Professional Documents

Culture Documents

Kwikstage Shoring Guide

Uploaded by

KallumRowlandsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kwikstage Shoring Guide

Uploaded by

KallumRowlandsCopyright:

Available Formats

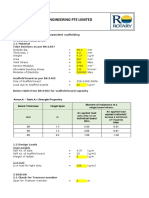

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 1 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

Technical

Data

Sheet

Products

Mabey Hire Ltd.

Scout Hill,

Ravensthorpe,

Dewsbury,

West Yorkshire

WF13 3EJ

United Kingdom

Telephone: +44 (0) 1924 460 601

Facsimile: +44 (0) 1924 457 932

Email: action@mabeyhire.co.uk

Website: www.mabeyhire.co.uk

Kwi kst age

Shori ng

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 2 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

Index

Reference Description Page No.

Contents 2

1.0 Introduction 3

2.0 Section Properties, Capacities & Weights 4

2.1 Standards 4

2.1.1 Details 4

2.1.2 Section Properties 4

2.1.3 Load Capacity Axial 5

2.1.4 Standards Capacity End Details 5

2.2 Braces 6

2.2.1 Shoring Ties 6

2.2.2 Trigger Braces 6

2.2.3 Shoring J ack Brace 7

2.3 Base and Head J acks 8

2.3.1 Base J ack Details 8

2.3.2 Head J ack Details 9

2.3.3 Load Capacity Base & Head J acks 10

3.0 Typical Connection Details 16

4.0 Bracing of Adjustable U Heads 17

5.0 Eccentric Loadings 18

6.0 Erection of Kwikstage Shoring 19

7.0 Equipment List 21

Contents

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 3 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

Application

This Technical Data Sheet is designed to provide information of sufficient content and detail as to enable engineers,

competent in structural analysis & structural steelwork design to safely design structures incorporating Kwikstage Shoring.

Design Codes

Kwikstage Shoring is a modular system primarily for use in temporary works and as such complies with the following codes:-

BS 449:1969 inc. 1989 Amendment - Specification for the use of Structural Steel in Buildings

BS 5975:2008 - Code of Practice for Temporary Works Procedures and the Permissible Stress Design of Falsework

Eurocodes

The equipment is currently being assessed to Eurocodes. Strengths relating to these codes will be published in a future

revision to this document. Please refer to Mabey Hire Ltd. engineering team for the latest information.

Safe Working Loads

The casting and wedge fitting at the end of a Shoring Tie combine to create a very rigid connection between the horizontal and

vertical members of the Kwikstage Shoring System.

The rigidity enables improved load capacities to be obtained in standards compared with those achievable when Kwikstage

Ledgers or Propping Ties are used.

A minimum of two Shoring Ties connected at right angles at set positions up a standard provide sufficient restraint to allow

these increased loads to be justified.

An extensive and exhaustive testing programme has achieved verification of theoretical load capacities.

Shoring Ties are normally placed in the highest and lowest possible sets of V pressings on a standard. In certain cases the

second set of V pressings may be used, but allowable loads are much reduced.

Product Use

For the handling and use of Kwikstage Shoring, please refer to Sections 3.0 to 6.0.

1.0 Introduction

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 4 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.1 Standards

2.1.1 Details

The Standards are fabricated from standard steel scaffold tube to BS EN 39:2001.

The two types of standards are identified by, Standards which have a device (spigot) at one end to allow the standards to be

connected end to end, and an Open Ended Standard which allows the use of U Heads and Base J acks at either end.

Each type of standard has V pressings attached, 4No. around the circumference of the tube, at right angles to each other,

and at 495mm vertical centers along the tube.

The V pressings allow the Shoring Ties to be connected to the standards.

2.1.2 Section Properties

Part No.

Length

(m)

Weight

(kg)

End

Type

KS-SEU/1.48 1.473 7.9

Spigot KS-SEU/1.98 1.981 12.0

KS-SEU/2.97 2.972 17.4

KS-OEU/0.99 0.991 5.3

Open

Ended

KS-OEU/1.48 1.473 7.9

KS-OEU/1.98 1.981 12.0

Outer Diameter

Nominal Wall

Thickness

Mass per

Linear

Metre

Cross

Sectional

Area, A

Moment

of Inertia,

I

Radius of

Gyration,

r

Modulus

of

Elasticity

Design

Strength

(mm) (mm)

(Kg/m)

(cm

2

)

(cm

4

) (cm) (N/mm

2

) (N/mm

2

)

BS EN 39:2001

Steel Tube

48.3 +/- 0.5 4.0 4.37 5.57 13.8 1.57 210,000 235

2.0 Section Properties, Capacities & Weights

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 5 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.1.3 Load Capacity - Axial

The maximum axial capacity is 55kN.

2.1.4 Standards Capacity End Details

Application of the load at the ends of the Standards should be through a standard U Head or Base J ack.

