Professional Documents

Culture Documents

Data Sheet - Pex 240DW

Uploaded by

Christine ThompsonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet - Pex 240DW

Uploaded by

Christine ThompsonCopyright:

Available Formats

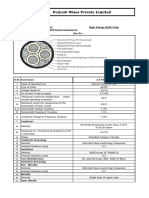

Technical Specifications

Unit: PEX 240 DW

1 Total Cooling Capacity- kW 39.4

2 Sensible Cooling Capacity – kW 38.4

3 Tonnage 11.2

4 Total Cooling Capacity at 22 Deg C inside (kW) 37.5

5 Sensible cooling Capacity 37.2

6 Tonnage (at 20 Deg C) 10.7

7 Total Cooling Capacity at 20 Deg c inside (kW) 35.6

8 Sensible cooling Capacity 36

9 Tonnage (at 20 Deg C) 10.1

a. Manufacturer Emerson Network Power India

b. Country of Origin India

c. Unit Model No. PeX 240 DW

d. Total Electrical power requirement

i. Compressor (KW) 8.84

ii. Condenser fan/s (KW) 3.08

iii. Blower (KW) 4.4

iv. Heaters (KW) 9

v. Humidifier (KW) 3.8

Compressor

a. Country of origin USA

b. Manufacturer Copeland

c. Type of compressor Scroll

d. Number of Compressors 2 No.

e. Model No. ZR – 68KC

f. Nominal capacity 5.6 TR

g. Suction temperature 9 Deg C

h. Discharge temperature 56 Deg C

i. Actual capacity at 20 Deg C/50% NA

j. BHP consumption NA

k. Total input current per compressor per phase 20 Amps

l. Type of refrigerant R-22

m. Operating Speed 2900RPM

n. Safety controls Yes

HP cutout (manual reset) Yes

LP cutout (auto reset)

o. Protections O/L, HP, LP, Phase Reversal

p. Operating voltage 415 ± 10% V

q. Type of vibration isolators Rubber Grommet

Air-cooled Condenser

a. Country of origin India

b. Manufacturer Emerson Network

c. Model No. LS - 40

d. Face Area (SqM) 1.75 SqM

e. Number of rows 2

f. Fins material Aluminum

g. Type of fins Louvered fins

h. No. of fins per inch 12

i. Air flow (Cfm) 7200 CFM

j. Air velocity across coil (FPM) NA

k. Pressure drop (Ft of water) NA

l. Tube material Copper

m. Tube dia (mm) 9.525mm

n. Tube thickness (mm) 0.3mm

o. Water side tube surface area NA

p. Refrigerant side tube surface area 10.78

q. No. of fans 2 No./Cond.

r. Dia. of each fan 500mm

s. Motor rating (KW) 0.77 X 2 Nos.

t. Motor protection MCB

u. Motor full load current 6.8 Amps

v. Overall dimensions 1418 (L) X 980 (H) X 985 (D)

Cooling Coil

a. Manufacturer Emerson Network Power

b. Tube dia and thickness (mm) 3/8” & 29G

c. Tube material Copper

d. Fin material Aluminum

e. Bonding of fins Hydraulically Mechnaical Bonding

f. Fin Spacing 14FPI

g. Coil face velocity (MPM/FPM) 141 MPM

h. Coil face area (SqM/Sft) 0.95 Sqmt.

Fan & Fan motor

a. Manufacturer Emerson Network Power

b. Type of fan Forward Curved Centrifugal Fan D/DW

c. Number of fans 1

d. Length & dia of blower 12” X 12” / EACH

e. Air quantity in Cfm 9330

f. Outlet velocity (MPM) NA

g. Motor rating per motor 2.2kW

h. Type of motor Squirrel Cage Induction

i. Rated speed 1400RPM

j. Electrical characteristics 400/3/50

Humidifier

a. Manufacturer Emerson Network Power

b. Type Immersed Electrode Steam Generation

c. Capacity (Kg/Hr) 5

d. Input Current 3.8

e. Operating voltage 230V

f. Cleaning action Self Flush Cycle

g. Water supply pressure range (kPa) 100-700

h. Drain connection (mm) 2”

i. Connection supply (BSP Female) ½”

Electrical Strip Heater

a. Manufacturer Emerson Network Power

b. Type Finned Tubular

c. Quantity 2

d. Material of sheath Nickel Plated Steel

e. Material of fins Aluminum

f. Power rating (KW) 9.0kW

g. Surface temperature of the element when tested in still NA

air at 20 deg C ambient

h. Type of protections O/I Relay / Tempearture Protection

Filters

a. Manufacturer Emerson Network Power

b. Type HDPE

c. Numbers of filters 2

d. Size (mm) 790 X 790 X 100

e. Material Dry Media / Disposable

f. Efficiency 95% Down TO 5 μ

Cont

a. Standard protections CEMS 100

Built-in single phasing preventor.

