Professional Documents

Culture Documents

Pak UK Associates (PVT.) Limited (Profile)

Uploaded by

PAK UK GROUPOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pak UK Associates (PVT.) Limited (Profile)

Uploaded by

PAK UK GROUPCopyright:

Available Formats

CONTENTS

1. INTRODUCTION

2. REGISTRATION CERTIFICATES

( SECP, PEC, NTN, GST, ICCI, CAP, IIC )

3. QUALITY POLICY, SAFETY POLICY, SAFETY MANUAL & CODE OF CONDUCT

4. ORGANIZATIONAL CHART OF THE COMPANY

5. LIST OF KEY PERSONNEL / ENGINEERS / CVs

6. LIST OF MACHINERY/ VEHICLES

7. ENLISTMENT/PRE-QUALIFICATION WITH DEPARTMENTS/AGENCIES

8. LIST OF COMPLETED PROJECTS WITH COMPLETION CERTIFICATES (DURING LAST 05

YEARS)

9. LIST OF ON GOING PROJECTS WITH AWARD LETTERS

10. FINANCIAL CAPABILITY, TAX CERTIFICATES AND AUDITED BALANCE SHEETS, AVERAGE

ANNUAL CONSTRUCTION TURNOVER

11. BANK CERTIFICATES

12. AFFIDAVIT OF THE COMPANY ( NON-LITIGATION, NON-BLACK LISTMENT)

INTRODUCTION 1

INTRODUCTION

M/S Pak UK Associates (Pvt.) Ltd. was established in 2005, started its

construction activities since then. Pak UK Associates is committed to creating and

utilizing the most innovative, state-of-the-art, fully equipped and financial backing

to carry out the construction projects of every nature and complexity, the Company

has completed numerous housing projects, high-rise residential and commercial

buildings, office buildings for Government, Semi-Government and Private

Organizations, of similar size and nature.

Pak UK Associates is dedicated to maintaining a strong, committed management

team, supported by a staff of highly competent qualified engineers and specialists.

Combined with the flexibility and readiness to incorporate and utilize changing and

challenging environments, we can adapt to circumstances that extend beyond

cultural and social barriers.

OUR VISSION

To be the premier construction Company in the market we serve.

OUR MISSION

To be an effective construction and engineering unit, ensuring quality, price, time

commitment and post completion service.

OUR CORE VALUES

Our values are the foundation of our Company and reflect our guiding Principles:

1. Integrity 2. Innovation 3. Mutual Respect

4. Sense of Urgency 5. Safety 6. Community

M/S Pak UK Associates (Pvt.) Ltd. has diversified experience in operating

construction projects in accordance with stipulated period of contract and with

quality assurance procedures to the best satisfaction of the client.

REGISTRATION CERTIFICATES 2

Certificate Of Incorporation Security & Exchange Commission of Pakistan (SECP)

Pakistan Engineering Council (PEC)

National Tax Number Certificate (NTN) Federal Board Of Revenue (FBR)

General Sales Tax (GST)

Islamabad Chamber Of Commerce & Industry (ICCI)

Constructors Association of Pakistan (CAP)

International Industrial Certification ( IIC ) - ISO 9001 : 2008

Pakistan Institute Of Cost And Contracts (PICC)

QUALITY POLICY/SAFETY POLICY & MANUAL

& CODE OF CONDUCT

3

QUALITY POLICY

We have always believed:

Quality is never an accident. It is always the result of high intentions, sincere efforts, and

determination and proficient execution. It represents the wise choice of many alternatives

It has always been our motive to deliver highest quality construction with in the parameters

ordained by our employers. Keeping in view our mission and vision we are invariably going

through the process of developing and implementing systems, which enable us to accomplish our

objectives. The focus of our system revolves around adherence to specifications, supervising staff or

supervising Consultants requirements. The emphasis of our system evolution process also

circumambulates around good financial management of the company, which is extremely critical to

achieving our clients satisfaction.

While enrooting to become a good quality company we have worked on developing procedures that

inter connect our material requisition work orders with project schedule, available/ projected cash

flows.

We have also worked on making supervision objective to our supervising staff, so as to reduce the

element of subjectivity in supervision and make it objective to them. The objectivity in supervision

in achieved by highlighting critical objects at the beginning of every project. The propose of this

exercise is to attain zero punch lists at the end of the project.

Our procedures also focus around increasing participation of our employees and staff in attaining

quality. We keep making sure the adaptability of our procedures to varied environments of

different clients. Before the start of every project we go through the exercise of aligning our

systems with that our employer so as to achieve maximum client satisfaction.

Avoiding working in orthodox manner we keep ourselves equipped with the most recent

technologies and software. We also keep our staff aware of these changes and other prevailing

changes in and other prevailing changes in construction industry. All this is done to achieve better

results in client satisfaction.

SAFETY MANUAL

1. Management Support and Direction

Implementing such procedures and molding them into part of your company procedures should

start from the top of the hierarchy. Our Project Managers are well educated with the safety

measure to be implemented at site and follow them religiously and rigorously try to implement

them on site.

2. Safety Behavior and Development

A safety supervisor is assigned at site who keeps of a watch for any unsafe practices and for all

the equipment, tools or any other accessories required for safe execution of works.

3. Safe Behavior and Development

The safety supervisor constantly literates the labor and other contractors working at site

regarding safe procedures and identifies hard hat areas, hard shoes areas and, no go areas

where works are being carried out at height. The safety supervisor also gives instructions to the

security personnel at site to restrict entry of unconcerned people as they would not be aware of

the safety measures.

4. Job Site Audits

Informal safety audits are carried out by the higher management at least twice a month to check

if the safety measures are being complied.

5. Incident Investigation and Reporting

The safety office carries out a complete investigation of any incident at site and prepares a

detail report for the higher management to review with proposed measure that should be taken

up to minimize or decimate any chances of occurrence of incident of similar nature.

6. First Aid Help

First aid kit is available at all sites and one or two members of the staff are briefly trained in

carrying out first aid procedures. All site staff and personnel are informed about place of first

aid kit and its assigned place for incase of emergency and are specially informed about the

emergency contact numbers.

7. Site Security

Site security is kept strict 24 hrs for any unauthorized access, which also limits the injury to be

caused to any trespasser.

8. Mobile Equipment Safety

All equipments are run by trained personnel who are assigned to specific equipments. An

Equipment specialist checks the equipment thoroughly before it is put to use. The equipment is

specially checked for any loose nuts bolts and covers. The lubricants are checked on regular

basis to prevent any damage to the engine which in return would also non-environment

friendly. Special arrangements are made for the shifting of heavy equipments by using cranes

and fork lifts, which are operated by trained personnel.

9. Material Safety

All materials being delivered at site are kept at separate repositories specially those materials

that are susceptible to fire or can cause explosion.

10. Fire Safety

1. The water reservoirs made at site are made large enough to cater the

requirement to extinguish fire.

2. Fire extinguishers are also made available at site.

3. All explosive and materials prone to fire are kept in safe repositories.

11. Safe Work Practices

a. Works with Cement

All workers carrying out works with cement are required to wear.

