Professional Documents

Culture Documents

Use Manual: Yin Huan Apparatus Commercial Company

Uploaded by

Lye Yp0 ratings0% found this document useful (0 votes)

99 views12 pages1. The document provides information about various flow meter products from Yu Yao Yin Huan Flow Apparatus Company Ltd, including rotor flow meters of the LZB, LZJ, and LZT series.

2. It describes the structure, measuring principles, and installation diagrams of the company's common type rotor flow meters and anticorrosion flow meters.

3. Key details are provided on product specifications, materials, quality standards, and the company's contact information for orders and customer service.

Original Description:

eew

Original Title

Float Flow Meter

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document provides information about various flow meter products from Yu Yao Yin Huan Flow Apparatus Company Ltd, including rotor flow meters of the LZB, LZJ, and LZT series.

2. It describes the structure, measuring principles, and installation diagrams of the company's common type rotor flow meters and anticorrosion flow meters.

3. Key details are provided on product specifications, materials, quality standards, and the company's contact information for orders and customer service.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

99 views12 pagesUse Manual: Yin Huan Apparatus Commercial Company

Uploaded by

Lye Yp1. The document provides information about various flow meter products from Yu Yao Yin Huan Flow Apparatus Company Ltd, including rotor flow meters of the LZB, LZJ, and LZT series.

2. It describes the structure, measuring principles, and installation diagrams of the company's common type rotor flow meters and anticorrosion flow meters.

3. Key details are provided on product specifications, materials, quality standards, and the company's contact information for orders and customer service.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Use manual

LZB LZJ LZT series

The common type rotor flow meter anticorrosion flow meter

the whol e stai nl ess stel es rotor fl ow meter pl asti c tube rotor

flow meter

These products carry out JB/T9255-1999 standards

These products have already passed ISO9001 international

quality system

MC

Zhe zhi 02810103

YuYao YinHuan flow apparatus company ltd

Zhe jiang YuYao flow qpparatus factory

Address: Yu Yao northeast street industry zone cai hong road No1

Code:315400

Telephone:0574-62689088

(sale fax) 0574-62689099 62689077

Open on account :Yu Yao industry and commerce bank

Accoun:3901310009102001630

The Ningbo economic technical zone

Yin huan apparatus commercial company

The guide to the order

Before assembling using and maintaining , must read pressnt

the guide to the order.

In order to cooperating your work , avoiding unnecessary

waste,in time ordering your flowmeters and your accessories

certainly distinguish model and standards (liquid,gas),especiall y

flow range,and in time selecting must explain illustrate.All of

measuring corrosive media,please,selecting LZB-F series.

All of measuring ketone,ester and amines, please,contact with

our factory.

All of correcting viscosity or ordering model for special medium

must to supply name viscosity density concentration

temperature and working pressure, we gladly willingly design

and make products for you.

Before assembling flow meter draw out supporting materials in

tube.

Yu Yao Yin Huan flow apparatus company ltd has commercial

company i n the Ni ngbo economi c techni cal zone whi ch

undertakes whole business.

1.

2.

3.

4.

5.

6.

1

Your company think what problem does in our products

exist?How to improve it better?

Does Your company also have requests to our products?

Customer information feedback list

1.

2.

2

315400

Yu Yao northeast street industry zone cai hong road No1

Yu Yao yin huan flow apparatus company ltd

Commercial company

One Introduction

The rotor flow meter (call flow meter as follows ) mainly used

f or a chemi cal engi neer i ng, pet r ol eum, l i ght i ndust r y ,

medicine,chemical fertilizer,papermaking,food ,environmental

protection and science research department , which are

convenient to measure non-pulsation and single phase fluid

(liquid and gas).

Anti-corrosive flow meter is mainly used for measuring

the corrosive liquid gas ,for example acid liquid (hydrofluoric

acid excepted),a sodium liquid (sodium of thick hydrogen

oxidizes excepted ), oxidizing liquid , organic liquid and

corrosive gas.

Two Structure and principle

The main measurng component of the flow meter is a

tapered tube,its small end is downward , a its large end is

upward , installing perpendicularly. In the tapered tube there

is a float which can move up and down freely . When the

liquid flows from top to bottom through the tapered tube

between upside and downside of the float creates deffirence

of pressure so the float moves up or down.

When this rising force floating force of float force of

viscosity and the gravity of float is equal , the float is placed

in a equilibrium position .Therefore, the fluind flows through

the flow meter, the float increases height here exists a

certain proportion, postition of float as a measuring quantity.

