Professional Documents

Culture Documents

NTPC DLN Systems Vamsi

Uploaded by

Abhishek Prakash Srivastava0 ratings0% found this document useful (0 votes)

262 views13 pagesOriginal Title

NTPC DLN Systems Vamsi[1]

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

262 views13 pagesNTPC DLN Systems Vamsi

Uploaded by

Abhishek Prakash SrivastavaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

NTPC Workshop

Dry Low NOx (DLN) Systems

Vamsi Duraibabu

September 14, 2010

Hyderabad

India

2

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

Copyright 2010 General Electric Company. Proprietary.

All Rights Reserved. No part of this document may be reproduced,

transmitted, stored in a retrieval system nor translated into any human or

computer language, in any form or by any means, electronic, mechanical,

magnetic, optical, chemical, manual, or otherwise, without the prior written

permission of the General Electric Company.

GE Energy

3

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

Emissions Technology Advancement

N

O

x

(

p

p

m

)

Technology Enablers

3D Reacting Flow

Advanced Materials / Coatings

Active Fuel Staging

Smart GT Controls

85 90 10 95

DLN +

DLN +

DLN - Dry Low NOx

DLN - Dry Low NOx

25 PPM 25 PPM

Water Injected

Water Injected

42 PPM 42 PPM

9 PPM 9 PPM

15 PPM 15 PPM

< 5 PPM < 5 PPM

Leader in Low Emissions Technology

4

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

Dry Low NOx (DLN) Technology Evolution

NOx

CO

Stability

&

Premix

Range

Reliability

&

Component

Life

DLN 1.0

( 6B / 9E )

DLN 1.0+

( 7EA )

DLN 2.0

( 9FA )

DLN 2.6

( 6FA )

DLN 2.0+

( 9FA+e )

DLN 2.6+

( 9FB )

DLN Design

A Four

Sided Box

DLN Technology 30 years of Design Evolution

5

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

DLN Combustion System - Summary

1327

1411

1327

1327

1288

1135

Firing

Temp

(

o

C )

9FA+e

9FBA

9FA+e

6FA+e

9FA

6B

9E

GT Model

40%

38%

30 mg/Nm

3

30 mg/Nm

3

4 DLN 2.6+

60% 50 mg/Nm

3

3 DLN 2.0+

50% 30 mg/Nm

3

4 DLN 2.6

60% 50 mg/Nm

3

4 DLN 2.0

#

65%

75%

30 mg/Nm

3

2 DLN 1.0

Turndown *

( % GT Load )

Emission

(NOx 15% O

2

)

No. of

Fuel

Circuits

DLN Type

#

Not Offered for New units

* ISO Day ( 15

o

C , 60% RH )

6

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

DLN 1.0 System Frame 6B & 9E

The original Dry Low NOx

Combustion System, first fielded

in early 80s.

Operates in Diffusion mode,

Piloted-premixed mode, and

Fully premixed mode.

Can be retrofitted on to existing

turbines to replace Diffusion

flame combustors

Second largest single-digit NOx

DLN fleet, behind the 7FA+e.

Lean Premixed System

FUEL STAGING

7

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

DLN 2.0+ System - Frame 9FA+e

Premix

PM1

PM4

PM4

PM4 PM4

Diffusion

D5

D5

D5

D5

D5

Sub Piloted Premix

D5

D5

D5

D5

D5

PM1

Piloted Premix

D5

D5

D5

D5

D5

PM1

PM4

PM4

PM4

PM4

Premix

PM1

PM4

PM4

PM4 PM4

Diffusion

D5

D5

D5

D5

D5

Sub Piloted Premix

D5

D5

D5

D5

D5

PM1

Piloted Premix

D5

D5

D5

D5

D5

PM1

PM4

PM4

PM4

PM4

FUEL STAGING

Ignition - 95% Speed

95% Speed - 10% Load

10% - 50% Load

50% - 100% Load

DLN-2+ retains the basic architecture of

the DLN-2

Fuel nozzle ( Swozzle Design ) redesigned

with cleaner aerodynamics for improved

Flame Holding Margin & Pressure drop.

Accept fuels with wide wobbe Index

ranging from 28 to 52.

