Professional Documents

Culture Documents

Instructions Stirling Motor1

Uploaded by

Luis GraciaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instructions Stirling Motor1

Uploaded by

Luis GraciaCopyright:

Available Formats

You should have :

2 x Bearing bracket 1 x Diaphragm and con rod 2 x Brass connectors 1x Displacer Cylinder

2 x M4 x 12 ashers 2 x M4 !ashers "small# 3 x 1$ mm %eat shrink tubing 1 x Diaphragm holder

2 x M4 hex nuts 2 x Brass connectors drilled 1 x Displacer connecting rod 1 x Main Connecting rod

2 x M4 bolts 2 x &pacers 1 x Cranksha't 1 x (ea light candle1

1.) Cut around the templates and tape them don

to the corrugated cardboard)

2.) *ierce through the all o' the bearing points

"marked + # using a draing pin)

3.) Cut out the internal cut outs 'irst) (he slots in

the middle plate and baseplate should be the

same thickness as the cardboard)

4.) Cut out all o' the pieces "not all o' pieces are

shon in the photo#

5.) ,ssemble the middle plate- base plate and

side pieces as shon)

6.) Check that the middle plate rests 1..mm "4/#

above the base plate) 0lue the pieces together)

7.) Bolt one o' the bearing brackets onto the

middle plate using M4 bolts and M4 !ashers)

*ierce a starter hole using a bradal to allo the

bolt to pass through the cardboard)

8.) Be'ore bolting on the second bearing bracket-

'it the cranksha't through the small holes in the

bearing brackets) (he second bracket it bolted

using an M4 bolt and ashers)

9.) 0lue the to beam cut outs together- so they

rest on top o' each other)

10.) 1it the bearing bars through the bearing

holes on the ends o' the alking beam) (here

should be about o' the 12mm protruding through

on one side- this side is secured ith hot melt

glue)

11.) ,ssemble the parts onto the bearings bars as

'ollo: 1 x M4 !asher- 1 x Drilled brass

connector- 1 2ength o' heat the shrink) (he brass

connector should be able to move easily) &ecure

the heat shrink using a 'lame or heat gun)

12.) 1it the alking beam into place) (he

alking beam bar goes through it3s centre ith a

spacer on each side)

13.) Connect the main con rod beteen the

cranksha't and the alking beam) 1it it into the

brass connectors and tighten the locking scres)

14.) ,dd brass connectors onto the cranksha't

on each side) (he 'lyheels ill be glued to this)

15.) &lide on the 'lyheels and glue them to the

brass connectors)

14)# 1it the displacer cylinder into the displacer

cylinder cut out in the middle plate)

15) # ,ttach the displacer ire connector to the

other brass connector that on the alking beam)

18.) (ie the displacer ire onto the displacer

connecting rod)

19.) (he displacer connecting rod may need to

bent so that hen the alking beam is at it3s

highest point- the displacer should be pulled to

near the top o' the can "see notes 'or more in'o#)

20.) 0lue one o' the diaphragm shel' pieces

beteen the upright side pieces) 6t should be

level ith the top o' the top cut out in the side

pieces)

21.) 0lue the diaphragm holder in place) (he

tube should rest on the diaphragm shel' pieces

and it should be centred beteen the side pieces)

22.) 0lue the other diaphragm shel' piece on so

that it supports the top edge o' the diaphragm

holder) 6t should be glued to the diaphragm

holder)

23.) 1it the diaphragm over the diaphragm

holder) Connect the diaphragm connecting rod

to the brass connector in the middle o' the main

connecting rod) You ill need to cut it to si7e)

You might also like

- China Courses 2017 PDFDocument27 pagesChina Courses 2017 PDFJose Alberto Cruz MarteNo ratings yet

- Sanei N10 User - ManualDocument15 pagesSanei N10 User - ManualLuis GraciaNo ratings yet

- Training Manual PageMaker 6.5Document490 pagesTraining Manual PageMaker 6.5Luis GraciaNo ratings yet

- Stop Motion Pro: Quickstart GuideDocument20 pagesStop Motion Pro: Quickstart GuideRodrigo FloNo ratings yet

- Blender 3D BasicsDocument118 pagesBlender 3D BasicsLes LewisNo ratings yet

- Blender 3D BasicsDocument118 pagesBlender 3D BasicsLes LewisNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ashirvad CPVC - Price List - 1st March 2021Document14 pagesAshirvad CPVC - Price List - 1st March 2021Ujwal Elijah Gurram100% (1)