Reading digital of flow meter canbe read accordingthe

figure 1

Figure 1 reaing diagram of various floats

Our factory produces flow meters which contain LZB

series LZJ seriesand LZT series etc. They mainly are

3 4

40

10

20

Center line

of tanered tube

Reading

position

Reading

position

Reading

position

Reading

position

5

1. outflow mouth

2. upper base

3. upper gland

4. tapered tube

5. otganic glass shell

6. suppotting plate

7. float

8. lower gland

9. lower base

10. inflow mouth

11. Needle valve

Figure 2-2 LZB-4, 6,10 shape diagram

6

comosed of tapered tube float upper base lower base

upper stopping Lower stopping V supporting plate outside

cover and sealed ring etc . Flowmeter for caliber less then

10mm adopts a hose conjunctinons and has a needle valve to

regulate quantity of flow as shown in figutr 2 For the caliber

above 15mm is used flange conjunction (flange conjunction

according to the JB78-59iron casting ,methodrule), thety ?

Structure ard shon in fighre3, shape and junction size are in

tales 1 2 3.

Figure 3-1 is the structure of flowmeter LZB with caliber DN

25 above. Diffeence in structures between DN 15 and DN 25

above is that , in DN 15 there is no guide pol which can make

float to move uo and down calmly and protects the tapered

tube.

The LZT-Tseries have same measuring principle, thery

strutures are shown in the figure4

Figure 2-1 LZB-2, 3 shape diagram

1 instralling diagram of lowre base 6 installing diagram of

lower base

2 joint of hose tube 7 brand

3 float 8 shell

4 tapered tube 9 cross screw

5 support plate 10 cross screw

1

2

3

4

5

6

7

8

26

21

31

26

10

9

LZB-3

2

-

M

6

2

-

M

8

X

1

1

0

1

3

2

1

5

0

model

caliber(mm)

measuring ratio

working pressure(Mpa)

starting pressue(mmHO )

2

accurate grade( %)

-2

2

1:10

1

20

4

0.4 4

0.6 6

1 10

1.6 16

6 60

10 100

16 160

28 250

-2

2

1:10

1

20

4

2.5 25

4 40

6 60

10 100

40 400

60 600

100 1000

160 16000

m

e

a

s

u

r

i

n

g

s

c

o

p

e

liquid

(ml/mim)

gas

(ml/mim)

9

10

11

2

x

1

1

6

E(length X width)

C B A

1

2

3

4

5

6

7

8

Figure 3-1 LZB-15-100 shape size

Connection:hose conjunctions

4,6,10 base material of anti-corrosive flowmeter 1Cr18Ni9Ti

1 .base

2 . Brand

3. Shell

4.tapered tube

5.float

6.gland

7. Supporting plate

8. Screw

9.stopping

10. Bush

Table 1 LZB -4,10 shape installing diagram

Our anti-corrosive flowmnter LZB-F series are mainly composed

of F4 float (polytetraflioroethylene) P4 upper base P4Lower

base upper stopping suppirting front and back shellV sealed

ring and seal diaphragm etc. In the anti-corrosive flowmeters

are used flange conjunctions (flange conjunction according to

the JB78-59iron casting method rule), its schematic diagram of

structure is shown in the figure 3-2 . The shape connection

size is the same as Lzb series . See table 2.

Table 2 LZB LZJ 15-100 shape installing size

Connection: hose conjuctions

1. Base

2. Brand

3. Shell

4.tapered tube

5.float

6. Gland

7. Sealed ring and diaphragm

8. Screw

9. Stopping

10. Bush

Figure 3-2 LZB-15F-100F installing diagram

7 8

9

10

D E

7

8

6

5

4

3

2

1

size(mm)

caliber

(mm)

4

6

10

40x34(front side) 170

170

170 208

208

208

238

238

238

40x34(front side)

40x34(front side)

E A B C D

11

11

11

Caliber

(mm)

15

25

40

50

80

100

Size (mm)

A B C D E

95

115

145

160

185

205

65

85

110

125

150

170

470

470

570

570

570

170

15

25

40

50

80

100

4- 14

4- 14

4- 18

4- 18

4- 18

4- 18

9

10

D E

B

1

2

3

4

5

6

7

8

C

The structure of LZJ-40F, LZJ-50F gas rotor flowmeter is like

figure 3-2 or similar as gifure3-2.The structure of LZB-F

Dn80Dn100 anty-corrosive flowmeter is simliar as figure 3-2,

defference in the structure is that in the float therer is a guide

pole, which makes float to move up and down calmly and

protect the tapered tube.

