Professional Documents

Culture Documents

VM Products Gain Test Box2

Uploaded by

carlos100%(1)100% found this document useful (1 vote)

132 views16 pagesThis document provides instructions for certifying the calibration of an eddy current instrument without sending it off-site. It describes using a gain test box connected to the instrument to verify its internal oscillator frequency and amplitude, as well as the receiver's gain, linearity, and stability. The verification procedure involves using an oscilloscope and frequency counter to measure the instrument's outputs and responses to known inputs from the gain test box, and comparing the results to specifications. Upon passing verification, a certificate of calibration would be issued to confirm the instrument is properly calibrated for use.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides instructions for certifying the calibration of an eddy current instrument without sending it off-site. It describes using a gain test box connected to the instrument to verify its internal oscillator frequency and amplitude, as well as the receiver's gain, linearity, and stability. The verification procedure involves using an oscilloscope and frequency counter to measure the instrument's outputs and responses to known inputs from the gain test box, and comparing the results to specifications. Upon passing verification, a certificate of calibration would be issued to confirm the instrument is properly calibrated for use.

Copyright:

© All Rights Reserved

Available Formats

Download as PPS, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

132 views16 pagesVM Products Gain Test Box2

Uploaded by

carlosThis document provides instructions for certifying the calibration of an eddy current instrument without sending it off-site. It describes using a gain test box connected to the instrument to verify its internal oscillator frequency and amplitude, as well as the receiver's gain, linearity, and stability. The verification procedure involves using an oscilloscope and frequency counter to measure the instrument's outputs and responses to known inputs from the gain test box, and comparing the results to specifications. Upon passing verification, a certificate of calibration would be issued to confirm the instrument is properly calibrated for use.

Copyright:

© All Rights Reserved

Available Formats

Download as PPS, PDF, TXT or read online from Scribd

You are on page 1of 16

Perform Calibration Certification

on Your Own Eddy Current Instrument without

Costly Shipments and Down Time !

P.O. Box 44926, Tacoma, WA 98444

Tel: (253) 841-2939 / Fax: (253) 841-3016

www.vmproducts.net * sales@vmproducts.net

VM Products, Inc.

Specialists in Eddy Current Probes,

Reference Standards, Applications,

Research & Development

Are you sure the inspection results you obtain from

your Eddy Current Instrument are accurate?

Is your instrument actually performing at the

frequency you have selected?

Is the screen display showing you a true representation

of the defect?

Now, you can Measure and Verify your Eddy Current

Instrument Calibration.

The VMGTB-100 Gain Test Box system will Verify:

Internal Oscillator Frequency

Internal Oscillator Amplitude

Receiver Amplification Gain

Receiver Linearity

Receiver Stability

Alarms

The military does not presently require periodic

certification of eddy current instrument

calibration. Instruments not working properly

could possibly be used for critical inspections.

This is not the case in the commercial aviation

sector. The FAA does require periodic certification

of instrument calibration.

This presents the problem of taking the

instrument out of service for the period of time it

takes to send it in for calibration. This also creates

another expense for the operator.

This procedure together with the normal

calibration using a certified reference standard

before performing an inspection, will ensure the

integrity of the instrument for the job.

This Calibration Verification procedure can be divided into

two parts.

Part # 1 Internal Oscillator Output

Part # 2 Receiver (Detection and Amplification)

The internal oscillator provides the signal to the

probe and has to meet frequency and amplitude

requirements.

The probe signals are processed by electronic

circuits such as detectors and amplifiers, before

they are sent to the display. The Gain and

Linearity of this part of the instrument needs to

be tested.

This verification method follows the guidelines set

forth in Section 5.2.2 Instrument

Calibration/Certification of:

Boeing Specification Support Standard - BSS 7048,

Eddy Current Inspection, Discontinuities.

This method for eddy current instrument

certification has been in satisfactory operation at

the Boeing Metrology Laboratory for over 7 years

and has been acceptable to the FAA.

