Professional Documents

Culture Documents

Lecture 3a - Sizing Basic Circuits - Rev2013

Uploaded by

Carter Siy0 ratings0% found this document useful (0 votes)

421 views34 pagesThis document discusses sizing basic branch circuits and wiring fundamentals. It covers:

- Definitions of branch circuit types (single phase, three phase)

- Relevant code requirements for sizing conductors, load limits, and overcurrent protection

- Factors that affect ampacity ratings like ambient temperature, number of conductors, and continuous loads

- Examples of properly sizing circuits based on these considerations like conductor size, overcurrent protection, and derating factors

Original Description:

Philippine Electrical Code Design PEC EE511 ppt powerpoint Sizing Ciruits

Original Title

Lecture 3a _sizing Basic Circuits - Rev2013

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses sizing basic branch circuits and wiring fundamentals. It covers:

- Definitions of branch circuit types (single phase, three phase)

- Relevant code requirements for sizing conductors, load limits, and overcurrent protection

- Factors that affect ampacity ratings like ambient temperature, number of conductors, and continuous loads

- Examples of properly sizing circuits based on these considerations like conductor size, overcurrent protection, and derating factors

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

421 views34 pagesLecture 3a - Sizing Basic Circuits - Rev2013

Uploaded by

Carter SiyThis document discusses sizing basic branch circuits and wiring fundamentals. It covers:

- Definitions of branch circuit types (single phase, three phase)

- Relevant code requirements for sizing conductors, load limits, and overcurrent protection

- Factors that affect ampacity ratings like ambient temperature, number of conductors, and continuous loads

- Examples of properly sizing circuits based on these considerations like conductor size, overcurrent protection, and derating factors

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 34

SIZING BASIC CIRCUITS

BRANCH CIRCUIT WIRING FUNDAMENTALS

1. What is a branch circuit? (PEC 2009 ART 2.10)

The circuit conductors between the final

overcurrent device protecting the circuit

and the outlet.

a. Single phase branch circuit -

two wires + ground (commonly called

single phase 3 wires)

b. Three phase branch circuit three wires

+ neutral wire +ground wire ( commonly

called 3phase 5 wires)

Four Categories

Branch Circuit, Appliance

A branch circuit that supplies energy to one

or more outlets to which appliances are to be

connected and that has no permanently

connected luminaires (lighting fixtures) that

are not part of an appliance

Branch Circuit, General Purpose A

branch circuit that supplies two or more

receptacles or outlets for lighting and

appliances.

Branch Circuit, Individual- A branch

circuit that supplies only one utilization

equipment

Branch Circuit, Multiwire A branch

circuit that consists of two or more

ungrounded conductors that have voltage

between them, and a grounded conductor

that has equal voltage between it and each

ungrounded conductor of the circuit and

that is connected to the neutral or

grounded conductor of the system

2. Relevant Code Requirements

a. The ampacity of branch circuit conductors must not be less than the

maximum load to be served (PEC ART 2.10.2.1)

b. The maximum load to be served by the branch circuit conductors

when supplying two or more receptacles must not be more than 80%

of the ampacity of the conductors. (PEC ART2.10.2.3 (a), (b) ,(c) )

Table 2.10.2.3(b)2

c. The rating of a branch circuit is established or defined by the rating or

setting of its protective device. (PEC ART2.10.2.2 (a) thru (d)

d. The ampacity of the branch circuit conductors must not be less than

the rating of the branch circuit.

e. The total load of on any overcurrent device in a panelboard must not

exceed 80%of the rating of the overcurrent device.

