Professional Documents

Culture Documents

Steam Engine4

Uploaded by

Dragos Negoitescu0 ratings0% found this document useful (0 votes)

27 views8 pagesengine 4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentengine 4

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views8 pagesSteam Engine4

Uploaded by

Dragos Negoitescuengine 4

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Here's the finished i ob

as she'll look when you

makethe parts described

in this last installment

The slide valve i s located on the valve rod by a

pair of locking nuts that provide travel adiust-

ment. The nuts must be a tight fit on the thread.

Steam chest and valve assembly. The valve i s not

clamped .snugly but floats between the nuts so that

steam pressure can hold it against the port face.

,174 POPULAR SCIENCE

I

Building the

T ONCE the most fascinating and the

A most difficult part of this engine to

build, the reverse gear is derived from Ste-

phenson's famous link motion. The valve

rod, which moves the slide valve over the

ports, is not connected directly to an eccen-

tric at all, but to a small block that slides

in a slotted quadrant or link. Two eccen-

trics, oppositely offset to give the correct

advance for both forward and reverse run-

ning, are connected to the two ends of this

link. A control lever connected through a

drag link can shift the slotted quadrant and

its connecting eccentric rods one way or the

other, bringing the link block and conse-

quently the valve into line with either the

forward or the backward eccentric, and so

determining which way the engine will run.

When the link block is midway in the

slot, no motion is imparted to the valve

i

even if the crankshaft is turning, and the

engine will soon stop. Either side of this

position, though, the valve will operate with

reduced travel. Steam will be cut off during

a greater part of the stroke, saving on fuel,

a condition analogous to high gear in an

automobile transmission and precisely that

which obtains in a steam locomotive run-

ning at high speed with a moderate load.

The slide valve consists of two pieces of

bronze, the face a piece of %" plate in which

a rectangle is cut by drilling and filing to

form the steam cavity or recess. To this is

silver-soldered a bronze block. The hole for

the valve rod is filed slightly oval with a

needle file so that the valve has some slight

play against the port face and may be held

on it firmly by steam pressure.

Turn the valve rod from 5/16" square

steel rod, shouldering the end to a sliding fit

in the guide atop the steam chest and thread-

ing the stem with some fine thread such as

8-36 or 6-40. Drill the square end for the

3/32" pin that will connect it to the link

block, cut the slot, and file to shape.

Eccentrics can be turned from short ends

of stock. Chuck a piece 3/32" off center,

turn the hub, and drill and ream the 9 6 ' ' shaft

hole. Then chuck the piece truly in the

three jaw to turn the 1" outside diameter

and the 76" groove, and cut off. Make a sec-

ond eccentric with no hub. [ T u T ~ the page.]

Precise work in laying out, machining, and hand fifting will be rewardi ng wi t h these parts.

JULY 1947 175

Face both smooth, slip them on a short piece

of %'/ rod, and rivet together at exactly the

angle shown in the drawings.

1'

To make the eccentric straps, cut two

I

pieces 1%" long from 3/16" by Y" cold-rolled

steel for each strap. Lay out, drill, and tap

the bolt holes for fastening the two halves

together. Those in the lower half are drilled

out to clear the 7/64" bolts. With the halves

bolted together, each blank is chucked and

bored to a running fit on its eccentric. The

outside is then roughly sawed and brought

to final shape by hand filing.

Eccentric rods are turned from Ti" square

steel. They should be cut slightly long to

allow for shortening in the bend. Lay out

the hole in the fork end after bending,

measuring from the shoulder at the threaded

end. Drill, slot, and file the fork to shape.

With dividers, carefully lay out the reverse

link on %" steel plate. To make the slot,

drill a series of undersized .holes, drill be-

tween to overlap them, and finally file to the

radiuses. Drill for the eccentric-rod pins and

finish ihe outside by filipg to shape. Note

that the link block has sides of the same

curvature as the link slot, in which it should

be a perfect sliding fit, without play.

The reverse lever and its quadrant, drag

link, and clamping nut offer no special diffi-

culties. With the various short pins and the

valve-rod nuts, you are ready to assemble

the valve gear. One of the photos shows it

in a trial assembly, less the reverse lever.

Assemble the steam chest, valve, valve

rod and adjusting nuts, and gland as in the

photo on page 174. Be sure the valve rides

freely on the rod so that its face may be

lifted a trifle above the bolting surface of

the chest in the position shown-enough to

allow for more than the thickness of a gasket

between chest and port face. To allow full

contact with the port face, the adjustment

nuts should be drawn up only to position

the valve, not to clamp it. Either tap the

nuts somewhat less than full thread depth

for a tight fit on the rod, or make two thin

nuts out 6f each one to provide locking.