This presentation will feature the Nortec 2000D Eddy

Current Instrument as an example.

Required Equipment will include:

We have selected the Fluke 123 Scopemeter because it

incorporates the Oscilloscope and Frequency Counter in one

small package.

Standard Oscilloscope with a minimum of 20 MHz bandwidth & 10 mVolt

sensitivity

Frequency Counter with a minimum range of 100Hz - 2MHz

Gain Test Box VMGTB-100

Adapter Cable VM99L16-102F Lemo 16-pin to Fischer Triaxial adapter

VM99BB2 BNC to BNC Cable, 2 Ft. long

Test Set-Up

Attach the VM99L16-102F Adapter Cable to the Nortec 2000D

and the VMGTB-100 Gain Test Box.

Attach the counter/oscilloscope to the Coil A connector on the test

box using the BNC-BNC cable.

Preliminary Set Up for the Fluke 123 Scopemeter

Turn Instrument ON

Press SCOPE MENU Select DC & NORMAL under

INPUT A, Select DC & OFF under INPUT B. Press the

ENTER key.

Press SCOPE MENU Press the F1 key under SCOPE

OPTIONS Select NORMAL for SCOPE MODE and

SMOOTH under WAVEFORM MODE. Press the ENTER

key.

Press SCOPE MENU Press the F2 key under PROBES

Select PROBE on A. Press the ENTER key.

Select 1:1 LEADS under INPUT A. Press the ENTER key.

Press SCOPE MENU Press the F3 key under TRIGGER

Select A under INPUTSelect FREE RUN under SCREEN

UPDATE Select 15Hz under AUTO RANGE. Press the

ENTER key.

Press the V Hz A key under A. Select Hz and press the

ENTER key.

Press the V Hz A key. under B. Select OFF and PEAK.

Press the ENTER key.

Press the mV/V key under A until 1V/d appears in the lower

left of the screen.

Press the TIME key until 10s/d appears in the lower left of the

screen, next to V/d.

Set the FREQ to 100 kHz

Set the ANGLE to 92

Set the H-GAIN & V-GAIN to 82.0 dB

Set the LP FILTER to 100

Set the HP FILTER to OFF

Set the CONT NULL to OFF

Set the DISPLAY to SWEEP OFF

Set both the V-POS & H-POS to 50.0%

Set all ERASE to OFF

Set DOT/BOX to DOT

Set GRATICULE to ON

On SETUP MENU select PROBE DRIVE LOW

On SETUP MENU select FREQ SINGLE

General Set-Up for the Nortec 2000D Eddy Current

Instrument

Internal Oscillator Frequency Verification

BSS 7048 section 5.2.2.2.a. Internal Oscillator Output requires that instrument

frequency be within 20% of the indicated value and shall not drift more than 10%

in a 15 minute period.

FREQUENCY 20% MINIMUM MAXIMUM STABILITY

100 Hz 80 Hz 120 Hz

Check (at a

frequency of 100

kHz only) that

any frequency

drift is below

10% during 15

minutes.

Pass / Fail

500 Hz 400 Hz 600 Hz

1 kHz 800 Hz 1.2 kHz

5 kHz 4 kHz 6 kHz

10 kHz 8 kHz 12 kHz

50 kHz 40 kHz 60 kHz

100 kHz 80 kHz 120 kHz

500 kHz 400 kHz 600 kHz

1 MHz 800 kHz 1.2 MHz

5 MHz 4 MHz 6 MHz

10 MHz 8 MHz 12 MHz

12 MHz 9.6 MHz 14.4 MHz

Set the Nortec 2000D to the frequencies listed in the first column of the following

table. Adjust the Scopemeter sweep display up or down using the TIME button to

maintain enough cycles to trigger the readings. Observe the frequency displayed on

the Scopemeter display.

Internal Oscillator Amplitude Verification

BSS 7048 section 5.2.2.2.a. Internal Oscillator Output requires that signal amplitude

shall not vary more than 10% in a 15 minute period or more than 20% over the

calibration period.