Relevant Code Requirements (continuation)

f. Circuit conductors shall be protected against over- current in

accordance to their ampacities, but where the ampacity of the

conductor does not correspond with the standard ampere rating of a

fuse or circuit breaker, the next higher rating shall be permitted only if

this rating does not exceed 800 amperes (PEC ART 2.40.1.4)

g. The normal ampacities of conductors in cable or raceways are given

in PEC Table 3.10.1.16 copper and aluminum based on a 30

o

C ambient

temperature. For ambient temperature over or under 30

o

C, correction

factors must be considered. (to be found just below Table 3.10.1.16)

h. These normal ampacities may have to be reduced or derated where

there are more than three conductors in a cable or raceway. This means

a change in ampacities of circuit conductors (Table3.10.1.15(b)(2)a)

i. The current permitted to be carried by the branch circuit may have to

be reduced if the load is continuous. This does not mean a change in

the ampacities of the conductor but the rule refers to a limit of the load

to be carried by the conductors.

j. Continuous load refers to a load that operates for three hours or

more such as store lighting, office lighting and similar lighting loads.

k. Overcurrent protection for any single non- motor operated appliance

with ratings of 10 amperes or more must not be more than 150%of its

ampere rating.

l. General purpose receptacle outlet other than dwelling shall be taken

as a load of 180va for each single or for each multiple receptacle on

one yoke. (ART 2.20(k))

20Amps Circuit Breaker

3.5mm2 THW, ampacity is 20A

Case 1:

The circuit is in accordance with the code requirement. The

rating of this circuit is 20 Amperes. The load therefore

must be only 16A maximum allowed by the code

16 amps maximum continuous load

Lighting outlets

20Amps Circuit Breaker

2.0mm2 THWampacity is 15A

Case 2:

The circuit is in violation of the code requirement. The

rating of this circuit is greater than the ampacity of the

circuit conductors. The conductors will be overloaded even

before the overcurrent device works.

12 amps maximum continuous load

Lighting outlets

20Amps Circuit Breaker

8mm2 THW, ampacity is 40A

Case 3:

The circuit is in accordance with the code requirement. The

rating of this circuit is 20 amperes not 40 amperes. The

circuit should be loaded continously at 16 amperes

maximum

16 amps maximum continuous load

Lighting outlets

Number of Current carrying

Conductors

%Values in Tables 3.10.1.16-19

as adjusted for ambient

temperature if Necessary

4 to 6 80%

7 to 9 70%

10-20 50%

21-30 45%

31-40 40%

41 and above 35%

TABLE 3.10.1.15(B)(2)A Adjustment Factors for More than

Three current Carrying Conductors in a Raceway or Cable

3. DERATING CONDUCTOR AMPACITIES

a. The preceding illustrations are true if the wires are placed in conduits

not exceeding 3 current- carrying conductors in ambient temperature

of 30

o

C.

Typical Circuit Distribution in a Panelboard

In this example the ampacity of 8 of # 3.5MM2THW

conductors (20 amps) has to be derated to 70%

or 14 amps. Correspondingly the circuit protection

shall be resized to 15 amps based on the new

ampacity of 14 amps

Notes: Limiting the load to 80%for being continous load

(office lighting loads that operate for three hours or more

Must not be construed as a change in ampacity of the

Circuit conductors

Eight #3.5MM2THW

Cu circuit

conductors serving

continuous loads

Derated ampacity

= 20 x 0.70 x 0.80

=11.2Amps

4. CORRECTION FACTORS IN TEMPERATURES OVER 30

o

C

a. On top of the derating factors due to the large number of

conductors in a conduit or cable, there is a correction to the conductor

ampacities when installed or operated at temperatures over or under

30

o

C.

b. In tropical countries like Philippine setting, especially circuits

installed in between ceiling and the roofing, the factor corresponding

31- 40 deg C has to be applied. Consideration must likewise to be

observed in hot rooms in industrial plants as boiler rooms, furnace

areas and the like.