In the JZB-50F rotor flowmeter , there is another packing.

After opening the Packing , as figure 3-3,at first law down

horizontally and put a float into it , after installingring slowly

put the tapered tube to vertical position, only after that install

tapered tube on the piipe.

Figure 3-3 JZB-50F installing diagram

9 10

In the spare parts, which contect anti-corrosicve flowmeter

and midum, is used anti-corrosive material-fluorine plastice F4,

which have good anti-corrosive quality and very dependable

valid.

1. connection pipe

2. nut

3. 0 type seal ting

4. lower stopping

5. float

6. taperad tube

7. standare scale

8. upper stopping

Figure 4 LZT-15-65S installing diagram

Table 3 LZT-S shape install size

Caliber

(mm)

LZT-15S

Size (mm)

L D D

280

380

435

430

20

32

63

75

45

68

98

122

Suitable piping caliber

LZT-25S

LZT-50S

LZT-65S

DN

15

25

50

65 75

D

d

1

2

3

4

5

6

7

8

1

2

3

When open the packing boxes should carefully examine

them whether any damage or not during the process of

transport. For LZB flow meter with guide pole should take

out supporting filling materials and to check whether the

float can move up and down freely or not.

Flow meter must be installed in the vertical position(Angle

between center or flow meter and plumb line is not more

than five degress), and the right support, and to prevent

any spread of stress.Before installing washed and the

smallest end of the tapered tube always must be set at the

bottom.

In order to replace parts in the process of using in time

installation it should allow sufficient surrounding space.

For maintenance repair replacement of flow meter and

cleaning pipe recommend flow meter installation according

to the figure 5.

1.

2.

3.

4.

11

Three install and use

5.

6.

12

In the upstream of flow meter should be installed a valve,

in the downstream 5-10 times of caliber should be installed

the flow control valve.

To prvernt back stremaing in the pipe or damage due to

action of water cone after the downstream valve should be

installed a one-way valve.

If the measured fluid contains larger particles or dirt ,

should be installed filters on the flow meter.

If the measured mainstream is pulsed, so the float can not

correctly measure flow, in that case upstream valver

should be all opened and set the timer and buffer.

Figure5 bypass pipe install diagram

7.

8.

flew

meter

flew

meter

flew

meter

Yashing

Bypass

tube

Bypass

tube

Bypass

tube

One-

1.

2.

3.

4.

13

Use

In time of using flow meter should slowly open the

upstream control valve. After that adjust flow by control

valve of downstream, and then close flow meter flow

contrlol valve.

In time of suing shoukd avoid the intense changers of

measured liquid pressure.

Read reading of float as shown in the figure1.

If the working diameter of float is injured, should make

calibration again

In time of using flow meter if take place leaking, should

evenly fasten bolts or gland, at this time should avoid

fastening over and break the cone

In time of Rrplacing sealed packing, tapered tube or float

at first carefully evenly removed shell bolts or gland and

then support plate the upper and lower base. In the

proccess do not force too large and to be careful.

If the floater and the tapered tube were polluted should

clean them in time.

6.

7.

5.

8.

9.

14

I f t he st at e of Measur i ng f l ui d( densi t y, t emper at ur e,

pressure,viscosity etc.is not the same as indicated.

Should make temperature of our LZB producdts--- -20 - + 20 .

Calibration again

Suitable

Four value revise of flowmeter

In the using the liquid and its state often is different from

calibration conditions, therefore, customers have to carry

on correction to get correct value of the flow.

In out factory carry out calibration, using water or air in

the standard state:water at 20 , air at 20 ,

1.03X10Pa(760mmHg), therefore , correction all takes int the

standard state.

1. Revise when measuring liquid

Counting flow through flowmeter in the using state:

-----------(1)

(P -P) Py r S

Q =Qy

S

(Pf -PN)Py

In the formula:

Qs----- the actual flow value.

Qn-----reading value of flowmeter

Pf------density of float

Pn-----density of measuring media in the standard state.

PS-----density of measuring liquid.

Revise of measuring gas

(1) Couting flow through flowmeter in the using state for

dry gas:

In the formula:Pn, Tn, pn-------In the standard state abso

lute pressure 1,03X10Pa (760mmHg), absolute tempaerature

(273.15+20)K and density of measuring media (air);

Ps, Ts, psn ------absolute pressure, absolute temperature

and density of measuring gas in the standard state of

measuring gas.