1. Special gloves

2. Boots

3. Helmets

4. Goggles

In order to keep their hands, feet, head and eyes safe from cement.

b. Works with Cement

All workers carrying out works with cement are required to wear.

1. Special gloves

2. The Tower/ scaffolding are secured against any movement. The working

platform is properly clamped against the structure.

3. The structure is maintained fee from grease and rust.

4. The work level of structure carries a abdomen level to restrict the falling over.

CODE OF CONDUCT

Our Core Values represent who we are and provide, without question, the standard of

behavior by which we conduct business. These values are the heart, soul, and character of

Pak UK. Our Code embodies the vision of our company founders and encompasses the

values that have been and will continue to be vital to future success of the Company. Our

Core Values represent how we treat each other, how we deal with our customers, how we

respond to our stakeholders, and how we hold each other and ourselves accountable. This

is the legacy we will leave for generations to come.

The following eight ethical Core Values represent the cornerstone of our Code of Conduct.

While achieving these high standards may be difficult to attain, we nonetheless aspire to live

our lives and conduct our business with:

Honesty

Be truthful, accurate and straightforward.

Be candid and non-deceptive in communication and conduct.

Integrity

Maintain consistency between your beliefs and your behavior- walk your talk!

Have the courage to contend boldly for that, which is right, and reject firmly that,

which is wrong.

Fairness

Endeavor to be reasonable, open-minded, impartial, even-handed, and non-

discriminatory in all your dealings.

Genuinely partner and actively collaborate within and outside the Company.

Maintain, without deviation, an attitude of sincerity, tolerance, consideration, and

assistance towards others, regardless of position.

Accountability

Accept responsibility for your own actions or inactions and for those whom you

supervise.

Take prompt, constructive steps to correct mistakes or defects.

Promote teamwork by holding each other accountable-rejection behaviors

inconsistent with this Code of Conduct.

Consideration of Others

Practice the principles of the Golden Rule.

Respect the dignity, rights, safety, and personal property of others.

Be open to the ideas and opinions of others.

Exercise patience and remain positive under all circumstances.

Assure that those whom you supervise are not put in compromising situations.

Pursuit of Excellence

Consistently apply diligence, perseverance, attention to detail, and good work habits

to ensure quality projects, products and excellent customer service.

Build capabilities through continuous learning, coaching, mentoring and teaching.

Never accept complacency or indifference.

Remain flexible and open to possibilities.

Reliability

Only make realistic commitments and follow-through on the commitments you make.

Be prompt and responsive in business dealings within and outside the company.

Citizenship

Comply with all governmental laws, rules and regulations.

Show consideration for the safety and welfare of everyone, including our natural

environment.

Respond to the impact our work has on the natural environment by consistently

evaluation and improving our efforts so that our projects and processes work in

harmony with the environment.

Cultivate and organization that actively encourages us to be the best of who we are

and continuously strives to make a difference in our communities and the world.

c. Electric Works

1. All electricians carrying out electrical works are conditionally required to wear

special gloves and rubber sold boots to prevent getting electric shock.

2. All wires will be used with appropriate plugs. Temporary wiring will be run in

steel conduits held loosely.

3. All switch boards/ panels will be placed securely at heights. Cable will be free of

wear and tear.

4. All electrical operated equipment will be earthed. All electrical wiring and

boards will be kept remote from flammables.

5. Multiple plugs in one socket shall not be used.

d. Hot Works

1. Adequate arrangements for fire fighting shall be available at site.

2. Work area shall be volatile vapor free.

e. Works during Rain

1. Electrical cables shall be safely secured and laid.

2. All personnel working at height shall wear safety shoes helmets and belts.

Standing near under construction area shall be prohibited.

3. Warning signs shall be place near collapsible areas.

12. House Keeping

1. All Waste materials shall be disposed of to assigned areas on regular basis.

Proper stacking of materials in use shall be done.

2. Daily cleaning of site after work has been finished shall be done. Identification

tags for hazardous materials shall be place.

3. Walkways shall be kept clear of obstacles.

4. The Site will be cleaned daily for such items at work finish so as to avoid

accumulation that not only pose ugly but can foster any emergency.

ORGANIZATIONAL CHART 4

ORGANIZATION CHART

LIST OF KEP PERSONS 5

LIST OF KEY PERSONELS

BOARD OF DIRECTORS

S No. Name of Candidate Designation

1. Muhamamd Pervaiz

Chughtai

Chief Executive

2. Engr. Sohail Shamshad Director Projects

3. Nasir Mehmood Kiyani Executive Director

MANAGEMENT

S No. Name of Candidate Designation

1. Abdul Salam General Manager

(Admin/Finance)

2. Muhammad Altaf Assistant Manager

3. Saad Suleman Admin/IT Assistant

4. Pervaiz Khan Accountant

5. Niaz Ahmed Accountant

6. Adnan Accountant

7. Ghulam Mohyyudin Store Keeper

SURVEYOR SUPERVISOR AND FOREMAN

S No. Name of Candidate Designation

1. Ehsan-ur-Rahman Surveyor-1

2. Tasaddiq Surveyor-2

3. Nasir Ahmed Surveyor-3

4. Gulshan Iqbal Quantity Surveyor

5. Nasim Ullah General Foreman

6. Toqeer Akhtar Haider Quantity Surveyor

LIST OF ENGINEERS

S No. Engineers Name Designation

1. Engr. Sohail Shamshad Project Manager/Director

Projects

2. Engr. Mohammad Azhar

Khan

E & ME Manager

3. Engr. Mohammad

Shafqat

Project Engineer/Project

Manager

4. Engr. Mohammad

Abdullah

Planning Engineer

5. Engr. Mamoon Iqbal

Cheema

Site Engineer

6. Engr. Fakhar-e-Azam Quality Control Manager

7. Engr. Saad Zaheer Site Engineer

LIST OF ASSOCIATE ENGINEERS

S No. Name of Candidate Designation

1. Muhammad Shabbir Construction Manager

2. Malik Amir Hussain Surveyor

3. Qazi Muhammad Burhan Construction Manager

4. Muhammad Ikram Surveyor

5. Azmat Kamal Quantity Surveyor

6. Ehsan-ur-Rahman Foreman

7. Tasaddiq Surveyor

8. Nasir Ahmed Foreman

9. Gulshan Iqbal Quantity Surveyor

10. Nasim Ullah General Foreman

11. Toqeer Akhtar Haider Quantity Surveyor

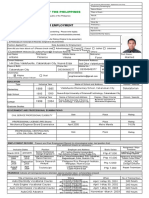

Name: SohailShamshad S/O Shamshad Ahmed

D.O.B: 09-05-1968

CNIC No: 17301-2295474-7

CONTACT NO. 0312-5542190

Qualification: B.Sc. Civil Engineering

PEC Reg. No: CIVIL/13184

EMPLOYMENT RECORD:

