Professional Documents

Culture Documents

Setup Guide No 4 Weld Inspection Weldcheck

Uploaded by

carlosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Setup Guide No 4 Weld Inspection Weldcheck

Uploaded by

carlosCopyright:

Available Formats

Purpose

Equipment Required

Pre Inspection Setup

Single Frequency Weld Inspection (Weldcheck)

Typical Welding Inspection Procedure (Single Frequency

Instruments):

Pre Inspection:

road!and Pro!e "#$P# (Paint Pro!e) Weld

Re%erence Standard #"&$$'

Setup (uide )ote )o *

Weld Inspection

These notes are ofered as a guide to help carry out a demonstration for weld

inspection using the WeldScan Probes. The notes have been based on using one

of the Phasec/Locator Eddy urrent !nstruments.

Weldchec" instrument

Weld inspection "it

oating Thic"ness# !f the weld is coated i.e. painted$ it is important to ascertain

the thic"ness of this layer prior to the inspection to compensate for it. !f this is

not performed incorrect sensitivity levels may be selected and thus possible

defects missed. This achieved with a %roadband Probe &Paint Probe' ()*P) and

+eference Standard )(,**-$ utilising the . yellow plastic shims. Each shim is

appro/imately *.0 mm thic".

)ote# The fre1uency used for this inspection is (* "23$ which is outside the

normal fre1uency range 1uoted on the probe.

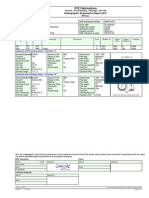

Set up (uide )otes %or +oating E,aluation

-se similar settings as !elo./

Paramet

er

0alue

1ode )ormal

Single

Frequen

cy

"$ k23

Pro!e &!solute

(ain 456 7$d57$d

Filter

2P58P

9+5#$$

23

Input

(ain

2igh

9ri,e $

asic Paint Pro!e Settings

STE

P

T&S:

(. +onnect Paint Pro!e to instrument and s.itch on/

4. alance pro!e in air/

). Place pro!e on Re%erence Stand Part )o: #"&$$' a.ay %rom

E91 slots and edges and !y using the phase control rotate the

signal to o!tain a ,ertical signal amplitude/

.. Increase the ; Full Screen 2eight (FS2) o% the signal to

<"$$; FS2 !y using the gain control/

0. Position " plastic shim on re%erence standard and place pro!e

on it= noting the ; FS2 o% the signal/ -sing the gain control

ad>ust signal amplitude to appro?imately '$; Full Screen

2eight (FS2)/

5. Remo,e pro!e %rom shim and place another shim on top o% the

other/ )ote ; FS2 o% the signal/

6. Repeat step * %or the remaining 7 shims/

-. )o. the instrument has !een set up place the pro!e on the

area to !e inspection= noting the ; FS2 o% the signal

amplitude/

7. 1atch the ; FS2 o% the signal %rom the inspection area to that

gi,en %rom the re%erence standard5shim com!ination/

Typical Signals o!tained %rom Shims

Setup (uide )oted %or Weld Inspection

Paramet

er

0alue

1ode )ormal

Single

Frequen

cy

"$$ k23

Pro!e ridge

(ain 456 @$d5@$

d

Filter

2P58P

9+5#$$

23

Input

(ain

2igh

9ri,e A'

asic Weld Inspection Settings

STE

P

T&S:

"/ 9isconnect the BPaint Pro!eC and connect a suita!le WeldScan

Pro!e/

#

/

-tilising the Re%erence Standard Part )o: #"&$$' (.ith the

correct num!er o% shims) place pro!e on it a.ay %rom any E19

slots and edges and !alance/

are 1etal D $

Shims

" Shim E

$/@ mm

7 Shims E "/$

mm

# Shims E "/@

mm

* Shims E 7/$

mm

)ote# To enable to show

screen shot$ the phase has

been rotated by (*8 for

each coating thic"ness

measurement.

