Professional Documents

Culture Documents

FEED FOCUS: Pigs

Uploaded by

Milling and Grain magazineCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FEED FOCUS: Pigs

Uploaded by

Milling and Grain magazineCopyright:

Available Formats

Digital Re-print -

July | August 2014

FEED FOCUS: Pigs

www.gfmt.co.uk

Grain & Feed Milling Technology is published six times a year by Perendale Publishers Ltd of the United Kingdom.

All data is published in good faith, based on information received, and while every care is taken to prevent inaccuracies,

the publishers accept no liability for any errors or omissions or for the consequences of action taken on the basis of

information published.

Copyright 2014 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form

or by any means without prior permission of the copyright owner. Printed by Perendale Publishers Ltd. ISSN: 1466-3872

M

ost of the feed and food safety assurance systems are

focused on prevention of contamination of feed and food

materials with undesirable substances or microbiologi-

cal agents.

A certification scheme has three main components: the normative

references, the assurance and corrective action tools, and the rules

of certification.

The normative references determine what is considered as a

safe product for consumption, or what is sustainable or responsible

related to environment or society. The rules of certification are about

the certification process of companies obtaining for a certificate

against the involved certification scheme, which the certification bod-

ies have to apply and comply with.

The assurance & corrective action tools are the instruments and

procedures, which the company obtaining a certificate have to apply

in the daily business operations.

The assurance tools are focused on preventive actions and

measurements in order to avoid the occurrence of contamination.

A starting point for the control of potential risk is the application

of prerequisite programs in order to create a basic level of control.

The Hazard Analysis Critical Control Points (HACCP) approach

is important to identify in advance the remaining risks in the process

and operations and to determine appropriate control measures, as

well as a monitoring plan. A risk could be the purchased / supplied

ingredients.

For feed or food safety, a full control of the supply chain can

be an option, like followed in the GMP+ Feed Safety Assurance

certification. In case of product responsibility other supply chain

models (material accounting system) can be applied, like book and

claim, mass balance and segregated system. Application of a quality

management system makes it possible to ensure control measures

and monitoring plan in the daily operations in a consistent way.

Besides the preventive measures, also corrective actions need to

be applied for the case of the occurrence of contamination.

It is about traceability, recall procedures and early warning. The

aim is to reduce the distribution of contaminated lot(s) of feed or

food material in the market or withdraw it.

EWS applied within the GMP+ Feed Safety Assurance (FSA)

certification operates as follows. If a certified company determines

a level of undesirable substance(s) exceeding the maximum permit-

ted level, it is obliged besides taking the appropriate control and

corrective measurements and informing its customers to notify

the scheme manager GMP+ International as well as the involved

certification body.

The primary focus of the certification body is to monitor the

application of the appropriate actions and measurements by the

involved feed company. The primary focus of GMP+ International is

to alert the other GMP+ FSA participants about the occurrence of a

concrete contamination event in the market, if the contaminated lots

are delivered by supply chain partner(s), or the contaminated lots are

or can be delivered to other companies in the market.

In that case, GMP+ International informs all other GMP+ FSA

participants about the involved product (generic name), the kind of

undesirable substance(s), the detected level(s), and the country of

origin. When other GMP+ FSA participants are also buying or dealing

with the reported product from the mentioned origin, they can take

the right measures, like sampling and analysing or asking guarantees

of his supplier.

In 2013, GMP+ International published 29 EWS messages, in

2014 until end July already totally 25.

Sometimes more than one EWS message has been related to the

same case. It was about Aflatoxin B1 in maize and copra, lead in deer

meal, dioxins in pre-mixture and dried beet pulp, peas, maize and

soybean extractions, non-dioxin liked PCBs in fatty acids, dioxin liked

PCBs in apple pulp, chloramphenicol in pre-mixtures and vitamins,

ergot in triticale, wheat and rye, ethyl-esters in fish oil, DON and

ZEA in maize and maize gluten feed, ambrosia in maize, hydrogen

cyanide in linseed, biogenic amines in fish meal, etc.

Only a limited number was related to a more or less serious

feed safety emergency. Most of the reported issues were controlled

in an early stage. GMP+ International always tries to find out the

source and cause of contamination, because that could be relevant

for the risk assessments and could contribute to avoid occurrence

in the future. The GMP+ FSA certified companies observe these

EWS messages as worthwhile, because it increases their alertness

regarding specific risks.

It add also value in comparison of the Rapid Alerts System Feed

& Food (RASFF) of the European Union, due to more details and

sometimes quicker publication.

Of course, the functioning of EWS depends on the willingness

of companies to notify a perceived contamination. The increasing

number of EWS notifications is a signal of increasing awareness of the

common interest of EWS notification. Recently, GMP+ International

tightened the obligation to notify contaminations by classifying non-

conformity with this obligation as critical nonconformity.

My final conclusion is that EWS is a worthwhile measurement in

addition to all kind of preventive actions. It contributes to reduce the

spread out of contaminated material in the market and therefor, it

contributes to reduce the size of a feed safety emergency.

FEED FOCUS

PIGS

Added value of

early-warning

systems (EWS)

by Johan den Hartog, Managing

Director GMP+ International

28 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

M

ost of the feed and food safety assurance systems are

focused on prevention of contamination of feed and food

materials with undesirable substances or microbiologi-

cal agents.

A certification scheme has three main components: the normative

references, the assurance and corrective action tools, and the rules

of certification.

The normative references determine what is considered as a

safe product for consumption, or what is sustainable or responsible

related to environment or society. The rules of certification are about

the certification process of companies obtaining for a certificate

against the involved certification scheme, which the certification bod-

ies have to apply and comply with.

The assurance & corrective action tools are the instruments and

procedures, which the company obtaining a certificate have to apply

in the daily business operations.

The assurance tools are focused on preventive actions and

measurements in order to avoid the occurrence of contamination.

A starting point for the control of potential risk is the application

of prerequisite programs in order to create a basic level of control.

The Hazard Analysis Critical Control Points (HACCP) approach

is important to identify in advance the remaining risks in the process

and operations and to determine appropriate control measures, as

well as a monitoring plan. A risk could be the purchased / supplied

ingredients.

For feed or food safety, a full control of the supply chain can

be an option, like followed in the GMP+ Feed Safety Assurance

certification. In case of product responsibility other supply chain

models (material accounting system) can be applied, like book and

claim, mass balance and segregated system. Application of a quality

management system makes it possible to ensure control measures

and monitoring plan in the daily operations in a consistent way.

Besides the preventive measures, also corrective actions need to

be applied for the case of the occurrence of contamination.

It is about traceability, recall procedures and early warning. The

aim is to reduce the distribution of contaminated lot(s) of feed or

food material in the market or withdraw it.

EWS applied within the GMP+ Feed Safety Assurance (FSA)

certification operates as follows. If a certified company determines

a level of undesirable substance(s) exceeding the maximum permit-

ted level, it is obliged besides taking the appropriate control and

corrective measurements and informing its customers to notify

the scheme manager GMP+ International as well as the involved

certification body.

The primary focus of the certification body is to monitor the

application of the appropriate actions and measurements by the

involved feed company. The primary focus of GMP+ International is

to alert the other GMP+ FSA participants about the occurrence of a

concrete contamination event in the market, if the contaminated lots

are delivered by supply chain partner(s), or the contaminated lots are

or can be delivered to other companies in the market.

In that case, GMP+ International informs all other GMP+ FSA

participants about the involved product (generic name), the kind of

undesirable substance(s), the detected level(s), and the country of

origin. When other GMP+ FSA participants are also buying or dealing

with the reported product from the mentioned origin, they can take

the right measures, like sampling and analysing or asking guarantees

of his supplier.