Oscillator Output

(PROBE DRIVE)

MINIMUM MAXIMUM STABILITY

(HIGH)

Nominal = 12 Volts

12 Volts 20%

= 9.6 Volts

12 Volts + 20%

= 14.4 Volts

Check (at a

frequency of

100 kHz only)

that the

amplitude has

a variation of

less than 10%

during 15

minutes.

Pass / Fail

(MID)

Nominal = 6 Volts

6 Volts 20%

= 4.8 Volts

6 Volts + 20%

= 7.2 Volts

(LOW)

Nominal = 2 Volts

2 Volts 20%

= 1.6 Volts

2 Volts + 20%

= 2.4 Volts

* The voltage on the Scopemeter will read the actual value on the Nortec 2000D.

Double this reading for actual voltage.

Measure Peak to Peak

Voltage X 2

With frequency set at 100 kHz, measure and record the following peak to peak

amplitudes using the oscilloscope (measure the base waveform, disregarding the

spikes. These are outside of the frequency band and do not affect the eddy current

test).

Receiver Verification

BSS 7048 section 5.2.2.2.b. Receiver requires that the instrument produce deflection

of 80% of full scale given a calibrated input. The signal response must not vary more

than 10% in a 15 minute period or more than 20% over the calibration period.

Null the instrument

Depress the button on the gain test box toward coil A.

Adjust the phase so that the resultant indication moves

horizontally to the left and that depressing the button

towards B moves the indication to the right.

Adjust Gain to verify that the signal moves at least 80%

of full screen. Record Pass or Fail.

Adjust Gain so that depressing the button on the gain test

box yields an indication of 5 divisions on the instrument

screen (approximately 84 dB setting).

While holding the button depressed toward Coil A, use

the phase control to rotate the dot around the screen and

verify that a circle with a radius of 5 divisions division

is drawn on the screen. Record Pass or Fail.

Gain must be within 2 dB for any combination of gain setting changes. Vertical and

horizontal displays must be within 5% of the full scale calibrated height and width.

The alarm shall activate when the signal is within 10% of the indicated alarm value.

Receiver Verification (Continued)

-3dB (70%)

-6dB (50%)

-20dB (10%)

Repeat while holding the button depressed toward Coil

B. Record Pass or Fail.

Reduce Gain by 3 dB and verify that the circle is reduced

to a radius of 3.5 divisions (70%) 0.35 divisions for both

Coil A and B. Record Pass or Fail.

Reduce Gain by 6 dB from the initial Gain setting and

verify that the circle is reduced to a radius of 2.5 divisions

(50%) division for both Coil A and Coil B.

Record Pass or Fail.

Reduce Gain by 20 dB from the initial Gain setting and

verify that the circle is reduced to a radius of .5 divisions

(10%) with no visible ovality for both Coil A and Coil

B. Record Pass or Fail.

Return Gain to the initial setting and verify that the circle

does not change more than division over a 15 minute

period for both Coil A and Coil B. Record Pass or

Fail.

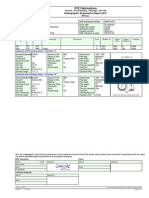

CERTIFICATE OF CALIBRATION

Nortec 2000D Eddy Current Test Instrument

Serial Number: ________

Test Date: __________ Date Due: __________

Technician: ________________

Counter: __________ Ser #: ___________ Cal Due Date: _________

Oscilloscope: __________ Ser #: ___________ Cal Due Date: _________

Gain Test Box: __________ Ser #: ___________ Cal Due Date: _________

Frequency (+/-20%):

100 Hz ______

500 Hz ______

1 kHz ______

5 kHz ______

10 kHz______

50 kHz______

100 kHz______

500 kHz______

1 MHz ______

5 MHz ______

10 MHz______

12 MHz______

Frequency Drift (+/-10% over 15 min.): Pass ____ Fail ____

Oscillator Amplitude (+/-20%):

