Professional Documents

Culture Documents

Fuchs Cement Brochure

Uploaded by

shani55730 ratings0% found this document useful (0 votes)

234 views8 pagesThe document is a brochure from FUCHS LUBRITECH GmbH describing their specialty lubricant products and services for the cement industry. It discusses how cement is produced and some of the key machines involved, such as crushers, mills, kilns, and coolers. It explains that these machines require special lubricants to protect parts from wear under high heat, abrasive conditions, and vibrations. FUCHS LUBRITECH offers a range of lubricants developed over 50 years specifically for the demands of cement production. It also provides services like machine inspections, gear repairs, and an online system to monitor lubricant performance and machine conditions.

Original Description:

Fuchs Cement Brochure

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a brochure from FUCHS LUBRITECH GmbH describing their specialty lubricant products and services for the cement industry. It discusses how cement is produced and some of the key machines involved, such as crushers, mills, kilns, and coolers. It explains that these machines require special lubricants to protect parts from wear under high heat, abrasive conditions, and vibrations. FUCHS LUBRITECH offers a range of lubricants developed over 50 years specifically for the demands of cement production. It also provides services like machine inspections, gear repairs, and an online system to monitor lubricant performance and machine conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

234 views8 pagesFuchs Cement Brochure

Uploaded by

shani5573The document is a brochure from FUCHS LUBRITECH GmbH describing their specialty lubricant products and services for the cement industry. It discusses how cement is produced and some of the key machines involved, such as crushers, mills, kilns, and coolers. It explains that these machines require special lubricants to protect parts from wear under high heat, abrasive conditions, and vibrations. FUCHS LUBRITECH offers a range of lubricants developed over 50 years specifically for the demands of cement production. It also provides services like machine inspections, gear repairs, and an online system to monitor lubricant performance and machine conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

FUCHS LUBRITECH GmbH

Tel.: +49 (0) 6301 / 3206-0

Fax: +49 (0) 6301 / 3206-940

E-mail: info@fuchs-lubritech.de

www.fuchs-lubritech.com

A Member of the

FUCHS PETROLUB Group

Brilliance at Work!

Specialty Lubricants for

the Cement Industry

Foto: Mederer

Range of Services

Cement is an inorganic, nely ground substance. When mixed with water it

sets and hardens independently as a result of chemical reactions. After har-

dening, cement remains solid and resistant, even under water. The current

designation cement dates back to the Romans who named concrete-type

masonry made of quarry stones with burnt lime as binding agent Opus Cae-

mentitium. They used it as early as from 118 to 125 BC when building the

Pantheon in Rome.

Some of the key machines in cement production are crushers, mills, kilns,

and coolers. All of these machines are exposed to the rough environmental

conditions of a Cement Plant, involving highly abrasive dust, high process

temperatures, vibrations, and high loads.

Most of the key machines require special lubricants to protect the machine

parts like bearings, gear boxes, Open Gears, tyre rings and bolts from seizu-

re, wear and failure. Conventional lubricants are not designed to cope with

the tremendous vibrations in the crushing and grinding process or with the

heat the parts are exposed to in the kiln section. For more than 50 years

FUCHS LUBRITECH has been the expert for such high-performance lubricants,

especially developed for the specic requirements of the Cement Industry.

Cement

Lubricants

Machines

FUCHS LUBRITECH offers a large range of services for

the Cement Industry including oil and grease analysis,

in-house and on-site training via the FLT-ACADEMY.

FUCHS LUBRITECH provides thorough machine inspec-

tions and a unique repair service for Open Gears.

With the FLT Inspector, FUCHS LUBRITECH makes a

unique online documentation available that enables

the customers to retrieve all relevant information on

their systems and the lubricants used therein at any

time.

The FLT Inspector is the perfect online reporting tool

with integrated graphical trend analysis.

As far as we know the information in this brochure reects the current state of knowledge and of our research. They cannot, however, be

taken as an assurance about the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using

our products the purchaser must, therefore, check their suitability and assure himself of their performance. Our products are continually

being updated. We therefore reserve the right to alter the information in this brochure at any time and without prior announcement.

Check of spray pattern.

The Inspections

Checking the spray system

Assessment of the contact pattern

and the condition of the load-

carrying surfaces

Measurement of the temperature

prole across the tooth width

Documentation of the condition

of the anks (photographic, blue

print...)

Written documentation of the

whole inspection, including tren

ding of the measured values

The FLT-Inspector

Availability of all reports at

a glance

Online access at any time

Instant check via

trafc light system

Graphical trend analysis for

temperatures and vibrations

Rapid transmission of data

and reports

Individual access hierarchy

Optional extra information

(attachments) for each inspection

report

The Repair Service

Re-proling the tooth anks

Grinding pittings or larger

damages

Smoothing of scufngs

Forced running-in

Assistance with the alignment

of the transmission gear

Treatment of the working tooth anks.

Foto: Heidelberger Zement AG

Falz Falz Falz Anschnitt Anschnitt

RZ_FLT_Zement_8Seiter.indd 1 18.01.13 15:50

FUCHS LUBRITECH GmbH

Tel.: +49 (0) 6301 / 3206-0

Fax: +49 (0) 6301 / 3206-940

E-mail: info@fuchs-lubritech.de

www.fuchs-lubritech.com

A Member of the

FUCHS PETROLUB Group

Brilliance at Work!

Specialty Lubricants for

the Cement Industry

Foto: Mederer

Range of Services

Cement is an inorganic, nely ground substance. When mixed with water it

sets and hardens independently as a result of chemical reactions. After har-

dening, cement remains solid and resistant, even under water. The current

designation cement dates back to the Romans who named concrete-type

masonry made of quarry stones with burnt lime as binding agent Opus Cae-

mentitium. They used it as early as from 118 to 125 BC when building the

Pantheon in Rome.

Some of the key machines in cement production are crushers, mills, kilns,

and coolers. All of these machines are exposed to the rough environmental

conditions of a Cement Plant, involving highly abrasive dust, high process

temperatures, vibrations, and high loads.

Most of the key machines require special lubricants to protect the machine

parts like bearings, gear boxes, Open Gears, tyre rings and bolts from seizu-

re, wear and failure. Conventional lubricants are not designed to cope with

the tremendous vibrations in the crushing and grinding process or with the

heat the parts are exposed to in the kiln section. For more than 50 years

FUCHS LUBRITECH has been the expert for such high-performance lubricants,

especially developed for the specic requirements of the Cement Industry.

Cement

Lubricants

Machines

FUCHS LUBRITECH offers a large range of services for

the Cement Industry including oil and grease analysis,

in-house and on-site training via the FLT-ACADEMY.

FUCHS LUBRITECH provides thorough machine inspec-

tions and a unique repair service for Open Gears.

With the FLT Inspector, FUCHS LUBRITECH makes a

unique online documentation available that enables

the customers to retrieve all relevant information on

their systems and the lubricants used therein at any

time.

The FLT Inspector is the perfect online reporting tool

with integrated graphical trend analysis.

As far as we know the information in this brochure reects the current state of knowledge and of our research. They cannot, however, be

taken as an assurance about the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using

our products the purchaser must, therefore, check their suitability and assure himself of their performance. Our products are continually

being updated. We therefore reserve the right to alter the information in this brochure at any time and without prior announcement.

Check of spray pattern.

The Inspections

Checking the spray system

Assessment of the contact pattern

and the condition of the load-

carrying surfaces

Measurement of the temperature

prole across the tooth width

Documentation of the condition

of the anks (photographic, blue

print...)

Written documentation of the

whole inspection, including tren

ding of the measured values

The FLT-Inspector

Availability of all reports at

a glance

Online access at any time

Instant check via

trafc light system

Graphical trend analysis for

temperatures and vibrations

Rapid transmission of data

and reports

Individual access hierarchy

Optional extra information

(attachments) for each inspection

report

The Repair Service

Re-proling the tooth anks

Grinding pittings or larger

damages

Smoothing of scufngs

Forced running-in

Assistance with the alignment

of the transmission gear

Treatment of the working tooth anks.