In 2013, GMP+ International published 29 EWS messages, in

2014 until end July already totally 25.

Sometimes more than one EWS message has been related to the

same case. It was about Aflatoxin B1 in maize and copra, lead in deer

meal, dioxins in pre-mixture and dried beet pulp, peas, maize and

soybean extractions, non-dioxin liked PCBs in fatty acids, dioxin liked

PCBs in apple pulp, chloramphenicol in pre-mixtures and vitamins,

ergot in triticale, wheat and rye, ethyl-esters in fish oil, DON and

ZEA in maize and maize gluten feed, ambrosia in maize, hydrogen

cyanide in linseed, biogenic amines in fish meal, etc.

Only a limited number was related to a more or less serious

feed safety emergency. Most of the reported issues were controlled

in an early stage. GMP+ International always tries to find out the

source and cause of contamination, because that could be relevant

for the risk assessments and could contribute to avoid occurrence

in the future. The GMP+ FSA certified companies observe these

EWS messages as worthwhile, because it increases their alertness

regarding specific risks.

It add also value in comparison of the Rapid Alerts System Feed

& Food (RASFF) of the European Union, due to more details and

sometimes quicker publication.

Of course, the functioning of EWS depends on the willingness

of companies to notify a perceived contamination. The increasing

number of EWS notifications is a signal of increasing awareness of the

common interest of EWS notification. Recently, GMP+ International

tightened the obligation to notify contaminations by classifying non-

conformity with this obligation as critical nonconformity.

My final conclusion is that EWS is a worthwhile measurement in

addition to all kind of preventive actions. It contributes to reduce the

spread out of contaminated material in the market and therefor, it

contributes to reduce the size of a feed safety emergency.

FEED FOCUS

PIGS

Added value of

early-warning

systems (EWS)

by Johan den Hartog, Managing

Director GMP+ International

28 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

Paul Phillips gets back 6 for every 1 spent on

Digest-it

Digest-it treatment boosts slurry value

Increasing the fertiliser value of slurry from the pig-finishing unit

on Brian and Paul Phillipss 670 acre Bridge Farm, Northallerton,

is showing good results part-way through a 12 month trial

period. They have been treating the slurry in the under-floor

storage tanks of their slatted pig-finishing houses with Digest-it

, a

live culture of aerobic bacteria. So far, before and after treatment

analysis has shown a 6:1 return on the investment in Digest-it in

terms of artificial fertiliser replacement value.

Bridge Farm is a mixed enterprise growing cereals, fattening

beef cattle and lambs, and running a 200 sow unit with progeny

taken through to finish in slatted finishing units. Introduction

of NVZ regulations in 2002 raised awareness of the fertiliser

potential of the pig manure, and careful consideration of crop

nutrient requirements has increased the earning potential of the

pig enterprise.

The aerobic bacteria in Digest-it break down slurry solids,

releasing the potash and phosphate and converting ammonia

nitrogen into organic, plant-available nitrogen. Because increased

aerobic microbial activity in the store reduces the levels of the

putrefying toxic anaerobic bugs, slurry is converted from a smelly

waste to a valuable source of nutrients that support soil fertility

and health, and reduces ammonia and smell emissions.

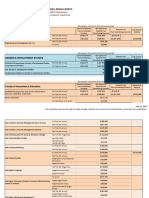

The results of the first 4 months treatment are shown below.

Conclusion

Digest-it treated slurry has improved the fertiliser value by

2.30 per m

3

at an input cost of 0.36 per m

3

. This represents a

cost effective ratio of 6.4:1.

Slurry is removed from the under-slat storage tanks twice

a year: in February, when it is injected into silage ground, and

again in the summer onto stubble turnip fields. In the past, stir-

ring the slurry has had the potential to cause problems with the

pigs housed above it, due to the release of ammonia and other

noxious gases. Smell has also been a problem when application

to land near housing has been necessary. Digest-it reduces smell

significantly, and also helps to keep the slurry in a homogenous

liquid state, reducing or eliminating the need for agitation, and

making injection easier.

Digest-it is supplied as a liquid which Paul dilutes and pours

into the slats from a watering-can once a week. So far the

analysis has shown a really worthwhile improvement, says Paul,

and with fertiliser costs increasing, every little helps.

PIG SLURRY ANALYSIS

Analysis date: 03/02/12 07/06/12 Difference

Sample No.: 244 296 -

Sample ID: Pre-

Treated

Post-

Treated

-

Total Nitrogen % 0.600 0.836 +39%

Total Phosphate % 0.125 0.054 -57%

Total Potash % 0.404 0.688 +70%

Slurry Fertiliser Value /m

3

5.87 8.53 +45%

Digest-it Input Cost /m

3

--- 0.36 ---

Net Benefit +5.87 +8.17 +2.30

(+48%)

*Slurry Fertiliser Value is based on the following fertiliser unit prices,

Nitrogen - 0.96, Phosphate - 0.70, Potash - 0.70.

Digest-it is priced at 8.00 per litre, with an application rate of 1 litre per

22m3 of slurry.

July - August 2014 | 29 GRAIN

&

FEED MILLING TECHNOLOGY

EXCELLENCE IN YEAST

EXCELLENT IN FEED

REAL

BREWERS

YEAST

Made in Germ

a

n

y

M

a

d

e

i n

G

e

r

m

a

n

y

M

a

d

e i n G e r m a n y M

a d

e

i n

G

e

r

m

a

n

y

M

a

d

e

in

G

e

rm

any

Biolex MB40

Leiber GmbH

Hafenstrae 24

49565 Bramsche

Germany

Tel. +49 (0)5461 9303-0

Fax +49 (0)5461 9303-29

www.leibergmbh.de

info@leibergmbh.de

acts prebiotic

for immunity & resistance

optimizes digestion

processes

Hall 14 Stand F28

11. 14. November

Produktanzeige Biolex 90 x 270 Grain & Feed_EuroTier.indd 1 11.07.14 11:58

F

T

he British pig industry is small in sow

numbers but large in global terms

due to the widespread export and

influence of UK pig genetics. Furthermore,

there are several essential features of the

industry:

Specialised and highly professional

Market-focused

Quality driven with the highest

standards of welfare and safety

Integrated quality assurance

Whole supply chain starting with

advanced genetics.

Much of the excellent performance of

UK pigs comes from the genetic potential

supplied with the advanced genetics. British

breeders are proud of their achievements in

continuing to maintain high levels of genetic

progress with very little evidence of any

plateau effect.

A recent publication reported that the

achieved commercial value of this genetic

progress in the UK was US$19.5 million per

year, while current forecasts suggest that

future progress could be worth US$30 mil-

lion per year.

Among the main techniques employed

by British geneticists and breeders to achieve

these high levels of genetic progress have

been:

40 years of focussed within line

selection

Initially emphasis on growth and carcase

Now increasing emphasis on

reproductive performance

Maximising hybrid vigour

Different sire and dam line selection

objectives

Accurate performance testing

Advanced Best Linear Unbiased

Prediction (BLUP)

Sophisticated selection indices

Intensive selection on commercial

rations

Rapid uptake of new technologies,

including biotechnology

Excellent genetic progress

The results of this strategy have been

excellent genetic progress across a range of

important economic traits.

As a direct result, the British pig is

proving itself consistently superior in

the international market place in inde-

pendent comparisons. Recent examples

of international success are outlined

below:

Added value

One of the main tools used in the suc-

cessful superior breeding of British pigs has

been the use of advanced BLUP, combining

trait EBVs into sophisticated selection indices.

These indices utilise genetic parameters,

population data and industry economic val-

ues.