High (4.5 Vp-p) ______

Mid (3 Vp-p) ______

Low (1 Vp-p) ______

Oscillator Amplitude Drift (+/-10% over 15 min.): Pass ____ Fail ____

Receiver Gain (80% full screen deflection): Pass ____ Fail ____

Receiver Linearity (+/-5% full scale height & width):

Frequency 1:

Gain Display

Reduction Amplitude Coil A Amplitude Coil B Amplitude

Ref 100% Pass ____ Fail ____ Pass ____ Fail ____

-3dB 70% Pass ____ Fail ____ Pass ____ Fail ____

-6dB 50% Pass ____ Fail ____ Pass ____ Fail ____

-20dB 10% Pass ____ Fail ____ Pass ____ Fail ____

Receiver Linearity Drift (+/-10% over 15 min.): Pass ____ Fail ____

Alarm: Pass ____ Fail ____

Alarm Level (+/- 10% of indicated value): Pass ____ Fail ____

Oscillator Amplitude Drift (+/-20% over test period): Pass ____ Fail ____

Receiver Linearity Drift (+/-10% over test period): Pass ____ Fail ____

You might also like

- 8210-Service Manual (070525)Document31 pages8210-Service Manual (070525)Douglas AtkinsNo ratings yet

- Tek 454Document321 pagesTek 454mnemennthNo ratings yet

- Model 224X Service Manual Performance Tests and Calibration GuideDocument22 pagesModel 224X Service Manual Performance Tests and Calibration GuideKaraseva OlgaNo ratings yet

- Document Change Record: Calibration SheetDocument7 pagesDocument Change Record: Calibration Sheetmikedlt100% (2)

- Panasonic TX-21at1p Chassis Z-8tDocument22 pagesPanasonic TX-21at1p Chassis Z-8taureliancoNo ratings yet

- MODEL 4011A: 5 MHZ Function GeneratorDocument39 pagesMODEL 4011A: 5 MHZ Function GeneratorEric ChevereNo ratings yet

- Rca Tv-D52w20yx1 Chassis Atc221 (ET)Document48 pagesRca Tv-D52w20yx1 Chassis Atc221 (ET)IoanDomutaNo ratings yet

- 29fu1rg ZK CW 91aDocument20 pages29fu1rg ZK CW 91aNina PankovskaNo ratings yet

- Digital Sound Level Meter: User's GuideDocument6 pagesDigital Sound Level Meter: User's GuideJoko YantoNo ratings yet

- Daewoo 14C4T - 20C4Tch - CP005 PDFDocument7 pagesDaewoo 14C4T - 20C4Tch - CP005 PDFHelder MartinsNo ratings yet

- Site Master™: Maintenance Manual Model S251C Antenna and Cable AnalyzerDocument16 pagesSite Master™: Maintenance Manual Model S251C Antenna and Cable AnalyzerBert En Sonya PauwelsNo ratings yet

- Service Manual: MODEL FG-8110 Sweep/Function GeneratorDocument31 pagesService Manual: MODEL FG-8110 Sweep/Function GeneratorxxNo ratings yet

- Energy Metering IC With On-Chip Fault Detection: 8% (30 PPM/ C Typical)Document16 pagesEnergy Metering IC With On-Chip Fault Detection: 8% (30 PPM/ C Typical)saandoNo ratings yet

- FG 7002 CDocument28 pagesFG 7002 CAlejandro Alfredo Fernandez AntezanaNo ratings yet

- Akira tv1 CT 21ns9r 3s10Document13 pagesAkira tv1 CT 21ns9r 3s10nikaweratiyacustomermapingNo ratings yet

- Instruction Manual: Model 4040ADocument49 pagesInstruction Manual: Model 4040AMartin TorizNo ratings yet

- TV LG 21fu1rDocument16 pagesTV LG 21fu1rpurwants100% (1)