The primary beam, passing through the U Head should be centralised in the U head using timber wedges or similar.

If no wedges are to be used then the U Head should be turned so that opposite flanges of the U head are touching the sides

of the primary beam. This ensures that the primary beam is central in the U Head.

Otherwise the capacity of the Adjustable U Head will then be limited by eccentric loading.

Compression Capacity

Tension

Capacity

Shoring Ties at

1.5m Vertical

Centres

Shoring Ties at

2.0m Vertical

Centres

Shoring Ties 495mm

above or below last V

Pressing

Axial Load Capacity (kN) 55 40 See Graphs 11 and 12

0

2.0 Section Properties, Capacities & Weights

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 6 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.2 Braces

2.2.1 Shoring Ties

The Shoring Ties are horizontal members, which are connected to the V pressings on the Standards with a quick-acting

positive wedge fitting. The holes in the cast ends provide automatic node point location for the Shoring Trigger Braces.

2.2.2 Trigger Braces

These provide nodal triangulation of panels and transfer horizontal loads to the bottom of the Falsework via standards.

Part No.

Bay Width (B)

(m)

Weight

(kg)

KS-ST/0.6 0.6 4.0

KS-ST/0.9 0.9 5.1

KS-ST/1.2 1.2 6.9

KS-ST/1.8 1.8 9.6

Part No.

Bay Size

Pin

Centres

(L) (m)

Allowable

Axial

Load

(kN)

Horizontal

Load

Capacity

(kN)

Induced

Vertical

Load (kN)

Weight

(kg)

Width (m) Height (m)

KS-TB/1.173

0.9

1.0 1.173 10.90 7.33 8.07 4.8

KS-TB/1.598 1.5 1.598 10.08 5.22 8.62 6.1

KS-TB/1.373

1.2

1.0 1.373 10.53 8.12 6.71 5.4

KS-TB/1.750 1.5 1.750 9.77 6.14 7.60 6.5

KS-TB/2.175 2.0 2.175 8.86 4.59 7.58 7.8

KS-TB/1.856

1.8

1.0 1.856 9.54 8.36 4.60 6.9

KS-TB/2.150 1.5 2.150 8.91 6.87 5.67 7.8

KS-TB/2.508 2.0 2.508 8.14 5.47 6.02 8.9

2.0 Section Properties, Capacities & Weights

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 7 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.2.3 Shoring Jack Brace

Allowable loads in these units are a function of either the slip value of its half coupler fitting or strut buckling. These braces

may be used in standard panels as well as base and head jack situations. The following table gives allowable axial loads,

horizontal load capacities and induced vertical loads for these items in various applications.

Part No.

Pin Centres (L)

(m)

Weight

(kg)

KS-SJ B-1 0.8 1.3 5.8

KS-SJ B-2 1.118 1.929 9.0

KS-SJ B-3 1.939 2.75 10.5

Bay Size Allowable

Axial Load

(kN)

Horizontal

Load Capacity

(kN)

Induced

Vertical

(kN) Width (m) Height (m)

0.9

Base J ack 6.25 4.32 4.49

Head J ack 6.25 4.11 4.68

1.0 6.25 4.19 4.61

1.5 6.25 3.23 5.33

2.0 6.10 2.52 5.55

1.2

Base J ack 6.25 4.91 3.83

Head J ack 6.25 4.74 4.04

1.0 6.25 4.80 3.97

1.5 6.25 3.91 4.85

2.0 5.88 3.05 5.03

1.8

Base J ack 6.25 5.53 2.28

Head J ack 6.25 5.42 3.08

1.0 6.25 5.46 3.00

1.5 5.93 4.57 3.78

2.0 5.31 3.57 3.93

2.0 Section Properties, Capacities & Weights

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 8 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.3 Base and Head Jacks

Bracing requirements for base and head jacks are dependant upon five factors:

1) J ack Extension

2) Axial Load in the Standard

3) Horizontal Loading

4) Bay Size

5) Lift Height

2.3.1 Base Jack Details

Various combinations of items are available to provide base adjustment in Kwikstage Shoring.

On level surfaces, base adjustment is achieved using Kwikstage Adjustable Base J ack.

Shoring J ack Braces can be connected to these bases using the Shoring Adapter.

The Flat Baseplate allows a standard to

be secured on the peg for cases where no

adjustment is required at the base.

KS-AB

Adjustable Base

Wt: 11.0kg

KS-SAB

Short Adjustable Base

Wt: 6.6kg

KS-FBP

Flat Baseplate

Wt: 1.0kg

The Shoring Adapter is a half

coupler with lug attachments.

It is joined to an Adjustable

Base J ack or Socket Base to

provide a location point for the

Shoring J ack Brace.

On sloping surfaces a

combination of Adjustable

Stem and Shoring Sloping

Base Unit is used.

The maximum rotation angle

that can be reached is 30.