Foto: Heidelberger Zement AG

Falz Falz Falz Anschnitt Anschnitt

RZ_FLT_Zement_8Seiter.indd 1 18.01.13 15:50

Kiln, Tyre Ring

Tyre rings on kilns have to com-

pensate the heat extension of the

kiln shell, keep the kiln shell in its

circular shape and prevent the

kiln from bending. As a kiln tyre

is never entirely xed to the kiln

shell it needs to be lubricated to

avoid seizure and wear between

the tyre pads and the tyre itself.

Any moving parts of semi-xed

tyres have to be lubricated as well.

CEPLATTYN HT and CEPLATTYN TL are reliable lubricants

for this task. They are easy and safe to apply using conven-

tional spray units. Both products penetrate into the inner

tyre ring, their base uids evaporate slowly, and their high

content of solid lubricants stays in the tyre for a safe, long-

term dry lm lubrication.

The copper paste gleitmo 160 Neu is additionally used for

maintenance and mounting during shutdown.

Crusher

The rst step in raw material pre-

paration is crushing. This can be

done e.g. by impact crusher, cone

crusher or hammer crusher.

The bearings of these crushers

are exposed to extreme vibra-

tions loads, dust and environ-

mental conditions. Therefore

greases with extreme working

stability, exceptional pressure resistance and good sealing

capabilities are to be used.

URETHYN MP 2 and LAGERMEISTER XXL full these de-

mands. Even at low temperatures they are pumpable in

central lubrication systems. URETHYN MP 2 and LAGER-

MEISTER XXL warrant safe running conditions at maxi-

mum service intervals.

Kiln, Open Gear

Most small kilns and in particu-

lar kilns with more than 3 roller

stations are equipped with an

open running gear drive. The

tooth anks of kiln gears are

exposed to radiation heat from

the kiln shell and, compared to

other Open Gears, are subjected

to axial movements. Due to slow

sliding movements between the tooth anks, solid lub-

ricant-containing open gear lubricants are the optimum

solution.

In general, graphite-containing CEPLATTYN KG 10 HMF as

well as the light-colored CEPLATTYN GT range are the best

solutions for open gear lubrication.

Because of their solid lubricant content and their eleva-

ted base oil viscosity, both CEPLATTYN grades provide an

excellent wear protection even under critical running con-

ditions.

Blending Beds

No other moving parts in the Ce-

ment Industry are exposed to du-

sty environments and their highly

abrasive nature as much as con-

veyor chains of blending beds.

That causes extreme wear on

chain links, chain bolts and spro-

cket wheels. Chain oils with mini-

mum dust attraction but good lu-

brication properties are necessary to prolong the lifetime

and maintenance cycles of this equipment.

STABYLAN G 1000 provides very good creeping properties

to reach and lubricate the inner chain. Friction and wear

are drastically reduced. Throw-off losses are minimal. The

graphite content of STABYLAN G 1000 offers excellent

emergency running properties

Roller Press

Roller Presses are used for raw

material preparation and nish

grinding. The high-pressure grin-

ding bed built between the two

rollers leads to a signicant re-

duction of energy consumption

compared to common ball mills.

Bearings of roller presses are

subject to extremely high shock

loads and, especially in the nish

grinding process, to elevated temperatures. In terms of lu-

brication, grease-lubricated bearings have to be distingu-

ished from oil-lubricated bearings.

Grease-lubricated bearings: The grease is fed in relatively

high volumes using conventional lubrication systems. The

high volumes are necessary to provide a sufcient sealing

effect on the bearing to prevent a back-ow of dust into

the grinding chamber into the bearing.

Roller Press

Greases for the grinding bearings

have to be extremely stress re-

sistant and must provide a good

damping effect to cushion

the bearings. In addition to that

a good self-sealing effect is re-

quired to prevent a dust back-

ow from the grinding chamber

to the inner bearing. STABYL HD

is the most suitable and widely

approved lubricant for these bearings. Its high base oil vis-

cosity and its content of solid lubricants provide the ideal

combination for these extremely challenging conditions.

Oil-lubricated bearings: They are equipped with a fully

sealed circulation system.

GEARMASTER SYN and GEARMASTER ECO are the proper

synthetic oils to be used in these systems.

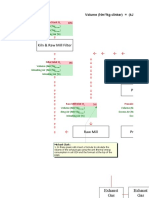

RAW MATERIAL PREPARATION HOT PROCESSING PACKAGING CEMENT GRINDING

Grinding Rollers, Vertical Mills

Vertical mills are commonly used

for raw material and cement grin-

ding. In terms of lubrication, the

most critical parts of vertical mills

are the bearings of the grinding

rollers, the separator bearings

and the gear box. The bearings

of the grinding rollers are expo-

sed to extremely high vibrations

(short time overloads), elevated

temperatures and, depending on their design, the dust

loaded environment within the grinding chamber.

GEARMASTER PGP 680 and 1000 were especially develo-

ped for the lubrication of such highly loaded bearings.

They are based on a fully synthetic oil, thus ensuring thi-

ckest lubrication lms under extreme temperatures and

loads.

Separator Bearings, Vertical Mills

Separator bearings of vertical

mills face a critical combination

of load, revolutions and size. In

addition they are positioned in

the airstream and thus heavily

exposed to elevated temperatu-

res and dust.

URETHYN MP 2 was especially

developed to lubricate these be-

arings. It provides a good pumpability and guarantees

good lubricity under elevated temperatures and loads.

GEARMASTER CLP and GEARMASTER SYN oils ensure a

reliable operation lubrication with substantially extended

service intervals.

Gear Box

Within a cement plant many high

powered gear boxes transmit

forces to drive different machi-

nes. This can be the back gear or

the planetary gear for the fric-

tion drive of the kiln, the central

drive or back gear of a tube mill,

the gear box of a vertical mill or a

roller press or drives for crushers,

traveler grates and various con-

veyor belts. All these gears have one thing in common:

The challenging environment in a Cement Plant.

The GEARMASTER range provides a solution for every sin-

gle gear box within a Cement Plant. GEARMASTER CLP is

a mineral oil-based gear oil allowing longest service inter-

vals compared to standard mineral oils. GEARMASTER SYN

is a synthetic gear oil providing maximum energy efcien-

cy as the optimum solution for gears running at elevated

temperatures.

Traveler Grate / Cooler

Depending on its design, a trave-

ler grate is equipped with many

bearings operating under expo-

sure to the radiation heat from

the hot clinker. To keep these

bearings running, high volumes

of standard greases have to be

used. However such greases fail

frequently because they harden

in the feeding lines.

URETHYN MP 2 was especially developed to meet these

requirements. It will not harden under elevated tempe-

ratures; its high-temperature thickener system combined

with its high base oil viscosity guarantees a reliable lubri-

cation with minimum grease quantities.

In addition, URETHYN MP 2 is used as a high-performance

multi-purpose grease for all heavily loaded and conside-

rably thermally loaded bearings in classiers, crushers, sie-

ves, etc.

Ball Mill

Even though ball mills are gra-

dually being replaced by vertical

mills and roller presses, they are

still the most common grinding

systems in todays Cement Plants.

The majority of ball mills is dri-

ven by Open Gears. Some have

central drives and enclosed gear /

bearing arrangements.

CEPLATTYN is the rst choice for spray and bath lubrica-

tion of Open Gears. It is available as black graphite-con-

taining grease, a as light-colored uid, or as light-colored

semi-uid with white reactive solid lubricants.

The entire CEPLATTYN range is the life insurance for an

Open Gear drive. For mills driven by central gear drives or

closed gear arrangements, the GEARMASTER CLP range is

the widely approved choice.

Silos / Packaging / Loading

Within the cement storage and

packaging section different ma-

chine parts need lubrication.

Silos are equipped with small

open running gear drives for the

discharging unit. They have to be

lubricated by CEPLATTYN BL if

applied via automatic greasers,

or by CEPLATTYN 300, if applied

manually.