- Color TV: Service ManualDocument23 pagesColor TV: Service ManualVictor Gonzales SanchezNo ratings yet

- Gen Func Protek B-810Document25 pagesGen Func Protek B-810scremohentaiNo ratings yet

- Tv2kr-Txt 40-Mntv2kr-l2t Tda935x 6x 8xps n2 Uc3842Document16 pagesTv2kr-Txt 40-Mntv2kr-l2t Tda935x 6x 8xps n2 Uc3842Danutz FcsNo ratings yet

- STR De245Document32 pagesSTR De245Xavier LoáisigaNo ratings yet

- Manual Servicio JVC AV-21VT15Document50 pagesManual Servicio JVC AV-21VT15diegonlineNo ratings yet

- Panasonic TC-21FX20,21 Service ManualDocument29 pagesPanasonic TC-21FX20,21 Service ManualPratik Gandhi83% (12)

- Agilent 34401A Multimeter 33K8!4!1029-1Document14 pagesAgilent 34401A Multimeter 33K8!4!1029-1Serrot OnaivlisNo ratings yet

- Digital Multimeter CalibrationDocument11 pagesDigital Multimeter CalibrationprettywomenNo ratings yet

- English: Operating InstructionsDocument23 pagesEnglish: Operating InstructionsCarloxs YTNo ratings yet

- Daewoo Cm537 Chassis Dth14q1es TV SMDocument78 pagesDaewoo Cm537 Chassis Dth14q1es TV SMsergionelNo ratings yet

- Daewoo Cn150 Chassis Dtq14p1fc TV SMDocument35 pagesDaewoo Cn150 Chassis Dtq14p1fc TV SMzxcvbnm12548796No ratings yet

- Admiral TKF3400A (Manual)Document24 pagesAdmiral TKF3400A (Manual)crisarg_10No ratings yet

- Daewoo DVN-14F6N, DVN-20F6N Chassis CN-140 TV VCR PDFDocument142 pagesDaewoo DVN-14F6N, DVN-20F6N Chassis CN-140 TV VCR PDFplatonvhmNo ratings yet

- Tv2Kr - TXT: Service ManualDocument13 pagesTv2Kr - TXT: Service ManualCarp CornelNo ratings yet

- LG 21fu7rl Chasis CW81B PDFDocument22 pagesLG 21fu7rl Chasis CW81B PDFjoscar7No ratings yet

- BN TACH100 Standalone Digital Tachometer Datasheet 176063Document9 pagesBN TACH100 Standalone Digital Tachometer Datasheet 176063Yasmine SalehNo ratings yet

- Digital Multimeter CalibrationDocument6 pagesDigital Multimeter CalibrationKhalidNo ratings yet

- BC-8000 Field Calibration Procedure 55 AMPDocument11 pagesBC-8000 Field Calibration Procedure 55 AMP김덕용No ratings yet

- 60 PV 450Document56 pages60 PV 450Dan PrewittNo ratings yet

- Panasonic TC 14jr1p TX 21 Jr1p z7Document31 pagesPanasonic TC 14jr1p TX 21 Jr1p z7dann222No ratings yet

- Sony STR-De635 Ver 1.1Document58 pagesSony STR-De635 Ver 1.1rumendm100% (1)

- 14FES1BN AkiraDocument36 pages14FES1BN AkiraIleana RuvalcabaNo ratings yet

- Training LG 50pa4500-Dm 50pa4510-Dj CH - Pb23aDocument48 pagesTraining LG 50pa4500-Dm 50pa4510-Dj CH - Pb23aFrancisco Orozco50% (4)

- Sweep Function Generator Operation ManualDocument23 pagesSweep Function Generator Operation ManualAhmed Sherif CupoNo ratings yet

- Sylvania Srt2232x Service ManualDocument56 pagesSylvania Srt2232x Service ManualIgnatius ReillyNo ratings yet