The latter are very important as they

allow the optimum ranking and weighting of

traits. Brief details on the values are shown

in Appendix 1. They are:

Value of 0.1 FCR = US$1.73

Value of growth (1 day) = US$0.426

Value of 1 mm P2 Backfat = US$1.84

Value of one extra pig = US$51.59

Averaged across all the presented results,

the added value of British sows is US$214

per year. With annual production of 22.5

pigs sold per year, the total added value per

sow is a staggering US$374!

Finally, as well as excellent performance,

data from the IRTA (Spain) Central Test

programme also show significant advantages

to UK pigs in conformation across a range of

important structural traits:

World leader

Results from independent international

comparisons are showing superior perfor-

mance over British global competitors.

The added value of these benefits is

highly significant at more than US$200

per sow per year and over US$7 per pig

produced. These combine to give a margin

of some US$375 for a breeder/finisher

using British genes compared with other

breeding stock.

Growth

Metabolic body weight = LiveWt0.75

70kg pig has M body wt = 700.75 = 24.2

Maintenance need per kg M body wt =

0.48MJ DE/day

Maintenance feed requirement = 24.2 x

0.48 = 11.61 MJ/day

At diet of 13.5 MJ/DE = 0.86kg/day

Feed cost saving = 0.86 x US$0.216 =

US$0.186

Fixed Costs

Typical fixed costs to 105kg = US$43

From this it is possible to estimate the

saving per day

A 180 day lifetime gives a fixed cost per

day = US$0.24

Add the cost savings from faster growth

= US$0.186

Value of growth (1 day) = US$0.426

Acknowledgements

With thanks to the British Pig Association

and UPB for access to some of the data

presented.

The added value of British pig

genetics and feed converstion

by Dr Rex Walters, International Genetics Consultant

Appendix 1:

Current UK economic values of key traits

Feed Conversion

Weight gain: 25 to 105kg = 80kg

0.1 FCR saves 80 x 0.1kg of feed = 8kg

Feed cost per tonne = US$216

Feed cost per kg = US$0.216

Feed saving = US$0.216 x 8 = US$1.73

Value of 0.1 FCR = US$1.73

British Others Advantage

General

conformation

7.85 7.74 +0.11

Head, neck, colour,

skin

8.23 7.83 +0.40

Back, loin, thorax 8.14 8.03 +0.09

Ham 8.06 7.91 +0.15

Legs 7.74 7.53 +0.21

Reproductive

organs

8.39 8.13 +0.26

Figure 2: Grower/finisher performance - Terminal

sire trials in Germany. Trials in Saxony compared

four terminal sire genotypes (British, German

Landrace, German Large White and German

Pietrain) on a Field performance test

Age Weight Growth

Fat

British 173 120.3 698 8.8

Landrace 182 123.9 681 12.0

Large White 185 127.4 689 11.9

Pietrain 204 123.9 609 8.5

Average of three measurements (mm)

(Source: SSZV, Germany)

Figure 1: Sow performance Litters and

weaned performance (international review)

Litters/sow Weaned/

lifetime

Britain 5.4 52.8

Netherlands 4.6 39.3

France 4.2 37.6

US 4.2 36.8

(Source: Gill)

FEED FOCUS

PIGS

30 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

T

he British pig industry is small in sow

numbers but large in global terms

due to the widespread export and

influence of UK pig genetics. Furthermore,

there are several essential features of the

industry:

Specialised and highly professional

Market-focused

Quality driven with the highest

standards of welfare and safety

Integrated quality assurance

Whole supply chain starting with

advanced genetics.

Much of the excellent performance of

UK pigs comes from the genetic potential

supplied with the advanced genetics. British

breeders are proud of their achievements in

continuing to maintain high levels of genetic

progress with very little evidence of any

plateau effect.

A recent publication reported that the

achieved commercial value of this genetic

progress in the UK was US$19.5 million per

year, while current forecasts suggest that

future progress could be worth US$30 mil-

lion per year.

Among the main techniques employed

by British geneticists and breeders to achieve

these high levels of genetic progress have

been:

40 years of focussed within line

selection

Initially emphasis on growth and carcase

Now increasing emphasis on

reproductive performance

Maximising hybrid vigour

Different sire and dam line selection

objectives

Accurate performance testing

Advanced Best Linear Unbiased

Prediction (BLUP)

Sophisticated selection indices

Intensive selection on commercial

rations

Rapid uptake of new technologies,

including biotechnology

Excellent genetic progress

The results of this strategy have been

excellent genetic progress across a range of

important economic traits.

As a direct result, the British pig is

proving itself consistently superior in

the international market place in inde-

pendent comparisons. Recent examples

of international success are outlined

below:

Added value

One of the main tools used in the suc-

cessful superior breeding of British pigs has

been the use of advanced BLUP, combining

trait EBVs into sophisticated selection indices.

These indices utilise genetic parameters,

population data and industry economic val-

ues.

The latter are very important as they

allow the optimum ranking and weighting of

traits. Brief details on the values are shown

in Appendix 1. They are:

Value of 0.1 FCR = US$1.73

Value of growth (1 day) = US$0.426

Value of 1 mm P2 Backfat = US$1.84

Value of one extra pig = US$51.59

Averaged across all the presented results,

the added value of British sows is US$214

per year. With annual production of 22.5

pigs sold per year, the total added value per

sow is a staggering US$374!

Finally, as well as excellent performance,

data from the IRTA (Spain) Central Test

programme also show significant advantages

to UK pigs in conformation across a range of

important structural traits:

World leader

Results from independent international

comparisons are showing superior perfor-

mance over British global competitors.

The added value of these benefits is

highly significant at more than US$200

per sow per year and over US$7 per pig

produced. These combine to give a margin

of some US$375 for a breeder/finisher

using British genes compared with other

breeding stock.

Growth

Metabolic body weight = LiveWt0.75

70kg pig has M body wt = 700.75 = 24.2

Maintenance need per kg M body wt =

0.48MJ DE/day

Maintenance feed requirement = 24.2 x

0.48 = 11.61 MJ/day

At diet of 13.5 MJ/DE = 0.86kg/day

Feed cost saving = 0.86 x US$0.216 =

US$0.186

Fixed Costs

Typical fixed costs to 105kg = US$43

From this it is possible to estimate the

saving per day

A 180 day lifetime gives a fixed cost per

day = US$0.24

Add the cost savings from faster growth

= US$0.186

Value of growth (1 day) = US$0.426

Acknowledgements

With thanks to the British Pig Association

and UPB for access to some of the data

presented.

The added value of British pig

genetics and feed converstion

by Dr Rex Walters, International Genetics Consultant

Appendix 1:

Current UK economic values of key traits

Feed Conversion

Weight gain: 25 to 105kg = 80kg

0.1 FCR saves 80 x 0.1kg of feed = 8kg

Feed cost per tonne = US$216

Feed cost per kg = US$0.216

Feed saving = US$0.216 x 8 = US$1.73

Value of 0.1 FCR = US$1.73

British Others Advantage

General

conformation

7.85 7.74 +0.11

Head, neck, colour,

skin

8.23 7.83 +0.40

Back, loin, thorax 8.14 8.03 +0.09

Ham 8.06 7.91 +0.15

Legs 7.74 7.53 +0.21

Reproductive

organs

8.39 8.13 +0.26

Figure 2: Grower/finisher performance - Terminal

sire trials in Germany. Trials in Saxony compared

four terminal sire genotypes (British, German

Landrace, German Large White and German

Pietrain) on a Field performance test

Age Weight Growth

Fat

British 173 120.3 698 8.8

Landrace 182 123.9 681 12.0

Large White 185 127.4 689 11.9

Pietrain 204 123.9 609 8.5

Average of three measurements (mm)

(Source: SSZV, Germany)

Figure 1: Sow performance Litters and

weaned performance (international review)

Litters/sow Weaned/

lifetime

Britain 5.4 52.8

Netherlands 4.6 39.3

France 4.2 37.6

US 4.2 36.8

(Source: Gill)

FEED FOCUS

PIGS

30 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

July - August 2014 | 31 GRAIN

&

FEED MILLING TECHNOLOGY

Precision Sensors

for inline production

Analog & Digital RF-Solutions

Suitable for solid,

granular and

powdered materials

High speed

measurement

Non-nuclear

technology

www.work-microwave.de

Premium Quality

Foods

Sensor

F

FEED FOCUS

P

rotease enzymes, an important factor

in protein digestion, hydrolyze the

proteins found in animal feeds and

break them down into more useable

peptides which are short chains of amino

acids.