Built-in under voltage cut out.

Built-in thermal over load for compressor.

b. Switchgear Unit main disconnect isolator.

Compressor circuit breaker & contactor.

Main fan circuit breaker & contactor.

Humidifier circuit breaker & contactor.

Heater circuit breaker & contactor.

Condenser fan circuit breaker.

Control power circuit breaker.

Refrigerant Piping

a. Material for pipes Copper

b. Pipe wall thickness (mm) NA

c. Material of fittings Wood

d. Material of valves Brass

e. Make of valves Danfoss

f. Make of refrigerant float if any NA

g. Pressure gauges NA

i. Make -

ii. Range -

Unit Construction

a. Cabinet Material CRAC Powder Coated

b. Surface Finish Powder Coated

c. Color and Shade APO Grey

d. Paint Thickness 1.6mm

e. Cabinet Insulation Thickness (mm) 1”

f. Insulation Material Fibre Glass Covered With Acoustic Material

g. Density 48kg/M3

Unit capacity (Actual)

a. Total Capacity (TR) 11.2

b. Sensible Capacity (TR) 10.9

c. Sensible Heat Ratio 0.975

Physical Sizes

a. Overall dimensions (mm) 1700 X 850 X 1950

b. Services Clearances (mm) 800mm (FRONT)

c. Operating Weight (Kg.) 512

d. Type of Vibration Isolator Rubber Grommet

You might also like

- What is Intermodulation InterferenceDocument3 pagesWhat is Intermodulation InterferencedekcarcNo ratings yet

- No. of Units 2: No. Description Unit Parameters Per UnitDocument3 pagesNo. of Units 2: No. Description Unit Parameters Per Unitvipul gandhiNo ratings yet

- Technical Specification: Dry Cooler-60 HZDocument3 pagesTechnical Specification: Dry Cooler-60 HZRathikaNo ratings yet

- Guranteed Technical Particulars of Potential Transformer FormatDocument5 pagesGuranteed Technical Particulars of Potential Transformer FormatVikas VikasNo ratings yet

- Tech Specification Apepdcl TN 99Document23 pagesTech Specification Apepdcl TN 99Suresh SharmaNo ratings yet

- No. of Units 2: No. Description Unit Parameters Per UnitDocument1 pageNo. of Units 2: No. Description Unit Parameters Per Unitvipul gandhiNo ratings yet

- Project Specifications for 12,000 BTU Portable Air ConditionerDocument1 pageProject Specifications for 12,000 BTU Portable Air ConditionerJose Enrique Sanchez ThompsonNo ratings yet

- Technical Service Manual for Midea Rooftop Package UnitsDocument141 pagesTechnical Service Manual for Midea Rooftop Package UnitsTermosoluciones sasNo ratings yet

- Spesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryDocument1 pageSpesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryBaelish PeterNo ratings yet

- Fcu TechnicalDocument22 pagesFcu Technicaltran duyNo ratings yet

- Ahu Data SheetDocument8 pagesAhu Data Sheetvasanth kumarNo ratings yet

- 145KV HCB GTPDocument3 pages145KV HCB GTPVishnu ShankerNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- Equipo FWW1400F DaikinDocument1 pageEquipo FWW1400F DaikinKevinCostasCaceresNo ratings yet

- Technical Data Bio-Ethanol - M&EDocument57 pagesTechnical Data Bio-Ethanol - M&EJack NgNo ratings yet

- 400PX3 5caywyxlpeDocument2 pages400PX3 5caywyxlpeAnonymous SDeSP1No ratings yet

- Attachment 1Document31 pagesAttachment 1EmrahCayboyluNo ratings yet

- Technical Schedule 3Document16 pagesTechnical Schedule 3Prasenjit DeyNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- Technical Data Air Cooled Chiller 105 TRDocument3 pagesTechnical Data Air Cooled Chiller 105 TRHaris Siena100% (1)

- Spec - AG DC Inverter 7-11K V2.0 Neoclima de La EugenDocument2 pagesSpec - AG DC Inverter 7-11K V2.0 Neoclima de La EugenMagdalena LazarNo ratings yet

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetDocument2 pagesPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESNo ratings yet

- Datasheet-W-017UAY (1)Document1 pageDatasheet-W-017UAY (1)Oscar Barres MoreiraNo ratings yet