With the cylinder and running gear as-

sembled, mount the steam chest temporarily

without the cover and connect the eccentric

rods to the link. Set the two eccentrics on

the shaft so that the crankpin throw bisects

the angle between the eccentrics. You can

then observe the valve travel by turning

the crankshaft.

Steam ports should just begin to open as

the piston reaches top or bottom dead cen-

ter. The valve should uncover both ports to

an equal degree, and at no point expose the

exhaust port. These conditions will best be

observed at full forward and full reverse set-

ting, with the link block at the two ends of !

the slot. At intermediate positions valve

travel will be shortened, and cutoff-the

closing of the port last admitting steam-will

occur earlier in the stroke. If setting the

valve nuts does not correct valve 'travel, it 1

Each eccentric is turned separately. Round stock

i s chucked 3/32" off. center and the shaft hole is

drilled. I t is then centered and the outside turned.

The eccentrics, one without a hub, are then riveted

or pinned together. Af t er each pair of strap halves

i s bolted together, the inside diameters are bored.

One or both eccentric rods are offset slightly so

as t o bring the centerlines of their forks direct-

ly over the centerline of the assembled eccentric.

may be necessary to reset the eccentrics, or

even shorten or lengthen their rods.

Assemble the engine, using oil freely on

all moving parts, with gaskets and graphited

gland packing. Run it in at low speed on

steam or air, or by outside power, until the

parts have worn to a good fit nncl lost any,

initial tightness. The steam line shoulcl have

a lubricator to oil the cylinder.

Beware the temptation to throw over the

reverse lever at high speed. While the en-

gine should stop at mid-clu:~drnnt setting,

you'll want a throttle valve for fuller control.

It's well to add asbestos lagging and a

sheet-metal jacket to the cylincler to mini-

mize condensation, and to start up slowly

until the cylinder is hot and any condensate

has escaped via the exhaust. Being of

cast iron, the engine will safely stand pres-

sures up to 100 lb. END

A short pi vot stud connects t he dr ag link t o t he Chucked i n the four-i aw, a pi ece of '/4" square steel

reverse link. Al so above is t he link block, shaped i s turned down t o f or m the handl e of t he reverse

t o mat ch t he slot, which fi ts t he valve-rod fork. lever. Hol es must be l ocat ed as i n t he drawing.

How the reverse gear will be assembled on t he en- At i ts lower end, t he lever pi vots on a stud t hat

gine. The quadr ant on t he steam chest receives t he screws i nt o t he ri ng, which will i tsel f be bol t ed

cl amp screw t hat locks t he reverse-lever setting. t o the bare. The cl amp nut i s f i t t ed wi t h a handle.

REVERSE

LEVER

Sf ee/

1

k A

DRILL 3/3y

yl

I

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bible SymbolsDocument2 pagesBible SymbolsAndre SmithNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- C AL Coding Guidelines 2015Document94 pagesC AL Coding Guidelines 2015Dragos NegoitescuNo ratings yet

- Bible NumbersDocument2 pagesBible Numbersmikurysan100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Inquisition and MartyrdomDocument66 pagesInquisition and MartyrdomDragos Negoitescu100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

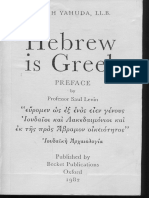

- Joseph Yahuda - Hebrew Is Greek PDFDocument711 pagesJoseph Yahuda - Hebrew Is Greek PDFDragos Negoitescu100% (10)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- IntroToMassoreticoCriticalByGinsburg Vol2 PDFDocument584 pagesIntroToMassoreticoCriticalByGinsburg Vol2 PDFDragos NegoitescuNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Ellison1920 theAmateurTelescopeDocument106 pagesEllison1920 theAmateurTelescopeastroScribii100% (3)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- D100 Repair ManualDocument107 pagesD100 Repair ManualDragos NegoitescuNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- IntroToMassoreticoCriticalByGinsburg Vol1 PDFDocument485 pagesIntroToMassoreticoCriticalByGinsburg Vol1 PDFDragos NegoitescuNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Pronuntie EnglezaDocument1 pagePronuntie EnglezaDragos NegoitescuNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- D2Hs RepairManualDocument109 pagesD2Hs RepairManualDragos NegoitescuNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Inquisition and MartyrdomDocument66 pagesInquisition and MartyrdomDragos Negoitescu100% (1)

- DSO-Observer-guide-full - IllustratedDocument162 pagesDSO-Observer-guide-full - IllustratedencyclopedeiaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Ellison1920 theAmateurTelescopeDocument106 pagesEllison1920 theAmateurTelescopeastroScribii100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Steam Engine3Document4 pagesSteam Engine3Dragos NegoitescuNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Bible NumbersDocument2 pagesBible Numbersmikurysan100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Genesis - Mechanical TranslationDocument448 pagesGenesis - Mechanical TranslationDragos Negoitescu100% (1)