DATE ORGANIZATION DESIGNATION RESPONSIBILITIES

15-03-2009 to

On word

M/S Pak UK Associates

Islamabad

Projects Director Worked as I/C of Civil work

activities, administration,

Technical calculation for

different tender enquiries

01-01-2001 M/S Shani Group of

Companies Islamabad

Manager

Operations

Multistory buildings & Pre-

Fabricated Buildings

31-12-2000 M/S Al-Nafio Enterprises

Rawalakot AJ&K

Site Manager Involved in Design &

Development of Buildings at

Different sites

01-01-1996 M/S Al-Nafio Enterprises

Rawalakot AJ&K

Site Engr. Involved in Design Survey of

land, Highway, Road, Structure

of Buildings (small bridges) at

different sites

01-06-1992 M/S Al-Nafio Enterprises

Rawalakot AJ&K

Site Engr. Involved in Design, Survey of

land, Highway, Road, Structure

of Buildings (small bridges) at

different sites

01-07-1991 M/S Al-Nafio Enterprises

Rawalakot AJ&K

Asst. Engr. Practical understanding &

Orientation of all on Going

Projects

CURRICULUM VITAE

MUHAMMAD AZHAR KHAN

Date of Birth: 20

th

September 1963

CNIC NO. 33303-2063158-1

Qualification: M. Sc. (Mechanical Production Engineering)

PEC Reg. No: Mech/7277

Postal Address: House # NA-104, New Malpur, 7

th

Road Satellite Town, Rawalpindi.

Permanent Address: 18/2-A, Canal Rest House Road, Toba Tek Singh.

Phone #: 051-2203311

Cell #: 0347-7645577

E-mail: m_azharkhan88@yahoo.com

ACADEMIC QUALIFICATION:

Degree/ Certificate Year University/

Institute

Marks %age Major Subject

M.Sc. (Mechanical

Production

Engineering)

1994 U.E.T. Lahore 781/

1200

65 % Plasticity in production process.

PPC, Production management.

Work design & Measurement.

Dimensional Metrology, production

cost analysis.

B.Sc(Mechanical

Engineering)

1988 U.E.T. Taxila 55833/

8000

70 % Applied Math, Industrial materials.

Mechanics of Materials.

Engg. Drawing, Applied

thermodynamics, Statistics & Quality

control, Heat & Mass Transfer,

production managements, Energy

Resources & utilization, Gas dynamics.

F.Sc. (Add Math) 1982 Private 668/

1000

66.8 %

F.Sc. (Pre-Medical) 1980 Govt. College

Faisalabad

628/

1000

62.8 %

S.S.C (Science Group) 1978 Govt. High

School TTS.

665/

850

78 %

SKILLS

SKILL NAME LEVEL USED

Windows XP Excellent Currently Working

M.S Office (Word, P.Point and Excel) Excellent Currently Working

Auto CAD Excellent Currently Working

EXPERIENCE:

DATE ORGANIZATION DESIGNATION RESPONSIBILITIES

Jan, 2006 to

On word

M/S Pak UK

Associates (Pvt.)

Ltd. Islamabad

Project Consultant Preparing Cost Estimates of various Buildings

Preparing Tender Documents

Detail Supervision/ Site Monitoring

Preparing Monthly Progress Report

Preparation of MB

Organizing manpower of the Directorate for

ongoing works

Jan, 1995

to

July,1999

HMC TAXILA Deputy Manager

(Five Years)

As I/C Q.A looked for all sections i.e.

Fabrication Shop, M/C Shop, Assy Shop, Forge

Shop, Auxiliary Shops, IMI, Labs, Steel Foundry,

and Cast Iron Factory.

Additional charge of ISO9001 certification

team Formed to get HMC ISO9001 certified.

Moreover worked as internal auditor for

ISO9001 certification.

Jan, 1994

to

Dec, 1994

HMC TAXILA Deputy Manager

(One Year)

As I/C incoming Material inspection of HMC 1

& 2.

Jan 1993

to

Dec, 1993

HMC TAXILA Assistant Manager

(One Year)

Addition charge of Incoming material

inspection of HMC2.

Jan, 1990

to

Dec 1992

HMC TAXILA Assistant Manager

(Three Years)

Worked as I/C Q.A in Machine Shop

Jan 1989

to

Dec 1990

HMC TAXILA Assistant Manager

(One Year)

Worked as I/C Q.A in Forge shop & Hydraulic

press Shop

In 1996 started vender ship in different organizations. In 1999 Resigned from job and established own

organization, since 1999 Working as registered vendor in different defense & private organizations

under name of M/S Al-Johad Associates , A registered Firm. Moreover, working as project consultant

with M/S Pak UK Associates since 2006 and also managed different projects through Al-Johad as sub-

contractor for different private/ semi private organization

MAJOR PROJECTS (Done by AL-JOHAD ASSOCIATES)

YEARS PROJECTS DETAILS

2011,

2010,

2009

Along with under mentioned projects, we have been involved in other projects of Fabrications

&Errection of steel structure under different designs of schools/ multipurpose insulated buildings in

earthquake affected areas in KPK and AJ&K at different sites as subcontractor.

We, in addition to said projects, have been also completed turn key projects of pre-fab. Buildings

except civil work in already referred areas as sub-contractor.

2008 Along with U/M telecommunication projects we have been involved in design, development and

fabrication of 20 & 40 long containers as sub-contractor, to be used for different purpose like

transportation and food transpiration, office, residence etc.

2007 Involved in different projects of manufacturing &errection of towers, shed of different

telecommunication companies as sub-contractor at different sites in KPK, Punjab, AJ&K territories.

YEARS PROJECTS DETAILS

2006 Design and development of an injection mould for a Battery Housing for NDC

Design and development of injection moulds for Different Jobs for different private organizations.

Design and development of injection mould for Rubber Gloves for a Private organizations.

Manufacturing Pressure parts of CNG industry related in SS like manifolds etc.

2005 Fabricated STOP LOGES for Mangla Dam Raising project in association with SUN-ENGINEERS.

Fabricated of stainless steel structures and parts for different private organizations.

Fabricated different jobs for NDC as per their drawings.

Machined different jobs for NDC in M.S, C.S and S.S and different kinds of plastics as per their

drawings.

2004 Established Aluminum Anodization set up which can anodizes parts up to 6feet x 6feet.

We also develop color anodization process for medium sized parts.

We also developed alodine coating process of medium sized parts.

Developed Soft Magnetic material for thermostats which can be magnetized by heating for a private

organization.

Design and developed dies for pressure die casting of Safety Valve for a private organization.

2003 Design and Development of cutting punching and bending dies for 22 different sheet metal parts of

a 9200 series wireless set for Pak Army for National Radio and telecommunication Corporation. We

developed 108 dies in aggregate.

Established Tin plating and Zinc plating set up.

2002 DIE MOULD PROJECTS:

Design and development of Dies for pressure die casting of three parts of Charging Housing of

Missile Green Arrow for Dr. A. Q. Khan Labs. which involves also machining, powder coating and

assembly work, having total weight 4.5 Kg.

Design and development of Dies for pressure die casting of Vacuum Clamps for Dr. A. Q. Khan Labs.

2001 Turn key project of Rolling Mill which can roll soft metal strip 10 wide and 0.08mm thick for Dr. A.

Q. Khan Labs.

Development of housing for battery consisting 3 parts for BakterShikan Missile by using gravity

casting technique for Dr. A. Q. Khan Labs.

