Professional Documents

Culture Documents

Lecture 21

Uploaded by

Arjun CpCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 21

Uploaded by

Arjun CpCopyright:

Available Formats

MIT OpenCourseWare

http://ocw.mit.edu

2.61 Internal Combustion Engines

Spring 2008

For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.

Diesel injection, ignition, and fuel air mixing

1. Fuel spray phenomena

2. Spontaneous ignition

3. Effects of fuel jet and charge motion on mixing-

controlled combustion

4. Fuel injection hardware

5. Challenges for diesel combustion

DIESEL FUEL INJECTION

The fuel spray serves multiple purposes:

Atomization

Fuel distribution

Fuel/air mixing

Typical Diesel fuel injector

Injection pressure: 1000 to 2200 bar

5 to 20 holes at ~ 0.15 - 0.2 mm diameter

Drop size 0.1 to 10 m

For best torque, injection starts at about 20

o

BTDC

Injection strategies for NOx control

Late injection (inj. starts at around TDC)

Other control strategies:

Pilot and multiple injections, rate shaping, water emulsion

Diesel Fuel Injection System

(A Major cost of the diesel engine)

Performs fuel metering

Provides high injection pressure

Distributes fuel effectively

Spray patterns, atomization etc.

Provides fluid kinetic energy for charge mixing

Typical systems:

Pump and distribution system (100 to 1500 bar)

Common rail system (1000 to 1700 bar)

Hydraulic pressure amplification

Unit injectors (1000 to 2500 bar)

Piezoelectric injectors (to 1800 bar)

Electronically controlled

EXAMPLE OF DIESEL INJECTION

(Hino K13C, 6 cylinder, 12.9 L turbo-charged diesel

engine, rated at 294KW@2000 rpm)

Injection pressure = 1400 bar; duration = 40

o

CA

BSFC 200 g/KW-hr

Fuel delivered per cylinder per injection at rated

condition

0.163 gm ~0.21 cc (210 mm

3

)

Averaged fuel flow rate during injection

64 mm

3

/ms

8 nozzle holes, at 0.2 mm diameter

Average exit velocity at nozzle ~253 m/s

Fuel Atomization Process

Liquid break up governed by balance between

aerodynamic force and surface tension

gas

u

2

d

Webber Number (W

b

) =

Critical Webber number: W

b,critical

~ 30; diesel fuel

surface tension ~ 2.5x10

-2

N/m

Typical W

b

at nozzle outlet > W

b,critical

; fuel shattered

into droplets within ~ one nozzle diameter

Droplet size distribution in spray depends on further

droplet breakup, coalescence and evaporation

Droplet size distribution

f(D)

Size distribution:

f(D)dD = probability of finding

particle with diameter in

the range of (D, D + dD)

1=

f(D)dD

D

0

Average diameter Volume distribution

1 dV f(D) D

3

D =

f(D)DdD

V dD

=

0

f(D)D

3

dD

0

Sauter Mean Diameter (SMD)

f(D) D

3

dD

D

32

=

0

f(D) D

2

dD

0

Droplet Size Distribution

Image removed due to copyright restrictions. Please see Fig. 10-28 in Heywood, John B. Internal Combustion

Engine Fundamentals. New York, NY: McGraw-Hill, 1988.

Fig. 10.28 Droplet size distribution measured well downstream; numbers on the curves are

radial distances from jet axis. Nozzle opening pressure at 10 MPa; injection into air at 11 bar.

Droplet Behavior in Spray

Small drops (~ micron size) follow gas stream;

large ones do not

Relaxation time d

2

Evaporation time d

2

Evaporation time small once charge is ignited

Spray angle depends on nozzle geometry and

gas density : tan(/2) (

gas

/

liquid

)

Spray penetration depends on injection

momentum, mixing with charge air, and droplet

evaporation

Spray Penetration: vapor and liquid (Fig. 10-20)

Shadowgraph image

showing both liquid

and vapor penetration

Image removed due to copyright restrictions. Please see Fig. 10-20 in Heywood, John B. Internal Combustion

Engine Fundamentals. New York, NY: McGraw-Hill, 1988.