Swirl-Stabilized Premixed System

8

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

DLN 2.6+ System - Frame 9FA+e / 9FB

Diffusion

D5

D5

D5

D5

D5 D5

Sub Piloted Premix

D5

D5

D5

D5

PM1

D5

D5

Piloted Premix

D5

D5

D5

D5

D5

PM3

PM3

PM3

PM1

Sub Premix

PM3

PM3 PM3

PM1

D5

Premix

PM3

PM2

PM3 PM3

PM1

PM2

Diffusion

D5

D5

D5

D5

D5 D5

Sub Piloted Premix

D5

D5

D5

D5

PM1

D5

D5

Piloted Premix

D5

D5

D5

D5

D5

PM3

PM3

PM3

PM1

Sub Premix

PM3

PM3 PM3

PM1

D5

Premix

PM3

PM2

PM3 PM3

PM1

PM2

Diffusion

D5

D5

D5

D5

D5 D5

Sub Piloted Premix

D5

D5

D5

D5

PM1

D5

D5

Piloted Premix

D5

D5

D5

D5

D5

PM3

PM3

PM3

PM1

Sub Premix

PM3

PM3 PM3

PM1

D5

Premix

PM3

PM2

PM3 PM3

PM1

PM2

Ignition - 95% Speed

95% Speed - 20% Load

FUEL STAGING

20% - 30% Load

30% - 40% Load

40% - 100% Load

Based on the DLN 2+ fuel nozzle with DLN 2.6

architecture

Designed for Sub 9 ppm NOx / CO Emissions

Fuel Staging Flexibility Solution for Yellow plume

New Unit or Retrofit

Advanced Swirl-stabilized System

9

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

DLN2.6+ System w/ OpFlex AutoTune

Model Based Control Technology

Applications

Fuel flexibility

Wobbe index variation

Eliminates combustion

retuning requirement

Performance enhancement

Output & efficiency

Fuel Supply pressure

reduction

Start-up fuel flexibility

Larger start up fuel

variances

Start-up emissions

improvements

Lower start up NOx

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

L

o

o

p

S

e

l

e

c

t

i

o

n

S

t

r

u

c

t

u

r

e

ARES - Parameter

Estimation

Engine Model

Virtual

Sensors

Sensors

Effectors

Physics-Based

Boundary Models

L

i

m

i

t

S

c

h

e

d

u

l

i

n

g

CDM

Direct boundary control

Accommodates deterioration

Tuning schedules are adjusted

automatically

Key Features

10

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

Gas Turbine Combustion Laboratory

10 Test stands for testing and

validating all DLN Systems

Capability of blending NG with

H2, CO, CO2, N2 and Steam

Advanced monitoring and

diagnostic instrumentation (upto

400 sensors) for component

validation

Up to 230 High Pressure / High

Temperature Tests conducted

per year

World Class DLN Combustor Test Facility

CameraPremixed Flame

Overview

Appendix

12

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

DLN 2.6+ System - Frame 9FA/FA+e /FB

Super B

Thermal

Barrier

Coating

(TBC)

Extended Interval (EI) transition

piece cooling and sealing

DLN 2.6 style nozzle

arrangement (5+1)

Fuel flexibility retained

from DLN 2+

9FA+e (9351FA)

20/20 mg/Nm

3

NOx/CO to 50% load

30/30 mg/Nm

3

NOx/CO to 35% load

1

24k combustion interval

9FA (9311FA)

30/30 mg/Nm

3

NOx/CO to 50% load

24k combustion interval

9FB (9371FA)

30/12.5 mg/Nm

3

NOx/CO to 38% load

12k combustion interval

9FA+e (9351FA)

20/20 mg/Nm

3

NOx/CO to 50% load

30/30 mg/Nm

3

NOx/CO to 35% load

1

24k combustion interval

9FA (9311FA)

30/30 mg/Nm

3

NOx/CO to 50% load

24k combustion interval

9FB (9371FA)

30/12.5 mg/Nm

3

NOx/CO to 38% load

12k combustion interval

9FA+e launch in 2005

(12 operating, 7 ordered)

9FB launch in 2007

(18 operating, 32 ordered)

9FA (9311FA) launch in 2009

(1 operating, 4 ordered)

Dual fuel and wide wobbe

capable

9FA+e launch in 2005

(12 operating, 7 ordered)

9FB launch in 2007

(18 operating, 32 ordered)

9FA (9311FA) launch in 2009

(1 operating, 4 ordered)

Dual fuel and wide wobbe

capable

1

With OpFlex Extended Turndown software

13

General Electric Company

2010 General Electric Company. All Rights Reserved. This material may not be copied

or distributed in whole or in part, without prior permission of the copyright owner.