- Extech 407750 ManualDocument8 pagesExtech 407750 ManualTuấn LêNo ratings yet

- LG Rt-21sb4rg - rlx-t4 - z4 Chasis Cw81bDocument24 pagesLG Rt-21sb4rg - rlx-t4 - z4 Chasis Cw81bDeivid SaavedraNo ratings yet

- Sony ST SB920Document23 pagesSony ST SB920Dave HuntNo ratings yet

- Panasonic TX-28CK2P - Z-M3P Chassis CRT TV SMDocument25 pagesPanasonic TX-28CK2P - Z-M3P Chassis CRT TV SMPravin MevadaNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Build Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterFrom EverandBuild Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterRating: 5 out of 5 stars5/5 (4)

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Zetec Ultravision EC DatasheetDocument2 pagesZetec Ultravision EC Datasheetcarlos0% (1)

- Winter 2018 Registration FormDocument1 pageWinter 2018 Registration FormcarlosNo ratings yet

- Weld ProcedureDocument2 pagesWeld ProcedurecarlosNo ratings yet

- Eddyliner PX User ManualDocument146 pagesEddyliner PX User ManualcarlosNo ratings yet

- Ndtspec Radiographic Nde ReportDocument1 pageNdtspec Radiographic Nde ReportcarlosNo ratings yet

- RotoUTscan v8Document2 pagesRotoUTscan v8carlosNo ratings yet

- 1463520118Document2 pages1463520118carlosNo ratings yet

- Aerofab NDT Rotary Probes CatalogDocument23 pagesAerofab NDT Rotary Probes CatalogcarlosNo ratings yet

- Cygnus 1 Manual V617ADocument42 pagesCygnus 1 Manual V617AMichael JordanNo ratings yet

- 811 2800 - PFINDER 280 - Flyer - GB - v2Document1 page811 2800 - PFINDER 280 - Flyer - GB - v2carlosNo ratings yet

- Setup Guide No 4 Weld Inspection WeldcheckDocument7 pagesSetup Guide No 4 Weld Inspection WeldcheckcarlosNo ratings yet

- M-107/M-208 Wheel SpecificationDocument40 pagesM-107/M-208 Wheel SpecificationKristian Marchena100% (3)

- HDV Accessories: Videoscope Camera Probes & AccessoriesDocument1 pageHDV Accessories: Videoscope Camera Probes & AccessoriescarlosNo ratings yet

- Safety Data Sheet: SIR Chem® Dry Powder 63 RedDocument6 pagesSafety Data Sheet: SIR Chem® Dry Powder 63 RedcarlosNo ratings yet

- NDT MarketplaceDocument1 pageNDT MarketplacecarlosNo ratings yet

- 30mm CalibrationDocument10 pages30mm CalibrationcarlosNo ratings yet

- OmniSX MX2 Training 4A PA Calculator OverviewDocument10 pagesOmniSX MX2 Training 4A PA Calculator OverviewcarlosNo ratings yet

- 3 OmniSX GettingStarted PA Weld AnalysisDocument16 pages3 OmniSX GettingStarted PA Weld AnalysiscarlosNo ratings yet

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- 3dii BrochureDocument6 pages3dii BrochurecarlosNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- OmniSX MX2 Training 5A Weld and Part Wizard UseDocument15 pagesOmniSX MX2 Training 5A Weld and Part Wizard Usecarlos100% (1)

- OmniScan SX \ MX2 Training - Phased Array Wedge OverviewDocument37 pagesOmniScan SX \ MX2 Training - Phased Array Wedge OverviewcarlosNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- Tofd PCNDocument22 pagesTofd PCNmarforall5205No ratings yet

- OmniSX MX2 Training 4B Phased Array ProbesDocument49 pagesOmniSX MX2 Training 4B Phased Array Probescarlos100% (2)

- 1 OmniSX GettingStarted Touchscreen UseDocument25 pages1 OmniSX GettingStarted Touchscreen UsecarlosNo ratings yet