Bearings of conveyors and various parts of sack packaging

machines are to be lubricated by a state-of-the-art grease

such as LAGERMEISTER XXL. Its stable thickener system

and elevated base oil viscosity allow LAGERMEISTER XXL

to be widely used as a multi-purpose grease within a Ce-

ment Plant where moderate to high temperatures or me-

dium to high loads are to be covered. It is compatible with

most other greases.

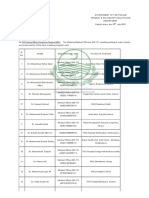

MACHINE COMPONENT TYPE OF LUBRICANT PRODUCT

Kiln / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 HMF

range CEPLATTYN GT 10

Kiln / Inner Tyre Ring

Sprayable high-temperature uids

with solid lubricants

CEPLATTYN HT

CEPLATTYN TL

Kiln / Bearings of Support

and Trust Rollers

Extreme pressure oils based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Kiln / Back Gear

Gear oils, mineral oil-based or

synthetic oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Ball Mill / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 range

CEPLATTYN SF range

CEPLATTYN GT range

Ball Mill / Pinion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Trunion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Back Gear Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Grinding Roller

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER PGP 680 /

GEARMASTER PGP 1000

GEARMASTER SYN 1000*

*(FLSmidth only)

Vertical Mill / Main Gear Box Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Separator Bearings

Special grease for high temperature

and high loads

URETHYN MP2

Roller Press (grease lubricated) /

Main Bearings and Slide Rails

Heavy-duty grease with solid lubricants

STABYL HD

Roller Press (oil lubricated)

Extreme pressure oil, based on synthetic oil

Grease for labyrinth sealing

GEARMASTER ECO 460/680

GEARMASTER SYN 460/680

Stabyl Eco EP2

LAGERMEISTER TS

Crusher / Bearing Heavy-duty bearing grease

URETHYN MP2

LAGERMEISTER XXL

Traveler Gate /Bearings High-temperature grease

URETHYN MP2

Blending Bed / Chains Graphite-containing chain oil

STABYLAN G 1000

Silo / Gear of Discharger Adhesive lubricant with graphite

CEPLATTYN BL

CEPLATTYN 300

Packaging Machines / Bearings Multi-purpose grease

LAGERMEISTER XXL

Gear Boxes / Various Applications

Gear oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Bearings / Various Applications Multi-purpose grease

LAGERMEISTER XXL

Disclaimer: The above-mentioned products are our general suggestions. The lubricants recommended by individual machine and component manufacturers may include

different products. Our advice is to adhere to the manufacturers recommendations. For detailed information please refer to our Product Information sheets or contact us at

www.fuchs-lubritech.com

The Right Lubricant for each Process Step

Foto: Gebr. Pfeiffer SE Foto: Gebr. Pfeiffer SE

Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG

Foto: ThyssenKrupp Polysius AG

Falz Falz Falz Anschnitt Anschnitt

RZ_FLT_Zement_8Seiter.indd 2 18.01.13 15:50

Kiln, Tyre Ring

Tyre rings on kilns have to com-

pensate the heat extension of the

kiln shell, keep the kiln shell in its

circular shape and prevent the

kiln from bending. As a kiln tyre

is never entirely xed to the kiln

shell it needs to be lubricated to

avoid seizure and wear between

the tyre pads and the tyre itself.

Any moving parts of semi-xed

tyres have to be lubricated as well.

CEPLATTYN HT and CEPLATTYN TL are reliable lubricants

for this task. They are easy and safe to apply using conven-

tional spray units. Both products penetrate into the inner

tyre ring, their base uids evaporate slowly, and their high

content of solid lubricants stays in the tyre for a safe, long-

term dry lm lubrication.

The copper paste gleitmo 160 Neu is additionally used for

maintenance and mounting during shutdown.

Crusher

The rst step in raw material pre-

paration is crushing. This can be

done e.g. by impact crusher, cone

crusher or hammer crusher.

The bearings of these crushers

are exposed to extreme vibra-

tions loads, dust and environ-

mental conditions. Therefore

greases with extreme working

stability, exceptional pressure resistance and good sealing

capabilities are to be used.

URETHYN MP 2 and LAGERMEISTER XXL full these de-

mands. Even at low temperatures they are pumpable in

central lubrication systems. URETHYN MP 2 and LAGER-

MEISTER XXL warrant safe running conditions at maxi-

mum service intervals.

Kiln, Open Gear

Most small kilns and in particu-

lar kilns with more than 3 roller

stations are equipped with an

open running gear drive. The

tooth anks of kiln gears are

exposed to radiation heat from

the kiln shell and, compared to

other Open Gears, are subjected

to axial movements. Due to slow

sliding movements between the tooth anks, solid lub-

ricant-containing open gear lubricants are the optimum

solution.

In general, graphite-containing CEPLATTYN KG 10 HMF as

well as the light-colored CEPLATTYN GT range are the best

solutions for open gear lubrication.

Because of their solid lubricant content and their eleva-

ted base oil viscosity, both CEPLATTYN grades provide an

excellent wear protection even under critical running con-

ditions.

Blending Beds

No other moving parts in the Ce-

ment Industry are exposed to du-

sty environments and their highly

abrasive nature as much as con-

veyor chains of blending beds.

That causes extreme wear on

chain links, chain bolts and spro-

cket wheels. Chain oils with mini-

mum dust attraction but good lu-

brication properties are necessary to prolong the lifetime

and maintenance cycles of this equipment.

STABYLAN G 1000 provides very good creeping properties

to reach and lubricate the inner chain. Friction and wear

are drastically reduced. Throw-off losses are minimal. The

graphite content of STABYLAN G 1000 offers excellent

emergency running properties

Roller Press

Roller Presses are used for raw

material preparation and nish

grinding. The high-pressure grin-

ding bed built between the two

rollers leads to a signicant re-

duction of energy consumption

compared to common ball mills.

Bearings of roller presses are

subject to extremely high shock

loads and, especially in the nish

grinding process, to elevated temperatures. In terms of lu-

brication, grease-lubricated bearings have to be distingu-

ished from oil-lubricated bearings.

Grease-lubricated bearings: The grease is fed in relatively

high volumes using conventional lubrication systems. The

high volumes are necessary to provide a sufcient sealing

effect on the bearing to prevent a back-ow of dust into

the grinding chamber into the bearing.

Roller Press

Greases for the grinding bearings

have to be extremely stress re-

sistant and must provide a good

damping effect to cushion

the bearings. In addition to that

a good self-sealing effect is re-

quired to prevent a dust back-

ow from the grinding chamber

to the inner bearing. STABYL HD

is the most suitable and widely

approved lubricant for these bearings. Its high base oil vis-

cosity and its content of solid lubricants provide the ideal

combination for these extremely challenging conditions.

Oil-lubricated bearings: They are equipped with a fully

sealed circulation system.

GEARMASTER SYN and GEARMASTER ECO are the proper

synthetic oils to be used in these systems.

RAW MATERIAL PREPARATION HOT PROCESSING PACKAGING CEMENT GRINDING

Grinding Rollers, Vertical Mills

Vertical mills are commonly used

for raw material and cement grin-

ding. In terms of lubrication, the

most critical parts of vertical mills

are the bearings of the grinding

rollers, the separator bearings

and the gear box. The bearings

of the grinding rollers are expo-

sed to extremely high vibrations

(short time overloads), elevated

temperatures and, depending on their design, the dust

loaded environment within the grinding chamber.

GEARMASTER PGP 680 and 1000 were especially develo-

ped for the lubrication of such highly loaded bearings.

They are based on a fully synthetic oil, thus ensuring thi-

ckest lubrication lms under extreme temperatures and

loads.

Separator Bearings, Vertical Mills

Separator bearings of vertical

mills face a critical combination

of load, revolutions and size. In

addition they are positioned in

the airstream and thus heavily

exposed to elevated temperatu-

res and dust.