KS-SA

Shoring Adaptor

Wt: 1.4kg

KS-SSBU

Shoring Sloping Base Unit

Wt: 7.8kg

2.0 Section Properties, Capacities & Weights

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 9 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.3.2 Head Jack Details

Various combinations of items are available to provide head adjustment in Kwikstage Shoring.

U Heads or Shoring U Head Units are used with Adjustable Stems to provide adjustment at the top of the Shoring system.

KS-STEM

Adjustable Stem

c/w Cast Collar

Wt: 10.0kg

KS-AUH

Adjustable U Head

Wt: 13.8kg

KS-AUHL

Adjustable U Head Large

Wt: 14.3kg

Shoring U Head fits onto an Adjustable

Stems & its four lugs provide direct fixing

points for Shoring J ack Braces. With the

braces in position, it can be rotated to

centralise or accommodate skewed primary

members. The range of adjustment with this

assembly is from 183mm fully closed to

743mm fully open.

KS-SUH

Shoring U Head

Wt: 6.0kg

2.0 Section Properties, Capacities & Weights

The Adjustable Stem must

be used with the Shoring

Sloping Base Unit and the

Shoring U-Head

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 10 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

ShoringSlopingBase0.9x1.5

Graph1A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

2.3.3 Load Capacity Base and Head Jacks

The following graphs give permissible combinations of jack extension, horizontal loading and axial load for which no restraint is

required, for both standard and sloping head and base jack configurations. In sloping conditions, the average jack extension in

a run of legs may be taken to establish, from the graphs, whether there is a need to provide restraint.

The maximum leg load on any leg in the run must be used for this purpose, and bracing provided to resist the total horizontal

force. This is because the introduction of braces into the scaffolding creates stiff zones, which will attract load in preference to

the jacks, which need theoretically to move slightly before they mobilize their resistance to horizontal load.

2.3.3.1 Graphs for Bay Size 0.9m x 1.5m

2.0 Section Properties, Capacities & Weights

AdjustableBaseJack0.9x1.5

Graph1

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringUHead0.9x1.5

Graph2

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringSlopingHead0.9x1.5

Graph2A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

200

300

400

500

600

H

o

r

i

z

o

n

t

a

l

L

o

a

d

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 11 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.3.3.2 Graphs for Bay Size 1.2m x 1.5m

AdjustableBaseJack1.2x1.5

Graph3

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringSlopingBase1.2x1.5

Graph3A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

2.0 Section Properties, Capacities & Weights

ShoringSlopingHead1.2x1.5

Graph4A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringUHead1.2x1.5

Graph4

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 12 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.3.3.3 Graphs for Bay Size 1.8m x 1.5m

2.0SectionProperties,Capacities&Weights

AdjustableBaseJack1.8x1.5

Graph5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringSlopingBase1.8x1.5

Graph5A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringUHead1.8x1.5

Graph6

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringSlopingHead1.8x1.5

Graph6A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40 45 50 55

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

2.0 Section Properties, Capacities & Weights

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 13 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.3.3.4 Graphs for Bay Size 1.2m x 2.0m

AdjustableBaseJack1.2x2.0

Graph7

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringSlopingBase1.2x2.0

Graph7A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringUHead1.2x2.0

Graph8

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringSlopingHead1.2x2.0

Graph8A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

2.0 Section Properties, Capacities & Weights

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 14 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

2.3.3.5 Graphs for Bay Size 1.8m x 2.0m

ShoringSlopingHead1.8X2.0

Graph10A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

AdjustableBaseJack1.8x2.0

Graph9

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringUHead1.8x2.0

Graph10

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

2.0 Section Properties, Capacities & Weights

ShoringSlopingBase1.8x2.0

Graph9A

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

10 15 20 25 30 35 40

AxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

40

500

600

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 15 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

AllowableLoadsInUnBracedUHeadsWithTiesInSecond

VPressing(AllBays)Graph12

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

AllowableAxialLoadkN

H

o

r

i

z

o

n

t

a

l

L

o

a

d

k

N

200

300

400

500

600

ShoringJackBraceAllowableLoadChart

Graph13

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

4.8 4.9 5 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 6 6.1 6.2 6.3

AllowableAxialLoadkN

J

a

c

k

B

r

a

c

e

L

e

n

g

t

h

m

m

2.0 Section Properties, Capacities & Weights

NB: The most economical leg make-up

for a Shoring scheme may sometimes be

achieved by fixing the top and bottom row of

Shoring Ties in the second cluster of V pressing

of a standard.

The allowable load in such a situation is

dependant upon the jack extension, the type of U

head being used and whether or not the jack is

braced. The stem of the jack is always situated

above the Shoring Ties fixed in the second cluster

of V pressings and consequently the strength of

the length of the standard above the Shoring Tie

level determines the load capacity of the system.

Graph 11 shows the relationship

between the jack extension and the allowable

axial load for the Shoring U Head, when in

conjunction with a Adjustable Stem in a braced

condition.