- Steam Engine3Document4 pagesSteam Engine3Dragos NegoitescuNo ratings yet

- Letters - FrontDocument4 pagesLetters - Frontblastcs666No ratings yet

- Tenis 10Document98 pagesTenis 10Dragos NegoitescuNo ratings yet

- Nikon D70 ManualDocument219 pagesNikon D70 ManualTonyologyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AIR Conditioner: Owner'S ManualDocument52 pagesAIR Conditioner: Owner'S Manualashley diazNo ratings yet

- Airport Security Post 9-11Document7 pagesAirport Security Post 9-11lewisNo ratings yet

- B737-3 ATA 23 CommunicationsDocument112 pagesB737-3 ATA 23 CommunicationsPaul RizlNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Investigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseDocument5 pagesInvestigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseEditor IJTSRDNo ratings yet

- Ecological Quality RatioDocument24 pagesEcological Quality RatiofoocheehungNo ratings yet

- TheBasicsofBrainWaves - RS PDFDocument4 pagesTheBasicsofBrainWaves - RS PDFOnutu Adriana-LilianaNo ratings yet

- Eco Exercise 3answer Ans 1Document8 pagesEco Exercise 3answer Ans 1Glory PrintingNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Chap 4 - Basic Principles of ElectricityDocument31 pagesChap 4 - Basic Principles of ElectricityAdiseshuMiddeNo ratings yet

- Conceptual Artist in Nigeria UNILAGDocument13 pagesConceptual Artist in Nigeria UNILAGAdelekan FortuneNo ratings yet

- Synthesis Essay Coming To Grips With GenesisDocument11 pagesSynthesis Essay Coming To Grips With Genesisapi-259381516No ratings yet

- Asaali - Project Estimation - Ce155p-2 - A73Document7 pagesAsaali - Project Estimation - Ce155p-2 - A73Kandhalvi AsaaliNo ratings yet

- Maritime Management SystemsDocument105 pagesMaritime Management SystemsAndika AntakaNo ratings yet

- DJI F450 Construction Guide WebDocument21 pagesDJI F450 Construction Guide WebPutu IndrayanaNo ratings yet

- Surface Finish Measurement NotesDocument32 pagesSurface Finish Measurement NotesAneez ShresthaNo ratings yet

- Exam 3 DynamicsDocument7 pagesExam 3 DynamicsJulioNo ratings yet

- Orbitol Motor TMTHWDocument20 pagesOrbitol Motor TMTHWRodolfo ErenoNo ratings yet

- Critical Analysis of W.H Auden Poems The PDFDocument8 pagesCritical Analysis of W.H Auden Poems The PDFMöĤämmĔd äĹ-ŚäÁdï100% (1)

- Integration ConceptDocument34 pagesIntegration ConceptJANELLA ALVAREZNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Metaphysics of LucretiusDocument6 pagesMetaphysics of LucretiusChristopher BennettNo ratings yet

- Bravo MRI II Operation ManualDocument45 pagesBravo MRI II Operation ManualLuis100% (1)

- Document List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Document18 pagesDocument List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Naceri Mohamed RedhaNo ratings yet

- Stopping by Woods On A Snowy EveningDocument9 pagesStopping by Woods On A Snowy EveningJulia Garces100% (2)

- Reading Part 2Document14 pagesReading Part 2drama channelNo ratings yet

- Kelas ChondrichtyesDocument15 pagesKelas ChondrichtyesanitagustinawatiNo ratings yet

- T.A.T.U. - Waste Management - Digital BookletDocument14 pagesT.A.T.U. - Waste Management - Digital BookletMarieBLNo ratings yet

- Phrasal Verbs Related To HealthDocument2 pagesPhrasal Verbs Related To HealthKnuckles El Naco Narco LechugueroNo ratings yet

- Pusheen With Donut: Light Grey, Dark Grey, Brown, RoséDocument13 pagesPusheen With Donut: Light Grey, Dark Grey, Brown, RosémafaldasNo ratings yet

- Test09 Eoc Algebra2 ReducedDocument33 pagesTest09 Eoc Algebra2 ReducedkristymadimikeNo ratings yet

- 988611457NK448908 Vehicle Scan ReportDocument5 pages988611457NK448908 Vehicle Scan ReportVictor Daniel Piñeros ZubietaNo ratings yet

- The Indian & The SnakeDocument3 pagesThe Indian & The SnakeashvinNo ratings yet

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerFrom EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerRating: 4 out of 5 stars4/5 (5)

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveFrom EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNo ratings yet

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthFrom EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthRating: 4 out of 5 stars4/5 (59)