Professional Documents

Culture Documents

Fact Sheet IFHEIP

Uploaded by

tomychalil0 ratings0% found this document useful (0 votes)

25 views2 pagesheat exchanger fact sheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentheat exchanger fact sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views2 pagesFact Sheet IFHEIP

Uploaded by

tomychalilheat exchanger fact sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Gas Furnace Safety

Gas furnaces are known for their safety,

performance and longevity. This is largely due

to their certification to nationally recognized

safety standards and the building standards and

codes that require equipment be installed

according to the manufacturers installation

instructions.

Despite the excellent safety record of gas

furnaces, there have been infrequent reports of

gas furnace heat exchanger problems. To

address these situations, an industry-accepted

procedure known as the Three-Step Method

for Detecting Unacceptable Flue Gas Leakage

from Furnace Heat Exchangers has been used

since the early 1980's to conduct field

inspections of gas-fired furnace heat

exchangers.

Though this procedure has been effective for

testing heat exchangers in natural draft

furnaces, its effectiveness for testing heat

exchangers on induced-draft furnaces that

maintain a significant negative pressure within

the heat exchanger has been questioned.

Though it is unlikely for an induced-draft

furnace to leak flue products from the heat

exchanger to the circulated airstream, a new

test procedure has been developed that

enhances the existing three-step methodology

to make it more applicable, reliable and

repeatable for the inspection of induced-draft

furnace heat exchangers.

Five-Step Method

1

Step 1: Look for Flame Disturbances

Start the furnace and observe any changes

in the flame pattern as the circulating air

blower starts operating. Look for floating

flames, flame roll out or flame distortion.

These conditions indicate a possible split

seam, open crack, severe deterioration of

the heat exchanger or gasketing material,

or physical separation of the connected

parts.

Flame disturbance that occurs after the

blower comes on is a good indication that a

heat exchanger problem may exist.

Other air leaks in the vicinity of the burners

may also cause flame disturbances and

should be corrected. If these disturbances

are significant and cannot be corrected by

eliminating the air leaks near the burners,

skip to Step 5 for physical inspection of the

heat exchanger.

If no flame disturbances are observed,

proceed to Step 2 below.

Step 2: Measure CO Levels in the Airstream

NOTE: To ensure accuracy of the

measurements, take more than one reading

and average the results to obtain the CO level.

With the furnace still running, measure the

CO level in the return airstream near the

furnace and record the value.

Then measure the CO level in the supply

airstream at a location in the system where

the air is well mixed. Generally, a location

downstream of one or more bends in the

ductwork is a good place to take the sample

for this measurement. Record this value.

If there is no measurable difference in the

CO in the return and supply airstreams, it is

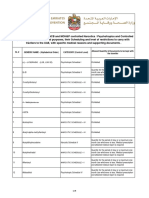

Induced-draft Furnace Heat Exchanger Inspection Procedure

1

This procedure is intended for use by qualified individuals trained and experienced in the servicing of this type of

furnace. All instrumentation used in the execution of this procedure must be in good working condition and

calibrated appropriately. A gas analyzer capable of measuring CO concentration with 1PPM resolution is required

for this procedure.

likely the furnace is not leaking CO into the

air stream. If the measured value is below 9

ppm, the OHSA acceptable maximum, go to

Step 3.

Step 2 Cond.:

If there is no difference in the CO

concentration between the return and

supply air, but there is CO detected in the

air stream, there may be another source of

CO in the home such as other gas-fired

appliances, an automobile operating in a

garage, or a fireplace in operation. Discuss

the elevated CO levels and the possible

sources with the home owner.

If the CO in the supply air is less than the

CO in the return air, it is possible that there

is an error in the measurement. Repeat

Step 2 with a different gas analyzer if

possible.

If the CO in the supply air is greater than

the CO in the return air, it is possible that

the furnace is generating the CO that is

leaking into the airstream. Proceed to Step

5.

NOTE: If the inspection described in Step 5

does not show holes, cracks or separated

seams, further investigation is necessary to

determine the source of the CO

contamination.

Step 3: Measure CO Levels in Flue Pipe

Allow the furnace to run for at least five

minutes.

Then measure the CO in the flue pipe, using

a properly calibrated combustion analyzer.

If the CO reading is less than 200 ppm, no

further action is necessary. If the CO

reading is 200 ppm or higher, proceed to

Step 4.