Endogenous proteases are naturally pro-

duced in the intestine.

The addition of a highly efficient exog-

enous protease to the feed improves the

digestibility of dietary protein.

Consequently, the feed cost is reduced

by allowing lower crude protein (CP) and

digestible amino acids (AAs) inclusion levels

in feed formulation. The levels of CP and

digestible AAs in the formu-

lation can be effectively low-

ered by up to 10 percent,

increasing the use of alterna-

tive feedstuffs in substitution

to soybean meal; therefore

reducing the risk of intes-

tinal disorders caused by

protein fermentation is also

bringing significant economic

benefits.

Recent research

Recent research with

poultry and swine has

shown that diets supple-

mented with a protease

enzyme support gut health

and optimise animal per-

formance as compared to

un-supplemented diets.

This was explained by the

effect the enzyme had on

reducing the anti-nutrition-

al effects of indigestible

proteins in the hindgut of

the animal (see Figure1).

The use of alternative

protein sources in place of

soybean meal (SBM), such

as cottonseed meal (CSM), canola meal,

rapeseed meal, meat and bone meal (MBM)

and corn distillers dried grains with solubles

(DDGS), can reduce the level of quality

protein and AA digestibility.

Supplementing with protease helps those

monogastrics that lack adequate levels of

endogenous enzymes to digest the proteins

in the diet. Supplemental protease also

reduces the flow of undigested protein and

other anti-nutritional factors entering the

large intestine.

Without supplemental protease, indi-

gestible protein serves as a fermentation

substrate in the gut for undesirable bacterial

strains such as Escherichia coli, Clostridium

perfringens, Salmonella and Campylobacter.

These harmful bacteria use the proteins

that are not digested by the animal, as nutri-

ents and can increase in population, shifting

the balance of intestinal microflora against

beneficial strains, a situation typically referred

to as Dysbacteriosis.

If pathogenic bacteria thrive, they can

produce toxic components such as bacte-

riotoxins as well as fermentation metabolites

such as biogenic amines, ammonia and

volatile sulfur compounds. All of which can

be detrimental to performance by favor-

ing oxidative stress, intestinal inflammation

and lesions, increasing both mortality and

morbidity rates.

Gut morphology

Poultry Research

In the gastrointestinal

system, the villi increase sur-

face area for absorption by

the intestinal wall. Measuring

the intestinal villus height-to-

crypt-depth ratio is a stand-

ard parameter for identifying

gut efficiency. Higher ratios

indicate better intesti-

nal function Wang, et al.

(Animal Feed Science and

Technology, 2008).

One study looked at

the effect of a serine-pro-

tease derived from Bacillus

licheniformis PWD-1 fer-

mentation on gut mor-

phology in broilers with

two protein sources.

Researchers fed one

group of broilers SBM as

a digestible protein while a

second group received half

of its protein requirement

from CSM which has a

higher level of indigestible

protein than SBM.

Highly efficient protease

enzymes reduce costs, optimise

performance and sustain optimum

health in Pigs & Poultry

Use of feed protease enzymes offer formulation cost savings by

allowing inferior quality protein alternatives to be used in feed. An

efficient protease improves the digestibility and availability of proteins

so alternative sources can be used when prices of grain and oilseed

meal fluctuate. Recently, poultry and swine research shows evidence

of added value from optimised animal health and performance upon

the use of such proteases in the feed.

by Dr Ajay Bhoyar, Senior Manager, Global Poultry Marketing, Novus

International Inc, USA

PIGS

Figure 1

Figure 2

32 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

FEED FOCUS

P

rotease enzymes, an important factor

in protein digestion, hydrolyze the

proteins found in animal feeds and

break them down into more useable

peptides which are short chains of amino

acids.

Endogenous proteases are naturally pro-

duced in the intestine.

The addition of a highly efficient exog-

enous protease to the feed improves the

digestibility of dietary protein.

Consequently, the feed cost is reduced

by allowing lower crude protein (CP) and

digestible amino acids (AAs) inclusion levels

in feed formulation. The levels of CP and

digestible AAs in the formu-

lation can be effectively low-

ered by up to 10 percent,

increasing the use of alterna-

tive feedstuffs in substitution

to soybean meal; therefore

reducing the risk of intes-

tinal disorders caused by

protein fermentation is also

bringing significant economic

benefits.

Recent research

Recent research with

poultry and swine has

shown that diets supple-

mented with a protease

enzyme support gut health

and optimise animal per-

formance as compared to

un-supplemented diets.

This was explained by the

effect the enzyme had on

reducing the anti-nutrition-

al effects of indigestible

proteins in the hindgut of

the animal (see Figure1).

The use of alternative

protein sources in place of

soybean meal (SBM), such

as cottonseed meal (CSM), canola meal,

rapeseed meal, meat and bone meal (MBM)

and corn distillers dried grains with solubles

(DDGS), can reduce the level of quality

protein and AA digestibility.

Supplementing with protease helps those

monogastrics that lack adequate levels of

endogenous enzymes to digest the proteins

in the diet. Supplemental protease also

reduces the flow of undigested protein and

other anti-nutritional factors entering the

large intestine.

Without supplemental protease, indi-

gestible protein serves as a fermentation

substrate in the gut for undesirable bacterial

strains such as Escherichia coli, Clostridium

perfringens, Salmonella and Campylobacter.

These harmful bacteria use the proteins

that are not digested by the animal, as nutri-

ents and can increase in population, shifting

the balance of intestinal microflora against

beneficial strains, a situation typically referred

to as Dysbacteriosis.

If pathogenic bacteria thrive, they can

produce toxic components such as bacte-

riotoxins as well as fermentation metabolites

such as biogenic amines, ammonia and

volatile sulfur compounds. All of which can

be detrimental to performance by favor-

ing oxidative stress, intestinal inflammation

and lesions, increasing both mortality and

morbidity rates.

Gut morphology

Poultry Research

In the gastrointestinal

system, the villi increase sur-

face area for absorption by

the intestinal wall. Measuring

the intestinal villus height-to-

crypt-depth ratio is a stand-

ard parameter for identifying

gut efficiency. Higher ratios

indicate better intesti-

nal function Wang, et al.

(Animal Feed Science and

Technology, 2008).

One study looked at

the effect of a serine-pro-

tease derived from Bacillus

licheniformis PWD-1 fer-

mentation on gut mor-

phology in broilers with

two protein sources.

Researchers fed one

group of broilers SBM as

a digestible protein while a

second group received half

of its protein requirement

from CSM which has a

higher level of indigestible

protein than SBM.

