Professional Documents

Culture Documents

Net Positive Suction Head or NPSH

Uploaded by

Sathish LingamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Net Positive Suction Head or NPSH

Uploaded by

Sathish LingamCopyright:

Available Formats

Copyright PipeFlow.co.

uk 1

Net Positive Suction Head

Net positive suction head is the term that is usually used to describe the absolute

pressure of a fluid at the inlet to a pump minus the vapour pressure of the liquid.

The resultant value is known as the Net Positive Suction Head available.

The term is normally shortened to the acronym NPSHa, the a denotes available.

A similar term is used by pump manufactures to describe the energy losses that occur

within many pumps as the fluid volume is allowed to expand within the pump body.

This energy loss is expressed as a head of fluid and is described as NPSHr (Net

Positive Suction Head requirement) the r suffix is used to denote the value is a

requirement.

Different pumps will have different NPSH requirements dependant on the impellor

design, impellor diameter, inlet type, flow rate, pump speed and other factors.

A pump performance curve will usually include a NPSH requirement graph expressed in

metres or feet head so that the NPSHr for the operating condition can be established.

Pressure at the pump inlet

The fluid pressure at a pump inlet will be determined by the pressure on the fluid

surface, the frictional losses in the suction pipework and any rises or falls within the

suction pipework system.

NPSHa calculation

The elements used to calculate NPSHa are all expressed in absolute head units.

The NPSHa is calculated from:

Fluid surface pressure + positive head pipework friction loss fluid vapour pressure

or

Fluid surface pressure - negative head pipework friction loss fluid vapour pressure

Copyright PipeFlow.co.uk 2

Gas bubbles within the fluid (cavitation)

The Vapour pressure of a fluid is the pressure at which the fluid will boil at ambient

temperature.If the pressure within a fluid falls below the vapour pressure of the fluid,

gas bubbles will form within the fluid (local boiling of the fluid will occur).

If a fluid which contains gas bubbles is allowed to move through a pump, it is likely that

the pump will increase the pressure within the fluid so that the gas bubbles collapse.

This will occur within the pump and reduce the flow of delivered fluid. The collapse of

the gas bubbles may cause vibrations which could result in damage to the pipework

system or the pump. This effect is known as cavitation.

To avoid cavitation the pressure within the fluid must be higher than the fluid vapour

pressure at all times.

Avoiding cavitation

In a system where the pipe work layout provides a positive head, the motive force to

move the fluid to the pump will be the fluid surface pressure plus the positive head.

Incorrect sizing of the supply pipe work and isolating valves may result in high frictional

losses which can still lead to situations where the NPSHa is still too low to prevent

cavitation.

Understanding NPSHa and NPSHr

Copyright PipeFlow.co.uk 3

In a system where the fluid needs to be lifted to the pump inlet , the negative head

reduces the motive force to move the fluid to the pump.

In these instances it is essential to size the supply pipe work and isolating valves

generously so that high frictional losses do not reduce the NPSHa below the NPSHr.

Comparison of NPSHa and NPSHr

All calculated values must be in the same units either m hd or ft hd.

If the NPSHa is greater than the NPSHr cavitation should not occur.

If the NPSHr is lower than the NPSHr then gas bubbles will form in the fluid and

caviation will occur.

Increasing the NPSH available

Many systems suffer from initial poor design considerations.

To increase the NPSHa consider the following:

a. Increase the suction pipe work size to give a fluid velocity of about 1 m/sec or 3

ft/sec

b. Redesign the suction pipework to eliminate bends, valves and fittings where

possible.

c. Raise the height of the fluid container.

d. Pressurise the fluid container, but ensure that the pressure in the container is

maintained as the fluid level is lowered.

High Fluid temperature

If the temperature of the fluid to be pumped is higher than normal the relative density of

the fluid will reduce. This may result in a reduction in pipe work friction losses, but this

reduction may be offset (or exceeded) by an increase in Fluid Vapour Pressure.

Copyright PipeFlow.co.uk 4

An example:

Water at 20C (68F) has a density of 998 kg/m

3

(62.303 lbs/ft

3

) the vapour

pressure of the fluid is 2.339 kPa.a (0.339 psi.a).

Water at 60C (140F) has a density of 984 kg/m

3

(61.429 lbs/ft

3

) the vapour

pressure of the fluid is 19.946 kPa.a (2.893 psi.a).