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- 4.omniscan Setup - Min-Wheel Encoder SetupDocument13 pages4.omniscan Setup - Min-Wheel Encoder SetupcarlosNo ratings yet

- Noritz N-063 Installation ManualDocument66 pagesNoritz N-063 Installation ManualbondsupplyNo ratings yet

- Project Equipment Load AnalysisDocument54 pagesProject Equipment Load Analysisrajeshmk2002100% (6)

- Murat Kenedy: Bu Içerik Tarafından HazırlanmıştırDocument2 pagesMurat Kenedy: Bu Içerik Tarafından HazırlanmıştırChatorg. orgNo ratings yet

- Artificial MusclesDocument8 pagesArtificial MusclespinnakapentiumNo ratings yet

- Generative NLP Robert DiltsDocument11 pagesGenerative NLP Robert DiltsTyler Durden100% (22)

- BSBCRT511 Project Portfolio - Revised - Answers IncludedDocument26 pagesBSBCRT511 Project Portfolio - Revised - Answers IncludedShivanee JhaumalNo ratings yet

- Planets Classification Malefic and BeneficDocument3 pagesPlanets Classification Malefic and Beneficmadhu77No ratings yet

- Final Koni FinalDocument124 pagesFinal Koni FinalBinod BoharaNo ratings yet

- Ese 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1Document44 pagesEse 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1het shahNo ratings yet

- Public Speaking RulesDocument12 pagesPublic Speaking RulesAnonymous 0ejRGUpmo1No ratings yet

- Gamma Ray Log ShamshadDocument36 pagesGamma Ray Log Shamshadgadi_143100% (6)

- Chapter 2 - Key Themes of Environmental ScienceDocument34 pagesChapter 2 - Key Themes of Environmental ScienceJames Abuya BetayoNo ratings yet

- Grade 3 Unit 3 (English)Document1 pageGrade 3 Unit 3 (English)Basma KhedrNo ratings yet

- Telescopic sight basics and reticle typesDocument18 pagesTelescopic sight basics and reticle typesKoala LumpurNo ratings yet

- Gabriel Feltran. "The Revolution We Are Living"Document9 pagesGabriel Feltran. "The Revolution We Are Living"Marcos Magalhães Rosa100% (1)

- Life Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity JointDocument244 pagesLife Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity Jointbee140676No ratings yet

- Standard 2Document10 pagesStandard 2Bridget GumboNo ratings yet

- Onward Journey Ticket Details E Ticket Advance ReservationDocument1 pageOnward Journey Ticket Details E Ticket Advance ReservationAnonymous yorzHjDBdNo ratings yet

- Sunward Rotary Drilling Rig Maintenance ManualDocument35 pagesSunward Rotary Drilling Rig Maintenance ManualPaul Kenneth AbayataNo ratings yet

- Generate power from solar roof tilesDocument4 pagesGenerate power from solar roof tilesshalinthNo ratings yet

- Off-Highway 6600 Series Transmission SpecsDocument2 pagesOff-Highway 6600 Series Transmission SpecsIng Dimatiguz0% (1)

- Army Aviation Digest - Feb 1967Document68 pagesArmy Aviation Digest - Feb 1967Aviation/Space History LibraryNo ratings yet

- TableDocument9 pagesTableShamlakan elghaoucheNo ratings yet

- Even Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityDocument2 pagesEven Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityprashantNo ratings yet

- Eco 201Document23 pagesEco 201Tâm TítNo ratings yet

- ACP160DDocument14 pagesACP160Dinbox934No ratings yet

- Speech Sound Disorders First Edition Ebook PDF VersionDocument57 pagesSpeech Sound Disorders First Edition Ebook PDF Versionzelma.bennett128100% (39)

- Trip WireDocument19 pagesTrip Wirepinky065558100% (2)

- Module 1 SIMPLE INTERESTDocument15 pagesModule 1 SIMPLE INTERESTElle Villanueva VlogNo ratings yet

- C ProgDocument29 pagesC ProgaishwaryaNo ratings yet