Back-lit image

showing liquid-

containing core

Auto-ignition Process

PHYSICAL PROCESSES (Physical Delay)

Drop atomization

Evaporation

Fuel vapor/air mixing

CHEMICAL PROCESSES (Chemical Delay)

Chain initiation

Chain propagation

Branching reactions

CETANE IMPROVERS

Alkyl Nitrates

0.5% by volume increases CN by ~10

Ignition Mechanism: similar to SI engine knock

CHAIN BRANCHING EXPLOSION

Chemical reactions lead to increasing number of radicals,

which leads to rapidly increasing reaction rates

Formation of Branching Agents

ChainInitiation

RO

2

+RH ROOH +R

RH +O

2

R

+HO

2

RO

2

R

CHO +R

O

ChainPropagation

DegenerateBranching

R

+O

2

RO

2

,etc.

ROOH RO

+O

H

R

CHO +O

2

R

O +HO

2

Cetane Rating

(Procedure is similar to Octane Rating for SI Engine; for details,

see10.6.2 of text)

Primary Reference Fuels:

Normal cetane (C

16

H

34

): CN = 100

Hepta-Methyl-Nonane (HMN; C

16

H

34

): CN = 15

(2-2-4-4-6-8-8 Heptamethylnonane)

Rating:

Operate CFR engine at 900 rpm with fuel

Injection at 13

o

BTC

Adjust compression ratio until ignition at TDC

Replace fuel by reference fuel blend and change blend proportion to

get same ignition point

CN = % n-cetane + 0.15 x % HMN

Ignition Delay

Ignit i on delays measured in a

small four-stroke cycle DI

diesel engine with r

c

=16.5, as a

Image removed due to copyright restrictions. Please see Fig. 10-36 in Heywood, John B.

Internal Combustion Engine Fundamentals. New York, NY: McGraw-Hill, 1988.

function of load at 1980 rpm, at

various cetane number

(Fig. 10-36)

Fuel effects on Cetane Number (Fig. 10-40)

Image removed due to copyright restrictions. Please see Fig. 10-40 in Heywood, John B. Internal Combustion

Engine Fundamentals. New York, NY: McGraw-Hill, 1988.

Ignition Delay Calculations

Difficulty: do not know local conditions (species concentration

and temperature) to apply kinetics information

Two practical approaches:

Use an instantaneous delay expression

(T,P) = P

-n

exp(-E

A

/ T)

and solve ignition delay (

id

) from

1=

t

si

+

id

1

dt

t

si (T(t),P(t))

Use empirical correlation of

id

based on T, P at an appropriate

charge condition; e.g. Eq. (10.37 of text)

1 1 21.2

0.63

id

(CA) =(0.36 +0.22S

p

(m/s))exp

E

A

(

R

~

T(K)

17190)

) +(

P(bar) 12.4

)

E

A

(J oules per mole) = 618,840 / (CN+25)

Diesel Engine Combustion

Air Fuel Mixing Process

Importance of air utilization

Smoke-limit A/F ~ 20

Fuel jet momentum / wall interaction has a larger influence

on the early part of the combustion process

Charge motion impacts the later part of the combustion

process (after end-of-injection)

CHARGE MOTION CONTROL

Intake created motion: swirl, etc.

Not effective for low speed large engine

Piston created motion - squish

Interaction of fuel jet and the chamber wall

Sketches of outer vapor boundary

of diesel fuel spray from 12

successive frames (0.14 ms apart)

Image removed due to copyright restrictions. Please see Fig. 10-21 in

of high-speed shadowgraph

Heywood, John B. Internal Combustion Engine Fundamentals. New York,

NY: McGraw-Hill, 1988.

movie. Injection pressure at 60

MPa.

Fig. 10-21

Interaction of fuel jet with air swirl

Schematic of fuel jet

air swirl interaction;

is the fuel equivalence

Image removed due to copyright restrictions. Please see Fig. 10-22 in

ratio distribution

Heywood, John B. Internal Combustion Engine Fundamentals. New York,

NY: McGraw-Hill, 1988.