9ow the thic"ness of the coating &if applicable' has been established$ it is

now re1uired to calibrate the !nstrument to perform the Weld !nspection.

*

/

Scan pro!e o,er "/$ mm slot and note the signal amplitude

and phase/

@

/

-sing the phase control rotate the signal to ,ertical and ad>ust

the gain to gi,e "$$; FS2 .hen scanning o,er the "/$ mm

slot/

F

/

+arry out inspection o% .eld as per company procedure/

Typical Signal Response %rom Re%erence Standard "/$ mm Slot

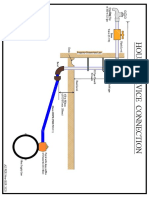

Typical Scanning Techniques:

9ual Frequency Weld Inspection (Weldcheck)

Setup (uide )otes %or Welding Inspection -sing 9ual Frequency

1ode

Scanning the +ap o% the

Weld

Scanning Toe G 2&H o% the

Weld

"$$; FS2 %rom " mm

E91 )otch

)ote: )o (raticule

alance point

&d,antages o% 9ual Frequency Inspections o,er Single Frequency

Inspections

The main advantage of using a :ual ;re1uency !nstrument over a Single

;re1uency !nstrument is that the coating thic"ness can be monitored

continuously during the inspection allowing ad<ustment of instrument

sensitivity for variations in coating thic"nesses. This procedure also only

re1uires the use of a single WeldScan probe$ thus eliminating the need to

interchange probes for coating thic"ness evaluations and weld inspections.

:ual ;re1uency Weld !nspection ,dvantages

Will reduce inspection time.

oating thic"ness variations can be observed while inspecting the weld$

permitting inspection sensitivity levels to be ad<usted as re1uired$

ensuring inspection 1uality is maintained.

=nly one probe is re1uired.

;or full details of scanning patterns and inspection procedure please refer to#

E) "I"": 7$$$ BEddy Current Examination of Welds by Complex

Plane Analysis

The illustrations below show typical scan patterns for the cap of the weld$

the toe of the weld and the 2eat ,fected >one &2,>'.

Paramete

r

0alue Paramete

r

0alue

Frequency

"

"$$ k23 Frequenc

y 7

"$ k23

Pro!e " ridge Pro!e 7 &!solut

e

(ain " 456 @$d5@$

d

(ain 7 456 @#d5@#

d

Filter "

2P58P

9+5#$$

23

Filter 7

2P58P

9+5"$

23

Input (ain

"

2igh Input

(ain 7

2igh

STEP T&S:

"/ +onnect WeldScan Pro!e to a 9ual Frequency instrument

and s.itch on the instrument/

7/ (o to main menu and select 1ode E )ormal 9ual= 0ie. E

F":F7 and alance E Split/

)ote: In BSplitC the 8e%t hand alance :ey alances F" and

Right 2and alance :ey alances F7

#/ Set the parameters as a!o,e (guide only)/ <ernati,ely go

to BRecall Set -psC in the menu and select BWeldScan 9ual

FeC/ )ote: Phase= (ain and !alance positionsmay require

ad>ustment/

*/ To &scertain +oating Thickness place the pro!e a.ay %rom

E91 slots and edges on the re%erence !ock (no shims) Part

)o: #"&$$' and !alance/

@/ Position all * plastic shim on re%erence standard and reD

place pro!e on the total stack= noting the ; FS2 o% the

signal/ -sing the gain control ad>ust signal amplitude to

appro?imately J@; Full Screen 2eight (FS2)/

F/ Remo,e pro!e %rom re%erence !lock and remo,e " shim/

Replace pro!e and note ; FS2 o% the signal/

I/ Repeat steps F %or the remaining shims

'/ &%ter ascertaining coating thickness use correct num!er o%

shims and place pro!e on re%erence !lock a.ay %rom E91

slots and edges and !alance F" and F7 +hannels/

asic 9ual Frequency Weld Inspection Settings

)ote: Frequency " E Weld Inspection +hannel/ Frequency 7 E

+oating +hannel/

F" +hannel F7 +hannel

J/ Scan pro!e o,er "/$ mm slot and note the signal amplitude

and phase/

"$/ -sing the phase control rotate the signal to ,ertical and

ad>ust the gain to gi,e "$$; FS2 .hen scanning o,er the

"/$ mm slot/ (or as per company procedures/)