+_

Sensors

Effectors

Control

Control Schedules

+_ +_

Sensors

Effectors

Control

Control Schedules

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

+_ +_

L

o

o

p

S

e

l

e

c

t

i

o

n

S

t

r

u

c

t

u

r

e

ARES - Parameter

Estimation

Engine Model

Virtual

Sensors

Sensors

Effectors

Physics-Based

Boundary Models

L

i

m

i

t

S

c

h

e

d

u

l

i

n

g

CDM

Good: Schedule-Based

Indirect boundary control

No explicit deterioration

accommodation

Coupled effectors

Better: Model-Based

Direct boundary

control

Accommodates

deterioration

De-coupled effectors

A different control paradigm

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BCAC Student Workbook CompleteDocument103 pagesBCAC Student Workbook CompleteÁlvarez JavierNo ratings yet

- Braking R2900 PDFDocument56 pagesBraking R2900 PDFJunior Enrique Yataco Ariza100% (2)

- MaxxForce 9 Y 10Document5 pagesMaxxForce 9 Y 10Eduardo Alvarez100% (2)

- ProtectiveDocument1 pageProtectiveAbhishek Prakash SrivastavaNo ratings yet

- 3boiler Steam Water Chemistry in Power PlantsDocument22 pages3boiler Steam Water Chemistry in Power PlantsAbhishek Prakash SrivastavaNo ratings yet

- Turbine Lub Oil SysDocument32 pagesTurbine Lub Oil SysAbhishek Prakash SrivastavaNo ratings yet

- Transmission LineDocument34 pagesTransmission LineAbhishek Prakash Srivastava100% (1)

- Presentation RIPDocument26 pagesPresentation RIPAbhishek Prakash SrivastavaNo ratings yet

- SWGRDocument26 pagesSWGRAbhishek Prakash SrivastavaNo ratings yet

- 2dm Plant OprDocument25 pages2dm Plant OprAbhishek Prakash SrivastavaNo ratings yet

- Generator Excitaion & AVRDocument70 pagesGenerator Excitaion & AVRashumanu427100% (2)

- Water Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniDocument24 pagesWater Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniAbhishek Prakash Srivastava100% (1)

- AOP JOP EOP turbine interlock functionsDocument27 pagesAOP JOP EOP turbine interlock functionsAbhishek Prakash SrivastavaNo ratings yet

- HVDC ManojDocument81 pagesHVDC ManojAbhishek Prakash SrivastavaNo ratings yet

- KVVidyanandan document 12-21-2011Document35 pagesKVVidyanandan document 12-21-2011Abhishek Prakash SrivastavaNo ratings yet

- FACT DevicesDocument28 pagesFACT DevicesAbhishek Prakash SrivastavaNo ratings yet

- Complete Oil AnalysisDocument33 pagesComplete Oil AnalysisAbhishek Prakash SrivastavaNo ratings yet

- Petrol Pump Hazards Risk Assessment ControlDocument6 pagesPetrol Pump Hazards Risk Assessment ControlAbhishek Prakash SrivastavaNo ratings yet

- Statistical Process Control (SPC)Document28 pagesStatistical Process Control (SPC)Abhishek Prakash SrivastavaNo ratings yet

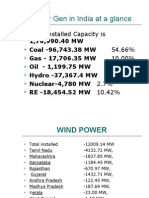

- Power GenDocument59 pagesPower GenAbhishek Prakash SrivastavaNo ratings yet

- CCGTDocument74 pagesCCGTAbhishek Prakash SrivastavaNo ratings yet

- GT Mtc. PracticesDocument59 pagesGT Mtc. PracticesAbhishek Prakash SrivastavaNo ratings yet

- Energy Audit in IndustriesDocument14 pagesEnergy Audit in IndustriesAbhishek Prakash SrivastavaNo ratings yet

- 2 Boiler HydroDocument16 pages2 Boiler HydroAbhishek Prakash SrivastavaNo ratings yet