If the head is not braced, the allowable

loads reduce dramatically as would be expected,

but the values are still sufficient for use in lightly

loaded areas of the Shoring system, such as

access ways at the edge of Falsework for a bridge

structure.

AllowableLoadsInBracedUHeadsWithTiesIn

SecondsVPressing(AllBays)Graph11

0

50

100

150

200

250

300

350

400

450

500

550

600

43 44 45 46 47 48 49 50 51 52 53 54 55

AllowableAxialLoadkN

J

a

c

k

E

x

e

n

t

s

i

o

n

m

m

ShoringUHead

Graph 11 shows the relationship between axial load

and allowable horizontal load for a range of jack extensions.

These values apply to Shoring U heads. If ties are positioned

in the second V pressings at the Base of the standard,

reference must be made to Graphs 12 and 13 below.

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 16 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

3.0 Typical Connection Details

Standard to Adjustable

Base Connection

Standard to Flat Base Plate Propping Tie to

Standard Connection

Scaffold Tube Runner

(Bracing) Between

Standards using Scaffold

Fixed Couplers

Scaffold Tube Runner (Bracing)

Between U Heads using Scaffold

Couplers

Adjustable U Head to

Open Ended Standard

Diagonal Scaffold Tube Bracing to

Scaffold Tube Runners via Scaffold

Swivel Coupler

3.0 Typical Connection Details

UHead

Tube

Bracing

90FixedCoupler

connectedto

tubularstemofU

Head(SCFC)

Propping

Tie

Standard

Wedgelocated

inVPressing

onStandard

Standard

Adjustable

Base

Standard

FlatBase

Plate

Diagonal

Scaffold

TubeBrace

Scaffold

Tube

Runner

Swivel

Coupler

(SCSC)

Adjustable

UHead

Heightof

UHead

adjusted

withcollar

Standard

Standard

Tube

Runner

90Fixed

Coupler

(SCFC)

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 17 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

4.0 Bracing of Adjustable U Heads

Bracing of U Heads and/or Bases is time consuming and is therefore best avoided wherever possible. If possible, select a leg

configuration which keeps the runouts less than 300mm at the U Heads and less than 425mm at the Bases, and then

determine the safe leg loads taking into account any eccentricity of loading and runout. The next best option is to extend the

bases and introduce bracing at the bottom where it is easier to fit. In cases where the slope of the soffit exceeds 1:15, please

consult Mabey Hire Ltd. for advice. All of the examples shown below may require additional bracing depending on the

horizontal loading requirements.

Level Soffit Formwork

Example where leg loads are such that no bracing is

required

Example where bracing is required: Primaries lace U

Heads in one direction Shoring J ack Brace lace U Heads

in other direction. Shoring J ack Brace as Diagonals

required in both directions typically every 6

th

U-Head.

Sloping Primaries (Slope Less Than 1:15)

Example where leg loads are such that no bracing is

required

Example where bracing is required: Primaries lace U

Heads in one direction Tube Runners lace U Heads in

other direction Diagonals required in both directions

typically every 6

th

U-Head.

4.0 Bracing of Adjustable U Heads

Adjustable

U-Head

Level Soffit

Primary

300mm or less

maximum

runout

Interface between primaries and U heads

must have adequate resistance against

sliding - either frictional or mechanical

Runout

Over

300mm

Shoring J ack

Brace lacing

U-Heads together

Shoring

U-Head

300mm or less

maximum

runout

Primary

Soffit on slope

Spike to

U-Head

Shoring

U-Head

Shoring J ack

Brace lacing

U-Heads together

Runout

Over

300mm

Wedges to extend

both sides of U

Heads to avoid

eccentric loading

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 18 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

5.0 Eccentric Loadings

Eccentric loading should be AVOIDED unless its effects have been taken into account in the design.

Eccentric loading can be induced in a number of situations:

a) At the U Heads from the Formwork Above

b) At the Bases from Uneven

or Sloping Ground

c) In the Uprights from

Horizontal Load Bearing

Ledgers

Plan and Side View

Primaries in the Shoring U head

5.1 Arrangement of Primary Members to Ensure Concentric Loading on Supports

Similar principles can be applied when proprietary products are used for secondary and/or primary bearers. For example,

when used as primaries, Soldiers can be bolted together end to end to make them continuous through the U Heads.

5.0 Eccentric Loadings

Random length primary Shutter Beams should not span more than 3

supports to ensure the uprights are concentrically loaded

System 160 spanning

3 supports

Interface between primaries and U

heads must have adequate

resistance against sliding either

frictional or mechanical

200mm wide

U Heads

(KS-AUHL)

Bolted joint in

U Head

Bolted joint in

span

Fly past

Wedges driven from either side

to ensure primary Shutter Beams are

over the centreline of the upright

Wedges

nailed

e

e

e

e

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 19 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

6.0 Erection of Kwikstage Shoring

6.0.1 Ground Work

Kwikstage Shoring is usually erected on substantial timber sole boards, timber sleepers or sheet piles to spread the load from

the standard. These may be bedded and haunched with lean mix concrete to further spread the load, prevent accidental

movement and eliminate foundation washout during inclement weather.