5. CONDUCTOR AMPACITY REQUIREMENTS

Example 1 Whats the circuit ampacity for three 30mm

2

THHN

conductors run in a raceway through the ambient temperatures zones

as shown in the figure

a) 115 amps

b) 110 amps

c) 120 amps

d) 100 amps

A

B C

D

Temp =28

o

C

1.00 correction

Temp =35

o

C

0.96 correction

Temp =22

o

C

1.04A correction

Temp =45

o

C

0.87correction

115A 110A 120A

100A

Ambient temperature ampacity

adjustment for 30mm

2

THHN (rated

115A)

The answer is d) 100. The ampacity for 30mm

2

THHN (90

o

C is

115amps, but the correction factors of table reduce the conductor

ampacity to only 100A ( 115amps x 0.87= 100)

Note: Where more than one calculated or adjusted ampacities

could apply to a given circuit length, the lowest ampacity must be

used for the entire circuit in calculations.

90

o

C conductor

6. CIRCUIT SIZING EXERCISES

Example 1:

A single phase circuit is to be wired in 75

o

C THW copper wire

dedicatedly installed inside a conduit in an area with an ambient

temperature of 36

o

C . If the circuit is supposed to carry 135 amps non-

continuous load current, what is the minimum size of wire and the

circuit overcurrent protection?

Answer:

a) Derating factor for 2 wires in a conduit = 100%

b) Correction factor, 36

o

C ambient temperature =88%

c) Non- continuous loading factor = 100%

Conductor size = 135A / (1.0 x 0.88 x 1.0)

Conductor size = 153.4 amps

Use 60mm

2

THW, Ampacity = 160 amps (Table 3.10.1.16 p. 350)

Derated ampacity = 160A x 0.88 = 141Amps

Use 150Amps standard rated MCCB

Example 2:

There are 2 single phase circuit to be wired in 75

o

C THW copper wire

installed inside a conduit in an area with an ambient temperature of 36

o

C . If

each circuit is designed to carry 135 amps continuous load current, what is

the minimum size of wire and the circuit overcurrent protection for each

circuit?

The branch circuit OCPD (or conductor) must have a rating of not less than

the noncontinupus load plus 125%of the continuous load before applying an

ampacity adjustment factor. {Articles 2.10.1.1(a) and 2.10.2.2(a)}

Answer:

a) Derating factor for 4 wires in a conduit = 80%(Table 3.10.1.15)

b) Correction factor, 36

o

C ambient temperature =88%

c) Continuous load limitation = 80%

Size of each conductor shall be:

Conductor size = 135A / (0.8 x 0.88 x 0.80)

Conductor size = 239.7 amps

Use 125mm

2

THW, Ampacity = 255 amps (Table 3.10.1.16 p. 350)

Derated ampacity = 255A x 0.8 x0.88 = 179.5Amps

(Note: 80%load limitation for continuous loads is not a derating factor)

Use 175Amps standard rated MCCB

Example 3:

Four single phase circuits are to be wired in 75

o

CTHW copper wire inside a

conduit passing through an area with an ambient temperature of 45

o

C . If

each circuit is designed to carry 12 amps continuous load current, what is

the minimum size of wire and the circuit overcurrent protection for each

circuit?

Answer:

a) Derating factor for 8 wires in a conduit = 70%(Table 3.10.1.15)

b) Correction factor, 45

o

C ambient temperature =82%

c) Continuous load limitation = 80%

Size of each conductor shall be:

Conductor size = 12A / (0.7 x 0.82 x 0.80)

Conductor size = 26.13 amps

Use 5.5mm

2

THW, Ampacity = 35 amps (Table 3.10.1.16 p. 350)

Derated ampacity = 35A x 0.7 x0.82 = 20.09Amps

(Note: 80%load limitation for continuous loads is not a derating factor)

Use 20 Amps standard rated MCCB

WIRES AND CABLES

7. SIZING CONDUCTORS BASED ON TEMPERATURE RATING

Question : If the engineer wants to use a THW wire , then we refer to the

75oC column

YES

If the engineer wants to use a THHN wire , then we refer to the 90

o

C

column

NOT QUITE

Has anyone heard of operational problems with THHN wires & cables? The

problem is in the difference in temperature ratings from device terminals

to wire terminals when connected together.