A REVERSE ENGG. PROJECT

We designed & developed a CNG Conversion Kit for Petrol practical performance test and got

satisfactory results.

2000 Turn key project of design and development of Wire Drawing Machine which can draw soft metal

wire from 1mm to 0.025mm i.e. 1000 microns to 25 microns for Dr. A. Q. Khan Labs.

1999 Developed a Cavity for pre-form molding plant of PEPSI in their GadoonAmazie Factory.

Made manufacturing drawings of Multi-Cavity mould of pre-form for reverse Engineering.

Along with these Major Projects we are being involved in manufacturing of

different parts/ assemblies/ items for different Civil and Defense organizations

by using processes like Machining, Fabrication, Forging, Heat Treatment, Press

Work, Spark Erosion (EDM) and Pre-fab & Steel Structure projects of Different

buildings.

Rana Muhammad shafqat

974/c,Mainstreet,National police Foundation o-9, Islamabad

Contact # 0313-5676678

Email:Shafqat.muhammad62@gmail.com

Personal Information

Name : Muhammad Shafqat

Fathers Name : Muhammad Shafi

Permanent Residence : Rawalpindi

NIC # : 61101-1885358-7

PROFESSIONAL OBJECTIVES

To pursue a challenging position in a professional, progressive & well reputed concern, utilizing

optimum capabilities with dedication

Qualification

B.Sc. civil Engg. From U E T Taxila in 1988

Computer Skills

M S word

M S Excel

Auto cad

M.S project

Professional Experience : 25 Years, major in Building construction

Key Skills

Quality Control

Execution & Finishing Works.

a. Industrial Structures

b. Residential Building (Multi Stories)

c. Commercial Buildings (Multi Stories)

d. Official Buildings (Multi Stories)

Man Power Management

Supervision Of Construction and Finishing Works.

Making of Cutting and Bar Bending Schedules.

Preparation of Working Schedules& Progress Reports

Preparation of cash flow Charts

Handling over of Buildings

Quantity Calculation / Estimation

Tendering & prequalification

Escalation, variations & claims

Technical correspondence with consultants & Govt. departments

Services & Experiences

1-05-2013---to-onwards

Organization: Pak Uk Associates Pvt Ltd.

Job Title: General Manager

Job Responsibilities:

Overall monitoring and coordianation of all projects of the company

To look after contractual matters of the company

To supervise / monitoring of pre-qualification tendering claims etc.

Correspondence with consultant clients , government department/

organizations

To monitor project progress and ensure timely completion.

1-06-2012 --- 30-04-2013

Organization: Design Advisor (Design & consulting firm)

Job Title: Resident Engineer

Project: Construction of Jordan Embassy & Ambassador

Residence Building at Diplomatic Enclave Islamabad

May 2010 to 30-6-2012

Organization : M.N Construction Co.

Job Title : Project Manager

Project : Construction of Federal Tribunals/Court Complex at sector

G-11, Islamabad, a multistory office complex with 2

basement and ground +3 floors

Consultant of project: Nespak, Islamabad

Client : Ministry of law, justice and parliamentary affairs

Cost of project : Rs.400 million

Job Responsibilities : i. Correspondence with consultant & client

ii. To make monthly progress reports

iii. To make claims, escalation & variations

iv. To Manage Labor for all execution activities.

v. Supervision of all construction works

vi. To look after all finishing works

vii. To check sub-contractors bills

2009 to 2010

Organization : M/S Guarantee Engineers Islamabad

Job Title : Manager quality control & planning

Project : Construction of residential complex for high

Commission of India in diplomatic enclave Islamabad.

Project consisted on construction of Bungalows

& houses. Project cost is Rs. 2000 million

Consultant Sechdeveggleston& associates, India

Job Responsibilities : i. to make construction schedules& cash flow charts

ii. To prepare monthly progress reports

iii. To submit daily progress report and manpower

& equipment report

iv. To submit samples of materials to consultant

For getting approval

v. To get lab tests of materials and check lab

2006 to 2009

Organization : Unique Builders Islamabad

Job Title : Project Manager

Projects : Multistory apartment buildings & houses in Bahria Town

Rawalpindi.

Job Responsibilities : i. To manage all construction activities, execution

through sub contractors and hiring manpower on daily

basis.

ii. To look after all construction activities

iii. To correspond with client

iv. To prepare work done bills& progress reports

v. To prepare bar bending schedules

Period 2002 to 2006

Organization : Bahria Town (Pvt.) Ltd.Rawalpindi

Job Title : Project Engineer

Projects : Safari executive villas in phase 3-E (100 luxury villas )

Corporate office building ofbahria Town in phase -2,

Commercial buildings in phase -1,

Job Responsibilities : Supervision of all construction activities, Labour

management, preparation of daily progress report & working

schedule.

Checking sub contractor bills, submission of cash flow

and materials demands

Period 2000 to 2002

Organization : R.M Gulistan (pvt) Ltd

Job Title : Project Manager

Project : Construction of R.C.C interceptor drains at Islamabad

Airport

Consultant Mott Macdonald Pakistan (pvt) Ltd

Job Responsibilities : Supervision of all construction activities, Labour

management, preparation of daily progress report & working

schedule.

Correspondence with consultant

Period 1998 to 2000

Organization : Qatar Building Engineering company, Doha , Qatar

Job Title : Site Engineer

Project : A multistory residential cum commercial complex building

Job Responsibilities: Execution of structural works, to make subcontractor bills,

Supervise manpower, to raise concrete demand

Period 1992 to1998

Organization : Ishaq Textile mills, Faisalabad

Job Title : civil Engineer

Project : Construction of weaving mills units, staff colonies, Yarn go

downs, Sizing mills foundations

:

Job Responsibilities : i. To get work to be done as per drawings and

specifications,

ii. To coordinate with consultant,to raise demand of

materials,

iii. To check contractors bills,to make estimates of new

projects

iv. To super wise contractors and daily wages labour

1988 to 1992

Organization : Akram& Company Pvt Ltd

Job Title : Site Engineer

Project : Construction of Yasir spinning mills Faisalabad, Bismillah

Textile mills Faisalabad, Sitara spinning mills Faisalabad

Job Responsibilities: Layout of Mills , supervision of manpower, making

barbending schedules, calculation of materials from

drawings.

Yours Faithfully

Muhammad Shafqat

Muhammad Abdullah

H#436-C St# 28 G-6/1-2,Islamabad,Pakistan.

Contact # 0345-5103927

Email: sunny_abdullah@hotmail.com

Personal Information

Name : Muhammad Abdullah

Fathers Name : Allah Ditta

DOB : 01-01-1990

Permanent Residence : Islamabad

Religion : Islam

Nationality : Pakistani

Languages : English, Urdu, Punjabi

Health : Good, No Physical limitations

Domicile : Islamabad

NIC # : 61101-4133202-5

Qualification

B.E Civil Engineering 2008-2012

National University of Sciences & Technology, Islamabad

Technical Skills

AutoCAD, Sap2000, Primavera P6, Arc GIS, DRAIN 3Dx.

Command over MS Office.