""/ Proceed .ith scanning monitoring F" +hannel %or de%ect

indications and F7 +hannel %or changes in +oating

Thicknesses/ When coating thickness changes are noted

stop inspection and ad>ust gain (Sensiti,ity 8e,els) to suit/

%are ?etal @ * Shims

( Shim A *.0 mm

4 Shims A (.* mm

) Shims A (.0 mm

. Shims A 4.* mm

4 Shims B (.* mm

( Shims B *.0 mm

%are ?etal

)ote#

(. To enable to show screen shot$ the

;( Phase has been rotated by C/@

(*8.

4. Probe scanned over (.* mm E:?

D(** ;S2 B %are ?etal

70E ;S2 B ( Shim

5*E ;S2 B 4 Shims

+oating Thickness &ssessment

EKects o% +oating Thickness 0ariations on Signal

&mplitude

You might also like

- Ultrasonic Testing Procedure for WeldsDocument11 pagesUltrasonic Testing Procedure for WeldsSaut Maruli Tua SamosirNo ratings yet

- Mil DTL 24441 - 35aDocument4 pagesMil DTL 24441 - 35aSinghalukKlumsatianNo ratings yet

- Painting of Structure Piping Equipment 22Document5 pagesPainting of Structure Piping Equipment 22Saurabh Kumar VermaNo ratings yet

- Holiday Detector 266DCDocument5 pagesHoliday Detector 266DCbis2501No ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetajuhaseenNo ratings yet

- Astm D4228 05R17Document3 pagesAstm D4228 05R17Johana Rivadeneira100% (1)

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Document5 pagesStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KNo ratings yet

- D4940 15 (Reapproved 2020) REDDocument3 pagesD4940 15 (Reapproved 2020) REDcarlos_k1555alejo100% (1)

- Sspc-Pa2 PDFDocument13 pagesSspc-Pa2 PDFEdgarDavidDiazCamposNo ratings yet

- Coating International StandardsDocument2 pagesCoating International StandardsAhmed AliNo ratings yet

- SP 18 Thoro Spot & Sweep 12-30-20Document7 pagesSP 18 Thoro Spot & Sweep 12-30-20Donzt Dontz FaujiNo ratings yet

- Dolly TestDocument1 pageDolly TestmaheshNo ratings yet

- ASTM D 714 - 87 r00Document6 pagesASTM D 714 - 87 r00Abi PutraNo ratings yet

- SSPC Protective Coatings InspectorDocument731 pagesSSPC Protective Coatings InspectorTeymur RegenmaisterNo ratings yet

- Astm D-4214Document4 pagesAstm D-4214Ahmad RoyaniNo ratings yet

- Surface Prep StandardsDocument2 pagesSurface Prep StandardsAnonymous 5mN1tLMNo ratings yet

- ASTM F21 Atomiser Test For Surface FilmsDocument5 pagesASTM F21 Atomiser Test For Surface Filmsazam RazzaqNo ratings yet

- Astm17 0303Document5 pagesAstm17 0303Edgardo Emilio CantillanoNo ratings yet

- Determining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumDocument3 pagesDetermining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumwerrteNo ratings yet

- William D. Corbett, KTA-Tator, Inc. Chair - SSPC Committee C.3.2 On Dry Film Thickness MeasurementDocument56 pagesWilliam D. Corbett, KTA-Tator, Inc. Chair - SSPC Committee C.3.2 On Dry Film Thickness MeasurementvtjoselineNo ratings yet