If the ground is sloping the foundation will need to accommodate the resultant horizontal forces.

6.0.2 Setting Out

Set out the shoring grid lines.

The setting out, for the Falsework, would normally be provided by the Main Contractor.

6.0.3 Erecting the Kwikstage

Before commencing work, users should ensure that they have:

A working drawing properly prepared by a suitable qualified & experienced person

Prepared a method statement and carried out a risk assessment for the work

Suitably qualified & experienced personnel to carry out the work

Inspected the equipment before use and rejected any damaged items

Checked that the foundations are at the correct levels and have suitable strength for the imposed loadings

Checked that there is sufficient striking height in the make up

Provided access equipment

Provided an adequate supply of good quality timber wedges, packing, etc.

Stage 1 Build a Single 4 Leg Braced Bay

1a) Erect the First Leg

1b) Add the Second Leg 1c) Add a Third Leg 1d) Complete the First Bay

Set Adjustable base to

the correct runout. Add

an Standard (spigot

uppermost)

Add the second leg &

connect the pair with

Shoring Ties.

Add a third leg & connect

with Shoring Ties.

Add a fourth leg, level and then

connect with Shoring Ties.

Fit diagonal Trigger Brace.

6.0 Erection of Kwikstage Shoring

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 20 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

Stage 2 Extend the Grid Sideways in Plan

Stage 3 Add the Next Vertical Lift(s) Stage 4 Add the Final Vertical Lift & Adjustable U Head

Due regard should be made for operatives working at height.

Safe access must be installed for the next lift(s). Note that the

SWL on a Shoring Tie acting as a board support is 150kg.

Add the next lift of Standards, bracing them as they are

installed.

Add the final vertical lift, which consists of open-ended

uprights to receive the adjustable U Heads. Fit the U heads

and adjust to the required runout. Install the formwork in the

U Heads and adjust and level. If the scheme requires, fit

Shoring J ack Braces to the Shoring U heads.

6.0.4 Dismantling the Kwikstage

The Kwikstage Shoring system can be dismantled by reversing the procedures outlined on these pages.

Dismantled components should NOT be dropped from a height as this may damage the equipment.

6.0 Erection of Kwikstage Shoring

If the scheme requires, fit Shoring J ack Braces to

Adjustable Bases using a Shoring Adapter.

Use a similar method to that shown in Stage 1

to add more legs to the grid.

First braced bay

TECHNI CA L DA TA SHEET

Kwi kst age Shor i ng

Document Ref: TDSKSS Page No. 21 of 21

THE I NFORMATI ON ON THI S DATA SHEET REMAI NS THE PROPERTY OF MABEY HI RE

LTD. AND I S NOT TO BE REP RODUCED WI THOUT WRI TTEN PERMI SSI ON.

WE RESERVE THE RI GHT TO AMEND THI S DATA AT ANY TI ME WI THOUT P RI OR

NOTI CE AND YOU SHOULD THEREFORE CHECK OUR WEBSI TE TO ESTABLI SH I TS

VALI DI TY.

Issue No: 02

Further Information

Tel: +44 (0) 1924 460 601

Issue Date: J uly 2013

www. mabeyhire. co. uk action@mabeyhire. co. uk

Part No. Description

Weight

(Kg)