Basic C++ programming

Surveying and Leveling

M.S project

Professional Skills

Good Socializing skills

Good Communication and commanding skills

Team Player

Hard Working

Eager to learn

Accomplishments & Activities

Received Rectors Gold Medal for best undergraduate project of the

year in civil engineering.

Participated in bridge innovation competition.

Raised funds for IDPs and Flood victims at NUST.

Attended international workshop on Education for Managing

Hydrological Extremes and Related Geo-Hazards.

Attended various seminars on seismic hazards and their vulnerability

assessment, Tunneling, Construction Safety Management etc.

Completed 2 weeks Construction machinery course from construction

technology training institute (CTTI) IJP road, Islamabad.

Professional Experiences

June 2012 to April 2013

Organization :Design Advisor Architecture, Consultant.

Job Title : Site Engineer

Project : Jordan Embassy & Ambassadors Residence Diplomatic

Enclave Islamabad, Pakistan.

Job Responsibilities :

Supervision of all construction works.

To look after all finishing works.

To look after all construction activities.

To get work to be done as per drawings and

specifications.

Calculation of materials from drawings.

To entertain all check request, manpower report, and

daily work done report.

May 2013 onwards

Organization: Pak Uk Associates Pvt Ltd.

Job Title: Planning Engineer

Job Responsibilities:

Tentative schedule based on tender drawings.

Comprehensive project schedule

Monthly and weekly work schedule

Monthly and daily progress report

Tool and plant report manpower reports

Materials demand on monthly basis

Procurement schedule

Name: MAMOON IQBAL CHEEMA

D.O.B: 22

nd

Nov,1983

CNIC No: 61101-0735188-5

Mobile No.: 0321-5258591

Email: mi_cheema1@yahoo.com

Cheema.engineer@gmail.com

Qualification: B.S (Civil Engineering)

EMPLOYMENT RECORD:

DATE

ORGANIZATION

DESIGNATION

RESPONSIBILITIES

30th Sep 2010-

Till Date

M/S Pak UK Associates

Islamabad

Site Engineer

-Monitoring the work at

site

-Supervision of labor on

site

8th Jan 2009 to

25thSep 2010

NESPAK, Islamabad

Engineer

- Technical Evaluation

- Financial Evaluation

- Variation Order

- TOC/EOT

1st Dec 2008-

1st Jan 2009

Syed & company

Site Engineer

-Drawing study for

implementation of it

-Calculate Bar bending

schedule

-Supervision of labor on

site

CURRICULUMVETAE

Address: - Village GanderiKhattak

Tehsil & P/O TakhtNasratiDistKarak.

Mobile No: - 0333-9552129

E-Mail Address:-engr_fakher@yahoo.com

OBJECTIVE:-

To join an ambitious team of engineers in a challenging environment where my

creative abilities can be best matured and enhanced to their peak limits so that I

can get best out of life.

PERSONAL I NFORMATI ON:-

Name: - Fakhr- e- Azam

Father Name:- Sher Azam khan

Marital Status: - Single

Nationality: - Pakistani

C.N.I.C No: - 14203-5738718-7

D.O.B: - February 20, 1986

Language: - Pashto, Urdu and English

Religion Islam

Hobbies: - Computer Games & Traveling.

ACADEMIC QUALIFICATION:-

1) B.Sc Civil Engineering, University of Engineering & Technology Peshawar in the year

2010.

2) H.S.S.C from Board of Intermediate & Secondary Education Kohat in the year 2005 in

1

st

division.

3) S.S.C from Board of Intermediate & Secondary Education Peshawar in the year 2002

in 1st division.

COMPUTER SKILL: -

Ms Windows 98 & XP

Internet

MS Office

Auto CAD 2006 - 2007.

Training professional

Field surveying course

Organisedby :University of Engineering & Technology Peshawar,

Period 23 Jan 2010 to 11 Feb 2010.

Final year project

Organisedby :University of Engineering & Technology Peshawar,

Utilization of Rain Water for Domestic Purposes using roof top rain water

harvesting technique

PROFESSIONAL EXPERIENCE

2). 1

st

Apr 2012 up to date.

Organization: -Sarhad Rural Support Programme.

Client: -Kpk Government.

Projects: - Link Roads & bridges, Micro hydral Power Generation installation, Sanitation

Facilities, Retaining Walls & Street Soling.

Designation: - Field Engineer.

Responsibilities: -

1. Survey of the Located Area.

2.Supervision the Construction of Link Roads & bridges, Micro hydral Power

Generation installation& Sanitation Facilities.

3.Preparation of Monthly Progress Report.

4. Preparing of Estimate & Drawings of the projects.

5.Worked as a TeamLeader.

1). 1

st

may 2010 up to 1

st

Apr 2012.

Organization: -Artova Engineering & Consultancy (Turkey).

Client: -(Bahria).

Projects: - Housing Project.

Designation: - Technical Officer & Site Engineer.

Responsibilities: -

1.Formulating daily site report.

2. Formulating daily Steel, Concrete & Material report.

3.Formulating Weekly & Monthly Progress Reports.

4. Drawing Work On Auto CAD.

5. Originating BOQ.

6. Originating Subcontractor bills.

7. Implementation & Execution of Construction Work.

8. Dealing with consultant for jointlySite supervision.

9. Managing & Controlling of manpower.

10. Managing,Dealing & controlling of subcontractors.

References:References will be furnished if required.

Contact Number (NEW): 0313-1266916

LIST OF KEP MACHINERY / EQUIPMENTS 6

List of Construction Machinery

Page # 1

S# Description Qty Year Make/ Model Capacity Condition

1. Batching Plant

(concrete)

One 2007 China 60 Cubic

Metter/H

Excellent

2. Batching Plant

(concrete)

One 2006 China 30 Cubic

Metter/H

Excellent

3. Mobile Crane One 2001 Americans 15 Tons Excellent

4. Dumper Four 1997 Mercedes 5-7 Ton Good

5. Mobile Concrete

Mixing Plant

One

China Fujian

Model:

YHZS2K,50,75

15 Ton Good

6. Pavers Machine One 2000 SPF-45 7000 KG Good

7. Soil compactor Six 1998 Dynapac 5000-

8000VPM

Good

8. Compactor Eighteen

9. Mixer Ten 1 Begs

10. Mixer Ten 0.5 Begs

11. Vibrator Twenty 2009

12. Roll Forming

Machine

Two Full Lenth Excellent

13. Dump level Four Excellent

14. Generator Seven 100 KV Good

15. Generator Twelve 50 KV Good

16. Sheep foot roller One 1998 SP 2111 16 Tons Good

17. Concrete batching Three 1998 Libra 42 MP Excellent

18. Concrete mixer Four 2000 Local (PECO) 18cft Excellent

19. Steel bending &

cutting machine

Four 2001 Catetpillar UK

Kamastu

2.5cy Good

20. Air compressor Two 2001 Caterpillar 300CFM Good

21. Gas cutter Four 2001 Japan 300CFM Good

22. Mobile water tank Three Local 3000Glns Good

23. Theodolite 1 inch Four 2002 Topcon

24. Welding plants Twenty

five

2004 UK and Japan 400&500AMP Excellent

25. Organ Set Fifteen 2009-

11

Excellent/Good

26. Cutting Torches Twenty

Five

2007-

11

Excellent/Good

27. Power Cutter Eight 2008-

11

Excellent/Good

28. Grinder 7 & 4 Fifteen 2009-

11

Excellent/Good

29. Pipe Scaffolding 150000Rft 2007-

11

Local Excellent/Good

30. Steel Shuttering

Plates

150000Sft 2006-

11

Local Excellent/Good

List of Transport Equipment

Page # 2

S# Description Qty Year Make/ Model Capacity Condition

31. Mobile Batching

Plant

One 120 QMH

32. Concrete Mixer

Truck

One Chassis Model

(EQ3260GJ)