- ASTM D4541 and ISO 4624: ?/sup InstrumentsDocument2 pagesASTM D4541 and ISO 4624: ?/sup InstrumentsTeguh SilaNo ratings yet

- Evaluate paint film cure with solvent rub testDocument3 pagesEvaluate paint film cure with solvent rub testNisa_nisheNo ratings yet

- ESD Flooring Audit ReportDocument11 pagesESD Flooring Audit Reportlaiju cs100% (1)

- Astm 4752Document8 pagesAstm 4752Martin ManriqueNo ratings yet

- Cathodic Disbonding TesterDocument1 pageCathodic Disbonding TesterfelavinNo ratings yet

- Astm and Iso Vocs in Coatings - Method Comparison MatrixDocument2 pagesAstm and Iso Vocs in Coatings - Method Comparison MatrixShaik ShahNo ratings yet

- Powder Coating TrainingDocument22 pagesPowder Coating Trainingakash.vd.1603No ratings yet

- Epoch 4 Operations ManualDocument164 pagesEpoch 4 Operations ManualpjhollowNo ratings yet

- ASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and ReagentsDocument2 pagesASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and Reagentsalin2005No ratings yet

- Astm E2491 06Document13 pagesAstm E2491 06phanthanhhungNo ratings yet

- Nuclear Containment FailuresDocument10 pagesNuclear Containment FailuresskdonaldsNo ratings yet

- BooksDocument1 pageBookswahNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- SSPC - Paint 41 PDFDocument5 pagesSSPC - Paint 41 PDFIvanSanchez100% (1)

- Astm D6670-2018Document21 pagesAstm D6670-2018damaso taracenaNo ratings yet

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- Iso CatalogosDocument9 pagesIso Catalogosenilson19670% (1)

- SSPC Standards Update NSRP PanelDocument30 pagesSSPC Standards Update NSRP PanelAnbalagan Ravichandran100% (1)

- Astm E2375Document2 pagesAstm E2375gregkilatonNo ratings yet

- Dye Penetrant InspectionDocument2 pagesDye Penetrant InspectionsuparnaNo ratings yet

- Surface Preparation Repair May 2020Document6 pagesSurface Preparation Repair May 2020Mel AnieNo ratings yet

- En 13920-2015Document8 pagesEn 13920-2015mihaiNo ratings yet

- Vdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsDocument1 pageVdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsEdgarDavidDiazCamposNo ratings yet

- Astm d7234Document14 pagesAstm d7234manuelguamanNo ratings yet

- How To Create Pid: Yohanneti RWH Process EngineerDocument22 pagesHow To Create Pid: Yohanneti RWH Process Engineeryohanneti rwhNo ratings yet

- Astm D4417Document3 pagesAstm D4417claudiaNo ratings yet

- ASTZM E1476-97 Metals Sorting Guide PDFDocument12 pagesASTZM E1476-97 Metals Sorting Guide PDFKewell LimNo ratings yet

- HEMPEL'S URETHANE 5595U High Gloss Protective CoatingDocument2 pagesHEMPEL'S URETHANE 5595U High Gloss Protective CoatingFreddy Carl FredricksenNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- 234 D7091 344Document7 pages234 D7091 344Ivan AlanizNo ratings yet

- SSPC Guide 3 - Paint Safety PDFDocument19 pagesSSPC Guide 3 - Paint Safety PDFAlexander SaulNo ratings yet

- Instrument Calibration ProcedureDocument7 pagesInstrument Calibration ProceduremullanjiNo ratings yet

- NFS2 3030 SpecificationDocument26 pagesNFS2 3030 SpecificationJC InquillayNo ratings yet

- D41 Safety Maintenance LogbookDocument35 pagesD41 Safety Maintenance LogbookjoreyvilNo ratings yet

- Section Testing, Identification and Administration of Fiber Infrastructure Part 1 - GeneralDocument10 pagesSection Testing, Identification and Administration of Fiber Infrastructure Part 1 - Generalssantos_303882No ratings yet