Zsn--------the compression factory of measurig gas in the

standard state.

2.

15

-----------(2)

3.

16

Zs-----the compression factory of measuring gas in Ps, Ts.

(2) Counting flow through flowmeter in the using state for

wet gas:

In the formula; Qsw------actual flow value of wet gaw;

S----- the relative humidity of measuring gas;

Pf-----density of float;

Pds ,pds ------saturated steam pressure and density

measured gas at Ts;

Zsn, Zs-------the compression factory of measuring gas in

the Ps Ts and Ts.

Revise of viscosity

In the using viscosity of measured liquid always is differ

ent from the calibration conditions , therefore.customer s

have to carry on correction to get correct value of viscosity.

Since measuring result is all influenced by the viscosity of

liquid flow and caliber of taperedd tube shape of float

etc., So the factory can hardly provide correct viscosity

coefficient,

Suggest customer oneself carries on calibration.

p -P T Z N s N s

Q =Qy

S

p -P T Z N s sN s s

. .

P T Z

N s s

Q =Q

N SW

p

(P P )T Z D N N sN s s s s

.

+ P

s Ds

p

N

-----------(3)

4.

17

-----------(2)

Value correction example

(1) measured as a liquid:

Suggest that measured media is clean water, indication of

flowmeter is 6m3/h, temperature of inflow mouth is 40 , a

pressure as 0.9 Mpa(9kgf/cm2), material of float as

stainless steel pf = 7900kg/m2, counting actual flow value

through flowmeter.

Soltutin:

Search in the manual:

At 40 pressure 0.9 Mpa (9Kg/cm2) (absolute pressure

1Mpa(10Kgf/cm2) ,therefore, water density ps =992.65kg/m2;

at 20 , absolute pressure 760mmHg (1.013X105Pa), then,

ps=998.303kg/m3.

Actual flow from formula 1 through flowmerer:

18

(2) measured gas as dry gas:

measured gas as a dry gas, indication of flowmeter is 50

m3/h,float material is 1Cr18Ni9Ti, temperature of inflow mouth

is 10 , absolute pressure PS=0.5MPa (5kgf/cm2). Counting

actual flow value throug flowmeter.

Solution: Sdearch density of dry air in the standard state in the

manual: ps=psn=1.2046kg/m3, the compression factory

Zs=0.9990, at 10 ,the comprssion factory Zs =0.9992.

From the formula 2 clounting actual volume flow through

flowmeter in the using state.

3

= 6.02m /h

p p p

( r n ) s

Q =Q

N S

p p p

( r s ) N = 6 7900-992.654 998.303

7900-998.303 992.654

3

= 21.978m /h

Q =Q

N S (p P T Z

N N S S = 50 1.2946 1 (273.15+10) 0.9992

1.2946 5 (273.15+20) 0.9990

(P P T Z

S S N SN

19

(3) measured gas as a wet gas :

Suggest that measured gas is a wet gas, relative humidity at

inflow mouth of flowmeter S=0.7, other conditions are the

same.

Solution : at 10 , absolute pressure 0.5 Mpa (5kg/cm2), then ,

saturated steam pressure Pts=0.0173kgf/cm2, steam Density

pds=0.01282kgf/cm3.

Actual flow of wet air through flow meter from formula 3:

Five the show of error

The show of error of flow meter as below:

In the formula:

Qn-------Value of flow meter;

Qn------actual flow of liquid through flow meter;

Qmax-------measuring limits of flowmeter.

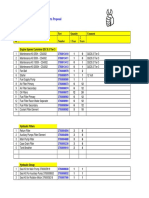

Table 4 technical parameters of rotor flow meter

20

notice:

Legal measuring unit 1kg. Cm2=9.80665X104Pa, for measuring

convenicence is taken 1kgf/cm2 105Pa 0.1MPa.