Highly efficient protease

enzymes reduce costs, optimise

performance and sustain optimum

health in Pigs & Poultry

Use of feed protease enzymes offer formulation cost savings by

allowing inferior quality protein alternatives to be used in feed. An

efficient protease improves the digestibility and availability of proteins

so alternative sources can be used when prices of grain and oilseed

meal fluctuate. Recently, poultry and swine research shows evidence

of added value from optimised animal health and performance upon

the use of such proteases in the feed.

by Dr Ajay Bhoyar, Senior Manager, Global Poultry Marketing, Novus

International Inc, USA

PIGS

Figure 1

Figure 2

32 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

Innovations for a better world.

Success comes with the original

product.

Quality always pays off. Bhler is setting standards in the grain processing industry for more than 150 years. Whether you

grind wheat, corn, rye, oat, buckwheat, soy, or malt grain our processes and equipment are finely tuned to get the most

from your grain. And this kind of process quality quickly pays off. The highest flour yields and best product quality ensure

fast return on investment. www.buhlergroup.com/milling

MDDR_2014_en_de_es.indd 1 07.05.2014 13:36:20

The CSM-fed group had damaged intes-

tinal morphology, suggesting a higher rate

of protein fermentation and more intestinal

challenges. Results showed that adding pro-

tease to the diet significantly increased the

guts efficiency, regardless of the protein

source. The protease overcame the negative

effects of the CSM.

Figure 2 shows the same effects when

even different types of diets were used, in

this case typical corn-SBM diets (Odetallah,

unpublished data 2003).

The photo on the left, from broilers fed

control feed with no protease, shows a dam-

aged intestine with small, misshapen villi and

deeper crypts. The image on the right, from

broilers fed the protease, highlights gut mor-

phology that is more adequate for nutrient

absorption with tall villi exhibiting uniform

height and shorter crypts as compared to

the control.

In a more recent study published in

Worlds Poultry Science Journal (Yan et al;

2012), researchers tested the effect of a

protease supplement in broilers challenged

with a triple-dose coccidiosis vaccine and fed

high-protein diets.

The control group was fed a standard,

22 percent protein diet. The other group

was fed excess protein at a 30 percent level

to specifically provoke a flow of indigestible

protein in the hindgut and measure the

impact of adding protease.

As previously mentioned, fermented pro-

teins can promote the growth of harmful

bacteria in the gut. This study, therefore,

measured C. perfringens levels

in digesta.

When the protein content

of the feed was increased, C.

perfringens levels increased sig-

nificantly (see Figure 3), which

is a well-known risk factor for

necrotic enteritis.

However, levels decreased

when protease was added with

the additional protein. A reduc-

tion effect was experienced in

regard to these pathogenic bac-

teria on the fermented protein,

as compared to the control

group.

Protease enzymes help

overcome several of the nega-

tive effects of protein fermenta-

tion by breaking down proteins

in the feedstuffs.

In addition to helping reduce pathogenic

bacteria, the protease enzyme also reduced

the secretion of acute-phase protein. Levels

of serum a-1-acid glycoprotein were meas-

ured to indicate gut barrier function and

inflammation. Study results show that adding

protease to the high-protein diet significantly

improved the inflammatory status of the

animals.

Gut Morphology Pig Research

With pigs, marked changes in gut struc-

ture and function occur after weaning, such

as villous atrophy and crypt hyperplasia.

These generally are associated with poor

performance as they can cause a temporary

decrease in feed intake, as well as in the

digestive and absorptive capacity of the small

intestine. In comparison, an increase in the

villus-to-crypt ratio is associated with better

nutrient absorption.

Intestinal inflammation cause villus atro-

phy and, thus, reduce nutrient digestibility.

The hypothesis that the immune

response to dietary antigens, some of which

are derived from soy protein such as glycinin

and b-conglycinin, leads to local inflammation

is considered one of the most plausible rea-

sons for the nutritional weaning-associated

morphological changes in the pig intestine.

Pro-inflammatory cytokines produced

Figure 3: Protease Controls the Effect of

Pathogenic Bacteria on Poultry

34 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

Turning ideas into opportunities.

PROGRESSIVE AQUAFEED PROCESSING

Imagine the possibilities

wenger.com

BELGIUM TAIWAN BRASIL CHINA TURKEY INDIA

Leave it to Wenger to redene aquatic feed production

via twin screw extrusion. Based on the proven Wenger

Magnum twin-screw series, the new TX-3000 features

barrel geometries that allow greater capacities than

any other extruder in its class.

The combined features allow increased production

capacity of up to 30 percent compared to previous

and competitive aquatic machines totally

redening cost/benet. The TX-3000 can be equipped

with either the High Intensity Preconditioner (HIP) or

the High-Shear Conditioner (HSC) to match specic

process and capacity requirements, making it ideal

for processing a full range of aquatic feed products.

Contact us now. With new concepts and visionary

leadership, were ready to help you select

the right tools for your extrusion and

drying needs.

Our business in life is not to get ahead of others, but to get ahead of ourselves.

Stewart B. Johnson, Dutch Artist

TX-3000 RAISES THE BAR ON AQUATIC FEED PRODUCTION

Wenger14.TX3000.Ad.210x147.indd 1 4/9/14 7:34 AM

F

The CSM-fed group had damaged intes-

tinal morphology, suggesting a higher rate

of protein fermentation and more intestinal

challenges. Results showed that adding pro-

tease to the diet significantly increased the

guts efficiency, regardless of the protein

source. The protease overcame the negative

effects of the CSM.

Figure 2 shows the same effects when

even different types of diets were used, in

this case typical corn-SBM diets (Odetallah,

unpublished data 2003).

The photo on the left, from broilers fed

control feed with no protease, shows a dam-

aged intestine with small, misshapen villi and

deeper crypts. The image on the right, from

broilers fed the protease, highlights gut mor-

phology that is more adequate for nutrient

absorption with tall villi exhibiting uniform

height and shorter crypts as compared to

the control.

In a more recent study published in

Worlds Poultry Science Journal (Yan et al;

2012), researchers tested the effect of a

protease supplement in broilers challenged

with a triple-dose coccidiosis vaccine and fed

high-protein diets.

The control group was fed a standard,

22 percent protein diet. The other group

was fed excess protein at a 30 percent level

to specifically provoke a flow of indigestible

protein in the hindgut and measure the

impact of adding protease.

As previously mentioned, fermented pro-

teins can promote the growth of harmful

bacteria in the gut. This study, therefore,

measured C. perfringens levels

in digesta.

When the protein content

of the feed was increased, C.

perfringens levels increased sig-

nificantly (see Figure 3), which

is a well-known risk factor for

necrotic enteritis.

However, levels decreased

when protease was added with

the additional protein. A reduc-

tion effect was experienced in

regard to these pathogenic bac-

teria on the fermented protein,

as compared to the control

group.

Protease enzymes help

overcome several of the nega-

tive effects of protein fermenta-

tion by breaking down proteins

in the feedstuffs.

In addition to helping reduce pathogenic

bacteria, the protease enzyme also reduced

the secretion of acute-phase protein. Levels

of serum a-1-acid glycoprotein were meas-

ured to indicate gut barrier function and

inflammation. Study results show that adding

protease to the high-protein diet significantly

improved the inflammatory status of the

animals.

Gut Morphology Pig Research

With pigs, marked changes in gut struc-

ture and function occur after weaning, such

as villous atrophy and crypt hyperplasia.

These generally are associated with poor

performance as they can cause a temporary

decrease in feed intake, as well as in the

digestive and absorptive capacity of the small

intestine. In comparison, an increase in the

villus-to-crypt ratio is associated with better

nutrient absorption.

Intestinal inflammation cause villus atro-

phy and, thus, reduce nutrient digestibility.

The hypothesis that the immune

response to dietary antigens, some of which

are derived from soy protein such as glycinin

and b-conglycinin, leads to local inflammation

is considered one of the most plausible rea-

sons for the nutritional weaning-associated

morphological changes in the pig intestine.