- Weld ProcedureDocument2 pagesWeld ProcedurecarlosNo ratings yet

- Winter 2018 Registration FormDocument1 pageWinter 2018 Registration FormcarlosNo ratings yet

- 1463520118Document2 pages1463520118carlosNo ratings yet

- Ndtspec Radiographic Nde ReportDocument1 pageNdtspec Radiographic Nde ReportcarlosNo ratings yet

- M-107/M-208 Wheel SpecificationDocument40 pagesM-107/M-208 Wheel SpecificationKristian Marchena100% (3)

- Safety Data Sheet: SIR Chem® Dry Powder 63 RedDocument6 pagesSafety Data Sheet: SIR Chem® Dry Powder 63 RedcarlosNo ratings yet

- NDT MarketplaceDocument1 pageNDT MarketplacecarlosNo ratings yet

- Zetec Ultravision EC DatasheetDocument2 pagesZetec Ultravision EC Datasheetcarlos0% (1)

- RotoUTscan v8Document2 pagesRotoUTscan v8carlosNo ratings yet

- Aerofab NDT Rotary Probes CatalogDocument23 pagesAerofab NDT Rotary Probes CatalogcarlosNo ratings yet

- Cygnus 1 Manual V617ADocument42 pagesCygnus 1 Manual V617AMichael JordanNo ratings yet

- HDV Accessories: Videoscope Camera Probes & AccessoriesDocument1 pageHDV Accessories: Videoscope Camera Probes & AccessoriescarlosNo ratings yet

- Eddyliner PX User ManualDocument146 pagesEddyliner PX User ManualcarlosNo ratings yet

- VM Products Gain Test Box2Document16 pagesVM Products Gain Test Box2carlos100% (1)

- 811 2800 - PFINDER 280 - Flyer - GB - v2Document1 page811 2800 - PFINDER 280 - Flyer - GB - v2carlosNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- 3dii BrochureDocument6 pages3dii BrochurecarlosNo ratings yet

- 30mm CalibrationDocument10 pages30mm CalibrationcarlosNo ratings yet

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- OmniScan SX \ MX2 Training - Phased Array Wedge OverviewDocument37 pagesOmniScan SX \ MX2 Training - Phased Array Wedge OverviewcarlosNo ratings yet

- OmniSX MX2 Training 5A Weld and Part Wizard UseDocument15 pagesOmniSX MX2 Training 5A Weld and Part Wizard Usecarlos100% (1)

- Tofd PCNDocument22 pagesTofd PCNmarforall5205No ratings yet

- OmniSX MX2 Training 4A PA Calculator OverviewDocument10 pagesOmniSX MX2 Training 4A PA Calculator OverviewcarlosNo ratings yet

- OmniSX MX2 Training 4B Phased Array ProbesDocument49 pagesOmniSX MX2 Training 4B Phased Array Probescarlos100% (2)

- 1 OmniSX GettingStarted Touchscreen UseDocument25 pages1 OmniSX GettingStarted Touchscreen UsecarlosNo ratings yet

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- 4.omniscan Setup - Min-Wheel Encoder SetupDocument13 pages4.omniscan Setup - Min-Wheel Encoder SetupcarlosNo ratings yet

- 3 OmniSX GettingStarted PA Weld AnalysisDocument16 pages3 OmniSX GettingStarted PA Weld AnalysiscarlosNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- Minicap FTC260, FTC262: Technical InformationDocument20 pagesMinicap FTC260, FTC262: Technical InformationAmanda PorterNo ratings yet

- Culinary History and Nouvelle CuisineDocument4 pagesCulinary History and Nouvelle CuisineARPITA BHUNIANo ratings yet

- Galaxy NanoporeDocument11 pagesGalaxy NanoporeDeborah ShirleenNo ratings yet

- Toxicology Compendium PDFDocument602 pagesToxicology Compendium PDFJUANNo ratings yet