URETHYN MP 2 was especially

developed to lubricate these be-

arings. It provides a good pumpability and guarantees

good lubricity under elevated temperatures and loads.

GEARMASTER CLP and GEARMASTER SYN oils ensure a

reliable operation lubrication with substantially extended

service intervals.

Gear Box

Within a cement plant many high

powered gear boxes transmit

forces to drive different machi-

nes. This can be the back gear or

the planetary gear for the fric-

tion drive of the kiln, the central

drive or back gear of a tube mill,

the gear box of a vertical mill or a

roller press or drives for crushers,

traveler grates and various con-

veyor belts. All these gears have one thing in common:

The challenging environment in a Cement Plant.

The GEARMASTER range provides a solution for every sin-

gle gear box within a Cement Plant. GEARMASTER CLP is

a mineral oil-based gear oil allowing longest service inter-

vals compared to standard mineral oils. GEARMASTER SYN

is a synthetic gear oil providing maximum energy efcien-

cy as the optimum solution for gears running at elevated

temperatures.

Traveler Grate / Cooler

Depending on its design, a trave-

ler grate is equipped with many

bearings operating under expo-

sure to the radiation heat from

the hot clinker. To keep these

bearings running, high volumes

of standard greases have to be

used. However such greases fail

frequently because they harden

in the feeding lines.

URETHYN MP 2 was especially developed to meet these

requirements. It will not harden under elevated tempe-

ratures; its high-temperature thickener system combined

with its high base oil viscosity guarantees a reliable lubri-

cation with minimum grease quantities.

In addition, URETHYN MP 2 is used as a high-performance

multi-purpose grease for all heavily loaded and conside-

rably thermally loaded bearings in classiers, crushers, sie-

ves, etc.

Ball Mill

Even though ball mills are gra-

dually being replaced by vertical

mills and roller presses, they are

still the most common grinding

systems in todays Cement Plants.

The majority of ball mills is dri-

ven by Open Gears. Some have

central drives and enclosed gear /

bearing arrangements.

CEPLATTYN is the rst choice for spray and bath lubrica-

tion of Open Gears. It is available as black graphite-con-

taining grease, a as light-colored uid, or as light-colored

semi-uid with white reactive solid lubricants.

The entire CEPLATTYN range is the life insurance for an

Open Gear drive. For mills driven by central gear drives or

closed gear arrangements, the GEARMASTER CLP range is

the widely approved choice.

Silos / Packaging / Loading

Within the cement storage and

packaging section different ma-

chine parts need lubrication.

Silos are equipped with small

open running gear drives for the

discharging unit. They have to be

lubricated by CEPLATTYN BL if

applied via automatic greasers,

or by CEPLATTYN 300, if applied

manually.

Bearings of conveyors and various parts of sack packaging

machines are to be lubricated by a state-of-the-art grease

such as LAGERMEISTER XXL. Its stable thickener system

and elevated base oil viscosity allow LAGERMEISTER XXL

to be widely used as a multi-purpose grease within a Ce-

ment Plant where moderate to high temperatures or me-

dium to high loads are to be covered. It is compatible with

most other greases.

MACHINE COMPONENT TYPE OF LUBRICANT PRODUCT

Kiln / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 HMF

range CEPLATTYN GT 10

Kiln / Inner Tyre Ring

Sprayable high-temperature uids

with solid lubricants

CEPLATTYN HT

CEPLATTYN TL

Kiln / Bearings of Support

and Trust Rollers

Extreme pressure oils based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Kiln / Back Gear

Gear oils, mineral oil-based or

synthetic oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Ball Mill / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 range

CEPLATTYN SF range

CEPLATTYN GT range

Ball Mill / Pinion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Trunion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Back Gear Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Grinding Roller

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER PGP 680 /

GEARMASTER PGP 1000

GEARMASTER SYN 1000*

*(FLSmidth only)

Vertical Mill / Main Gear Box Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Separator Bearings

Special grease for high temperature

and high loads

URETHYN MP2

Roller Press (grease lubricated) /

Main Bearings and Slide Rails

Heavy-duty grease with solid lubricants

STABYL HD

Roller Press (oil lubricated)

Extreme pressure oil, based on synthetic oil

Grease for labyrinth sealing

GEARMASTER ECO 460/680

GEARMASTER SYN 460/680

Stabyl Eco EP2

LAGERMEISTER TS

Crusher / Bearing Heavy-duty bearing grease

URETHYN MP2

LAGERMEISTER XXL

Traveler Gate /Bearings High-temperature grease

URETHYN MP2

Blending Bed / Chains Graphite-containing chain oil

STABYLAN G 1000

Silo / Gear of Discharger Adhesive lubricant with graphite

CEPLATTYN BL

CEPLATTYN 300

Packaging Machines / Bearings Multi-purpose grease

LAGERMEISTER XXL

Gear Boxes / Various Applications

Gear oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Bearings / Various Applications Multi-purpose grease

LAGERMEISTER XXL

Disclaimer: The above-mentioned products are our general suggestions. The lubricants recommended by individual machine and component manufacturers may include

different products. Our advice is to adhere to the manufacturers recommendations. For detailed information please refer to our Product Information sheets or contact us at

www.fuchs-lubritech.com

The Right Lubricant for each Process Step

Foto: Gebr. Pfeiffer SE Foto: Gebr. Pfeiffer SE

Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG

Foto: ThyssenKrupp Polysius AG

Falz Falz Falz Anschnitt Anschnitt

RZ_FLT_Zement_8Seiter.indd 2 18.01.13 15:50

Kiln, Tyre Ring

Tyre rings on kilns have to com-

pensate the heat extension of the

kiln shell, keep the kiln shell in its

circular shape and prevent the

kiln from bending. As a kiln tyre

is never entirely xed to the kiln

shell it needs to be lubricated to

avoid seizure and wear between

the tyre pads and the tyre itself.

Any moving parts of semi-xed

tyres have to be lubricated as well.

CEPLATTYN HT and CEPLATTYN TL are reliable lubricants

for this task. They are easy and safe to apply using conven-

tional spray units. Both products penetrate into the inner

tyre ring, their base uids evaporate slowly, and their high

content of solid lubricants stays in the tyre for a safe, long-

term dry lm lubrication.

The copper paste gleitmo 160 Neu is additionally used for

maintenance and mounting during shutdown.

Crusher

The rst step in raw material pre-

paration is crushing. This can be

done e.g. by impact crusher, cone

crusher or hammer crusher.

The bearings of these crushers

are exposed to extreme vibra-

tions loads, dust and environ-

mental conditions. Therefore

greases with extreme working

stability, exceptional pressure resistance and good sealing

capabilities are to be used.

URETHYN MP 2 and LAGERMEISTER XXL full these de-

mands. Even at low temperatures they are pumpable in

central lubrication systems. URETHYN MP 2 and LAGER-

MEISTER XXL warrant safe running conditions at maxi-

mum service intervals.

Kiln, Open Gear

Most small kilns and in particu-

lar kilns with more than 3 roller

stations are equipped with an

open running gear drive. The

tooth anks of kiln gears are

exposed to radiation heat from

the kiln shell and, compared to

other Open Gears, are subjected

to axial movements. Due to slow

sliding movements between the tooth anks, solid lub-

ricant-containing open gear lubricants are the optimum

solution.

In general, graphite-containing CEPLATTYN KG 10 HMF as

well as the light-colored CEPLATTYN GT range are the best

solutions for open gear lubrication.

Because of their solid lubricant content and their eleva-

ted base oil viscosity, both CEPLATTYN grades provide an

excellent wear protection even under critical running con-

ditions.

Blending Beds

No other moving parts in the Ce-

ment Industry are exposed to du-

sty environments and their highly

abrasive nature as much as con-

veyor chains of blending beds.

That causes extreme wear on

chain links, chain bolts and spro-

cket wheels. Chain oils with mini-

mum dust attraction but good lu-

brication properties are necessary to prolong the lifetime

and maintenance cycles of this equipment.