A comparison of the system with the two fluid temperatures:

The frictional resistance of the pipe work will reduce by about 10% due to the reduced

density and viscsoity of the fluid, but the vapour pressure of the fluid will increase by

about 1.8 m head (5.9 ft head).

It will be normally necessary to check the NPSHa for a normal ambient fluid

temperature and the higher fluid temperature under these circumstances.

You might also like

- Cepde - Valve Sizing (U16ch036, U16ch037, U16ch083)Document15 pagesCepde - Valve Sizing (U16ch036, U16ch037, U16ch083)VRUSHABHNo ratings yet

- Npsha Calculations: Liquids Line Sizing CriteriaDocument4 pagesNpsha Calculations: Liquids Line Sizing CriteriaDejan KovačNo ratings yet

- How To Size A Pump Blackmonk Engineering PDFDocument9 pagesHow To Size A Pump Blackmonk Engineering PDFRajesh KrishnamoorthyNo ratings yet

- Pump Suction CharacteristicsDocument10 pagesPump Suction Characteristicsvermaakash22No ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Sizing The Air ReceiverDocument5 pagesSizing The Air Receiveranon_151761797No ratings yet

- Ejectors: Wide Uses & Selection GuideDocument6 pagesEjectors: Wide Uses & Selection Guidehappale2002No ratings yet

- PumpDocument9 pagesPumpNguyen ChuyenNo ratings yet

- Positive Displacement Pumps ExplainedDocument5 pagesPositive Displacement Pumps ExplainedsikuetNo ratings yet

- Pump System CurveDocument6 pagesPump System CurveMohan MalavNo ratings yet

- Appendix-2 Ejector System TroubleshootingDocument13 pagesAppendix-2 Ejector System Troubleshootingmahmoud abd elfatahNo ratings yet

- 750-326 Blowdown Separator 11 2015Document10 pages750-326 Blowdown Separator 11 2015osamaNo ratings yet

- Heat exchanger tube rupture case study: Addressing metal embrittlement risksDocument6 pagesHeat exchanger tube rupture case study: Addressing metal embrittlement risksaegean227100% (1)

- Centrifugal Pump CharacteristicsDocument27 pagesCentrifugal Pump Characteristicskarioke mohaNo ratings yet

- Twin Screw Vs Centrifugal & Reciprocating ArticleDocument12 pagesTwin Screw Vs Centrifugal & Reciprocating ArticlecaratorresmNo ratings yet

- Control Valve & Actuator Sizing27012004173744Document23 pagesControl Valve & Actuator Sizing27012004173744Raju NaiduNo ratings yet

- Pipe Sizing Steam Supply and Condensate Return Lines Sizing Charts Chart CG-25, page CG-51, is the basic chart for determining the flow rate and velocity of steam in Schedule 40 pipe for various values of pressure drop per 100 ft, based on 0 psig saturated steam. Using the multiplier chart (Chart CG-24), Chart CG-25 can be used at all saturation pressures between 0 and 200 psig (see Example). These Charts are based on the Moody Friction Factor, which considers the Reynolds number and the roughness of the internal pipe surfaces. Notes: Based on Moody Friction Factor where flow of condensate does not inhibit the flow of steam. See Chart CG-24 for obtaining flow rates and velocities of all saturation pressures between 0 to 200 psig: see Example. Pipe Sizing Two principal factors determine pipe sizing in a steam system: 1. The initial pressure at the boiler and the allowable pressure drop of the total system. The total pressure drop in the system should not exceed 20% ofDocument3 pagesPipe Sizing Steam Supply and Condensate Return Lines Sizing Charts Chart CG-25, page CG-51, is the basic chart for determining the flow rate and velocity of steam in Schedule 40 pipe for various values of pressure drop per 100 ft, based on 0 psig saturated steam. Using the multiplier chart (Chart CG-24), Chart CG-25 can be used at all saturation pressures between 0 and 200 psig (see Example). These Charts are based on the Moody Friction Factor, which considers the Reynolds number and the roughness of the internal pipe surfaces. Notes: Based on Moody Friction Factor where flow of condensate does not inhibit the flow of steam. See Chart CG-24 for obtaining flow rates and velocities of all saturation pressures between 0 to 200 psig: see Example. Pipe Sizing Two principal factors determine pipe sizing in a steam system: 1. The initial pressure at the boiler and the allowable pressure drop of the total system. The total pressure drop in the system should not exceed 20% of1970acoNo ratings yet

- Calculating total system head in USCS unitsDocument9 pagesCalculating total system head in USCS unitsIrfanshah2013No ratings yet