- Intelligence, Reasoning, Creativity, and WisdomDocument3 pagesIntelligence, Reasoning, Creativity, and WisdomSammy DeeNo ratings yet

- Laplace Transform AssignmentDocument1 pageLaplace Transform AssignmentMohamad DuhokiNo ratings yet

- Tivax STB-T12 Owners ManualDocument32 pagesTivax STB-T12 Owners ManualJesseNo ratings yet

- Pic24fj256ga705 Family Data Sheet Ds30010118eDocument424 pagesPic24fj256ga705 Family Data Sheet Ds30010118eD GzHzNo ratings yet

- Khalid DL 01 ProfileDocument2 pagesKhalid DL 01 ProfileRipunjay MishraNo ratings yet

- Sony Ericsson K610i, K610m, and V630i Service ManualDocument53 pagesSony Ericsson K610i, K610m, and V630i Service ManualJane TodoroskiNo ratings yet

- Water Demand Fire Flow Calculation Hydraulic ModelingDocument110 pagesWater Demand Fire Flow Calculation Hydraulic ModelingArthur DeiparineNo ratings yet

- Finger Print Based Voting System For Rigging Free Governing SystemDocument2 pagesFinger Print Based Voting System For Rigging Free Governing SystemArvind TilotiaNo ratings yet

- Balance of Payment (BoP) Definition, Importance and ComponentsDocument21 pagesBalance of Payment (BoP) Definition, Importance and ComponentsAnkita Sharma PandeyNo ratings yet

- Section 09 - Traction Electrification SystemDocument47 pagesSection 09 - Traction Electrification SystemAbu Monsur Ali100% (1)

- Engagement & Akad PDFDocument3 pagesEngagement & Akad PDFedputriNo ratings yet

- Assignment IDocument2 pagesAssignment Ivaishnavi priyaNo ratings yet

- Civil Engineering Set 2Document13 pagesCivil Engineering Set 2Dev ThakurNo ratings yet

- Electric Charge: Conservation and Quantization Conductors, Insulators, and Induced ChargesDocument21 pagesElectric Charge: Conservation and Quantization Conductors, Insulators, and Induced ChargesAcadGucciManeNo ratings yet

- TTBR 10 January 2024 LDocument22 pagesTTBR 10 January 2024 Lfossil.tractor0sNo ratings yet

- Introduction: Use Chapter 2 Section 2 in Your Flexbook To Define The FollowingDocument5 pagesIntroduction: Use Chapter 2 Section 2 in Your Flexbook To Define The FollowingNathalieNo ratings yet

- CP I-O Modules PDFDocument91 pagesCP I-O Modules PDFVlad ChioreanNo ratings yet

- IRELAND - Rivers, Lakes and Mountains: Look at The Maps and Answer These QuestionsDocument2 pagesIRELAND - Rivers, Lakes and Mountains: Look at The Maps and Answer These QuestionsHannaNo ratings yet

- BSC Ag Syllabus 5th DeanDocument150 pagesBSC Ag Syllabus 5th Deansaurabh rNo ratings yet

- HTP 12 SkodaDocument3 pagesHTP 12 SkodamihnutzuNo ratings yet

- House Service Connection NEW BSR 2020-1Document1 pageHouse Service Connection NEW BSR 2020-1Deshraj BairwaNo ratings yet

- Descent of Darwin - Theosophy WatchDocument17 pagesDescent of Darwin - Theosophy Watchjorge_lazaro_6No ratings yet

- Mibk - TDS PDFDocument3 pagesMibk - TDS PDFMardianus U. RihiNo ratings yet

- Esquematicos CaterpillarDocument9 pagesEsquematicos Caterpillarluis alberto rodriguez100% (1)

- Why Britain Had Christianity EarlyDocument47 pagesWhy Britain Had Christianity EarlyChris WoodNo ratings yet

- The Effects of Oar-Shaft Stiffness andDocument9 pagesThe Effects of Oar-Shaft Stiffness andValentina DiamanteNo ratings yet