POINTS TO REMEMBER:

1. For device or equipment terminals rated 100A or less, or for 2.0mm2-

38mm2conductors, terminal sizes shall be based on the 60

o

C temperature

rating ( Art 1.10.1.14(c) )

Ex. What size THHN conductor does the PEC require for a 50A circuit if the

terminals are not marked with a temperature rating?

a) 5.5mm2 b) 8mm2 c) 14mm2 d) any of these

Ans c) 14mm2 (70 amps) and not 8mm2 (55amps) shall be used because

conductor size must be selected on the 60

o

C terminal rating of the device not

the 90

o

C rating of the insulation

Ex. What size THHN conductor does the PEC require for a 50A circuit if the

terminals are marked for use on 75oC temperature rating?

a) 5.5mm2 b) 8mm2 c) 14mm2 d) any of these

Ans. b) 8mm2 (55amps) .Size the conductors to the 75oC terminal rating of

the device and not 90oC.

2. Circuits over 100A - unless the terminals are marked otherwise, or for

conductors larger than 38mm2 equipment / device terminals rated over100A

shall be sized according to 75

o

C temperature rating (Art. 1.10.1.14(c) )

Ex. What size THHN conductor is required to supply a 225amps feeder

a) 50mm2 b) 60mm2 c)80mm2 d)125mm2

Ans. 125mm2 (265Amps). Size the conductors to the 75oC terminal rating

3. What then is the purpose of 90

o

C wire if we can not use its higher

ampacity?

Its rating comes into play when

adjusting conductor ampacity for elevated ambient temperature

or when bundling more than three current carrying conductors

together (derating).

The advantage is that it can keep the designer from using a larger

wire which requires larger raceways, greater labor and increased

material cost.

To Review:

Important in the electrical & thermal relationship for circuit

components are the conductor size, rated ampacity, the insulation

temperature rating and the permissible connector device temperature

limits

For instance, the ampacity for a conductor with 90degC insulation

(THHN) is generally greater than of a conductor of the same size but

with 60degC (TW) insulation.

However, the greater ampacity of a THHN conductor with 90degC

insulation is not always permitted to be used due to limitations of the

terminal temperature rating and /or the requirements of the PEC.

EXAMPLE: FEEDER CONTINUOUS LOAD

The feeder circuit OCPD (or conductor) must have a rating of not less than

the noncontinupus load plus 125%of the continuous load before applying

an ampacity adjustment factor. {Articles 2.15.1.2(1) and 2.15.1.3}

1. What size of OCPD/feeder THHN conductor does the PEC require for a 104A

continuous load?

a. 150A -50mm2 c. 125A 30mm2

b. 150A- 38mm2 d. 125A 38mm2

Step 1 : The overcurrent protective device (OCPD) must have a rating of

not less than 125% of the continuous load.

Thus , 104 A x 1.25=130A

The nearest OCPD rating is 150A protection

Step 2: The feeder conductor must have an ampacity of not less than 125%

of the continuous load before any ampacity adjustment. Thus the

feeder must be : 104A x 1.25= 130A

38mm2THHN is rated 130A at 75 deg C and the 150A overcurrent protection

device can protect it.

The answer is (b), 150A OCPD with 38mm2 THHN

SIZING AND INSTALLING PARALLEL CONDUCTOR SETS

In the case of high ampacity feeders, one conductor per phase may not be practical. Under

these circumstances , two or more conductors per phase may be desirable or even

necessary. The objective is to keep the resistance of each parallel path equal so the load

current will divide equally on each wire of the set. The wires and terminations heat up

when they carry current; therefore the resistance changes when the temperature of the wire

and terminations changes. For these reasons, special requirements are necessary when

installing parallel sets of wires. The following is a summary of some special installation

rules for sets of multiple conductors for each ungrounded conductor and grounded

conductor.

1. Power conductors are permitted to be paralleled only for size 50mm2 (#1/0 AWG) or

larger, except for special applications.

2. All parallel conductors of the phase or neutral set shall be of the same length.

3. All conductors of the phase and neutral set shall be of the same material, cross

sectional area, and the same insulation type.