Pro-inflammatory cytokines produced

Figure 3: Protease Controls the Effect of

Pathogenic Bacteria on Poultry

34 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

Turning ideas into opportunities.

PROGRESSIVE AQUAFEED PROCESSING

Imagine the possibilities

wenger.com

BELGIUM TAIWAN BRASIL CHINA TURKEY INDIA

Leave it to Wenger to redene aquatic feed production

via twin screw extrusion. Based on the proven Wenger

Magnum twin-screw series, the new TX-3000 features

barrel geometries that allow greater capacities than

any other extruder in its class.

The combined features allow increased production

capacity of up to 30 percent compared to previous

and competitive aquatic machines totally

redening cost/benet. The TX-3000 can be equipped

with either the High Intensity Preconditioner (HIP) or

the High-Shear Conditioner (HSC) to match specic

process and capacity requirements, making it ideal

for processing a full range of aquatic feed products.

Contact us now. With new concepts and visionary

leadership, were ready to help you select

the right tools for your extrusion and

drying needs.

Our business in life is not to get ahead of others, but to get ahead of ourselves.

Stewart B. Johnson, Dutch Artist

TX-3000 RAISES THE BAR ON AQUATIC FEED PRODUCTION

Wenger14.TX3000.Ad.210x147.indd 1 4/9/14 7:34 AM

F

during the immune response to infection

might alter protein and lipid metabolism and,

as a result, influence growth and efficiency

of gain.

Solving the dilemma of dietary

protein level at weaning

Supplementation with protease enzymes,

likewise, improved weight gain and feed

conversion for weaned pigs but reduced

feed intake. While most proteins in SBM are

easily digested in mature pigs, newly weaned

pigs lack ample endogenous protease activity

so some proteins are especially difficult for

them to digest.

In addition to that, piglets are very sensi-

tive to excess protein fermentation in the

intestines.

The challenge is that piglets have high

requirements for digestible proteins to pro-

mote early growth and muscle deposition.

However, as mentioned earlier, high-pro-

tein diets pose problems due to pathogenic

bacteria causing scours, intestinal disorders

and morbidity. While a common practice is

to lower the protein level in feed to reduce

health problems, this is done at the expense

of growth and performance

Moreover, newly weaned pigs are immu-

nosensitive to the allergenic SBM proteins

glycinin and b-conglycinin which make up

approximately 40 percent and 30 percent

respectively of total soybean globulin pro-

teins.

These proteins cause intestinal inflam-

mation and lead to villus atrophy, disruption

of gut barrier functions and loss of appetite.

They can impair immune function in newly-

weaned pigs. When combined with the

stress of weaning, the weaned pigs nutrient

metabolism and immune function can be

seriously impaired.

In a recent study when a highly efficient

protease was used, weaned piglet perfor-

mance was not affected by crude protein

levels, driven by the inclusion rate of soy-

bean meal.

This result is consistent with other stud-

ies. Adding a protease caused less produc-

tion of ammonia nitrogen, reduced the

E. coli population in the cecum, the total

anaerobes in the colon and the fecal score

in the same way as reducing crude protein,

while sustaining growth performance

Significant results in weaning

pigs

Research conducted by Wang et al.

(Asian-Aust J Anim Sci 2011) to study the

effect of a serine - protease on nutrient uti-

lization, gut health and performance during

the 21 days after weaning. A group of nurs-

Figure 4:

Protease

effect

on piglet

growth

rate and

feed

efficiency

Figure 5:

Protease

Effect on

Piglet Ileum

Morphology

July - August 2014 | 35 GRAIN

&

FEED MILLING TECHNOLOGY

F

ery pigs was fed a control diet

with 19 percent protein with

and without protease and the

other group a high protein diet

(22 percent) with and without

protease.

Study results showed a

significant improvement in

performance when diets were

supplemented with protease

as measured by a marked

improvement in growth and

a 14 percent improvement in

feed efficiency regardless of a

low- or high-protein diet (see

Figure 4).

Part of the reason for that

might be attributed to the

improvement in digestibility.

However, researchers also

found that protease was able

to break down 90 percent of

the allergenic components of

the SBM in vitro, the glycinin

and b-conglycinin, which may

be another reason why the

protease-supplemented piglets

performed better. Using pro-

tease also allows for improved

intestinal functions by support-

ing a better morphology as

evidenced by improved villus-

height-to-crypt-depth ratio in

this study.

Increased crypt depth in

both the jejunum and ileum

and a higher villus-to-crypt ratio

in the ileum were observed in

pigs supplemented with pro-

tease enzyme after weaning.

The improvement in appar-

ent total tract digestibility of

dry matter, gross energy, crude

protein, and phosphorus in

piglets fed diets supplemented

with protease enzymes is likely

a consequence of this improve-

ment in intestinal morphology

(see Figure 5).

Similar to the results in broil-

ers, using protease reduced

protein fermentation and lim-

ited the growth of pathogenic

bacteria in the intestine in this

case, E. coli. Reduction in total

E. coli can result in fewer health

problems such as diarrhea and

the release of pro-inflammatory

cytokines (see Figure 6).

Reduction in harmful

bacteria

In addition to lower num-

bers of E. coli, piglets fed diets

supplemented with protease

enzymes had higher numbers of

lactobacilli in the hindgut. These

results corresponded with less

ammonia nitrogen, less branch

chain volatile fatty acids in the

digesta and a numerically lower

pH value in the gut.

The lower pH might favor

the development of beneficial

bacteria and inhibit the develop-

ment of harmful bacteria. An

abnormally high intestinal pH

would provide a better environ-

ment for E. coli to colonize in

the villi, thus resulting in diar-

rhea.

The reduction in harm-

ful bacteria and the improved

biochemical condition of the

intestine could possibly enhance

the health of the gut ecology

as beneficial bacteria would be

more likely to thrive.

Diarrhea caused by infectious

diseases is a serious problem

in weaning animals and usually

leads to an increased incidence

of mortality.

Research results indicated

that supplementation with pro-

tease enzymes reduced diar-

rhea of piglets as shown by

lower fecal scores. This effect

might be due to lower fer-

mentation of protein, as well

as the hydrolysis of soybean

glycinin and b-conglycinin,

which increased the utilization

of nutrients for growth and

decreased numbers of E. coli.

This can be shown in (see

Figure 7).

When a protease was added

to the diet, there was no differ-

ence in fecal scores between

the low- and high-protein diets,

when typically fecal scores

would be much higher, that is

worse, in a high-protein diet.

Figure 6:

Protease Effect

on the Piglets

Intestinal

Environment

36 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

Decentral

including

Innovations for modern sh

farming and water treatment

New practical approaches

for practical applications

at Forum Aquaculture

Answers to your questions

at the Aquaculture Advisory

Centre

Get-together for the industry

Showcase Growth in Water

Dieses Projekt wird

von der Europischen

Gemeinschaft

kofinanziert.

This project is

being co-nanced

by the European

Community

The worlds leading trade fair for animal production

11 14 November 2014

Hanover, Germany

Fish & More

Marketplace for Aquaculture

www.eurotier.com/aquaculture

Hotline: +49 69 24788-265

E-Mail: expo@DLG.org

RZ_105x297_Anzeigen_Fisch ET_EN.indd 1 03.07.14 14:45

F

scalping and sieving

Sorting by length, using an

indented cylinder that can

pick up either the seed or

contaminant, depending on

the crop type

Separation by weight, using a

gravity table. The seeds pass

over an inclined, oscillating

mesh deck with a fan that

blows air up through the seed

Other cleanup processes

include colour sorting, spiral sepa-

ration and washing.