KS-SEU/1.48 Spigot Ended Standard 1.48m (4ft 10ins) 7.9

KS-SEU/1.98 Spigot Ended Standard 1.98m (6ft 6ins) 12.0

KS-SEU/2.97 Spigot Ended Standard 2.97m (9ft 9ins) 17.4

KS-OEU/0.99 Open Ended Standard 0.99m (3ft 3ins) 5.3

KS-OEU/1.48 Open Ended Standard 1.48m (4ft 10ins) 7.9

KS-OEU/1.98 Open Ended Standard 1.98m (6ft 6ins) 12.0

KS-ST/0.6 Shoring Tie 0.6m 4.0

KS-ST/0.9 Shoring Tie 0.9m 5.1

KS-ST/1.2 Shoring Tie 1.2m 6.9

KS-ST/1.8 Shoring Tie 1.8m 9.6

KS-TB/1.173 Trigger Brace 1.173m (0.9x1.0m) 4.8

KS-TB/1.373 Trigger Brace 1.373m (1.2x1.0m) 5.4

KS-TB/1.598 Trigger Brace 1.598m (0.9x1.5m) 6.1

KS-TB/1.750 Trigger Brace 1.750m (1.2x1.5m) 6.5

KS-TB/1.856 Trigger Brace 1.856m (1.8x1.0m) 6.9

KS-TB/2.150 Trigger Brace 2.150m (1.8x1.5m) 7.8

KS-TB/2.175 Trigger Brace 2.175m (1.2x2.0m) 7.8

KS-TB/2.508 Trigger Brace 2.508m (1.8x2.0m) 8.9

KS-SJ B-1 Shoring J ack Brace No. 1 (0.8 - 1.3m) 5.8

KS-SJ B-2 Shoring J ack Brace No. 2 (1.118 - 1.929m) 9.0

KS-SJ B-3 Shoring J ack Brace No. 3 (1.939 2.750m) 10.5

KS-PSA Pinned Spigot Adaptor 0.6

KS-AUH Adjustable U Head 13.8

KS-AUHL Adjustable U Head Large 14.3

KS-SUH Shoring U Head 6.0

KS-AB

Adjustable Base 17.0

KS-SAB

Short Adjustable Base 6.6

KS-STEM Adjustable Stem c/w Cast Collar 10.0

KS-SSBU Shoring Sloping Base Unit 7.8

KS-SA Shoring Adapter 1.4

KS-FBP Flat Baseplate 1.0

7.0 Equipment List

You might also like

- Module 4-Answer KeyDocument100 pagesModule 4-Answer KeyAna Marie Suganob82% (22)

- Scaff Wind CalcsDocument1 pageScaff Wind CalcsHari HaranNo ratings yet

- Nasc Tg20 Download - Google SearchDocument2 pagesNasc Tg20 Download - Google Searchjasonwu1115100% (1)

- Scaffold CalculationDocument6 pagesScaffold CalculationAnonymous BzGb2fnfE50% (4)

- Acrow Ring Lock Shoring SystemDocument20 pagesAcrow Ring Lock Shoring SystemYasserMohsen100% (1)

- Scaffolding Structural Design Criterion SA4Document2 pagesScaffolding Structural Design Criterion SA4engineerjames7767% (15)

- STR'L Calc. For Cuplock Scaffolding SystemDocument61 pagesSTR'L Calc. For Cuplock Scaffolding SystemZeeZ HNo ratings yet

- Golf Telescopic Props Design CalculationsDocument8 pagesGolf Telescopic Props Design Calculationsbijukoottala100% (2)

- Android Attendance Management SystemDocument54 pagesAndroid Attendance Management Systemskpetks75% (12)

- Scaffold Design Approval GuidelinesDocument22 pagesScaffold Design Approval Guidelinesgarych72No ratings yet

- Calc Load of Scaffold 2016Document3 pagesCalc Load of Scaffold 2016Nurul Nabila Sahri100% (1)

- Trove Research Carbon Credit Demand Supply and Prices 1 June 2021Document51 pagesTrove Research Carbon Credit Demand Supply and Prices 1 June 2021Ceren ArkancanNo ratings yet

- Design of Steel Tubular Scaffold Floor Height of 36 MetersDocument2 pagesDesign of Steel Tubular Scaffold Floor Height of 36 MetersJay Patel100% (1)

- Calculation Load Capacity of Scaffold Moke r2Document3 pagesCalculation Load Capacity of Scaffold Moke r2MIHDI PALAPUZNo ratings yet

- Calculating Scaffold LoadsDocument39 pagesCalculating Scaffold LoadsSotara RenNo ratings yet

- Scaffolding Design Summary (Mobile Scaffold)Document1 pageScaffolding Design Summary (Mobile Scaffold)Vincent Salarda BaldomeroNo ratings yet

- Temporary Load Bearing Scaffold (Front)Document1 pageTemporary Load Bearing Scaffold (Front)Suresh DharmarajuNo ratings yet

- Bridge Formwork Without AnchorsDocument35 pagesBridge Formwork Without AnchorsMirjana Veljkovic100% (4)

- First Floor Slab Formwork CalculationsDocument10 pagesFirst Floor Slab Formwork CalculationsGhayas Jawed0% (1)

- Calculation of Scaffolding LoadDocument18 pagesCalculation of Scaffolding LoadRaju100% (1)

- Falsework CheckingDocument8 pagesFalsework CheckingRsjBugtong100% (2)

- Calculation Sheet Formula Scaffolding LTDocument2 pagesCalculation Sheet Formula Scaffolding LTMIHDI PALAPUZNo ratings yet

- Tower Mobile Scaffolds Information SheetDocument2 pagesTower Mobile Scaffolds Information SheetthecrowdedhouseNo ratings yet

- Sample Shoring Calculation ReportDocument5 pagesSample Shoring Calculation Reportsaman2580No ratings yet

- Hoardings Design Cal FinalDocument10 pagesHoardings Design Cal FinalJay Senjalia100% (1)

- Ring Lock ScaffoldingDocument47 pagesRing Lock ScaffoldingYasserMohsen100% (1)