4. All conductors of a phase or neutral set shall be terminated in the same manner.

5. If run in more than one raceway, the raceways shall have the same physical properties,

and the same length, and shall be installed in the same manner

6. If more than one raceway is used, make sure each phase wire and neutral, if present, is

placed in each of the raceways to prevent eddy currents.

7. If an equipment grounding wire is present and there is more than one raceway, an

equipment grounding wire shall be in each raceway.

Example : Circuits with Overcurrent Protection Over 800A

If the circuit OCPD exceeds 800A, the circuit conductors must have an ampacity

not less than the rating of the OCPD {Art 2.40.1.4(c)}

Example : Feeder Continuous Load

1. What size feeder conductor does the PEC require for a 1200A service/feeder

paralleled in three raceways?

a. 200mm2 b. 300mm2 c. 250mm2 d. any of these

Step 1. Determine ampacity per parallel conductor, 1200/3 = 400A

Step 2. Select a conductor using Table 3.10.1.16 page 350 that has an ampacity of

435 at 75degC

A 325mm2 conductor (435 x 3 =1305A) is required arranged in three conduits

with three conductors per conduit. (470A is the ampacity of THHN at 90 degC)

But note that the 3//325mm2 THHN per phase in this case , is only seen at

1305A (435A x 3=1305A) ampacity basing at 75degC column.

You might also like

- Sample Load ComputationDocument12 pagesSample Load ComputationEric MendozaNo ratings yet

- Lecture 1 - Understanding The Value of PecDocument15 pagesLecture 1 - Understanding The Value of PecCarter SiyNo ratings yet

- Design AnalysisDocument10 pagesDesign AnalysisRyan RamosNo ratings yet

- Common Mistakes Electrical Grounding and Bonding - JAIME V MENDOZA PDFDocument103 pagesCommon Mistakes Electrical Grounding and Bonding - JAIME V MENDOZA PDFShang Divina EbradaNo ratings yet

- Don't Let Voltage Drop Get Your System Down: A Concise Guide to Calculating Voltage DropDocument6 pagesDon't Let Voltage Drop Get Your System Down: A Concise Guide to Calculating Voltage DropJoel E GonzálezNo ratings yet

- Electrical General NotesDocument5 pagesElectrical General NotesjustineNo ratings yet

- Total General Loads = 1348.32 + 1500 + 1000 = 3848.32 VADocument120 pagesTotal General Loads = 1348.32 + 1500 + 1000 = 3848.32 VARaymond CoronaNo ratings yet

- WiringDocument23 pagesWiringNoel NantesNo ratings yet

- The Philippine Electrical Code: P) E I T P A R Y Q W D T M O ODocument9 pagesThe Philippine Electrical Code: P) E I T P A R Y Q W D T M O Ojay garciaNo ratings yet

- 11a. Electrical ComputationsDocument1 page11a. Electrical Computationsronald bayanNo ratings yet

- Ufgs 33 70 02.00 10 (Manhole Standards)Document67 pagesUfgs 33 70 02.00 10 (Manhole Standards)Mohammad Jaradeh100% (1)

- Pec Reviewer1Document16 pagesPec Reviewer1Cielle negreteNo ratings yet

- Chapter 6 - Fire Protection SystemDocument4 pagesChapter 6 - Fire Protection SystemPhel FloresNo ratings yet

- CIV 0322 CE Laws, Ethics and Contracts Case AnalysisDocument7 pagesCIV 0322 CE Laws, Ethics and Contracts Case AnalysisJoseph Berlin Juanzon0% (1)

- 1.b Schedule of LoadsDocument4 pages1.b Schedule of LoadsJing JingNo ratings yet

- Shop Practice with Electrical Code IntroductionDocument14 pagesShop Practice with Electrical Code IntroductionApocalypse CabalNo ratings yet

- Pec Wire Sizes CompilationDocument2 pagesPec Wire Sizes Compilationjay garciaNo ratings yet