Model

caliber(mm)

measuring ratio

working pressure(MPa)

starting pressue (mmH0 ) 2

accurate grade ( %)

Measuring

Scope

Liquid

(L/h)

gas

(L/h)

-40

40

1:10

0.6

420

1.5

0.16-1.6

0.25-2.5

4-40

6-60

-50

50

1:10

0.6

160

1.5

0.4-4

0.6-6

1-10(Special)

10-100

16-160

-25

25

1:10

0.6

170

1.5

0.04-0.4

0.06-0.6

0.1-1

1-10

1.6-16

2.5-25

-80

80

1:5

0.4

500

1.5

1-10

1.6-16

7-30(Special)

50-250

80-400

-100

100

1:5

0.4

760

1.5

5-25

8-40

12-60(Special)

120-600

200-1000

Model

caliber(mm)

measuring ratio

working pressure(MPa)

starting pressue (mmH 0) 2

accurate grade ( %)

Measuring

Scope

Liquid

(L/h)

gas

(L/h)

-4

4

1:10

1

20

4

1-10

1.6-16

2.5-25

16-160

25-250

40-400

-6

6

1:10

1

40

2.5

2.5-25

4-40

6-60

40-400

60-600

100-1000

-15

15

1:10

0.6

100

2.5

16-160

25-250

40-400

250-2500

400-4000

600-6000

-10

10

1:10

1

70

2.5

6-60

10-100

16-160

100-1000

160-1600

250-2500

= 50 1.2046

(5-0.7 0.017375) (273.15+20) 0.9990

1.2046

3

= 22.35m/ h

+0.7 0.021282

1.0332 (273.15+10) 0.9992

. .

P T Z

N s s

Q =Q

N SW

p

(P P )T Z D N N sN s s s s

.

+ P s Ds

p

N

Qn-Q

=

100%

Qmax

21

Tbale 5 technical parmeters of Lzb rotor Flow meter

Table 6 Materials

notice:

1. Materials of all flow meter (LZT-Series excepted) are

made of high -borron silicon glass:

2. Material can be changed according to the request of

customers.

3. Material stainless steel of flow meter -1Cr18Ni9Ti.

Services for you

Table 7 Technical parameters of LZT-15-65S rotor

Flow meter

Model

caliber(mm)

measuring

scope(L/h)

liquid

accurate grade( %)

working pressure (Mpa)

LZB-15

15

4-90

2.5

0.6

LZB-25

25

70-700

2.5

0.6

LZB-50

50

450-7000

2.5

0.6

LZB-80

80

7000-30000

2.5

0.4

LZB-2, LZB-3, LZB-4, LZB-6, LZB-10

base stopping float sealflling

brass HP59-1 PTFE

stainless steel

1Cr18Ni9Ti

acid-resisting

alkali rubber

IV-1

LZB-15, LZB-25 , LZB-40

base Lead staff float sealflling

stainless steel

1Cr18Ni9Ti

acid-resisting

alkali rubber

ironinner pad

amino baking

lacquer

stainless steel

1Cr18Ni9Ti

sealflling

stainless steel

1Cr18Ni9Ti

stainless steel

1Cr18Ni9Ti

LZB-15, LZB-25 , LZB-40

base float

acid-resisting

alkali rubber

Ironinner pad

acid-resisting

alkali rubber IV-1

Lead staff

22

ABS ABS ABS AS

tapered tube float connection tube stopping

Model

caliber(mm)

measuring ratio

working pressure(MPa)

accurate grade ( %)

measuring

scope

LZT-15S

15

1:10

0.6

4

0.01-0.1

0.016-0.16

0.025-0.25

0.04-0.4

25

1:10

0.6

2.5

0.1-1

0.16-1.6

0.25-2.5

LST-65S

65

1:10

0.4

2.5

5-25

8-40

12-60

50

1:10

0.4

2.5

0.4-4

0.6-6

1-10

1.6-16

measuring

scope

3

(m /h)

LZT-25S LZT-50S

0.06-0.6

You might also like

- Flow MeterDocument2 pagesFlow MeterisaacalvareztejanoNo ratings yet

- Fluid FrictionDocument18 pagesFluid Frictioncakhoa100% (2)

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- Guided Valves Technical BulletinDocument15 pagesGuided Valves Technical BulletinVladimir VuletinNo ratings yet

- Addis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringDocument10 pagesAddis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringEskiasNo ratings yet

- Orifice Plate - Multi-Holes: DatasheetDocument10 pagesOrifice Plate - Multi-Holes: DatasheetMarcelo PellizzaNo ratings yet

- MAMCE/EIE/EI2303 - Industrial Instrumentation-Ii/Question BankDocument20 pagesMAMCE/EIE/EI2303 - Industrial Instrumentation-Ii/Question Banklakshg11No ratings yet

- Mark V Target Strain Gage Flowmeter Installation, Operation and Maintenance ManualDocument24 pagesMark V Target Strain Gage Flowmeter Installation, Operation and Maintenance Manualابزار دقیقNo ratings yet

- Aalborg EM201302 Rotameter ADocument68 pagesAalborg EM201302 Rotameter AmpicaNo ratings yet