STABYLAN G 1000 provides very good creeping properties

to reach and lubricate the inner chain. Friction and wear

are drastically reduced. Throw-off losses are minimal. The

graphite content of STABYLAN G 1000 offers excellent

emergency running properties

Roller Press

Roller Presses are used for raw

material preparation and nish

grinding. The high-pressure grin-

ding bed built between the two

rollers leads to a signicant re-

duction of energy consumption

compared to common ball mills.

Bearings of roller presses are

subject to extremely high shock

loads and, especially in the nish

grinding process, to elevated temperatures. In terms of lu-

brication, grease-lubricated bearings have to be distingu-

ished from oil-lubricated bearings.

Grease-lubricated bearings: The grease is fed in relatively

high volumes using conventional lubrication systems. The

high volumes are necessary to provide a sufcient sealing

effect on the bearing to prevent a back-ow of dust into

the grinding chamber into the bearing.

Roller Press

Greases for the grinding bearings

have to be extremely stress re-

sistant and must provide a good

damping effect to cushion

the bearings. In addition to that

a good self-sealing effect is re-

quired to prevent a dust back-

ow from the grinding chamber

to the inner bearing. STABYL HD

is the most suitable and widely

approved lubricant for these bearings. Its high base oil vis-

cosity and its content of solid lubricants provide the ideal

combination for these extremely challenging conditions.

Oil-lubricated bearings: They are equipped with a fully

sealed circulation system.

GEARMASTER SYN and GEARMASTER ECO are the proper

synthetic oils to be used in these systems.

RAW MATERIAL PREPARATION HOT PROCESSING PACKAGING CEMENT GRINDING

Grinding Rollers, Vertical Mills

Vertical mills are commonly used

for raw material and cement grin-

ding. In terms of lubrication, the

most critical parts of vertical mills

are the bearings of the grinding

rollers, the separator bearings

and the gear box. The bearings

of the grinding rollers are expo-

sed to extremely high vibrations

(short time overloads), elevated

temperatures and, depending on their design, the dust

loaded environment within the grinding chamber.

GEARMASTER PGP 680 and 1000 were especially develo-

ped for the lubrication of such highly loaded bearings.

They are based on a fully synthetic oil, thus ensuring thi-

ckest lubrication lms under extreme temperatures and

loads.

Separator Bearings, Vertical Mills

Separator bearings of vertical

mills face a critical combination

of load, revolutions and size. In

addition they are positioned in

the airstream and thus heavily

exposed to elevated temperatu-

res and dust.

URETHYN MP 2 was especially

developed to lubricate these be-

arings. It provides a good pumpability and guarantees

good lubricity under elevated temperatures and loads.

GEARMASTER CLP and GEARMASTER SYN oils ensure a

reliable operation lubrication with substantially extended

service intervals.

Gear Box

Within a cement plant many high

powered gear boxes transmit

forces to drive different machi-

nes. This can be the back gear or

the planetary gear for the fric-

tion drive of the kiln, the central

drive or back gear of a tube mill,

the gear box of a vertical mill or a

roller press or drives for crushers,

traveler grates and various con-

veyor belts. All these gears have one thing in common:

The challenging environment in a Cement Plant.

The GEARMASTER range provides a solution for every sin-

gle gear box within a Cement Plant. GEARMASTER CLP is

a mineral oil-based gear oil allowing longest service inter-

vals compared to standard mineral oils. GEARMASTER SYN

is a synthetic gear oil providing maximum energy efcien-

cy as the optimum solution for gears running at elevated

temperatures.

Traveler Grate / Cooler

Depending on its design, a trave-

ler grate is equipped with many

bearings operating under expo-

sure to the radiation heat from

the hot clinker. To keep these

bearings running, high volumes

of standard greases have to be

used. However such greases fail

frequently because they harden

in the feeding lines.

URETHYN MP 2 was especially developed to meet these

requirements. It will not harden under elevated tempe-

ratures; its high-temperature thickener system combined

with its high base oil viscosity guarantees a reliable lubri-

cation with minimum grease quantities.

In addition, URETHYN MP 2 is used as a high-performance

multi-purpose grease for all heavily loaded and conside-

rably thermally loaded bearings in classiers, crushers, sie-

ves, etc.

Ball Mill

Even though ball mills are gra-

dually being replaced by vertical

mills and roller presses, they are

still the most common grinding

systems in todays Cement Plants.

The majority of ball mills is dri-

ven by Open Gears. Some have

central drives and enclosed gear /

bearing arrangements.

CEPLATTYN is the rst choice for spray and bath lubrica-

tion of Open Gears. It is available as black graphite-con-

taining grease, a as light-colored uid, or as light-colored

semi-uid with white reactive solid lubricants.

The entire CEPLATTYN range is the life insurance for an

Open Gear drive. For mills driven by central gear drives or

closed gear arrangements, the GEARMASTER CLP range is

the widely approved choice.

Silos / Packaging / Loading

Within the cement storage and

packaging section different ma-

chine parts need lubrication.

Silos are equipped with small

open running gear drives for the

discharging unit. They have to be

lubricated by CEPLATTYN BL if

applied via automatic greasers,

or by CEPLATTYN 300, if applied

manually.

Bearings of conveyors and various parts of sack packaging

machines are to be lubricated by a state-of-the-art grease

such as LAGERMEISTER XXL. Its stable thickener system

and elevated base oil viscosity allow LAGERMEISTER XXL

to be widely used as a multi-purpose grease within a Ce-

ment Plant where moderate to high temperatures or me-

dium to high loads are to be covered. It is compatible with

most other greases.

MACHINE COMPONENT TYPE OF LUBRICANT PRODUCT

Kiln / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 HMF

range CEPLATTYN GT 10

Kiln / Inner Tyre Ring

Sprayable high-temperature uids

with solid lubricants

CEPLATTYN HT

CEPLATTYN TL

Kiln / Bearings of Support

and Trust Rollers

Extreme pressure oils based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Kiln / Back Gear

Gear oils, mineral oil-based or

synthetic oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Ball Mill / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 range

CEPLATTYN SF range

CEPLATTYN GT range

Ball Mill / Pinion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Trunion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Back Gear Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Grinding Roller

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER PGP 680 /

GEARMASTER PGP 1000

GEARMASTER SYN 1000*

*(FLSmidth only)

Vertical Mill / Main Gear Box Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Separator Bearings

Special grease for high temperature

and high loads

URETHYN MP2

Roller Press (grease lubricated) /

Main Bearings and Slide Rails

Heavy-duty grease with solid lubricants

STABYL HD

Roller Press (oil lubricated)

Extreme pressure oil, based on synthetic oil

Grease for labyrinth sealing

GEARMASTER ECO 460/680

GEARMASTER SYN 460/680

Stabyl Eco EP2

LAGERMEISTER TS

Crusher / Bearing Heavy-duty bearing grease

URETHYN MP2

LAGERMEISTER XXL

Traveler Gate /Bearings High-temperature grease

URETHYN MP2

Blending Bed / Chains Graphite-containing chain oil

STABYLAN G 1000

Silo / Gear of Discharger Adhesive lubricant with graphite

CEPLATTYN BL

CEPLATTYN 300

Packaging Machines / Bearings Multi-purpose grease

LAGERMEISTER XXL

Gear Boxes / Various Applications

Gear oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Bearings / Various Applications Multi-purpose grease

LAGERMEISTER XXL

Disclaimer: The above-mentioned products are our general suggestions. The lubricants recommended by individual machine and component manufacturers may include

different products. Our advice is to adhere to the manufacturers recommendations. For detailed information please refer to our Product Information sheets or contact us at

www.fuchs-lubritech.com

The Right Lubricant for each Process Step

Foto: Gebr. Pfeiffer SE Foto: Gebr. Pfeiffer SE

Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG

Foto: ThyssenKrupp Polysius AG

Falz Falz Falz Anschnitt Anschnitt

RZ_FLT_Zement_8Seiter.indd 2 18.01.13 15:50

Kiln, Tyre Ring

Tyre rings on kilns have to com-

pensate the heat extension of the

kiln shell, keep the kiln shell in its

circular shape and prevent the

kiln from bending. As a kiln tyre

is never entirely xed to the kiln

shell it needs to be lubricated to

avoid seizure and wear between

the tyre pads and the tyre itself.