Fig. 10-22

Rate of Heat Release in Diesel Combustion

(Fig. 10.8 of Text)

Image removed due to copyright restrictions. Please see Fig. 10-9 in Heywood, John B. Internal Combustion

Engine Fundamentals. New York, NY: McGraw-Hill, 1988.

DIESEL FUEL INJECTION HARDWARE

High pressure system

precision parts for flow control

Fast action

high power movements

Expensive system

Injection pressure

Positive displacement injection system

Injection pressure adjusted to accommodate plunger

motion

Injection pressure rpm

2

Injection characteristics speed dependent

Injection pressure too high at high rpm

Injection pressure too low at low rpm

CHALLENGES IN DIESEL COMBUSTION

Heavy Duty Diesel Engines

NOx emission

Particulate emission

Power density

Noise

High Speed Passenger Car Diesel Engines

All of the above, plus

Fast burn rate

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- FORD WSG1068 Service ManualDocument330 pagesFORD WSG1068 Service Manualjohan100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Balancing Overview: A Basic Guide To Balancing Theory and TerminologyDocument36 pagesBalancing Overview: A Basic Guide To Balancing Theory and Terminologyluis alberto cervantes barradasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Packard-Merlin Engine - Rcaf 01Document40 pagesPackard-Merlin Engine - Rcaf 01Armando Hernández100% (1)

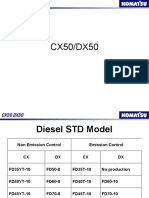

- CX50DX50 TrainingDocument174 pagesCX50DX50 TrainingPhan Dung100% (1)

- Parts Catalog: 3TNV70-XHTDocument25 pagesParts Catalog: 3TNV70-XHTJulio SierraNo ratings yet

- Synchronous GeneratorDocument15 pagesSynchronous GeneratorjvilasisNo ratings yet

- 9852 2024 01a Operator's Instructions ROC F9CR PDFDocument142 pages9852 2024 01a Operator's Instructions ROC F9CR PDFAhmad100% (2)

- Jigs - and Fixtures PDFDocument29 pagesJigs - and Fixtures PDFNiel Cool100% (1)

- WULING CONFERO Wiring Manual GuideDocument192 pagesWULING CONFERO Wiring Manual GuideLamro Tamba100% (2)

- Operator's Manual for Snow Thrower Models E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F, E6A4EDocument28 pagesOperator's Manual for Snow Thrower Models E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F, E6A4EMarkNo ratings yet

- StudyDocument1 pageStudyArjun CpNo ratings yet

- StudyDocument1 pageStudyArjun CpNo ratings yet

- StudyDocument1 pageStudyArjun CpNo ratings yet

- 12 Chapter 4Document13 pages12 Chapter 4Arjun CpNo ratings yet

- Combustion Chambers in Ic EnginesDocument22 pagesCombustion Chambers in Ic EnginesalagurmNo ratings yet

- Examination fee receipt details online registrationDocument1 pageExamination fee receipt details online registrationArjun CpNo ratings yet

- Lectures of Swami VivekanandaDocument102 pagesLectures of Swami VivekanandaArjun Cp100% (1)

- 2.61 Internal Combustion Engines: Mit OpencoursewareDocument26 pages2.61 Internal Combustion Engines: Mit OpencoursewareArjun CpNo ratings yet

- IplDocument2 pagesIplArjun CpNo ratings yet

- StudyDocument1 pageStudyArjun CpNo ratings yet

- Lecture 10Document8 pagesLecture 10mohsen_hitlor20No ratings yet

- Diesel Emissions and ControlDocument23 pagesDiesel Emissions and ControlSanthosh RamananNo ratings yet

- Super BrassDocument1 pageSuper BrassArjun CpNo ratings yet

- DiseaseDocument1 pageDiseaseArjun CpNo ratings yet

- ScienceDocument1 pageScienceArjun CpNo ratings yet

- DiseaseDocument1 pageDiseaseArjun CpNo ratings yet

- ThermodynamicsDocument1 pageThermodynamicsArjun CpNo ratings yet

- Super ScienceDocument1 pageSuper ScienceArjun CpNo ratings yet

- Marie CuriDocument1 pageMarie CuriArjun CpNo ratings yet

- Mechanical Gate Paper ADocument16 pagesMechanical Gate Paper AAbhilash G NairNo ratings yet