- Valvulas de Control FisherDocument16 pagesValvulas de Control FisherAnonymous GKTRypNo ratings yet

- Sucker Rod PumpingDocument27 pagesSucker Rod Pumpingzezo2011100% (4)

- Reduce Gas Entrainment in Pipe FlowDocument3 pagesReduce Gas Entrainment in Pipe FlowjamestppNo ratings yet

- Control Valve OcrDocument14 pagesControl Valve OcrpathakshashankNo ratings yet

- Fundamentals of Orifice Metering FMCDocument7 pagesFundamentals of Orifice Metering FMCapply19842371No ratings yet

- Orifice Flowmeter Straight RunDocument4 pagesOrifice Flowmeter Straight RunMuhammad ImranNo ratings yet

- Estimate Valve Pressure DropDocument3 pagesEstimate Valve Pressure DropFranklin Santiago Suclla PodestaNo ratings yet

- Pressure Loss in PipeDocument8 pagesPressure Loss in PipesaeidianNo ratings yet

- Types of Steam Flowmeters: Orifice Plates, Turbines & MoreDocument20 pagesTypes of Steam Flowmeters: Orifice Plates, Turbines & MoreLidijaSpaseskaNo ratings yet

- D10 311en Ecodos InstallationDocument2 pagesD10 311en Ecodos Installationantothoppil001No ratings yet

- Visual Flow Indicator Guide from Flow-MonDocument12 pagesVisual Flow Indicator Guide from Flow-Mondhanu_aquaNo ratings yet

- PipeFlowModelLibraryManual PDFDocument132 pagesPipeFlowModelLibraryManual PDFalspeer1905100% (1)

- Measurement Systems: Application and Design by Ernest O. DoebelinDocument17 pagesMeasurement Systems: Application and Design by Ernest O. DoebelinAlhji AhmedNo ratings yet

- Mechanical Instruction ManualDocument16 pagesMechanical Instruction ManualMorarescu AndreiNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- REPORTpp 1Document16 pagesREPORTpp 1gajulavamshikrishna02No ratings yet

- Head Flow MetersDocument27 pagesHead Flow Metersvashu patelNo ratings yet

- Rosemount 1195 Integral Orifice Primary Element: Quick Installation GuideDocument16 pagesRosemount 1195 Integral Orifice Primary Element: Quick Installation GuideJosé Carlos Batista SilvaNo ratings yet

- Clearview ManualDocument11 pagesClearview ManualSaint JossNo ratings yet

- S TL U VCF V-Cone Flow TransducerDocument42 pagesS TL U VCF V-Cone Flow TransducerAnonymous NnclpHRNo ratings yet

- Measurment of Fluid FlowDocument6 pagesMeasurment of Fluid FlowRajivparaj 李瑞杰No ratings yet

- Vivoil Xv3d enDocument6 pagesVivoil Xv3d enturbo_kidNo ratings yet

- Fisher v150Document16 pagesFisher v150Doug LambNo ratings yet

- Three Way Valve Technical OverviewDocument8 pagesThree Way Valve Technical OverviewWalter JosephNo ratings yet

- Re 10223Document26 pagesRe 10223medi38No ratings yet

- Thomson Roundrail 1VC Continuously Supported SpecsheetDocument2 pagesThomson Roundrail 1VC Continuously Supported SpecsheetElectromateNo ratings yet

- Index: Product List SR. NODocument40 pagesIndex: Product List SR. NOch_yustinusNo ratings yet

- Equi - Design DistillationDocument22 pagesEqui - Design Distillationjoker princeNo ratings yet

- 19 102be PDFDocument6 pages19 102be PDFSani PoulouNo ratings yet

- Cement Plug in A WellboreDocument14 pagesCement Plug in A Wellborextroni100% (1)

- VALVULAS - Series2200, NORRISEALDocument8 pagesVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoNo ratings yet

- Brooks Instrument FlowmeterDocument8 pagesBrooks Instrument FlowmeterRicardo VillalongaNo ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- Pipes and Fittings Lab Technical AppendixDocument9 pagesPipes and Fittings Lab Technical AppendixGeorge KouloherasNo ratings yet

- Dunlop Hoses and Fittings CatalogDocument242 pagesDunlop Hoses and Fittings CatalogBrandon Troc50% (4)