Engine Model (C300-20)

12500 KG Excellent

33. Backhoe Loader One 2003 Terramite T9 Diesel

4WD

Excellent

34. Dozer Crawler One 1998 Komastsu D-6/D-8 Good

35. Excavator Two 1998 Hitachi 1.25cy Good

36. Grader One 1989 Komatsu (GD405A2) Excellent

37. Road Roller One 1997 Dynapac (SD 100D) 25 Ton Good

38. Tractor with Dozer

blade

Two 1998 Local Good

39. Trolley with tractor Four 1998 Local 5 Ton Good

40. Trucks Four 2003 Mercedes 10 Ton Good

41. Dump trucks Two 2003 Bylarus (Russian) 30 Ton Good

LIST OF ENLISTMENT 7

PROOF ENLISTMENT WITH OTHER DEPARTMENTS/ NGOS

1. PUBLIC WORKS DEPARTMENT GOVERNMENT

2. GOVERNMENT OF AZAD JAMMU & KASHMIR

3. CAPITAL DEVELOPMENT AUTHORITY

4. NATIONAL HIGHWAY AUTHORITY

5. WORKS & SERVICE ORGANIZATION / PAKISTAN ATOMIC

ENERGY COMMISSION

LIST OF COMPLETED PROJECTS 8

List of Major Projects Completed During Last Five (05) Years

S.No

Month/ Year

(Period)

Name of work Clients

Contract

Amount

1 15/05/2009

Construction of BHU at Dalola UC Abbotabad

(KPK)

Caritas Pakistan 75.00 Million

2 5/3/2009

Construction of 10 Nos. of Schools Buildings in

Siran Valley Manshera (KPK)

Shelter for Life International

(US) Organization

168.00 Million

3 15/08/2011

Construction of Multifunctional Buildings

Complex at AlipurFarash - Islamabad

Inter Services Intelligence

(ISI)

60.00 Million

4 1/10/2006

Construction of Multistory Commercial Plaza at I-

8 Markaz Islamabad

AL-NAFAIO GROUP

INTERNATIONAL

150.00 Million

5

1/7/2009

200 Units Supporting Medium Term Pre-

Fabricated Shelters Needs for the Earthquake

Affected at Muzaffarabad (AJK)

International Organization for

Migration (IOM)

40.00 Million

6

13/04/2009

Construction of Two Skill Development Centers at

Balakot&Kahori (Muzaffarabad)

International Labour

Organization (ILO)

17.00 Million

8

14/02/2008

Construction and Manufacturing of 30 Nos. of Pre-

Fabricated Buildings for Telephone Exchange at

Muzaffarabad, Neelam, Bagh, Rawlakot, Kotli and

Mirpur (AJ&K)

Special Communication

Organization (SCO)

35.00 Million

8

26/08/2007

Construction of 01Nos. of Multi Story Telephone

Exchange Building at Bagh (AJ&K)

Special Communication

Organization (SCO)

18.00 Million

9

29/09/2006

Pre-Engineered Building for Blood Bank at AIMS

Muzaffarabad (AJK)

International Rescue

Committee (IRC) (US) NGO

5.00 Million

10

10/7/2009

Designing Construction and Manufacturing of 02

Nos. Pre-Engineering Buildings for BHU at Kot

Taryala and Rahim Kot Muzaffarabad

International Rescue

Committee (IRC)

7.00 Million

11

25/02/2008

Construction and Manufacturing of Pre-

Engineered Building for Government High School

Bagna U/C Dana, Muzaffarabad (AJK)

Human Development

Foundation (HDF) NGO

7.00 Million

12 24/02/2009

Manufacturing & Supply of Residential Caravans

at Khost 2B

Mari Gas Company Limited 10.00 Million

13 26/02/2008

Manufacturing of Portable Cabins at Batagram

(KPK)

Save the Children (USA) NGO 5.00 Million

14 22/02/2008

Construction/Manufacturing of Pre-Fab Building

at Bagh (AJK)

Save the Children (UK) NGO 3.00 Million

15 1/4/2007

Manufacturing and Suplly of 20 Nos. of Portable

Cabins for GSM Expension Shelter at Gilgit,

Sakardu, Khaplo, and Sust Northern Area

Special Communication

Organization (SCO)

5.00 Million

16 10/4/2006

Construction/ Manufacturing of Pre- Fab

Buildings and Portable Cabins at Islamabad,

Manshera, Batagram and Bana Alai (KPK)

International Rescue

Committee (IRC) NGO

6.00 Million

17 1/1/2006 Manufacturing of Portable Cabins at Bagh (AJK)

ATLAS Logistic and HANDICAP

International NGOs

6.00 Million

18 5/1/2006

Manufacturing of Portable Cabins at Batagram

(KPK) and Bagh (AJK)

OXFAM GB NGO 6.00 Million

19 1/12/2005

Manufacturing of Pre-Fab Buildings/ Portable

Cabins at Bagh (AJ&K)

MARCY Malaysia NGO 3.00 Million

20 1/11/2005 Manufacturing of Portable Cabins at Bagh (AJK) RedR NGO 3.00 Million

21 9/9/2005

Construction of PDA Commercial Complex No 2

Block A at Rawlakot (AJK)

PDA Government of (AJK) 60.00 Million

LIST OF ON-GOING PROJECTS 9

On Going Projects of Pre-Fabricated Buildings and Permanent

Construction Works

S.No

Month/

Year

(Period)

Name of work Clients

Contract

Amount

1 20/4/2012

Infrastructure Development Project,

Bagh City AJK

BCDP-CWE Bagh AJK

ERRA - SEERA

593.50 Million

2 23/5/2012

Construction of F.G. Public School,

Bagh City AJK

BCDP-CWE Bagh AJK

ERRA - SEERA

100.00 Million

3 10/7/2013

Construction of Academic Block-

Cadet College Muzaffarabad (AJ&K)

Cadet College

Muzaffarabad

97.50 Million

4 26/11/2009

Construction of Government Boys

Inter College (GBIC) at Mirpura

(AJ&K)

Saudi Fund for

Development & Kuwait

Fund (SFD & KF)

Government of AJK

92.00 Million

5 31/5/2012

Construction of Faculty Hostel at

King Abdullah Campus, University of

AJ&K Chattar Klass, Muzaffarabad

AJ&K University 90.00 Million

6 4/12/2010

Construction of Pre-Fab School

Building at SOS Children's Village

Rawalakot, AJ&K

SOS Children's Villages

of Pakistan

30.00 Million

7 8/7/2010

Construction of Jordanian Embassy

and Ambassadors Residence at

Diplomatic Enclave Islamabad

Jordan Embassy 250.00 Million

8 6/5/2010

Construction of GMOS Naka Dhal

Qazian at Bagh (AJ&K)