Following cleanup, the seeds

are dried to less than seven per-

cent moisture content in drying

bins, and then delivered to the

pelletiser by a V-bin.

Rotary treater produces

pellets

The pelletiser mixes seeds with

gypsum-based powder and a glue

binder (as noted earlier), forming

pellets, which are easier to plant

than single seeds. The machine

can also coat the seed with a film

containing colourant, fertiliser, fun-

gicide or a pesticide, says Pearson.

Seeds are weighed and then

discharged into the rotary treater,

while gypsum powder is delivered

by the flexible screw conveyors at

a rate of 3.5kg/min.

Following the rotary treatment,

seeds are dried and graded, then

packaged for sale in woven poly-

propylene bags, plastic pails, cans

and foil packages.

Seeds are sold by seed count

per kilogram in packages that

range from about 15kg for the

bags, down to a few grams in the

foil packages.

The company has installed

a similar Flexicon system in its

New Zealand sales warehouse in

Pukekohe.

MORE INFORMATION:

Flexicon Europe Ltd

182 John Wilson Business Park

Harvey Drive

Whitstable, Kent CT5 3RB

Tel: +44 1227 374710

Email: sales@flexicon.co.uk

Website: www.flexicon.co.uk

Website: www.southpacificseeds.com.au

July - August 2014 | 13 GRAIN

&

FEED MILLING TECHNOLOGY

www.hydronix.com

enquiries@hydronix.com

Hydronix sensors include:

Digital technology with precise linear output

Wide moisture measurement range

Suitable for chutes, silos, mixers or conveyors

Choice of measurement modes

Not affected by dust or colour

Different installation options

Temperature stable

Hydro-Mix VII

The Hydro-Probe XT has been specically designed to

measure moisture in organic materials, typically being

installed in or underneath silos or in the material on a

conveyor.

The Hydro-Mix VII is a ush mounted sensor that is

ideally suited to installation in mixers, augers or the inlet /

outlet of grain dryers.

Both sensors offer a choice of digital measurement

modes enabling the producer to select the best option for

the material being measured.

Hydro-Probe XT

Hydronix digital, microwave moisture sensors are

designed and manufactured in the UK and provide

accurate and cost effective moisture measurement and

control in feed meals and pellets, grain, cereal and pulses.

Hydronix Moisture Sensors

Save You Money

GFMT half page vertical 90 x 270 plus 3mm bleed not left.indd 1 13/01/2014 10:00:18

F

ery pigs was fed a control diet

with 19 percent protein with

and without protease and the

other group a high protein diet

(22 percent) with and without

protease.

Study results showed a

significant improvement in

performance when diets were

supplemented with protease

as measured by a marked

improvement in growth and

a 14 percent improvement in

feed efficiency regardless of a

low- or high-protein diet (see

Figure 4).

Part of the reason for that

might be attributed to the

improvement in digestibility.

However, researchers also

found that protease was able

to break down 90 percent of

the allergenic components of

the SBM in vitro, the glycinin

and b-conglycinin, which may

be another reason why the

protease-supplemented piglets

performed better. Using pro-

tease also allows for improved

intestinal functions by support-

ing a better morphology as

evidenced by improved villus-

height-to-crypt-depth ratio in

this study.

Increased crypt depth in

both the jejunum and ileum

and a higher villus-to-crypt ratio

in the ileum were observed in

pigs supplemented with pro-

tease enzyme after weaning.

The improvement in appar-

ent total tract digestibility of

dry matter, gross energy, crude

protein, and phosphorus in

piglets fed diets supplemented

with protease enzymes is likely

a consequence of this improve-

ment in intestinal morphology

(see Figure 5).

Similar to the results in broil-

ers, using protease reduced

protein fermentation and lim-

ited the growth of pathogenic

bacteria in the intestine in this

case, E. coli. Reduction in total

E. coli can result in fewer health

problems such as diarrhea and

the release of pro-inflammatory

cytokines (see Figure 6).

Reduction in harmful

bacteria

In addition to lower num-

bers of E. coli, piglets fed diets

supplemented with protease

enzymes had higher numbers of

lactobacilli in the hindgut. These

results corresponded with less

ammonia nitrogen, less branch

chain volatile fatty acids in the

digesta and a numerically lower

pH value in the gut.

The lower pH might favor

the development of beneficial

bacteria and inhibit the develop-

ment of harmful bacteria. An

abnormally high intestinal pH

would provide a better environ-

ment for E. coli to colonize in

the villi, thus resulting in diar-

rhea.

The reduction in harm-

ful bacteria and the improved

biochemical condition of the

intestine could possibly enhance

the health of the gut ecology

as beneficial bacteria would be

more likely to thrive.

Diarrhea caused by infectious

diseases is a serious problem

in weaning animals and usually

leads to an increased incidence

of mortality.

Research results indicated

that supplementation with pro-

tease enzymes reduced diar-

rhea of piglets as shown by

lower fecal scores. This effect

might be due to lower fer-

mentation of protein, as well

as the hydrolysis of soybean

glycinin and b-conglycinin,

which increased the utilization

of nutrients for growth and

decreased numbers of E. coli.

This can be shown in (see

Figure 7).

When a protease was added

to the diet, there was no differ-

ence in fecal scores between

the low- and high-protein diets,

when typically fecal scores

would be much higher, that is

worse, in a high-protein diet.

Figure 6:

Protease Effect

on the Piglets

Intestinal

Environment

36 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

Decentral

including

Innovations for modern sh

farming and water treatment

New practical approaches

for practical applications

at Forum Aquaculture

Answers to your questions

at the Aquaculture Advisory

Centre

Get-together for the industry

Showcase Growth in Water

Dieses Projekt wird

von der Europischen

Gemeinschaft

kofinanziert.

This project is

being co-nanced

by the European

Community

The worlds leading trade fair for animal production

11 14 November 2014

Hanover, Germany

Fish & More

Marketplace for Aquaculture

www.eurotier.com/aquaculture

Hotline: +49 69 24788-265

E-Mail: expo@DLG.org

RZ_105x297_Anzeigen_Fisch ET_EN.indd 1 03.07.14 14:45

F

Animal feed

trials at HGCA

by Tom Blacker, from a visit to

Cereals UK

The UKs Home Grown Cereals Authority

gave an exclusive presentation to

Grain and Feed Milling Technology

about its new steps in the world of

animal feed. Usually researching and

providing essential services in the wheat

and cereals areas, animal feed is a

new sector it is entering into. GFMTs

Tom Blacker spoke exclusively to Dr

Jos Houdijk, Reader in Animal Nutrition

and Health at Scotlands Rural College,

about this development.

P

rocessing grain in a feedmill requires

a lot of quantity. Companies such as

Cargill would tell us to come back with

an amount as large as 500 tonnes to process

as a minimum, the man from HGCA told me.

He found a small pilot plant in France,

working with quantities between 100 to 300kg.

We packed up 12 batches of variety spe-

cific whole seed grains on a ship to Paris and

Bordeaux and they will be processed and sent

back to us, says Dr Jos Houdijk, Reader in Animal

Nutrition and Health at Scotlands Rural College.

We are now in the process of charac-

terising their chemistry and putting them

through [feeding] chickens and pigs for the

research work.

In the end, what we are trying to achieve

is to say to levy payers that different varieties

of rapeseeds may have a different feeding

value when it comes to the effect on a pig

or chicken.

It is going to be a long process to

improve the varieties and improve the nutri-

tional qualities, even from a mix of varieties.

Nevertheless, if for arguments sake we sup-

pose that the range of varieties are split by

half: a good side and a bad side, and if the

bad ones can be phased out, quicker than

the good ones, then by definition, it should

go up in quality: this is what we are trying to

achieve, he added.