- Technical Specification for 110 kW Blast FreezerDocument2 pagesTechnical Specification for 110 kW Blast FreezerTrần Đinh MinhNo ratings yet

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- 660 MW TECH. DATA (As On 15-12-09)Document28 pages660 MW TECH. DATA (As On 15-12-09)saurabh018No ratings yet

- CH 7 D 3.35.1-EDocument3 pagesCH 7 D 3.35.1-Eวงศกร สิงห์เอี่ยมNo ratings yet

- HYGECO - Notice SB 0MAN052 H - ENGDocument20 pagesHYGECO - Notice SB 0MAN052 H - ENGmarius tothNo ratings yet

- RFQ Air CompressorDocument1 pageRFQ Air CompressorFRESKABIONo ratings yet

- Lats Polimarin Gedung Terpadu - OkDocument69 pagesLats Polimarin Gedung Terpadu - OkzavrianrohmanNo ratings yet

- LT Motors Technical SpecificationDocument4 pagesLT Motors Technical SpecificationManoj Nirgude100% (1)

- Alternator Data SheetDocument6 pagesAlternator Data Sheetnagraj204100% (1)

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- Marine Compressor FSD 505L, Water Cooled, 2605 M H, 14 Bar (G), 440 V 3...Document2 pagesMarine Compressor FSD 505L, Water Cooled, 2605 M H, 14 Bar (G), 440 V 3...Mazhar SafdarNo ratings yet

- Energy Audit Technical Detail FormatDocument6 pagesEnergy Audit Technical Detail FormatGreen BusinessNo ratings yet

- KRTK 100-400/454UEC2-S data sheetDocument5 pagesKRTK 100-400/454UEC2-S data sheetGhassan ABO ALINo ratings yet

- Air Cooler Data SheetDocument3 pagesAir Cooler Data Sheetarisandiyusuf0% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- FRLS 1.5 X 2 CoreDocument1 pageFRLS 1.5 X 2 CorerhladiNo ratings yet

- Odisha Power Transmission Corporation Limited Guaranteed Technical ParticularsDocument70 pagesOdisha Power Transmission Corporation Limited Guaranteed Technical ParticularsNarendra ChhatriaNo ratings yet

- 3C-ABC-Technical Spec 948Document9 pages3C-ABC-Technical Spec 948Kanwalnain madaanNo ratings yet

- LG180CDocument3 pagesLG180CMohamed ElsagerNo ratings yet

- CGAM - CGAM-1 - Consolidated Customer PackageDocument18 pagesCGAM - CGAM-1 - Consolidated Customer PackageVincent Aarón RodríguezNo ratings yet

- LT XLPE Cable Technical DataDocument1 pageLT XLPE Cable Technical DataVishal SharmaNo ratings yet

- CGAM - CGAM-1 - Consolidated Customer PackageDocument19 pagesCGAM - CGAM-1 - Consolidated Customer PackageAmeli RNo ratings yet

- Annex B - Performance DataDocument1 pageAnnex B - Performance DataCamille DiokoNo ratings yet

- 400PX3CHT33UEFLATDocument2 pages400PX3CHT33UEFLATjayesh95395No ratings yet

- Guaranteed Technical ParticularsDocument3 pagesGuaranteed Technical ParticularsGuru MishraNo ratings yet

- Air Cooled Screw Chiller Performance SpecificationDocument2 pagesAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- 2 5px3cywystrfrlsDocument2 pages2 5px3cywystrfrlsKrish0% (1)

- CH Aly080dDocument2 pagesCH Aly080dEngineer HassanNo ratings yet

- Technical Annex - Suratgarh - Rev01Document96 pagesTechnical Annex - Suratgarh - Rev01Prince MittalNo ratings yet

- Fsis09cxswyl004c006sa (FR LSH)Document1 pageFsis09cxswyl004c006sa (FR LSH)pkNo ratings yet

- 19.auxiliary Trafo GTPDocument11 pages19.auxiliary Trafo GTPAnkit VishwakarmaNo ratings yet

- Technical Specification AL-59 Conductor 893Document18 pagesTechnical Specification AL-59 Conductor 893pramjitNo ratings yet

- Lats Kanwil Tanjung Selor (R7)Document50 pagesLats Kanwil Tanjung Selor (R7)zavrianrohmanNo ratings yet

- GWC24AGDXE-K3DNA1A - Spec SheetDocument5 pagesGWC24AGDXE-K3DNA1A - Spec SheetJulius MuhimboNo ratings yet

