soldering time

RDC50, RDC90, RDC80 3505 3 s

RDC10, RD7 350 max. 3s max.

Series

Preheating Dip soldering

No. of solders

Soldering surface

temperature

Heating time

Soldering

temperature

Soldering time

RDC501, RDC502 100 to 150 1min. max. 2605 101s 1 time

RD7 100 max. 1min. max. 260 max. 5s max. 1 time

+1

0

Series A B O D E F G H I No. of ref|ows

RDC503

RDC506

250 230 180 150 2min. 5s 40s 4min. 1 time

RDC90 255 230 2min. 10s 1min. 4min. 1 time

RDC80 250 180 150 9030s 101s 1 time

Resistive Position Sensors Soldering Conditions

1. Cleaning Cleaning should not be attempted.

2. Type of solder to be used Use cream solder that contains 10 - 15 %wt ux.

3. Number of solder applications - apply solder only once

4. Recommended reow conditions

1. When using an infrared reow oven, solder may not always be applied as intended. Be sure to use a hot air reow oven or a

type that uses infrared rays in combination with hot air.

2. The temperatures given above are the maximum temperatures at the terminals of the potentiometer when employing a hot

air reow method. The temperature of the PC board and the surface temperature of the potentiometer may vary greatly

depending on the PC board material, its size and thickness. Ensure that the surface temperature of the potentiometer does

not rise to 250C or greater.

3. Conditions vary to some extent depending on the type of reow bath used. Be sure to give due consideration to this prior to

use.

Notes

You might also like

- Tunnel ConstructionDocument171 pagesTunnel ConstructionBhaskar Reddy94% (16)

- PETREL 1 Structural Modeling PDFDocument42 pagesPETREL 1 Structural Modeling PDFKuala Tambora100% (1)

- Resistive Position Sensors Specifications and Testing MethodsDocument4 pagesResistive Position Sensors Specifications and Testing MethodsshyhuNo ratings yet

- Resistive Position Sensors Linear Type Specifications and VarietiesDocument5 pagesResistive Position Sensors Linear Type Specifications and VarietiesshyhuNo ratings yet

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocument5 pagesLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNo ratings yet

- RDC40 RDC50 RDC90: Rotary TypeDocument6 pagesRDC40 RDC50 RDC90: Rotary TypeshyhuNo ratings yet

- DPDT Basic Switch For Two Independent Circuit ControlDocument5 pagesDPDT Basic Switch For Two Independent Circuit ControlShubham GuptaNo ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- 35mm Ring Encoder GuideDocument3 pages35mm Ring Encoder GuideshyhuNo ratings yet

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocument3 pages45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNo ratings yet

- 60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningDocument3 pages60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningshyhuNo ratings yet

- 21mm Ring Encoder Guide with Specs & Soldering TipsDocument4 pages21mm Ring Encoder Guide with Specs & Soldering TipsshyhuNo ratings yet

- Rotary Encoder GuideDocument3 pagesRotary Encoder GuideshyhuNo ratings yet

- C SB453H8A Sanyo 5.5TR CompressorDocument14 pagesC SB453H8A Sanyo 5.5TR CompressorHarsh Vani AroraNo ratings yet

- Special Purpose Basic SwitchDocument5 pagesSpecial Purpose Basic Switchng_viet_cuong_groupNo ratings yet

- Insulated Shaft Rotary EncodersDocument3 pagesInsulated Shaft Rotary EncodersshyhuNo ratings yet

- Metal Film Chip Resistors, Rectangular Type 0603, 0805, 1210 ERA 3Y, 6Y, 14Document4 pagesMetal Film Chip Resistors, Rectangular Type 0603, 0805, 1210 ERA 3Y, 6Y, 14Hassan FaroukNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- 40-character for detector switch documentDocument3 pages40-character for detector switch documentshyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDDocument3 pages50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDshyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- EC18A 18mm Insulated Shaft EncoderDocument4 pagesEC18A 18mm Insulated Shaft EncodershyhuNo ratings yet