PWD Buildings/

Reconstruction Bagh

(AJ&K)

8.23 Million

AVERAGE ANNUAL TUNOVER/ TAX

CERTIFICATES AND AUDIT CERTIFICATES

10

AVERAGE ANNUAL CONSTRUCTION TURNOVER

ANNUAL TURNOVER DURING LAST 03 YEARS

YEAR AMOUNT (PKR) USD (RATE) EQUIVALENT US $

2011-12 PKR: 419.603375 Million USD: 90.25 USD: 4.6493448 Million

2010-11 PKR: 335.682700 Million USD: 86.25 USD: 3.891973 Million

2009-10 PKR: 318.530390 Million USD: 86.00 USD: 3.7038417 Million

Total PKR: 1073.816465 Million ------------ USD: 12.2451595 Million

Average Annual Construction Turnover during the

last three years = 1073.816465/3

Rs.357.9388 Million

USD.4.081720 Million

AVERAGE ANNUAL CONSTRUCTION TURNOVER

ANNUAL TURNOVER DURING LAST 03 YEARS

YEAR AMOUNT (PKR) USD (RATE) EQUIVALENT US $

2011-12 PKR: 419.603375 Million USD: 90.25 USD: 4.6493448 Million

2010-11 PKR: 335.682700 Million USD: 86.25 USD: 3.891973 Million

2009-10 PKR: 318.530390 Million USD: 86.00 USD: 3.7038417 Million

Total PKR: 1073.816465 Million ------------ USD: 12.2451595 Million

Average Annual Construction Turnover during the

last three years = 1073.816465/3

Rs.357.9388 Million

USD.4.081720 Million

BAN CERTIFICATES 11

AFFIDAVIT OF NO LATIGATION / NO BLACK

LISTED

12

You might also like

- Prequalification DocumentDocument62 pagesPrequalification DocumentVishnu MenonNo ratings yet

- CR No Nizwa Porta Cabin. Company ProfileDocument29 pagesCR No Nizwa Porta Cabin. Company ProfileMohannad Bayzid100% (1)

- Memco ProfileDocument77 pagesMemco ProfileMohamed OmarNo ratings yet

- Victor Crescent Construction Interview InsightsDocument8 pagesVictor Crescent Construction Interview InsightsmphoNo ratings yet

- Quality Policies and Assurances by Shapoorji Pallonji EngineeringDocument5 pagesQuality Policies and Assurances by Shapoorji Pallonji EngineeringYash pawarNo ratings yet

- Company Profile - Indalo Rigging Pty LTDDocument9 pagesCompany Profile - Indalo Rigging Pty LTDapi-320288199No ratings yet

- Ahmed Construction Company: Engineering Your Dreams With UsDocument18 pagesAhmed Construction Company: Engineering Your Dreams With UsTalal MalikNo ratings yet

- Conpany Profile ConsDocument5 pagesConpany Profile Conssarge18No ratings yet

- Modern Bridge _ Profile 2024_NewDocument16 pagesModern Bridge _ Profile 2024_NewayaliyaenterprisesNo ratings yet

- Muhammad Hussain Khan. S/O Muhammad Ramzan: Career ObjectiveDocument8 pagesMuhammad Hussain Khan. S/O Muhammad Ramzan: Career ObjectivenabeelNo ratings yet

- Company Policies & Standard Operational Procedures: Saltaire Security LTDDocument45 pagesCompany Policies & Standard Operational Procedures: Saltaire Security LTDSidraNo ratings yet

- SAR - Quickrete - RMC - SteightDocument130 pagesSAR - Quickrete - RMC - SteightMariam ZaitaaNo ratings yet

- HaskemDocument8 pagesHaskemJom BonhayagNo ratings yet

- Hindustan Coca ColaDocument63 pagesHindustan Coca ColaAksMastNo ratings yet

- Report Insulco EmiratesDocument13 pagesReport Insulco EmiratesLena MirajNo ratings yet

- 2017-12-13 - DV - Omega Memory Camera Rental Agreement - ProdEng SADocument10 pages2017-12-13 - DV - Omega Memory Camera Rental Agreement - ProdEng SAEduardo OyarzunNo ratings yet

- Manadhar ProfileDocument14 pagesManadhar ProfileZeynel OzkayaNo ratings yet

- Safe line fire protection systems expert in UAEDocument31 pagesSafe line fire protection systems expert in UAEatk0404No ratings yet

- Orbital Resources LTD Company ProfileDocument46 pagesOrbital Resources LTD Company ProfileJolomi AmorighoyeNo ratings yet

- Business Plan - FencingDocument13 pagesBusiness Plan - FencingDessalegn GaminiNo ratings yet

- construction-company-profile-templateDocument30 pagesconstruction-company-profile-templateErwinNo ratings yet

- Future Engineerring ProfileDocument9 pagesFuture Engineerring Profilerahul bormonNo ratings yet

- IQE Corporate BrochureDocument10 pagesIQE Corporate BrochureravigurajapuNo ratings yet

- Cleaning & Pest Control ProfileDocument19 pagesCleaning & Pest Control ProfileBash ServicesNo ratings yet

- Shering Weighing Group HistoryDocument6 pagesShering Weighing Group HistoryRajesh Prabhu RNo ratings yet

- Business Plan Part 2Document5 pagesBusiness Plan Part 2John Patrick Sanay NunezNo ratings yet

- Mubashir ResumeDocument8 pagesMubashir ResumeHaroon RasheedNo ratings yet

- JD - Technical Manager - Inspection - NDT - Asset Integrity MGTDocument2 pagesJD - Technical Manager - Inspection - NDT - Asset Integrity MGTSamson ObinnaNo ratings yet

- Annexure II - HSEDocument17 pagesAnnexure II - HSEMaged gmailNo ratings yet

- Company Profil1Document6 pagesCompany Profil1john paroNo ratings yet

- Professional Construction CorporationDocument36 pagesProfessional Construction CorporationjulsNo ratings yet

- Pratibha Industries LimitedDocument5 pagesPratibha Industries LimitedavijitthakurNo ratings yet

- ITG ProfileDocument17 pagesITG ProfileJohn RoshdyNo ratings yet

- الهيكل الوظيفيDocument10 pagesالهيكل الوظيفيMoataz ElsawyNo ratings yet

- TMSM Engineering Company - Sample Company ProfileDocument10 pagesTMSM Engineering Company - Sample Company ProfileCHRISTIAN F. MAYUGANo ratings yet

- CV - House Keeping SupervisorDocument10 pagesCV - House Keeping SupervisorElango InthushanNo ratings yet

- Builders Company ProfileDocument18 pagesBuilders Company ProfileSSasasdasdNo ratings yet

- JMC Projects India Ltd. project report on construction techniquesDocument57 pagesJMC Projects India Ltd. project report on construction techniqueshjNo ratings yet