- Bypass RotameterDocument6 pagesBypass RotameterNavneet SinghNo ratings yet

- Use ISO 5167 To Find The Orifice Discharge Coefficient For An Orifice Flow MeterDocument10 pagesUse ISO 5167 To Find The Orifice Discharge Coefficient For An Orifice Flow MeterEuler CauchiNo ratings yet

- Large Size Quarter Turn Control Valves Can Improve Safety in PipelinesDocument19 pagesLarge Size Quarter Turn Control Valves Can Improve Safety in PipelinesgpuzoneNo ratings yet

- Flow MeasurementDocument15 pagesFlow MeasurementAhmed KamelNo ratings yet

- Series V100 Ball ValveDocument20 pagesSeries V100 Ball ValvejenniferNo ratings yet

- Rod Pump Ver3-201205Document199 pagesRod Pump Ver3-201205doner72No ratings yet

- Product Range - Variable Area Flow Meters Type 335-350Document40 pagesProduct Range - Variable Area Flow Meters Type 335-350Cornellius Surya AtmadjaNo ratings yet

- Flowmeter Gfdo 6168 4a LowendDocument40 pagesFlowmeter Gfdo 6168 4a LowendIsabel GutiérrezNo ratings yet

- VIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:Document28 pagesVIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:aco1970No ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Document3 pagesFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsNo ratings yet

- Calculate Mass Flow or Volumetric Flow For Any GasDocument2 pagesCalculate Mass Flow or Volumetric Flow For Any Gasvicbalt07No ratings yet

- Cpa6 LDDocument1 pageCpa6 LDLye YpNo ratings yet

- Pharmaceutical Waste Analysis: 1. EPA Wastewater Analysis and StandardsDocument37 pagesPharmaceutical Waste Analysis: 1. EPA Wastewater Analysis and StandardsLye YpNo ratings yet

- BW17V1D24Document5 pagesBW17V1D24Lye YpNo ratings yet

- Aerobic DigesterhDocument10 pagesAerobic DigesterhLye YpNo ratings yet

- 30601Document18 pages30601Lye YpNo ratings yet

- Selecting The Right Speed Reducer For MixersDocument12 pagesSelecting The Right Speed Reducer For MixersLye YpNo ratings yet

- Selecting The Right Speed Reducer For MixersDocument12 pagesSelecting The Right Speed Reducer For MixersLye YpNo ratings yet

- Cells Growth CharacteristicsDocument25 pagesCells Growth CharacteristicsMilo Kai HeeNo ratings yet

- PVCSuction Hose PDFDocument2 pagesPVCSuction Hose PDFLye YpNo ratings yet

- SVI Sludge Volume Index, ML/GDocument2 pagesSVI Sludge Volume Index, ML/GLye YpNo ratings yet

- Pipe Oil SkimmerDocument1 pagePipe Oil SkimmerLye YpNo ratings yet

- Kubota Main MBR BrochureDocument2 pagesKubota Main MBR BrochureLye YpNo ratings yet

- MBR Startup Optimization for Nutrient RemovalDocument17 pagesMBR Startup Optimization for Nutrient RemovalzizitroNo ratings yet

- Calcio HipocloritoDocument5 pagesCalcio Hipocloritoreh-No ratings yet

- Sample of Fit Up InspectionDocument3 pagesSample of Fit Up InspectionLye YpNo ratings yet

- HDPE FittingsFeb2013Document117 pagesHDPE FittingsFeb2013Felicia GlassNo ratings yet

- Spread Sheet 6494282 WorldChem GV GVF Series Datasheet 120dpiDocument4 pagesSpread Sheet 6494282 WorldChem GV GVF Series Datasheet 120dpiLye YpNo ratings yet

- Panel TestDocument2 pagesPanel TestLye YpNo ratings yet

- Ach Bank & Branch Code GuideDocument23 pagesAch Bank & Branch Code GuideLye YpNo ratings yet

- LancyDocument14 pagesLancyLye YpNo ratings yet

- Flange DimensionsDocument24 pagesFlange Dimensionsharoub_nasNo ratings yet

- 475hsbr UsgDocument2 pages475hsbr UsgLye YpNo ratings yet

- SK80 2.0 1000PP Model SignedDocument1 pageSK80 2.0 1000PP Model SignedLye YpNo ratings yet

- BOD TestDocument6 pagesBOD TestLye YpNo ratings yet

- HK Library Guide Small Sewage PlantsDocument29 pagesHK Library Guide Small Sewage PlantsLye YpNo ratings yet

- Appendix L XCG Report July 21 2008Document12 pagesAppendix L XCG Report July 21 2008Lye YpNo ratings yet