Any moving parts of semi-xed

tyres have to be lubricated as well.

CEPLATTYN HT and CEPLATTYN TL are reliable lubricants

for this task. They are easy and safe to apply using conven-

tional spray units. Both products penetrate into the inner

tyre ring, their base uids evaporate slowly, and their high

content of solid lubricants stays in the tyre for a safe, long-

term dry lm lubrication.

The copper paste gleitmo 160 Neu is additionally used for

maintenance and mounting during shutdown.

Crusher

The rst step in raw material pre-

paration is crushing. This can be

done e.g. by impact crusher, cone

crusher or hammer crusher.

The bearings of these crushers

are exposed to extreme vibra-

tions loads, dust and environ-

mental conditions. Therefore

greases with extreme working

stability, exceptional pressure resistance and good sealing

capabilities are to be used.

URETHYN MP 2 and LAGERMEISTER XXL full these de-

mands. Even at low temperatures they are pumpable in

central lubrication systems. URETHYN MP 2 and LAGER-

MEISTER XXL warrant safe running conditions at maxi-

mum service intervals.

Kiln, Open Gear

Most small kilns and in particu-

lar kilns with more than 3 roller

stations are equipped with an

open running gear drive. The

tooth anks of kiln gears are

exposed to radiation heat from

the kiln shell and, compared to

other Open Gears, are subjected

to axial movements. Due to slow

sliding movements between the tooth anks, solid lub-

ricant-containing open gear lubricants are the optimum

solution.

In general, graphite-containing CEPLATTYN KG 10 HMF as

well as the light-colored CEPLATTYN GT range are the best

solutions for open gear lubrication.

Because of their solid lubricant content and their eleva-

ted base oil viscosity, both CEPLATTYN grades provide an

excellent wear protection even under critical running con-

ditions.

Blending Beds

No other moving parts in the Ce-

ment Industry are exposed to du-

sty environments and their highly

abrasive nature as much as con-

veyor chains of blending beds.

That causes extreme wear on

chain links, chain bolts and spro-

cket wheels. Chain oils with mini-

mum dust attraction but good lu-

brication properties are necessary to prolong the lifetime

and maintenance cycles of this equipment.

STABYLAN G 1000 provides very good creeping properties

to reach and lubricate the inner chain. Friction and wear

are drastically reduced. Throw-off losses are minimal. The

graphite content of STABYLAN G 1000 offers excellent

emergency running properties

Roller Press

Roller Presses are used for raw

material preparation and nish

grinding. The high-pressure grin-

ding bed built between the two

rollers leads to a signicant re-

duction of energy consumption

compared to common ball mills.

Bearings of roller presses are

subject to extremely high shock

loads and, especially in the nish

grinding process, to elevated temperatures. In terms of lu-

brication, grease-lubricated bearings have to be distingu-

ished from oil-lubricated bearings.

Grease-lubricated bearings: The grease is fed in relatively

high volumes using conventional lubrication systems. The

high volumes are necessary to provide a sufcient sealing

effect on the bearing to prevent a back-ow of dust into

the grinding chamber into the bearing.

Roller Press

Greases for the grinding bearings

have to be extremely stress re-

sistant and must provide a good

damping effect to cushion

the bearings. In addition to that

a good self-sealing effect is re-

quired to prevent a dust back-

ow from the grinding chamber

to the inner bearing. STABYL HD

is the most suitable and widely

approved lubricant for these bearings. Its high base oil vis-

cosity and its content of solid lubricants provide the ideal

combination for these extremely challenging conditions.

Oil-lubricated bearings: They are equipped with a fully

sealed circulation system.

GEARMASTER SYN and GEARMASTER ECO are the proper

synthetic oils to be used in these systems.

RAW MATERIAL PREPARATION HOT PROCESSING PACKAGING CEMENT GRINDING

Grinding Rollers, Vertical Mills

Vertical mills are commonly used

for raw material and cement grin-

ding. In terms of lubrication, the

most critical parts of vertical mills

are the bearings of the grinding

rollers, the separator bearings

and the gear box. The bearings

of the grinding rollers are expo-

sed to extremely high vibrations

(short time overloads), elevated

temperatures and, depending on their design, the dust

loaded environment within the grinding chamber.

GEARMASTER PGP 680 and 1000 were especially develo-

ped for the lubrication of such highly loaded bearings.

They are based on a fully synthetic oil, thus ensuring thi-

ckest lubrication lms under extreme temperatures and

loads.

Separator Bearings, Vertical Mills

Separator bearings of vertical

mills face a critical combination

of load, revolutions and size. In

addition they are positioned in

the airstream and thus heavily

exposed to elevated temperatu-

res and dust.

URETHYN MP 2 was especially

developed to lubricate these be-

arings. It provides a good pumpability and guarantees

good lubricity under elevated temperatures and loads.

GEARMASTER CLP and GEARMASTER SYN oils ensure a

reliable operation lubrication with substantially extended

service intervals.

Gear Box

Within a cement plant many high

powered gear boxes transmit

forces to drive different machi-

nes. This can be the back gear or

the planetary gear for the fric-

tion drive of the kiln, the central

drive or back gear of a tube mill,

the gear box of a vertical mill or a

roller press or drives for crushers,

traveler grates and various con-

veyor belts. All these gears have one thing in common:

The challenging environment in a Cement Plant.

The GEARMASTER range provides a solution for every sin-

gle gear box within a Cement Plant. GEARMASTER CLP is

a mineral oil-based gear oil allowing longest service inter-

vals compared to standard mineral oils. GEARMASTER SYN

is a synthetic gear oil providing maximum energy efcien-

cy as the optimum solution for gears running at elevated

temperatures.

Traveler Grate / Cooler

Depending on its design, a trave-

ler grate is equipped with many

bearings operating under expo-

sure to the radiation heat from

the hot clinker. To keep these

bearings running, high volumes

of standard greases have to be

used. However such greases fail

frequently because they harden

in the feeding lines.

URETHYN MP 2 was especially developed to meet these

requirements. It will not harden under elevated tempe-

ratures; its high-temperature thickener system combined

with its high base oil viscosity guarantees a reliable lubri-

cation with minimum grease quantities.

In addition, URETHYN MP 2 is used as a high-performance

multi-purpose grease for all heavily loaded and conside-

rably thermally loaded bearings in classiers, crushers, sie-

ves, etc.

Ball Mill

Even though ball mills are gra-

dually being replaced by vertical

mills and roller presses, they are

still the most common grinding

systems in todays Cement Plants.

The majority of ball mills is dri-

ven by Open Gears. Some have

central drives and enclosed gear /

bearing arrangements.

CEPLATTYN is the rst choice for spray and bath lubrica-

tion of Open Gears. It is available as black graphite-con-

taining grease, a as light-colored uid, or as light-colored

semi-uid with white reactive solid lubricants.

The entire CEPLATTYN range is the life insurance for an

Open Gear drive. For mills driven by central gear drives or

closed gear arrangements, the GEARMASTER CLP range is

the widely approved choice.

Silos / Packaging / Loading

Within the cement storage and

packaging section different ma-

chine parts need lubrication.

Silos are equipped with small

open running gear drives for the

discharging unit. They have to be

lubricated by CEPLATTYN BL if

applied via automatic greasers,

or by CEPLATTYN 300, if applied

manually.

Bearings of conveyors and various parts of sack packaging

machines are to be lubricated by a state-of-the-art grease

such as LAGERMEISTER XXL. Its stable thickener system

and elevated base oil viscosity allow LAGERMEISTER XXL

to be widely used as a multi-purpose grease within a Ce-

ment Plant where moderate to high temperatures or me-

dium to high loads are to be covered. It is compatible with

most other greases.