- Dokumen - Tips Volvo d24 Engines Repair ManualDocument96 pagesDokumen - Tips Volvo d24 Engines Repair ManualdesterliNo ratings yet

- Icd WebDocument1 pageIcd WebWayne SeamanNo ratings yet

- 2017 Hardware Resources Functional Spec BookDocument115 pages2017 Hardware Resources Functional Spec BookEli MatucadNo ratings yet

- E+H-PROMAG W 400 - Tender Text - TTW400ENDocument2 pagesE+H-PROMAG W 400 - Tender Text - TTW400ENAJITHNo ratings yet

- Service Manual: CDP-CE245/CE345Document44 pagesService Manual: CDP-CE245/CE345André LeftNo ratings yet

- Room Air Conditioner: Service ManualDocument79 pagesRoom Air Conditioner: Service ManualPablosoNo ratings yet

- CUTECH 40160H-CT ManualDocument33 pagesCUTECH 40160H-CT Manualdarshh22No ratings yet

- Manual de Uso de La Estación Total CYGNUSDocument180 pagesManual de Uso de La Estación Total CYGNUSMario GPNo ratings yet

- Daftar Kalibrasi Alat RSKM ProvsumselDocument2 pagesDaftar Kalibrasi Alat RSKM ProvsumselNiko AndreanNo ratings yet

- RK2 1000 2000PE ManualDocument41 pagesRK2 1000 2000PE ManualMegat AlexanderNo ratings yet

- Air-Main Charging Systems: DHS 4.0 Series Compact Assistants That Make A Big DifferenceDocument12 pagesAir-Main Charging Systems: DHS 4.0 Series Compact Assistants That Make A Big DifferenceandreaNo ratings yet

- HRSL Dryer SequenceDocument3 pagesHRSL Dryer SequencesYaiRazi syaiNo ratings yet

- Use and maintain tools in automotive assessmentDocument27 pagesUse and maintain tools in automotive assessmentARSHAD TURINo ratings yet

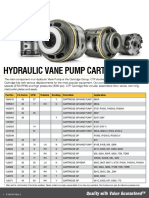

- Hydraulic Vane Pump Cartridges: Quality With Value GuaranteedDocument3 pagesHydraulic Vane Pump Cartridges: Quality With Value Guaranteedashraf elsayedNo ratings yet

- NCC-NGPD-HSE-JSA-026 MV Cable Splicing, Termination & TestingDocument15 pagesNCC-NGPD-HSE-JSA-026 MV Cable Splicing, Termination & TestingbabjihanumanthuNo ratings yet

- Spare Parts Manual: Milkoscan™ MinorDocument39 pagesSpare Parts Manual: Milkoscan™ MinorEdiz ÖzcanNo ratings yet

- Installation Operation Maintenance Instruction: Mechanical Diaphragm Metering PumpDocument24 pagesInstallation Operation Maintenance Instruction: Mechanical Diaphragm Metering PumpPablo Martin Ruiz VirruetaNo ratings yet

- Sie PC Encrotarydisswitchguide - OriginalDocument4 pagesSie PC Encrotarydisswitchguide - OriginalADJERID mohamedNo ratings yet

- Schematic Diagrams: LT-42DV1BJ, LT-42DV1BUDocument32 pagesSchematic Diagrams: LT-42DV1BJ, LT-42DV1BUmartin andres rodriguez rengifoNo ratings yet

- Ets 05Document3 pagesEts 05Sivagurunathan SpNo ratings yet

- HID Kits Metal HalideDocument1 pageHID Kits Metal HalideEliasNo ratings yet

- GROHE Specification Sheet 38994000-3Document2 pagesGROHE Specification Sheet 38994000-3aron222No ratings yet

- Internal LightingDocument52 pagesInternal Lightingaeliusmano100% (1)

- Multiply The Airflow VelocityDocument1 pageMultiply The Airflow VelocityrmuhumuzaNo ratings yet

- Trio TV85 VSI Parts Manual (SN. 078) PDFDocument25 pagesTrio TV85 VSI Parts Manual (SN. 078) PDFChancadores Chile100% (1)

- SSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVDocument28 pagesSSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVLucas PalombaNo ratings yet

- Vector 8100Document294 pagesVector 8100Kenan ÖztürkNo ratings yet

- 067 735 Cylinder 1st Compression StageDocument8 pages067 735 Cylinder 1st Compression StageNitesh MakwanaNo ratings yet