- Some Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsDocument10 pagesSome Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsRoberto Leon MendezNo ratings yet

- Acceleration Head For Reciprocating PumpsDocument2 pagesAcceleration Head For Reciprocating PumpsEng Alf100% (1)

- Flow Special - Sizing Orifice Plates - ISADocument4 pagesFlow Special - Sizing Orifice Plates - ISAamarnethaNo ratings yet

- Pressure Drop CalculationsDocument28 pagesPressure Drop Calculationshicham100% (1)

- Centrifugal pump specification summaryDocument1 pageCentrifugal pump specification summaryFrancis FeiNo ratings yet

- Vent Manifold Flare Manifold DesignDocument10 pagesVent Manifold Flare Manifold Designahsan888No ratings yet

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89No ratings yet

- A Guideline For Design Pressure - Part 1Document4 pagesA Guideline For Design Pressure - Part 1Said Ahmed SalemNo ratings yet

- Tank BlankettingDocument6 pagesTank BlankettingBaskar KannaiahNo ratings yet

- How to Size Liquid Ring Vacuum PumpsDocument3 pagesHow to Size Liquid Ring Vacuum PumpsdayrogNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryshunmugeshNo ratings yet

- Selection of Air Ejectors: Part I. Basic Design, Operating Information, and Operation Limitations of Air EjectorsDocument9 pagesSelection of Air Ejectors: Part I. Basic Design, Operating Information, and Operation Limitations of Air Ejectorsmyungkwan haNo ratings yet

- Disclaimer: This Calculation Provides An Estimate For Specifying Pumps. We Cannot Be Held Responsible For Its Use. AsDocument7 pagesDisclaimer: This Calculation Provides An Estimate For Specifying Pumps. We Cannot Be Held Responsible For Its Use. AsbratkpNo ratings yet

- A Guideline For Design Pressure - Part 2Document4 pagesA Guideline For Design Pressure - Part 2Said Ahmed SalemNo ratings yet

- Steam Ejector Pumps and Ejectors TheoryDocument5 pagesSteam Ejector Pumps and Ejectors TheorymahaveenNo ratings yet

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- Refinery Experience Provides Guidelines For Centrifugal Pump SelectionDocument5 pagesRefinery Experience Provides Guidelines For Centrifugal Pump SelectionCal100% (1)

- Calculate control valve CvDocument3 pagesCalculate control valve CvRio SamudraNo ratings yet

- Condensate Recovery Solutions SB S71 02 enDocument16 pagesCondensate Recovery Solutions SB S71 02 ensenthil031277No ratings yet

- Safety Valve SizingDocument33 pagesSafety Valve SizingAshok Kumar100% (1)

- Pump Calc ExampleDocument4 pagesPump Calc ExampleshahqazwsxNo ratings yet

- Pressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientDocument9 pagesPressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientRapee PuaksungnoenNo ratings yet

- The Mathematics of Pumping Water: AECOM Design BuildDocument9 pagesThe Mathematics of Pumping Water: AECOM Design Buildmabrouk2013No ratings yet

- Controlling Heat ExchangersDocument11 pagesControlling Heat ExchangersgermanaponteNo ratings yet

- A Simplified Approach To Water-Hammer AnalysisDocument4 pagesA Simplified Approach To Water-Hammer AnalysisChem.EnggNo ratings yet

- Pumps & NPSH-Avoid ProblemsDocument4 pagesPumps & NPSH-Avoid ProblemsChem.EnggNo ratings yet

- PIPING GUIDE How To Do Pump Piping With Layout Ex - 1579767576697 PDFDocument17 pagesPIPING GUIDE How To Do Pump Piping With Layout Ex - 1579767576697 PDFGiridhar Parab100% (1)

- Sizing Air Receiver TankDocument3 pagesSizing Air Receiver TankDennis DanielNo ratings yet

- Gas Line Sizing Rev1Document11 pagesGas Line Sizing Rev1Sermsak LimpadapunNo ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Metering Pumps - A New DefinitionDocument3 pagesMetering Pumps - A New DefinitionMoises JonesNo ratings yet

- Valve Sizing and Selection GuideDocument6 pagesValve Sizing and Selection GuideZeBocaoNo ratings yet

- Orifice Sizing PrinciplesDocument12 pagesOrifice Sizing Principlesjlcheefei9258100% (1)

- Tank Venting API STD 2000 Nov 2009 RevisDocument3 pagesTank Venting API STD 2000 Nov 2009 RevisCarlos Arias50% (2)