- SET1RMEDocument5 pagesSET1RMEJohn Paul BruanNo ratings yet

- MCQ in Philippine Electrical Code (PEC) Part 8 REE Board Exam QuestionsDocument19 pagesMCQ in Philippine Electrical Code (PEC) Part 8 REE Board Exam QuestionsManuel DizonNo ratings yet

- What Should Be The Contents of My Electrical Plan - Based On PEC 2017 - Electrical Engineer ResourcesDocument15 pagesWhat Should Be The Contents of My Electrical Plan - Based On PEC 2017 - Electrical Engineer ResourcesJCuchapin100% (1)

- Philippine Electrical Code For RME Hacked PDFDocument99 pagesPhilippine Electrical Code For RME Hacked PDFErwin Obenza75% (4)

- Electrical Design AnalysisDocument2 pagesElectrical Design AnalysisMaritel SumatraNo ratings yet

- EE-513-Updated-10-9-17 (1Document16 pagesEE-513-Updated-10-9-17 (1Victor DoyoganNo ratings yet

- How To Calculate The Circuit Breaker SizeDocument9 pagesHow To Calculate The Circuit Breaker SizeAl Patrick Dela CalzadaNo ratings yet

- MR - Mentoring EE Educators Towards PEEEngr. Cirilo Calibjo Nov. 27 2015Document74 pagesMR - Mentoring EE Educators Towards PEEEngr. Cirilo Calibjo Nov. 27 2015ramelNo ratings yet

- Lecture 12 Voltage Drop and Short Circuit Calculation PDFDocument12 pagesLecture 12 Voltage Drop and Short Circuit Calculation PDFGhunElardeNo ratings yet

- Pec 2Document5 pagesPec 2ImEngineeringCracklingsNo ratings yet

- REGISTERED MASTER ELECTRICIAN Evaluation PDFDocument3 pagesREGISTERED MASTER ELECTRICIAN Evaluation PDFAdrianne Aldrin AlarcioNo ratings yet

- RME Closed Door Part 2 - TechnicalDocument6 pagesRME Closed Door Part 2 - TechnicalMackeeNo ratings yet

- CCTV and Fdas DesignDocument19 pagesCCTV and Fdas DesignMayprill SarmientoNo ratings yet

- Electrical Design Analysis For Commercial Building SampleDocument14 pagesElectrical Design Analysis For Commercial Building SampleMichael AngeloNo ratings yet

- Short Circuit AnalysisDocument43 pagesShort Circuit AnalysisKouji Tomas0% (1)

- Electrical System Design Analysis: Hernan / Grace Guillena Lot 2, Blk. 8, Southside Subdivision, Sum-Ag, Bacolod CityDocument5 pagesElectrical System Design Analysis: Hernan / Grace Guillena Lot 2, Blk. 8, Southside Subdivision, Sum-Ag, Bacolod Cityharold de guzmanNo ratings yet

- Philippine Electrical Code Question BankDocument1,001 pagesPhilippine Electrical Code Question BankPaolo CasungcadNo ratings yet

- PEC Closed Door 1Document9 pagesPEC Closed Door 1Essej OrtsacNo ratings yet

- New Ee Law (Ra 7920)Document15 pagesNew Ee Law (Ra 7920)Kevin CabanteNo ratings yet

- Electrical Design 101 40Document1 pageElectrical Design 101 40jungatbuntonNo ratings yet

- Electrical code questions on wiring methods, protection devices and equipment ratingsDocument60 pagesElectrical code questions on wiring methods, protection devices and equipment ratingsQueeny Verba83% (12)

- AC Fire Pump Systems-4 Color Brochure (English)Document8 pagesAC Fire Pump Systems-4 Color Brochure (English)Biggie ColdAngelNo ratings yet

- Residential load calculation and short circuit analysisDocument10 pagesResidential load calculation and short circuit analysisRyan RamosNo ratings yet

- Grounding System Design For Isolated Locations and Plant SystemsDocument51 pagesGrounding System Design For Isolated Locations and Plant SystemsFedilino P. FornollesNo ratings yet