MACHINE COMPONENT TYPE OF LUBRICANT PRODUCT

Kiln / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 HMF

range CEPLATTYN GT 10

Kiln / Inner Tyre Ring

Sprayable high-temperature uids

with solid lubricants

CEPLATTYN HT

CEPLATTYN TL

Kiln / Bearings of Support

and Trust Rollers

Extreme pressure oils based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Kiln / Back Gear

Gear oils, mineral oil-based or

synthetic oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Ball Mill / Open Gear

Sprayable grease, black /

light coloured uids

CEPLATTYN KG 10 range

CEPLATTYN SF range

CEPLATTYN GT range

Ball Mill / Pinion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Trunion Bearings

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Ball Mill / Back Gear Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Grinding Roller

Extreme pressure oils, based on

mineral or synthetic oil

GEARMASTER PGP 680 /

GEARMASTER PGP 1000

GEARMASTER SYN 1000*

*(FLSmidth only)

Vertical Mill / Main Gear Box Gear oils, mineral oil-based

GEARMASTER CLP 220

GEARMASTER SYN 220

Vertical Mill / Separator Bearings

Special grease for high temperature

and high loads

URETHYN MP2

Roller Press (grease lubricated) /

Main Bearings and Slide Rails

Heavy-duty grease with solid lubricants

STABYL HD

Roller Press (oil lubricated)

Extreme pressure oil, based on synthetic oil

Grease for labyrinth sealing

GEARMASTER ECO 460/680

GEARMASTER SYN 460/680

Stabyl Eco EP2

LAGERMEISTER TS

Crusher / Bearing Heavy-duty bearing grease

URETHYN MP2

LAGERMEISTER XXL

Traveler Gate /Bearings High-temperature grease

URETHYN MP2

Blending Bed / Chains Graphite-containing chain oil

STABYLAN G 1000

Silo / Gear of Discharger Adhesive lubricant with graphite

CEPLATTYN BL

CEPLATTYN 300

Packaging Machines / Bearings Multi-purpose grease

LAGERMEISTER XXL

Gear Boxes / Various Applications

Gear oils, based on

mineral or synthetic oil

GEARMASTER CLP 220/320

GEARMASTER SYN 220/320

Bearings / Various Applications Multi-purpose grease

LAGERMEISTER XXL

Disclaimer: The above-mentioned products are our general suggestions. The lubricants recommended by individual machine and component manufacturers may include

different products. Our advice is to adhere to the manufacturers recommendations. For detailed information please refer to our Product Information sheets or contact us at

www.fuchs-lubritech.com

The Right Lubricant for each Process Step

Foto: Gebr. Pfeiffer SE Foto: Gebr. Pfeiffer SE

Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG Foto: ThyssenKrupp Polysius AG

Foto: ThyssenKrupp Polysius AG

Falz Falz Falz Anschnitt Anschnitt

RZ_FLT_Zement_8Seiter.indd 2 18.01.13 15:50

FUCHS LUBRITECH GmbH

Tel.: +49 (0) 6301 / 3206-0

Fax: +49 (0) 6301 / 3206-940

E-mail: info@fuchs-lubritech.de

www.fuchs-lubritech.com

A Member of the

FUCHS PETROLUB Group

Brilliance at Work!

Specialty Lubricants for

the Cement Industry

Foto: Mederer

Range of Services

Cement is an inorganic, nely ground substance. When mixed with water it

sets and hardens independently as a result of chemical reactions. After har-

dening, cement remains solid and resistant, even under water. The current

designation cement dates back to the Romans who named concrete-type

masonry made of quarry stones with burnt lime as binding agent Opus Cae-

mentitium. They used it as early as from 118 to 125 BC when building the

Pantheon in Rome.

Some of the key machines in cement production are crushers, mills, kilns,

and coolers. All of these machines are exposed to the rough environmental

conditions of a Cement Plant, involving highly abrasive dust, high process

temperatures, vibrations, and high loads.

Most of the key machines require special lubricants to protect the machine

parts like bearings, gear boxes, Open Gears, tyre rings and bolts from seizu-

re, wear and failure. Conventional lubricants are not designed to cope with

the tremendous vibrations in the crushing and grinding process or with the

heat the parts are exposed to in the kiln section. For more than 50 years

FUCHS LUBRITECH has been the expert for such high-performance lubricants,

especially developed for the specic requirements of the Cement Industry.

Cement

Lubricants

Machines

FUCHS LUBRITECH offers a large range of services for

the Cement Industry including oil and grease analysis,

in-house and on-site training via the FLT-ACADEMY.

FUCHS LUBRITECH provides thorough machine inspec-

tions and a unique repair service for Open Gears.

With the FLT Inspector, FUCHS LUBRITECH makes a

unique online documentation available that enables

the customers to retrieve all relevant information on

their systems and the lubricants used therein at any

time.

The FLT Inspector is the perfect online reporting tool

with integrated graphical trend analysis.

As far as we know the information in this brochure reects the current state of knowledge and of our research. They cannot, however, be

taken as an assurance about the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using

our products the purchaser must, therefore, check their suitability and assure himself of their performance. Our products are continually

being updated. We therefore reserve the right to alter the information in this brochure at any time and without prior announcement.

Check of spray pattern.

The Inspections

Checking the spray system

Assessment of the contact pattern

and the condition of the load-

carrying surfaces

Measurement of the temperature

prole across the tooth width

Documentation of the condition

of the anks (photographic, blue

print...)

Written documentation of the

whole inspection, including tren

ding of the measured values

The FLT-Inspector

Availability of all reports at

a glance

Online access at any time

Instant check via

trafc light system

Graphical trend analysis for

temperatures and vibrations

Rapid transmission of data

and reports

Individual access hierarchy

Optional extra information

(attachments) for each inspection

report

The Repair Service

Re-proling the tooth anks

Grinding pittings or larger

damages

Smoothing of scufngs

Forced running-in

Assistance with the alignment

of the transmission gear

Treatment of the working tooth anks.

Foto: Heidelberger Zement AG

FUCHS LUBRITECH GmbH

Tel.: +49 (0) 6301 / 3206-0

Fax: +49 (0) 6301 / 3206-940

E-mail: info@fuchs-lubritech.de

www.fuchs-lubritech.com

A Member of the

FUCHS PETROLUB Group

Brilliance at Work!

Specialty Lubricants for

the Cement Industry

Foto: Mederer

Range of Services

Cement is an inorganic, nely ground substance. When mixed with water it

sets and hardens independently as a result of chemical reactions. After har-

dening, cement remains solid and resistant, even under water. The current

designation cement dates back to the Romans who named concrete-type

masonry made of quarry stones with burnt lime as binding agent Opus Cae-

mentitium. They used it as early as from 118 to 125 BC when building the

Pantheon in Rome.

Some of the key machines in cement production are crushers, mills, kilns,

and coolers. All of these machines are exposed to the rough environmental

conditions of a Cement Plant, involving highly abrasive dust, high process

temperatures, vibrations, and high loads.

Most of the key machines require special lubricants to protect the machine

parts like bearings, gear boxes, Open Gears, tyre rings and bolts from seizu-

re, wear and failure. Conventional lubricants are not designed to cope with

the tremendous vibrations in the crushing and grinding process or with the

heat the parts are exposed to in the kiln section. For more than 50 years

FUCHS LUBRITECH has been the expert for such high-performance lubricants,

especially developed for the specic requirements of the Cement Industry.

Cement

Lubricants

Machines

FUCHS LUBRITECH offers a large range of services for

the Cement Industry including oil and grease analysis,

in-house and on-site training via the FLT-ACADEMY.

FUCHS LUBRITECH provides thorough machine inspec-

tions and a unique repair service for Open Gears.

With the FLT Inspector, FUCHS LUBRITECH makes a

unique online documentation available that enables

the customers to retrieve all relevant information on

their systems and the lubricants used therein at any

time.

The FLT Inspector is the perfect online reporting tool

with integrated graphical trend analysis.