- Submittal CTXS09DVJU - 2MXS18DVJU 07-06 - DaikinDocument1 pageSubmittal CTXS09DVJU - 2MXS18DVJU 07-06 - Daikinedward sabedraNo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Lit Crit TextDocument8 pagesLit Crit TextFhe CidroNo ratings yet

- PatternPro Variable Pitch GunDocument2 pagesPatternPro Variable Pitch GunVõ HòaNo ratings yet

- Microeconomics 5th Edition Hubbard Solutions Manual 1Document23 pagesMicroeconomics 5th Edition Hubbard Solutions Manual 1christina100% (48)

- Examples: Inability To Sit Still, Pacing, Wringing of Hands, or Pulling of ClothingDocument14 pagesExamples: Inability To Sit Still, Pacing, Wringing of Hands, or Pulling of ClothingFaith Dianasas RequinaNo ratings yet

- Amnesia With Focus On Post Traumatic AmnesiaDocument27 pagesAmnesia With Focus On Post Traumatic AmnesiaWilliam ClemmonsNo ratings yet

- Dladla Effect 2013Document231 pagesDladla Effect 2013TheDreamMNo ratings yet

- Preparation of Salts (Multiple Choice) QPDocument8 pagesPreparation of Salts (Multiple Choice) QPkhalil rehmanNo ratings yet

- Mitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedDocument221 pagesMitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedMROstop.comNo ratings yet

- Assignment of PsychologyDocument28 pagesAssignment of PsychologyMuhammad Hamza AshfaqNo ratings yet

- Barangay Ordinance Vaw 2018Document7 pagesBarangay Ordinance Vaw 2018barangay artacho1964 bautista100% (3)

- Fermenting For Health - Pip MagazineDocument2 pagesFermenting For Health - Pip MagazinePip MagazineNo ratings yet

- Coa Polivinilpirrolidona K-90 (PVP K-90) Lote 20221019Document1 pageCoa Polivinilpirrolidona K-90 (PVP K-90) Lote 20221019Ives AlbarracinNo ratings yet

- Diamond-Blackfan AnemiaDocument5 pagesDiamond-Blackfan AnemiaTalal 197No ratings yet

- Gas Booster Systems Brochure r7Document12 pagesGas Booster Systems Brochure r7ridwansaungnage_5580No ratings yet

- Chap-20 - Locomotion & MovementDocument52 pagesChap-20 - Locomotion & MovementMittal SavaniNo ratings yet

- Bhima Devi Poudel Adhikari Year 2 Assignment 1 - 220179000Document10 pagesBhima Devi Poudel Adhikari Year 2 Assignment 1 - 220179000api-525310113No ratings yet

- Weld Procedure Specification (WPS) : Joint Design Welding SequenceDocument1 pageWeld Procedure Specification (WPS) : Joint Design Welding SequenceRicardo SoaresNo ratings yet

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADocument3 pagesBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaNo ratings yet

- Sodium Chloride MSDSDocument5 pagesSodium Chloride MSDSIbaharmovic LpuNo ratings yet

- Summative Test in Respiratory SystemDocument2 pagesSummative Test in Respiratory SystemEden Manlosa100% (4)

- Insulation MBMA-NAIMA Acousticical Performance Guide Noise SoundDocument26 pagesInsulation MBMA-NAIMA Acousticical Performance Guide Noise SoundDianna LambertNo ratings yet

- Computed Tomography (CT) - BodyDocument7 pagesComputed Tomography (CT) - Bodyfery oktoraNo ratings yet

- Save and share GZCL training spreadsheets onlineDocument263 pagesSave and share GZCL training spreadsheets onlinejohn wick100% (1)

- 1 s2.0 S0975947621001923 MainDocument8 pages1 s2.0 S0975947621001923 Mainaman babuNo ratings yet

- M96SC05 Oleo StrutDocument6 pagesM96SC05 Oleo Strutchaumont12345No ratings yet

- What It Is and The Six Steps Necessary To Achieve ItDocument40 pagesWhat It Is and The Six Steps Necessary To Achieve ItMalory RobayoNo ratings yet

- Comparison of Infrastructure in Punjab and Andhra PradeshDocument7 pagesComparison of Infrastructure in Punjab and Andhra PradeshDivyam GXNo ratings yet

- Texture Crystallisation and Freezing Point DepressionDocument18 pagesTexture Crystallisation and Freezing Point DepressionJán PeterNo ratings yet

- Calculate Size of Transformer / Fuse / Circuit Breaker: Connected Equipment To TransformerDocument16 pagesCalculate Size of Transformer / Fuse / Circuit Breaker: Connected Equipment To TransformerHari OM MishraNo ratings yet