- I060619152532preview - CP 5-1998Document6 pagesI060619152532preview - CP 5-1998Lye YpNo ratings yet

- Design Procedure For Liquefaction Mitigation Using Dynamic CompactionDocument7 pagesDesign Procedure For Liquefaction Mitigation Using Dynamic CompactionLivian TeddyNo ratings yet

- Circular Motion, Buoyancy, and DensityDocument13 pagesCircular Motion, Buoyancy, and DensityAshutosh Kumar SinghNo ratings yet

- SolutionDocument3 pagesSolutionMohammed Alryani100% (1)

- g6099 250kw Spec Sheet KohlerDocument8 pagesg6099 250kw Spec Sheet Kohlerwilliam000111No ratings yet

- Pisten Bully 600 Hydraulic TS Guide FR 10039Document90 pagesPisten Bully 600 Hydraulic TS Guide FR 10039Jose Manuel Barroso Pantoja86% (7)

- 300DMonitorOperationManual v15Document129 pages300DMonitorOperationManual v15SerkanAl100% (2)

- Meenakshi Polymers 4M Change InspectionDocument4 pagesMeenakshi Polymers 4M Change InspectionKaran Malhi100% (1)

- ÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSDocument3 pagesÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSGiancarloNo ratings yet

- Atlas Copco - Portable Energy Division PDFDocument108 pagesAtlas Copco - Portable Energy Division PDFtarekNo ratings yet

- Geotechnical module stresses and settlementsDocument128 pagesGeotechnical module stresses and settlementsMAAbuBakarNo ratings yet

- Installation & Operation Manual. BiRotor Plus Positive Displacement Flow Meter B27X (3) B30X (6) B28X (4) B31X (8) B29X (6) B32X (10)Document37 pagesInstallation & Operation Manual. BiRotor Plus Positive Displacement Flow Meter B27X (3) B30X (6) B28X (4) B31X (8) B29X (6) B32X (10)tsaqova MuhammadNo ratings yet

- CS4002 U-Deck Recommended SparesDocument5 pagesCS4002 U-Deck Recommended SparesedwinNo ratings yet

- Rotational Equilibrium and DynamicsDocument3 pagesRotational Equilibrium and DynamicsJemjem PagalingNo ratings yet

- SM - 3 TransmissionDocument397 pagesSM - 3 TransmissionJanNo ratings yet

- Engineering College in HaryanaDocument9 pagesEngineering College in HaryanaUjjawal MathurNo ratings yet

- Orrcon National Product CatalogueDocument84 pagesOrrcon National Product CatalogueEswaran RajamaniNo ratings yet

- VW 1.8L 4-Cylinder Turbo Engine GuideDocument71 pagesVW 1.8L 4-Cylinder Turbo Engine GuideJai Bhandari100% (2)

- Typical Piping DeliverablesDocument4 pagesTypical Piping DeliverablesShyam Prasad K S100% (1)

- Mercedes Sensor CodesDocument2 pagesMercedes Sensor CodesBen SchopeeNo ratings yet

- A Review On Effect of Preheating and orDocument3 pagesA Review On Effect of Preheating and orKing SabiNo ratings yet

- 7 - Psy - Chart - XLS Cooling CoilDocument28 pages7 - Psy - Chart - XLS Cooling CoilRanu JanuarNo ratings yet

- Multicore Cable Schedule 21-12-01Document14 pagesMulticore Cable Schedule 21-12-01Archiford NdhlovuNo ratings yet

- Airconditioning - HTML: Solar "Commercial Air-Conditioning" Systems Our Achievements and Our GoalsDocument9 pagesAirconditioning - HTML: Solar "Commercial Air-Conditioning" Systems Our Achievements and Our GoalsWeyuma ToleraNo ratings yet

- Ооо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RDocument53 pagesОоо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RSiva baalan50% (2)

- Fluid Mixing Experiment ResultsDocument13 pagesFluid Mixing Experiment ResultsSanjeev ManutdNo ratings yet

- Course 1 PDFDocument3 pagesCourse 1 PDFSandeep BadigantiNo ratings yet

- 1018Document1 page1018Alonso ReynaNo ratings yet

- Vol0010 PDFDocument6 pagesVol0010 PDFFranciscoOliveiraNo ratings yet

- Commissioning Air PreheaterDocument14 pagesCommissioning Air Preheaterarvidkumar87060No ratings yet

- E468 38420Document6 pagesE468 38420Maria Cecilia Pontes Silva100% (1)