- QpmeDocument16 pagesQpmeSandeep PandeyNo ratings yet

- Mechanical ThermodynamicsDocument1 pageMechanical ThermodynamicsArjun CpNo ratings yet

- BrassDocument1 pageBrassArjun CpNo ratings yet

- Marie CuriDocument1 pageMarie CuriArjun CpNo ratings yet

- Mechanical ThermodynamicsDocument2 pagesMechanical ThermodynamicsArjun CpNo ratings yet

- Mechanical ThermodynamicsDocument2 pagesMechanical ThermodynamicsArjun CpNo ratings yet

- CNC Classnotes PDFDocument28 pagesCNC Classnotes PDFelangandhiNo ratings yet

- ME 311 Fluid Mechanics Chapter 9 Flow over Immersed BodiesDocument20 pagesME 311 Fluid Mechanics Chapter 9 Flow over Immersed BodiesArjun CpNo ratings yet

- WheelHorse Cultivator 7-1723 - 803965Document4 pagesWheelHorse Cultivator 7-1723 - 803965Kevins Small Engine and Tractor ServiceNo ratings yet

- Rotary Tool: GRO 12V-LI - 3 601 JC5 0L1Document5 pagesRotary Tool: GRO 12V-LI - 3 601 JC5 0L1achmade zakryNo ratings yet

- Shafts, Keys and CouplingsDocument11 pagesShafts, Keys and CouplingsNabinNo ratings yet

- Bao Dang Thai 2022 11 28Document71 pagesBao Dang Thai 2022 11 28KHOA LÊ ĐĂNGNo ratings yet

- Quadriciclo Yfz-450r 2009Document79 pagesQuadriciclo Yfz-450r 2009Antonio Alves Pereira FilhoNo ratings yet

- طراحی پایپینگ اطراف پمپ هاDocument25 pagesطراحی پایپینگ اطراف پمپ هاMorteza DianatfarNo ratings yet

- PSCS Periodic Service Check SheetDocument13 pagesPSCS Periodic Service Check SheetkkmechNo ratings yet

- Asl FD 260 - 380 (W)Document11 pagesAsl FD 260 - 380 (W)Comercial BrascomNo ratings yet

- DEUTZ 1015 Brochure PDFDocument8 pagesDEUTZ 1015 Brochure PDFRoslanNo ratings yet

- Automatic High Speed Single Head Screw Capping MachineDocument2 pagesAutomatic High Speed Single Head Screw Capping MachinePharmaceuticals Machinery KailashNo ratings yet

- CRB AODocument6 pagesCRB AOKandi ChandramouliNo ratings yet

- Mounting Instructions Ohlins SD534Document4 pagesMounting Instructions Ohlins SD534serg perNo ratings yet

- Impak CacaDocument30 pagesImpak Cacarbdubey2020No ratings yet

- 01 CW2Document16 pages01 CW2yashNo ratings yet

- KBK Classic and KBK Ergo Crane Construction Kits GuideDocument12 pagesKBK Classic and KBK Ergo Crane Construction Kits GuidedineshThangavelNo ratings yet

- Disk Brakes 2001-2003Document65 pagesDisk Brakes 2001-2003dickenszzNo ratings yet

- CBESDocument54 pagesCBESgargi yesareNo ratings yet

- Temper Switch PDFDocument3 pagesTemper Switch PDFShoaib AhmedNo ratings yet

- Manuel Americain 650 Annee 2000Document193 pagesManuel Americain 650 Annee 2000Zeka OusixNo ratings yet

- AE AP Question Bank3Document36 pagesAE AP Question Bank319951A2117 TANGUTOORI HARSHITH RAJNo ratings yet

- Esbe Vta323 HojaDocument1 pageEsbe Vta323 HojaGoheimNo ratings yet