- ATRS Optimizes Turbine StartupDocument47 pagesATRS Optimizes Turbine StartupAbhishek Prakash Srivastava100% (1)

- HarmonicsDocument2 pagesHarmonicsAbhishek Prakash SrivastavaNo ratings yet

- Basic Electrical CBIP 30-05-12Document81 pagesBasic Electrical CBIP 30-05-12Abhishek Prakash Srivastava100% (1)

- Article 3: What Is Reactive Power?Document8 pagesArticle 3: What Is Reactive Power?MAT JIBRUDNo ratings yet

- Fluid Power CircuitsDocument176 pagesFluid Power CircuitsMike Fredskilde97% (29)

- Premier Unleaded-Technical Data SheetDocument1 pagePremier Unleaded-Technical Data SheetJexelle Marteen Tumibay PestañoNo ratings yet

- Dalton's Law Partial Pressure WorksheetDocument2 pagesDalton's Law Partial Pressure WorksheetMary ruth DavidNo ratings yet

- FRP Pipelines Offer Safer Hydrogen DeliveryDocument2 pagesFRP Pipelines Offer Safer Hydrogen DeliveryAdrian AlexandruNo ratings yet

- двигатели VM Motori3Document205 pagesдвигатели VM Motori3ustyugov81100% (4)

- Serie T6 T7 T67 Catalogo BombasDocument76 pagesSerie T6 T7 T67 Catalogo BombasRafael Pérez PupoNo ratings yet

- High Pressure Washer Owner's Manual: Problems? Questions?Document20 pagesHigh Pressure Washer Owner's Manual: Problems? Questions?Greggo1010No ratings yet

- 017964Document536 pages017964Francesco Ledda100% (1)

- Positive Points in Pakistan's Fiscal Budget 2019-20Document3 pagesPositive Points in Pakistan's Fiscal Budget 2019-20Khurram AyubNo ratings yet

- Vital info for safe boiler operationDocument3 pagesVital info for safe boiler operationHarish SanjeeviNo ratings yet

- Natco Dual Polarity PsDocument2 pagesNatco Dual Polarity PsajostosNo ratings yet

- Artificial Lift in Unconventional ReservoirDocument34 pagesArtificial Lift in Unconventional ReservoirMaria IndiraNo ratings yet

- Universal Fire BrochureDocument12 pagesUniversal Fire BrochureRaveenaNo ratings yet

- 0903Document48 pages0903Ramiro R. Alcaraz GarciaNo ratings yet

- 4" Steel Model F4: Smith Meter PD Rotary Vane MeterDocument4 pages4" Steel Model F4: Smith Meter PD Rotary Vane MeterVictor FreireNo ratings yet

- Crank ShaftDocument49 pagesCrank Shaftpramo_dassNo ratings yet

- Seminar Report On Hydrogen As The Future FuelDocument63 pagesSeminar Report On Hydrogen As The Future FuelMOHIT MGMNo ratings yet

- How To Test The Fuel Injectors1Document7 pagesHow To Test The Fuel Injectors1ElliAbatziNo ratings yet

- First Aid For Accident With HFC/HCFCDocument2 pagesFirst Aid For Accident With HFC/HCFCSrini VasanNo ratings yet

- Masto GBDocument2 pagesMasto GBtheunauthorised100% (1)

- Recommendations For Api RP 2350Document8 pagesRecommendations For Api RP 2350Piotr Janowiak100% (1)

- Gas Cylinder Safety ProceduresDocument1 pageGas Cylinder Safety ProceduresSalwa CnNo ratings yet

- SFCU-B Data Sheet Flow BackDocument2 pagesSFCU-B Data Sheet Flow BackdinoNo ratings yet

- BIT CONDITION SUMMARYDocument1 pageBIT CONDITION SUMMARYMas KuncritNo ratings yet

- Accumulator, air hoists, API definedDocument6 pagesAccumulator, air hoists, API definedrcabrera90No ratings yet

- Certified Welding Inspector QA QC in USA Resume Matthew MerketDocument3 pagesCertified Welding Inspector QA QC in USA Resume Matthew MerketMatthewMerketNo ratings yet

- Sliding Contact Bearing NotesDocument4 pagesSliding Contact Bearing NotesSp PatelNo ratings yet