- Stepless Variable Capacity ControlDocument7 pagesStepless Variable Capacity Controlswapneel_kulkarniNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Understand The Basics of Centrifugal Pump Operation: Fluids/Solids HandlingDocument5 pagesUnderstand The Basics of Centrifugal Pump Operation: Fluids/Solids HandlingViệt Đặng XuânNo ratings yet

- Melab Act2Document2 pagesMelab Act2Theo AlapanNo ratings yet

- Centrifugal Pump - HandbookDocument26 pagesCentrifugal Pump - HandbookPrafull Dhakate100% (2)

- GPM RevDocument138 pagesGPM RevJuan Cortes TorizNo ratings yet

- NPSH For Metering PumpsDocument7 pagesNPSH For Metering PumpsRahul S. ChandrawarNo ratings yet

- Libro de BombasDocument260 pagesLibro de BombasBoris SalazarNo ratings yet

- Delval Flow Controls past supply reference list for ball & butterfly valvesDocument6 pagesDelval Flow Controls past supply reference list for ball & butterfly valvesSathish LingamNo ratings yet

- Manual GL Valve-Trouble ShootingDocument2 pagesManual GL Valve-Trouble ShootingSathish LingamNo ratings yet

- Flange BoltingDocument1 pageFlange BoltingSathish LingamNo ratings yet

- Flange BoltingDocument1 pageFlange BoltingSathish LingamNo ratings yet

- Expanded View of Quarter Turn ValveDocument1 pageExpanded View of Quarter Turn ValveSathish LingamNo ratings yet

- Ball Valve-OperationDocument1 pageBall Valve-OperationSathish LingamNo ratings yet

- Ball Valve DesignDocument1 pageBall Valve DesignSathish LingamNo ratings yet

- Manual GL Valve-OperationDocument1 pageManual GL Valve-OperationSathish LingamNo ratings yet

- BFV OperationDocument1 pageBFV OperationSathish LingamNo ratings yet

- BFV InstallationDocument1 pageBFV InstallationSathish LingamNo ratings yet

- Manual ValvesDocument1 pageManual ValvesSathish LingamNo ratings yet

- Manual ValvesDocument1 pageManual ValvesSathish LingamNo ratings yet

- Ball Valve InstallationDocument2 pagesBall Valve InstallationSathish LingamNo ratings yet

- Manual Ball ValveDocument1 pageManual Ball ValveSathish LingamNo ratings yet

- BLV-Trouble ShootingDocument1 pageBLV-Trouble ShootingSathish LingamNo ratings yet

- Average Run TorqueDocument1 pageAverage Run TorqueSathish LingamNo ratings yet

- ASTM Material of Valve Body & BonnetDocument1 pageASTM Material of Valve Body & BonnetSathish LingamNo ratings yet

- Density Vs StressDocument1 pageDensity Vs StressSathish LingamNo ratings yet

- Temperature Limit For Common PackingDocument1 pageTemperature Limit For Common PackingSathish LingamNo ratings yet

- Valve F To F STDDocument1 pageValve F To F STDSathish LingamNo ratings yet

- Gasket SelectionDocument2 pagesGasket SelectionSathish LingamNo ratings yet

- Types of GasketDocument3 pagesTypes of GasketSathish LingamNo ratings yet

- Hardness Conversion TableDocument1 pageHardness Conversion TableSathish LingamNo ratings yet

- Asbestos and Non-Asbestos PackingDocument1 pageAsbestos and Non-Asbestos PackingSathish LingamNo ratings yet

- Types of ValvesDocument2 pagesTypes of ValvesSathish LingamNo ratings yet

- Common Piping NomenclatureDocument2 pagesCommon Piping NomenclatureSathish LingamNo ratings yet

- Chemical Compatibility Guide: MediaDocument1 pageChemical Compatibility Guide: MediaSathish LingamNo ratings yet

- Standard Pipe DataDocument15 pagesStandard Pipe DataSathish LingamNo ratings yet

- Temp Limitation For Common PackingDocument1 pageTemp Limitation For Common PackingSathish LingamNo ratings yet

- Flanged BFV ValveDocument1 pageFlanged BFV ValveSathish LingamNo ratings yet

- Refrigeration Unit: Muhammad Tarmizi Bin Abdul Murad (2019883632)Document18 pagesRefrigeration Unit: Muhammad Tarmizi Bin Abdul Murad (2019883632)Lehbron JemsNo ratings yet