HGCA hopes to get the first results out

in the open by the end of 2014.

It will not be in time for drilling seeds

this year but hopefully for next years drill-

ing. Growth trials will follow when HGCA

understands the effect of grain variety on

digestible energy and standardized ileal

digestible amino acid levels.

Grower pigs may expect 7.5 percent of

their feed to be formed by these varieties

and older pigs at 10 to 12 percent.

In poultry, the level will be at about five

percent.

This new type of formulation will mean

HGCA can go higher in information and

advice on using rapeseed for two reasons:

first, the information it does have is 10 to

15 years old, the new information will mean

that feed formulations can go higher in the

amounts of these varieties used; second, a

country like Canada is using much higher

levels of rapeseed meals with pigs without

any side effects in production.

Therefore, the potential must be there

for the UK, HGCA extrapolates.

In Canada they use more current data

than us, in feed formulations based on stand-

ardised ileal digestible amino acids and net

energy levels. Here, we use that on values from

books that do not tell us information about

these varieties, which are the differences.

The effects on the animals should hope-

fully be better digestibility of proteins from

one variety compared to another. If we know

the digestibility of protein and other minor

assets in the protein its better. We can then

recommend using that variety in feed formu-

lations. This also means using lower amounts

of the other varieties in the feed matrix when

comparing varieties with soy, he says.

Benefits will include the feed industry

being more actively able to accordingly

formulate diets to requirements.

We can make better use of the differ-

ences between varieties. In the past, it was

not possible.

We will have a lot of data at the end of

this year that will hopefully be published in

papers and on the HGCA website, he says.

July - August 2014 | 37 GRAIN

&

FEED MILLING TECHNOLOGY

2

4

/

7 P

r

o

t

e

c

t

io

n

Watchdog Wrap advert.(paths).indd 1 27/03/2014 11:38

F

Controlled

Experiments

Provide

Conclusive

Evidence

Spray-dried porcine plasma

is a safe ingredient - and is

not a source of Infective PED

Virus

Research Report by the

North American Spray Dried

Blood and Plasma Producers

Association (NASDBPP)

P

orcine Epidemic Diarrhea virus (PEDv)

is difficult to control and causes high

death loss in suckling pigs less than two

weeks old, resulting in significant financial

loss to all sectors of the swine industry.

PEDv spreads quickly and easily.

The primary route of infection is through

direct contact with infected pigs or from the

manure of infected pigs. Other routes of

infection responsible for spreading the virus

may be contaminated transport vehicles,

farm equipment and farm workers and

visitors.

Industry leaders are actively discussing

and reviewing data concerning the role of

feed and feed ingredients in the spread of

PEDv. Speculation that PEDv is spread by

feed has led to implementation of costly bio-

security programs, often with little controlled

research or data supporting the necessity or

effectiveness of the program.

The first report of PEDv in Ontario,

Canada, and the subsequent investigation

resulted in the belief that nursery feed con-

taining porcine plasma may be the source of

PEDv infections.

The CFIA reported infective virus was

detected in samples of porcine plasma but

infective virus could not be detected in the

feed containing the porcine plasma.

Even with this conflicting data, many

industry professionals concluded spray-dried

porcine plasma is spreading the disease.

In addition, and despite the long history

of indisputable performance benefits, some

veterinarians have recommended removing

spray-dried porcine plasma and in some

cases all porcine-based ingredients from feed

for swine.

Epidemiology is a powerful scientific tool

that can be used to identify associations of

exposure to health outcomes. Epidemiologic

observation allows scientists to form a

hypothesis and then the hypothesis can be

tested in controlled experiments

Testing the hypothesis

Independently, NASDBPP and FDA con-

ducted controlled experiments to test the

hypothesis that spray-dried porcine plasma

may contain infective PEDv. The results of

these experiments support the conclusion

that spray-dried porcine plasma is a safe feed

ingredient.

The manufacturing process under indus-

try standards inactivates PEDv.

However, like any feed ingredient, post-

processing contamination is a constant risk

and may be the cause of the infective PEDv

found on porcine plasma as reported by

the CFIA.

Hypothesis: If PCR+ spray-dried porcine

plasma contains infective PEDv and is a vec-

tor spreading PED:

1: Spray drying inactivated PEDv

2: Retained plasma samples subjected to

bioassay studies by FDA and NASDBPP

were not infective for PEDv

3: Two independent studies using 21-day-

old weaned pigs fed five percent PEDv

PCR+ plasma in a meal diet for 21 or

28 days post-weaning did not infect pigs

with PEDv

4: PEDv inoculated on spray-dried plasma

did not survive by:

7 days stored at 71F (22C)

14 days stored at 54F (12C)

21 days stored at 39F (4C)

5: Millions of pigs in Brazil and western

Canada fed PEDv PCR+ porcine

plasma imported from the US since last

summer have not developed PEDv

Conclusion

Experimental results show that PCR+

spray-dried porcine plasma does not contain

infective PEDv. Infective PEDv reported by

CFIA on samples of spray-dried porcine

plasma collected from the field is likely the

result of post-processing contamination.

Spray-dried porcine plasma investigated

by CFIA did not contain infective PEDv

when it left the plant. Post-processing con-

tamination may have resulted in the detec-

tion of infective PEDv in the samples col-

lected by CFIA.

Less ammonia

produced

An important change in the

intestinal ecology of piglets fed

protease enzymes was that

less ammonia was produced

in the gut compared with pig-

lets fed unsupplemented diets.

Excessive ammonia nega-

tively affects the growth and

differentiation of intestinal epi-

thelial cells, leads to a higher

pH value, and increases the

incidence of diarrhea.

In addition, a reduction in

branched chain volatile fatty

acid is consistent with pro-

tease enzymes supplemen-

tation increasing the apparent total tract

digestibility of crude protein, which would

result in less protein being fermented in

the gut.

Still, however, the relationship between

epithelial barrier function and villous atrophy

at weaning and in young animals is not com-

pletely understood.

A compromise in epithelial barrier func-

tion possibly increases paracellular perme-

ability. With increased paracellular perme-

ability, toxins, allergenic compounds or

bacteria may enter systemic tissues, resulting

in inflammatory or immunologic responses.

Benefits to health

While the main reason for including

enzymes in poultry and swine diets has been

to reduce ration costs, supplementing the

feed with a highly efficient serine-protease

may also optimize health and

performance, adding even

more value for producers.

Not all the proteases are

the same.

To maximise the effect on

formulation cost, gut health and

dietary anti-nutritional factors, it

is important to use a protease

with a broad range of activity,

which allows diversifying the

source of proteins used in the

diet.

Moreover, a suitable pro-

tease must have a high speed of

hydrolysis of indigestible proteins

so the flow of protein entering

the hindgut is minimized.

On a commercial basis, Novus supports

health and performance with CIBENZA

DP100 which gathers these characteristics

and improves the protein digestibility in

feeds over the typical industry averages

by as much as 10 percent. This aggres-

sive, heat-stable, broad spectrum protease

complements the monogastrics endogenous

enzymes to hydrolyze less digestible protein

in animal feeds.

Figure 7: Protease Maintains Fecal Score in High Protein

Diets for Pigs

38 | July - August 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

Controlled

Experiments

Provide

Conclusive

Evidence

Spray-dried porcine plasma

is a safe ingredient - and is

not a source of Infective PED

Virus

Research Report by the

North American Spray Dried

Blood and Plasma Producers

Association (NASDBPP)

P

orcine Epidemic Diarrhea virus (PEDv)

is difficult to control and causes high

death loss in suckling pigs less than two

weeks old, resulting in significant financial