- Calculating Multi-Family Dwelling Unit Service SizesDocument5 pagesCalculating Multi-Family Dwelling Unit Service SizeslkakeanNo ratings yet

- Design Analysis Presentation-Engr AragonDocument21 pagesDesign Analysis Presentation-Engr AragonlloymarklloydNo ratings yet

- RME QuestionDocument1 pageRME QuestionReynel JazminNo ratings yet

- Pec Provisions For Electrical System DesignDocument133 pagesPec Provisions For Electrical System DesignMira Alvarez100% (1)

- Ra 7920Document16 pagesRa 7920Romel PanisNo ratings yet

- Feu Institute of Technology Mechanical Engineering DepartmentDocument21 pagesFeu Institute of Technology Mechanical Engineering DepartmentKATHLEEN DEL PILARNo ratings yet

- Pec 5Document4 pagesPec 5jhigz25100% (2)

- Electrical Systems Design Based On Pec 2009 PDFDocument2 pagesElectrical Systems Design Based On Pec 2009 PDFLydherson SepnioNo ratings yet

- Engineering Sciences and Allied SubjectsDocument10 pagesEngineering Sciences and Allied SubjectsNathanael TayorNo ratings yet

- Fire Detection and Alarm System Vendor-Neutral ApproachDocument99 pagesFire Detection and Alarm System Vendor-Neutral Approachwillardo c. mesa100% (2)

- Types of BreakersDocument28 pagesTypes of Breakersjayson platinoNo ratings yet

- Basic Relaying IieeDocument59 pagesBasic Relaying Iieejanine colladoNo ratings yet

- Pretest 204, 20pec 20& 20TS 2045Document7 pagesPretest 204, 20pec 20& 20TS 2045JohntreeNo ratings yet

- ME5507 - Electrical Services Volt Drop and OverloadDocument4 pagesME5507 - Electrical Services Volt Drop and OverloadpravishnNo ratings yet

- Sizing Electric Transformers PDFDocument2 pagesSizing Electric Transformers PDFrajnikNo ratings yet

- 14F3099X00 Ampacity Wire WisdomDocument2 pages14F3099X00 Ampacity Wire WisdomAnonymous IvZSKJCNo ratings yet

- Cable Sizing of Sub-Main Circuits, Working ExamplesDocument7 pagesCable Sizing of Sub-Main Circuits, Working ExamplesmaungsoekhinNo ratings yet

- Questions 241 - 260 Review (309A 2015) : 14-104 Rating of Overcurrent Devices (See Appendix B)Document11 pagesQuestions 241 - 260 Review (309A 2015) : 14-104 Rating of Overcurrent Devices (See Appendix B)arash sarikhaniNo ratings yet

- Fossil Fuels ReportDocument32 pagesFossil Fuels ReportCarter SiyNo ratings yet

- Static Electricity ExplainedDocument6 pagesStatic Electricity ExplainedCarter SiyNo ratings yet

- Lecture 2 - Design Principles PECDocument9 pagesLecture 2 - Design Principles PECCarter SiyNo ratings yet

- Solenoid ValvesDocument12 pagesSolenoid ValvesCarter SiyNo ratings yet

- Argumentative EssayDocument2 pagesArgumentative EssayCarter SiyNo ratings yet

- PRICE LIST June 2016 FIRE EXTINGUISHERSDocument11 pagesPRICE LIST June 2016 FIRE EXTINGUISHERSnaresh singlaNo ratings yet

- Solis - 2G-US - Installation - and - Operation - Manual INGLESDocument18 pagesSolis - 2G-US - Installation - and - Operation - Manual INGLESCesar RosilloNo ratings yet

- Universal Tool & Cutter GrinderDocument2 pagesUniversal Tool & Cutter GrinderabyzenNo ratings yet

- Electrical Plan DesignDocument4 pagesElectrical Plan Designmark lumbres100% (1)

- Solideal Max Duty Drop Center WheelsDocument4 pagesSolideal Max Duty Drop Center WheelsJohn RobinsonNo ratings yet