- Calculating Enthalpies of ReactionsDocument5 pagesCalculating Enthalpies of ReactionsPatrickNo ratings yet

- VSEPR Theory5Document18 pagesVSEPR Theory5Inaya ImranNo ratings yet

- HW 3Document2 pagesHW 3Purusharth SemwalNo ratings yet

- Trashrack DesignDocument12 pagesTrashrack DesignAnonymous b9DIaPTq6BNo ratings yet

- Racqb 2Document7 pagesRacqb 2ratchagaraja0% (1)

- P30 Unit Three Diploma ReviewDocument30 pagesP30 Unit Three Diploma ReviewhelloNo ratings yet

- MOTOR BASES FOR INDUSTRIAL APPLICATIONSDocument8 pagesMOTOR BASES FOR INDUSTRIAL APPLICATIONSbogdanalaciNo ratings yet

- Numerical investigation of RC beam-column connections under monotonic loadsDocument8 pagesNumerical investigation of RC beam-column connections under monotonic loadsCarter KandouNo ratings yet

- Grade 9 Lesson Plan 01Document2 pagesGrade 9 Lesson Plan 01RahmonGreenNo ratings yet

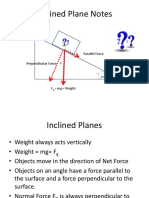

- Inclined Planes and Forces Notes PDFDocument19 pagesInclined Planes and Forces Notes PDFLeroy JenkinsNo ratings yet

- Design Calculation of Abutment StructureDocument39 pagesDesign Calculation of Abutment StructureMukesh JangidNo ratings yet

- Projectile MotionDocument15 pagesProjectile MotionAlina PetrușNo ratings yet

- Assignment-Ray OpticsDocument2 pagesAssignment-Ray OpticstejvanshsandhuNo ratings yet

- Form 4 Physics Formula ListDocument7 pagesForm 4 Physics Formula ListNoraini Ibrahim33% (3)

- Basement Wall Design Geotechnical AspectsDocument3 pagesBasement Wall Design Geotechnical Aspectssaber javidNo ratings yet

- B Tech Mechatronic Syllanus Sem I-Vi PDFDocument60 pagesB Tech Mechatronic Syllanus Sem I-Vi PDFprNo ratings yet

- 8 Rotational Flow: 8.1 Vorticity and CirculationDocument11 pages8 Rotational Flow: 8.1 Vorticity and CirculationdhandaNo ratings yet

- Pair-Ion Plasma Generation Using FullerenesDocument5 pagesPair-Ion Plasma Generation Using FullerenesAhmad Imran KhanNo ratings yet

- Sample Problems Free FallDocument3 pagesSample Problems Free FallguevarrajessphilipNo ratings yet

- Autoship Prediction For Ship ModelDocument5 pagesAutoship Prediction For Ship ModelTihomir MarkovicNo ratings yet

- Basic Structure of Eddy Current Brakes: Found in Cars As WellDocument7 pagesBasic Structure of Eddy Current Brakes: Found in Cars As Wellpseudo networkNo ratings yet

- Siemens Vacumm Contactor 3tl6Document15 pagesSiemens Vacumm Contactor 3tl6Yong Ee VonnNo ratings yet

- Continuous Time Fourier SeriesDocument46 pagesContinuous Time Fourier SeriesGauri Shanker GuptaNo ratings yet

- Heat Transfer of Non-Newtonian Fluids in Circular Micro-TubeDocument14 pagesHeat Transfer of Non-Newtonian Fluids in Circular Micro-TubeGaurav KhamesraNo ratings yet

- Chemical Solution Density & ViscosityDocument18 pagesChemical Solution Density & ViscosityLee JianNo ratings yet

- Remodeled Plan 2nd Quarter Chemical BondingDocument34 pagesRemodeled Plan 2nd Quarter Chemical Bondingapi-340406981No ratings yet

- Bài 5 - Lateral Motion (Stick Fixed) (2008)Document12 pagesBài 5 - Lateral Motion (Stick Fixed) (2008)neiht_ksNo ratings yet

- Properties of Pure SubstanceDocument26 pagesProperties of Pure SubstanceMahadi HasanNo ratings yet

- (CIGRE Green Books) Hiroki Ito - Switching Equipment (2019, Springer International Publishing)Document620 pages(CIGRE Green Books) Hiroki Ito - Switching Equipment (2019, Springer International Publishing)Fernanda Nistahuz Marca75% (8)