- Current Sensing Chip Resistors: NCST SeriesDocument6 pagesCurrent Sensing Chip Resistors: NCST Seriessavio77No ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- SKEGDocument4 pagesSKEGshyhuNo ratings yet

- Anti-Surge Thick Film Chip Re Sis Tors 0603, 0805, 1206, 1210 ERJ P03, P06, P08, P14Document5 pagesAnti-Surge Thick Film Chip Re Sis Tors 0603, 0805, 1206, 1210 ERJ P03, P06, P08, P14Francisco Lopez MoyaNo ratings yet

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pages10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNo ratings yet

- Low-Profile, 1.2mm Height, Long Travel TypeDocument3 pagesLow-Profile, 1.2mm Height, Long Travel TypeshyhuNo ratings yet

- 10mm Square Water-proof Tact Switch SpecificationsDocument5 pages10mm Square Water-proof Tact Switch SpecificationsshyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Sddje: 10A 250V AC Qualified TypeDocument6 pagesSddje: 10A 250V AC Qualified TypeshyhuNo ratings yet

- Low-Profile Tri-Directional Operation TypeDocument3 pagesLow-Profile Tri-Directional Operation TypeshyhuNo ratings yet

- EC35AH: 35mm Size ABC Switch TypeDocument4 pagesEC35AH: 35mm Size ABC Switch TypeshyhuNo ratings yet

- Spvqa: Water-Proof TypeDocument4 pagesSpvqa: Water-Proof Typeshyhu100% (1)

- E6f-C Ds csm499Document5 pagesE6f-C Ds csm499Achmad RamadhaniNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- Snap-in Tact Switch Specs and Soldering GuideDocument3 pagesSnap-in Tact Switch Specs and Soldering GuideshyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- SPED2 Push Switch SpecsDocument3 pagesSPED2 Push Switch SpecsshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 20mm Metal Shaft Encoder & Potentiometer GuideDocument4 pages20mm Metal Shaft Encoder & Potentiometer GuideshyhuNo ratings yet

- SKHH 6mm Square Tact Switch Product GuideDocument6 pagesSKHH 6mm Square Tact Switch Product GuideshyhuNo ratings yet

- HF2100 enDocument4 pagesHF2100 enBhakti PermanaNo ratings yet

- Snap-in switch documentDocument3 pagesSnap-in switch documentshyhuNo ratings yet

- K48-50 Carbon Film ResistorsDocument3 pagesK48-50 Carbon Film ResistorseminuscloudNo ratings yet

- G5Q PCB Relay: Ordering InformationDocument4 pagesG5Q PCB Relay: Ordering InformationLAU_CBrNo ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- Type RN73 Series: Key FeaturesDocument5 pagesType RN73 Series: Key FeaturesdannnirNo ratings yet

- Spvq5: Micro Switch Type With Female Connector TerminalDocument3 pagesSpvq5: Micro Switch Type With Female Connector TerminalshyhuNo ratings yet

- 6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationDocument4 pages6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationshyhuNo ratings yet

- SEO Rotary EncodersDocument4 pagesSEO Rotary EncodersshyhuNo ratings yet

- 265 6.1×3.7mm Compact Switch SpecsDocument3 pages265 6.1×3.7mm Compact Switch SpecsshyhuNo ratings yet

- Siemens - Tyco V23084 C2001 A303Document5 pagesSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- 35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchDocument3 pages35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchshyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- 1.2 (H) MM, Single-Side Recoil TypeDocument4 pages1.2 (H) MM, Single-Side Recoil TypeshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- List of Varieties: Resistive Position SensorsDocument1 pageList of Varieties: Resistive Position SensorsshyhuNo ratings yet

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDocument3 pagesSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNo ratings yet

- Medijski linč Gorana JevtićaDocument64 pagesMedijski linč Gorana JevtićashyhuNo ratings yet