As far as we know the information in this brochure reects the current state of knowledge and of our research. They cannot, however, be

taken as an assurance about the properties nor as a guarantee of the suitability of the product for the individual case in point. Before using

our products the purchaser must, therefore, check their suitability and assure himself of their performance. Our products are continually

being updated. We therefore reserve the right to alter the information in this brochure at any time and without prior announcement.

Check of spray pattern.

The Inspections

Checking the spray system

Assessment of the contact pattern

and the condition of the load-

carrying surfaces

Measurement of the temperature

prole across the tooth width

Documentation of the condition

of the anks (photographic, blue

print...)

Written documentation of the

whole inspection, including tren

ding of the measured values

The FLT-Inspector

Availability of all reports at

a glance

Online access at any time

Instant check via

trafc light system

Graphical trend analysis for

temperatures and vibrations

Rapid transmission of data

and reports

Individual access hierarchy

Optional extra information

(attachments) for each inspection

report

The Repair Service

Re-proling the tooth anks

Grinding pittings or larger

damages

Smoothing of scufngs

Forced running-in

Assistance with the alignment

of the transmission gear

Treatment of the working tooth anks.

Foto: Heidelberger Zement AG

Falz Falz Falz Anschnitt Anschnitt

RZ_FLT_Zement_8Seiter.indd 1 18.01.13 15:50

You might also like

- SMChap 018Document32 pagesSMChap 018testbank100% (8)

- NRSPDocument27 pagesNRSPMuhammad Farhan67% (3)

- TCCL Plant SpecificationDocument290 pagesTCCL Plant Specificationshani5573No ratings yet

- Turbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnerDocument4 pagesTurbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnermsvprasadNo ratings yet

- Cement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Document20 pagesCement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Abay ShiferaNo ratings yet

- Fundamental analysis of ACC Ltd and India's cement industryDocument5 pagesFundamental analysis of ACC Ltd and India's cement industryDevika SuvarnaNo ratings yet

- Paper Darab Cement Kiln SealDocument11 pagesPaper Darab Cement Kiln Sealomid1302No ratings yet

- FLSmidth SF Cooler UpgradeDocument2 pagesFLSmidth SF Cooler UpgradeMohammed AbdoNo ratings yet

- Compaction With Roller PressesDocument4 pagesCompaction With Roller PressesRollerJonnyNo ratings yet

- CKC Guidance Manual Jan 10 2008 PDFDocument34 pagesCKC Guidance Manual Jan 10 2008 PDFamk2009No ratings yet

- KHD Suspension PreheaterDocument3 pagesKHD Suspension PreheaterTamer FathyNo ratings yet

- Document List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FileDocument4 pagesDocument List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FilemkpqNo ratings yet

- Up Wear ResistantDocument14 pagesUp Wear ResistantIrshad HussainNo ratings yet

- Training PODFA: Roller Mill Quadropol - Hydraulic System ComponentsDocument69 pagesTraining PODFA: Roller Mill Quadropol - Hydraulic System ComponentsДен Стаднік100% (1)

- Assiut Cement PlantDocument17 pagesAssiut Cement PlantMahmoud RashadNo ratings yet

- Vertical Roller Mill IntroductionDocument2 pagesVertical Roller Mill Introductionemad sabriNo ratings yet

- Keystone's Revolutionary Clinker Cooler Cross-Bar DesignDocument7 pagesKeystone's Revolutionary Clinker Cooler Cross-Bar Designbasavaraju535No ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Cement Industry: Handy ManualDocument44 pagesCement Industry: Handy ManualMahmoudRadiNo ratings yet

- Technical Manual Sample PagesDocument4 pagesTechnical Manual Sample PagesmkpqNo ratings yet

- Kiln Eval Line IDocument1 pageKiln Eval Line IRaji SuriNo ratings yet

- Vade Mecum 2002Document168 pagesVade Mecum 2002Irshad HussainNo ratings yet

- 17.00 Loïc Pottier, Fives FCBDocument11 pages17.00 Loïc Pottier, Fives FCBMohd AliNo ratings yet

- (Grate Cooler Assessment) June 2012Document13 pages(Grate Cooler Assessment) June 2012Phillip007No ratings yet

- Kiln Readings 23 06 17Document4 pagesKiln Readings 23 06 17zain140No ratings yet

- Pro Wearflex2000ht UkDocument1 pagePro Wearflex2000ht UkJagadeesh GuttiNo ratings yet

- Inspection Form Atox Mill 70000196-1: Measurement of Bottom PlateDocument2 pagesInspection Form Atox Mill 70000196-1: Measurement of Bottom PlatemkpqNo ratings yet

- Application Note - Cement KilnsDocument2 pagesApplication Note - Cement KilnsMarcNo ratings yet

- MarchDocument70 pagesMarchdexter1850No ratings yet

- StanexDocument2 pagesStanexSamehibrahemNo ratings yet

- FivesFCB Brochure Horomill GBDocument6 pagesFivesFCB Brochure Horomill GBpeymanNo ratings yet

- Cooling TowerDocument3 pagesCooling Toweradearyani4No ratings yet

- PILLARD AKTUEL Progressive BurningDocument3 pagesPILLARD AKTUEL Progressive BurningSteveih100% (1)

- Design of A Cement Plant For Producing 1Document20 pagesDesign of A Cement Plant For Producing 1Shehabul Hasan MamunNo ratings yet

- Industrial Waste As Alternative Fuel in Cement Industry: Its Impact On EnvironmentDocument7 pagesIndustrial Waste As Alternative Fuel in Cement Industry: Its Impact On EnvironmentBilal El YoussoufiNo ratings yet

- 09.work Instruction For Operation of Additive Ball MillDocument9 pages09.work Instruction For Operation of Additive Ball MillRahul VermaNo ratings yet

- Cement Production ProcessDocument2 pagesCement Production ProcessNishant Ajitsaria100% (1)

- Ball Main Motor Rated Power Calculation With Gear Box DetailsDocument1 pageBall Main Motor Rated Power Calculation With Gear Box DetailsVijay BhanNo ratings yet

- Coal BurnerDocument11 pagesCoal BurnerGeorge Markas50% (2)

- Grinding Mill Computer Model: For Preliminary DesignsDocument19 pagesGrinding Mill Computer Model: For Preliminary DesignssendsatyaNo ratings yet

- 09.30 Cemengal Tanger BK6 FDDocument18 pages09.30 Cemengal Tanger BK6 FDMohd AliNo ratings yet

- A Critical Review of SAG Mill Design ProceduresDocument3 pagesA Critical Review of SAG Mill Design ProceduresAbhay BodhmageNo ratings yet

- Ball MillDocument3 pagesBall MillpassionNo ratings yet

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- Atox Coal MillDocument8 pagesAtox Coal MillLijosh JamesNo ratings yet

- 2 200901loeschetadipatri 120803014722 Phpapp01Document4 pages2 200901loeschetadipatri 120803014722 Phpapp01Sai Sricharan ReddyNo ratings yet

- Ercom Brief ProfileDocument57 pagesErcom Brief ProfileKarthik DhayalanNo ratings yet

- Performing A Cement Plant Operations AuditDocument6 pagesPerforming A Cement Plant Operations AuditJa Phe TiNo ratings yet

- Cement grinding and production overviewDocument9 pagesCement grinding and production overviewMob Morphling KurustienNo ratings yet

- Pyroprocessing For The Minerals Industry: Rupp Industrial SolutionsDocument8 pagesPyroprocessing For The Minerals Industry: Rupp Industrial SolutionsawfahaddadinNo ratings yet

- Loesche Grinding Plants for Coal GasificationDocument45 pagesLoesche Grinding Plants for Coal GasificationMaxim Polevoy100% (1)

- Effect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierDocument51 pagesEffect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierNam HuynhNo ratings yet

- 06 Mill Body Upper HousingDocument15 pages06 Mill Body Upper HousingDavid Vilca MamaniNo ratings yet