- Implement Health & Safety StandardsDocument13 pagesImplement Health & Safety StandardsasanNo ratings yet

- Company Profile Max EngineeringDocument8 pagesCompany Profile Max EngineeringbicagencyNo ratings yet

- Curriculum Vitae-2llDocument6 pagesCurriculum Vitae-2llMd ShamsuddohaNo ratings yet

- Revive-Profile Updated 18-05-2021-For WorkDocument32 pagesRevive-Profile Updated 18-05-2021-For WorkManikantan ThappaliNo ratings yet

- Robotic Tank Inspection & Cleaning BrouchreDocument16 pagesRobotic Tank Inspection & Cleaning BrouchreJayson PintoNo ratings yet

- We Believe Good Support Creates Stronger Business: Stork Industry Services OffshoreDocument2 pagesWe Believe Good Support Creates Stronger Business: Stork Industry Services OffshoreGeert Henk WijnantsNo ratings yet

- Sitco 2018 BrochureDocument16 pagesSitco 2018 Brochureﺍﺣﻤﺪ ﺣﺴﻦNo ratings yet

- Shree Hari EngineeringDocument28 pagesShree Hari EngineeringChaitanya GandluriNo ratings yet

- Tecnip Umbilical Systems PDFDocument20 pagesTecnip Umbilical Systems PDFAndré ParavidinoNo ratings yet

- Ayaz Khan Resume For Safety OfficerDocument5 pagesAyaz Khan Resume For Safety OfficerMuhammad HarisNo ratings yet

- Salaar Group Company Profile 2014Document24 pagesSalaar Group Company Profile 2014ranausmansNo ratings yet

- Sapients 2020 ProfileDocument7 pagesSapients 2020 ProfileVaradaraj CkNo ratings yet

- Safety ResumeDocument6 pagesSafety Resumee771k2gb100% (1)

- 101 Win Themes For All OccasionsDocument6 pages101 Win Themes For All OccasionstausarpaoNo ratings yet

- Our Story: ENTCCO's Journey to ExcellenceDocument16 pagesOur Story: ENTCCO's Journey to Excellenceقرآن - Quran (قرآن Quran)No ratings yet

- Field Assistant Report on Amandeep Buildcon Pvt. LtdDocument13 pagesField Assistant Report on Amandeep Buildcon Pvt. LtdaasimNo ratings yet

- BrochureDocument28 pagesBrochureNiyas TkNo ratings yet

- Hse CV Examples UkDocument4 pagesHse CV Examples Ukiuhvgsvcf100% (2)

- Quality Manual ChurchesDocument10 pagesQuality Manual ChurchesNyi NandarsheinnNo ratings yet

- Proposed Method StatementDocument4 pagesProposed Method StatementMonquerJacobsNo ratings yet

- Trimax Company ProfileDocument8 pagesTrimax Company Profilerajeshjoel26No ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- February 2017Document104 pagesFebruary 2017Cleaner MagazineNo ratings yet

- People Soft HCM 9.0 Business Process MapsDocument198 pagesPeople Soft HCM 9.0 Business Process MapslokeshmehraNo ratings yet

- Workers Seriously Injured in Conveyor AccidentsDocument2 pagesWorkers Seriously Injured in Conveyor AccidentsGissmoNo ratings yet

- GDPR Privacy Notice For DHL International UK LTD PDFDocument4 pagesGDPR Privacy Notice For DHL International UK LTD PDFnnigeltaylorNo ratings yet

- Code of Conduct For Nursing Midwifery - v02 (2Document13 pagesCode of Conduct For Nursing Midwifery - v02 (2Rrichard Prieto MmallariNo ratings yet

- Compensation AdministrationDocument2 pagesCompensation Administrationfrancine olilaNo ratings yet

- PERSONAL HISTORY STATEMENTDocument7 pagesPERSONAL HISTORY STATEMENTJoshuaLavegaAbrina100% (2)

- Human Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDocument3 pagesHuman Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDavid SabaflyNo ratings yet

- Police Officers Bill of Rights California Codes Government Code Section 3300-3311Document3 pagesPolice Officers Bill of Rights California Codes Government Code Section 3300-3311api-240360438No ratings yet

- Human Resource Planning EssentialsDocument10 pagesHuman Resource Planning EssentialsRashmi ShiviniNo ratings yet

- Francisco Vs Bahia Shipping ServicesDocument4 pagesFrancisco Vs Bahia Shipping ServicesJanice F. Cabalag-De VillaNo ratings yet

- 203 Practice WTR 2013 PDFDocument22 pages203 Practice WTR 2013 PDFKarim IsmailNo ratings yet

- Introducing Groundwork LeedsDocument12 pagesIntroducing Groundwork LeedsGroundwork LeedsNo ratings yet

- Some Costing Questions PDFDocument85 pagesSome Costing Questions PDFHarshit AggarwalNo ratings yet

- Application For Employment: 1995 1989 SalutatorianDocument3 pagesApplication For Employment: 1995 1989 Salutatoriangemma antonioNo ratings yet

- Employee Empowerment: A Case Study On Starbucks: Submitted To: Ma'am Shanza Submitted By: Namira SiddiqueDocument4 pagesEmployee Empowerment: A Case Study On Starbucks: Submitted To: Ma'am Shanza Submitted By: Namira SiddiquenamiraNo ratings yet

- Understanding Organizational Behavior and Its Key ConceptsDocument3 pagesUnderstanding Organizational Behavior and Its Key Conceptsrez dianne evidaNo ratings yet

- FICCI - Ernst & Young ReportDocument48 pagesFICCI - Ernst & Young ReportGlobal_Skills_SummitNo ratings yet

- Elements of A ProfessionDocument15 pagesElements of A ProfessionMc Robinson Regucera79% (34)

- Davao BIOSCI 1 PDFDocument14 pagesDavao BIOSCI 1 PDFPhilBoardResults0% (1)

- Employee Resourcing ProcessDocument6 pagesEmployee Resourcing ProcessZaky MfaNo ratings yet

- Fundamentals of Human Resource Management Book by Raymond A. Noe - Chapter 015Document18 pagesFundamentals of Human Resource Management Book by Raymond A. Noe - Chapter 015Patrick100% (1)

- Ethics and Decision-Making at Tata SteelDocument19 pagesEthics and Decision-Making at Tata SteelDelish SebastianNo ratings yet

- RAVS Requirements Fit For DutyDocument2 pagesRAVS Requirements Fit For DutyJason FlowersNo ratings yet

- Important links for simulation, case studiesDocument4 pagesImportant links for simulation, case studiesbinodNo ratings yet

- RF-HRU-JAF Job Application FormDocument4 pagesRF-HRU-JAF Job Application FormAlfer FernandezNo ratings yet

- 9 - Fem V MurilloDocument2 pages9 - Fem V MurilloCheyz ErNo ratings yet

- Abdul Hakim CLDocument1 pageAbdul Hakim CLTheHeat phNo ratings yet

- Neri V NLRCDocument3 pagesNeri V NLRCMikaela Denise PazNo ratings yet

- Human Resource ManagementDocument24 pagesHuman Resource ManagementCarlos SilvaNo ratings yet