- WM 00013Document127 pagesWM 00013shyhuNo ratings yet

- Quiet Surface Mount Switch SpecificationsDocument3 pagesQuiet Surface Mount Switch SpecificationsshyhuNo ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- 265 6.1×3.7mm Compact Switch SpecsDocument3 pages265 6.1×3.7mm Compact Switch SpecsshyhuNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Measuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsDocument1 pageMeasuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsshyhuNo ratings yet

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuNo ratings yet

- Emft Iii (T2)Document73 pagesEmft Iii (T2)athembo georgeNo ratings yet

- Reinforced Concrete Structures Analysis and DesignDocument4 pagesReinforced Concrete Structures Analysis and DesignJulio Cesar ValdiviesoNo ratings yet

- Sample Calculus Problems: Single Variable FunctionsDocument155 pagesSample Calculus Problems: Single Variable Functionsmoustafa.mehanna7564No ratings yet

- Experiment 2Document2 pagesExperiment 2vijaysai77No ratings yet

- Lecture #5: Content To Be CoveredDocument15 pagesLecture #5: Content To Be CoveredPiyush BhatnagarNo ratings yet

- Bdm100 User ManualDocument36 pagesBdm100 User Manualsimon_someone217No ratings yet

- Structures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDocument11 pagesStructures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDilum VRNo ratings yet

- PhysicsX PDFDocument124 pagesPhysicsX PDFcitsNo ratings yet

- Magnetism NotesDocument4 pagesMagnetism NotesvenuNo ratings yet

- MODULE 6.5 FastenersDocument12 pagesMODULE 6.5 FastenerssreeramNo ratings yet

- Alg Lesson 4-1Document4 pagesAlg Lesson 4-1Camilo MartinezNo ratings yet

- Getting Started With ANSYSDocument19 pagesGetting Started With ANSYSThulasi RamNo ratings yet

- Secondary DatabasesDocument21 pagesSecondary DatabasesDaljit SinghNo ratings yet

- Materials Finer Than 75 - : Standard Test Method For M (No. 200) Sieve in Mineral Aggregates by WashingDocument3 pagesMaterials Finer Than 75 - : Standard Test Method For M (No. 200) Sieve in Mineral Aggregates by WashingLuis Alejandro Sánchez LópezNo ratings yet

- Nuclei QB XiiDocument23 pagesNuclei QB XiiToshani GuptaNo ratings yet

- Ageing of Zinc Alloys: January 2011Document23 pagesAgeing of Zinc Alloys: January 2011Alicia Jara ChavezNo ratings yet

- Fishers LDADocument47 pagesFishers LDABinduNo ratings yet

- The PA Bible Addn 13 The Electric Guitar Loudspeaker PDFDocument3 pagesThe PA Bible Addn 13 The Electric Guitar Loudspeaker PDFjosiasns5257No ratings yet

- TDS PH MacTexMXL May2014Document1 pageTDS PH MacTexMXL May2014Catherine MagnayeNo ratings yet

- Insertion Ultrasonic Flow MeterDocument3 pagesInsertion Ultrasonic Flow Meterbsanidhya10No ratings yet

- EsdDocument44 pagesEsdAbhishek MatNo ratings yet

- Implementing A Virtual TrackballDocument4 pagesImplementing A Virtual Trackballkinny1974No ratings yet

- CH 6Document21 pagesCH 6Narendran KumaravelNo ratings yet

- EC3-611 Rack Controller and ECD-000 Display UnitDocument8 pagesEC3-611 Rack Controller and ECD-000 Display UnitMaria DazaNo ratings yet

- Calibration & Testing: ISO 17025 (NABL Accredited)Document7 pagesCalibration & Testing: ISO 17025 (NABL Accredited)Spectro Analytical Labs LimitedNo ratings yet

- 3ap1 FG: High-Voltage Circuit-BreakerDocument2 pages3ap1 FG: High-Voltage Circuit-BreakerFernando VacaNo ratings yet

- Unit 1 Test ReviewDocument4 pagesUnit 1 Test Reviewandrew culkinNo ratings yet

- Passive Flow Separation Control Over NACA 63018Document1 pagePassive Flow Separation Control Over NACA 63018miladrakhshaNo ratings yet