- Properties of Standard Scaffold TubesDocument2 pagesProperties of Standard Scaffold TubesDaniel Sarmiento100% (1)

- Design Calculations: Scaffold Contrcator: Project: ClientDocument19 pagesDesign Calculations: Scaffold Contrcator: Project: Clientjmsxd0% (1)

- Formwork & Falsework Design for New RC Slab at Sha Tin CollegeDocument27 pagesFormwork & Falsework Design for New RC Slab at Sha Tin Collegelyu ting100% (1)

- Design Calculation For Raising PlateformDocument15 pagesDesign Calculation For Raising PlateformAbdul Hameed100% (1)

- ScaffoldCouplers14Document8 pagesScaffoldCouplers14Guatemalan1979No ratings yet

- Scaffolding 2Document53 pagesScaffolding 2Tri SubaktiNo ratings yet

- Form Work, Scaffolding & Shoring: Muhammad Arslan, Department of Civil Engineering Uet LahoreDocument61 pagesForm Work, Scaffolding & Shoring: Muhammad Arslan, Department of Civil Engineering Uet LahoreMuhammad ArslanNo ratings yet

- Design Calculations For Load Bearing ScaffoldDocument82 pagesDesign Calculations For Load Bearing ScaffoldChidi Asiegbunam100% (1)

- Safe Working Loads for Props Loaded Eccentrically or ConcentricallyDocument1 pageSafe Working Loads for Props Loaded Eccentrically or Concentricallykj55No ratings yet

- Kwikstage Propping RMD Kwikform UAE 8705 Low 5Document10 pagesKwikstage Propping RMD Kwikform UAE 8705 Low 5vINODNo ratings yet

- Independent scaffolding calculation 12ADocument12 pagesIndependent scaffolding calculation 12APriya G67% (3)

- Calculate Scaffolding Inedependent Common TowerTube 4mmDocument4 pagesCalculate Scaffolding Inedependent Common TowerTube 4mmDunya Fildzah100% (1)

- Build 145 30 Build Right Scaffolding in The FrameDocument3 pagesBuild 145 30 Build Right Scaffolding in The Frameanon_657324417100% (2)

- Design of basement retaining wall shutteringDocument4 pagesDesign of basement retaining wall shutteringSenthilkumar KNo ratings yet

- Yew Huat Frame Scaffold Catalogue PDFDocument14 pagesYew Huat Frame Scaffold Catalogue PDFLi ChianNo ratings yet

- Special FormworkDocument14 pagesSpecial Formworkastra0007100% (4)

- Culvert Design (1-Barrel 1x1.5m)Document7 pagesCulvert Design (1-Barrel 1x1.5m)Waqas AnjumNo ratings yet

- Scaffolding Formwork Design CalculationsDocument17 pagesScaffolding Formwork Design Calculationsbhadrakmishra100% (3)

- Scaffolding - Designing Buildings WikiDocument3 pagesScaffolding - Designing Buildings WikiKailas AnandeNo ratings yet

- Back ProppingDocument6 pagesBack ProppingMihai CojocaruNo ratings yet

- Investigation FalseworkDocument211 pagesInvestigation FalseworkRichard OonNo ratings yet

- KUS Scaffolding NewDocument19 pagesKUS Scaffolding Newanon_97464092No ratings yet

- SLAB Cuplock With H20-01Document7 pagesSLAB Cuplock With H20-01Manu MohanNo ratings yet

- IRC 87-1984 Falsework For Road BridgesDocument22 pagesIRC 87-1984 Falsework For Road BridgesKarki2No ratings yet

- App 33 Scaffolding Measurement 20200512 FINAL 230709 175132Document16 pagesApp 33 Scaffolding Measurement 20200512 FINAL 230709 175132oscarNo ratings yet

- Handbook of Structural Steelwork EE 55-13-SecureDocument11 pagesHandbook of Structural Steelwork EE 55-13-SecureAhmed Yousry AbbasyNo ratings yet

- RingLock Brocure 110812Document17 pagesRingLock Brocure 110812Mohammed AdnanNo ratings yet

- Soil and water pressure dataDocument11 pagesSoil and water pressure dataUpali KarunarathneNo ratings yet

- GL - Apprval - Design - Scaffold - 2016Document22 pagesGL - Apprval - Design - Scaffold - 2016JhayaNo ratings yet

- Sheetpile CalculationDocument2 pagesSheetpile CalculationTeddy TPNo ratings yet

- Rotational Tubestand With Transverse Slide: Model No. S206 Installation and Service Manual C538-01 REV. KDocument30 pagesRotational Tubestand With Transverse Slide: Model No. S206 Installation and Service Manual C538-01 REV. KArt MessickNo ratings yet

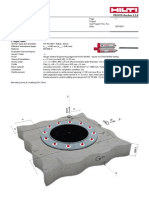

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNo ratings yet

- Modern Pulley Design Techniques And Failure AnalysisDocument17 pagesModern Pulley Design Techniques And Failure AnalysisSiva SubramaniNo ratings yet