- Nova-L: Technical Data SheetDocument2 pagesNova-L: Technical Data SheetparaboolNo ratings yet

- 86°C Mixed Gas Upright Freezers MUQ 7770 SeriesDocument8 pages86°C Mixed Gas Upright Freezers MUQ 7770 SeriesAhmad ibrahimNo ratings yet

- Caterpillar C11-C13 Engine SchematicDocument4 pagesCaterpillar C11-C13 Engine SchematicMikeas Yaz75% (4)

- RXZE2M114M Schneider ElectricDocument3 pagesRXZE2M114M Schneider Electricstreet l CNo ratings yet

- Manual Sierra 400Document27 pagesManual Sierra 400Isaac de Jesus Martinez PerezNo ratings yet

- Mde 4424Document29 pagesMde 4424schmersalNo ratings yet

- Electrical Heaters: G Nuovo PignoneDocument4 pagesElectrical Heaters: G Nuovo Pignonecvg ertdNo ratings yet

- Optimize Shinko AC Servo Motor and Driver ManualDocument55 pagesOptimize Shinko AC Servo Motor and Driver ManualkoksienNo ratings yet

- SD Series User ManualDocument85 pagesSD Series User ManualRemigild PeterNo ratings yet

- Klasifikasi Pesawat Angkat Dan Pesawat Angkut: Oleh: Arief SuponoDocument80 pagesKlasifikasi Pesawat Angkat Dan Pesawat Angkut: Oleh: Arief SuponoAhmad MultidasaNo ratings yet

- Tenryu CatalogDocument40 pagesTenryu CatalogCarbide Processors IncNo ratings yet

- Honeywell Pressuretrol Reset Manual L4079A - L4079B - L4079WDocument4 pagesHoneywell Pressuretrol Reset Manual L4079A - L4079B - L4079WUrielNo ratings yet

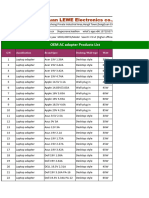

- AC Adapter Product ListDocument12 pagesAC Adapter Product Listbiloaayissi7No ratings yet

- BlackBoard CR3000 Reader Installation GuideDocument16 pagesBlackBoard CR3000 Reader Installation GuidetractorbobNo ratings yet

- 3-Pole AF Contactors For 24 V DC Control 1SBC101438D0201Document15 pages3-Pole AF Contactors For 24 V DC Control 1SBC101438D0201Ergün PoyrazNo ratings yet

- Panduan Troubleshoot OLT HuaweiDocument8 pagesPanduan Troubleshoot OLT HuaweiDony Nurmi S100% (1)

- PC Imc300Document154 pagesPC Imc300JorgeNo ratings yet

- FWP HB I Part II JUN 2016Document360 pagesFWP HB I Part II JUN 2016Roberto Grieco100% (2)

- Circuit Breakers SF6 Inspection and TestingDocument3 pagesCircuit Breakers SF6 Inspection and TestingHoneylyn IgnacioNo ratings yet

- ZIGZAG Transformer and Resistance GroundingDocument2 pagesZIGZAG Transformer and Resistance GroundingMichael Camit EsoNo ratings yet

- YPED-3054 List of Solenoid Valve For CGL and CCLDocument7 pagesYPED-3054 List of Solenoid Valve For CGL and CCLGodfrey OdieroNo ratings yet

- Common Wire Splices and JointsDocument14 pagesCommon Wire Splices and JointsRoselleAntonioVillajuanLinsanganNo ratings yet

- NEXUS Cross Reference - PERJ0028 (V. 2)Document161 pagesNEXUS Cross Reference - PERJ0028 (V. 2)LENIN JHAIR VALDERRAMA SEGURA100% (1)

- TM Ze304slh 5 41044507044a FramDocument690 pagesTM Ze304slh 5 41044507044a FramKot878No ratings yet

- Method Statement For Mep Installations PDFDocument24 pagesMethod Statement For Mep Installations PDFAnonymous j8lxlTlLk100% (11)