- ODCS All ChaptersDocument414 pagesODCS All Chaptersmarlon marasiganNo ratings yet

- Rebar and CAB Brochure 09Document4 pagesRebar and CAB Brochure 09wijesinghetkNo ratings yet

- ALLOY-20 - FI - US - EN Very Good All AboutDocument55 pagesALLOY-20 - FI - US - EN Very Good All Aboutmahmoud_allam3No ratings yet

- 667 Ds 20664 000Document19 pages667 Ds 20664 000ALDONSANo ratings yet

- Redbot GRP Scaffold Tower User GuideDocument4 pagesRedbot GRP Scaffold Tower User GuideKallumRowlandsNo ratings yet

- Weldable CouplersDocument4 pagesWeldable CouplersKallumRowlandsNo ratings yet

- Pmax CalculationDocument1 pagePmax CalculationKallumRowlandsNo ratings yet

- Polyjoint FlyerDocument2 pagesPolyjoint FlyerKallumRowlandsNo ratings yet

- 2012 - 03 - Online Doka Formwork Engineering DesignDocument148 pages2012 - 03 - Online Doka Formwork Engineering Designmma87No ratings yet

- Timber H20 BeamDocument12 pagesTimber H20 BeamKallumRowlands100% (1)

- F.D. Accesssory BrochureDocument34 pagesF.D. Accesssory BrochureKallumRowlandsNo ratings yet

- Management of Temporary WorksDocument12 pagesManagement of Temporary WorksKallumRowlandsNo ratings yet

- FD Max User Guide UKDocument34 pagesFD Max User Guide UKKallumRowlandsNo ratings yet

- Marksmanship: Subject: III. Definition of TermsDocument16 pagesMarksmanship: Subject: III. Definition of TermsAmber EbayaNo ratings yet

- Health Information System Developmen T (Medical Records)Document21 pagesHealth Information System Developmen T (Medical Records)skidz137217100% (10)

- E Learning: A Student Guide To MoodleDocument16 pagesE Learning: A Student Guide To MoodleHaytham Abdulla SalmanNo ratings yet

- CH - 3Document3 pagesCH - 3Phantom GamingNo ratings yet

- W1inse6220 PDFDocument11 pagesW1inse6220 PDFpicalaNo ratings yet

- Manual Bombas CHWDocument16 pagesManual Bombas CHWFred GarciaNo ratings yet

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocument20 pagesPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNo ratings yet

- Homo Sapiens ActivityDocument8 pagesHomo Sapiens ActivityJhon Leamarch BaliguatNo ratings yet

- April 3rd - Asynchronous Class - Questions-4Document3 pagesApril 3rd - Asynchronous Class - Questions-4alidrissiNo ratings yet

- Biomechanics of Advanced Tennis: January 2003Document7 pagesBiomechanics of Advanced Tennis: January 2003Katrien BalNo ratings yet

- Dr. Malik's Farms BrochureDocument18 pagesDr. Malik's Farms BrochureNeil AgshikarNo ratings yet

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Document28 pagesMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palNo ratings yet

- Fda PDFDocument2 pagesFda PDFVictorNo ratings yet

- T23 Field Weld Guidelines Rev 01Document4 pagesT23 Field Weld Guidelines Rev 01tek_surinderNo ratings yet

- Introduction To Streering Gear SystemDocument1 pageIntroduction To Streering Gear SystemNorman prattNo ratings yet

- Mesopotamia CivilizationDocument56 pagesMesopotamia CivilizationYashika TharwaniNo ratings yet

- Ne 01 20 09 2018Document436 pagesNe 01 20 09 2018VaradrajNo ratings yet

- Intec Waste PresiDocument8 pagesIntec Waste Presiapi-369931794No ratings yet

- Rakpoxy 150 HB PrimerDocument1 pageRakpoxy 150 HB Primernate anantathatNo ratings yet

- Product Catalog 2016Document84 pagesProduct Catalog 2016Sauro GordiniNo ratings yet

- Jesus - The Creator Unleashes Our Creative PotentialDocument1 pageJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongNo ratings yet

- Agricultural Sciences P1 Nov 2015 Memo EngDocument9 pagesAgricultural Sciences P1 Nov 2015 Memo EngAbubakr IsmailNo ratings yet

- Linguistics: Chapter 1 - 10Document41 pagesLinguistics: Chapter 1 - 10Ahmad A. JawadNo ratings yet

- PGP TutorialDocument21 pagesPGP TutorialSabri AllaniNo ratings yet

- IEC-60721-3-3-2019 (Enviromental Conditions)Document12 pagesIEC-60721-3-3-2019 (Enviromental Conditions)Electrical DistributionNo ratings yet

- Power Bi ProjectsDocument15 pagesPower Bi ProjectssandeshNo ratings yet