Step 4: Verifying Proper Installation

Verify that the furnace installation complies

with the manufacturers requirements and

any applicable codes. Refer to the

manufacturers installation instructions if

available.

Verify the gas orifice size, gas input rate and

manifold pressure, proper conversion for

fuel type and altitude (if applicable), vent

lengths, duct static pressure and the

provision for adequate combustion air to

the furnace.

Check the furnace for any damaged or

disconnected wires or hoses.

Check for misaligned burners.

Inspect the vent system and combustion air

pipe (if applicable) to check for holes or

blockage.

Make corrections as necessary and then

recheck CO in a flue gas sample. If the CO is still

at 200 ppm or higher in the flue gas, proceed to

Step 5.

Step 5. Visually Inspect Heat Exchanger

Disassemble the furnace until you can visually

inspect all heat exchanger exterior surfaces.

Any crack or hole that is big enough to affect

combustion will be easily visible to the naked

eye. DO NOT use water or smoking agents to

check for leaks.

Furnace heat exchangers joints are not

hermetically sealed, so a small amount of

leakage is normal. If there are any abnormal

splits, cracks or holes, the heat exchanger must

be replaced.

You might also like

- Fluorokote 1 2200 Hour Salt Fog TestDocument3 pagesFluorokote 1 2200 Hour Salt Fog TesttomychalilNo ratings yet

- CNC Table Waterjet Cutting MachineDocument9 pagesCNC Table Waterjet Cutting MachinetomychalilNo ratings yet

- Timing Belt Tooth Profiles and PitchesDocument3 pagesTiming Belt Tooth Profiles and PitchestomychalilNo ratings yet

- F DST 216 Bakery Confectionery ProductsDocument127 pagesF DST 216 Bakery Confectionery ProductsAdil Anwar0% (1)

- Dr2 - Spec - Non-Destructive Examination Req of PipingDocument20 pagesDr2 - Spec - Non-Destructive Examination Req of Pipingtomychalil100% (1)

- SOP-Attachment 7 - General Project ProceduresDocument42 pagesSOP-Attachment 7 - General Project ProcedurestomychalilNo ratings yet

- SOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12Document20 pagesSOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12tomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Annex C Robust Analysis: (Normative)Document1 pageAnnex C Robust Analysis: (Normative)tomychalil0% (1)

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- Guidance PT IlcDocument11 pagesGuidance PT IlcAurelia BucurNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- Vickers Calibration DetailsDocument1 pageVickers Calibration DetailstomychalilNo ratings yet

- UAE travel restrictions on controlled drugsDocument25 pagesUAE travel restrictions on controlled drugstomychalilNo ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- Building LayoutDocument1 pageBuilding LayouttomychalilNo ratings yet

- Lab Temp - MonitoringDocument28 pagesLab Temp - MonitoringtomychalilNo ratings yet

- COMPANY NAME> Business Continuity PlanDocument12 pagesCOMPANY NAME> Business Continuity PlantomychalilNo ratings yet

- Interlaboratory Comparison of FatigueDocument26 pagesInterlaboratory Comparison of FatiguetomychalilNo ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- Interlaboratory Comparison of FatigueDocument26 pagesInterlaboratory Comparison of FatiguetomychalilNo ratings yet

- Lab Temp - MonitoringDocument28 pagesLab Temp - MonitoringtomychalilNo ratings yet

- NCHM Jee 2018 SeatsDocument5 pagesNCHM Jee 2018 SeatsAnonymous 05nABj8m100% (1)

- Gallery Pages PDFDocument1 pageGallery Pages PDFtomychalilNo ratings yet

- 1 Business Environment PDFDocument6 pages1 Business Environment PDFtomychalilNo ratings yet

- F2-01 Accounting For Management PDFDocument10 pagesF2-01 Accounting For Management PDFtomychalilNo ratings yet

- List of FTTH Cities PDFDocument3 pagesList of FTTH Cities PDFSaurabh KumarNo ratings yet

- Annealingnormalizingquenchingmartensitictransformation1 140326023046 Phpapp02Document22 pagesAnnealingnormalizingquenchingmartensitictransformation1 140326023046 Phpapp02Immanuel Budiman PasaribuNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Real Talk GrammarDocument237 pagesReal Talk GrammarOmar yoshiNo ratings yet

- Cloning of CELLDocument43 pagesCloning of CELLsashaikh1213No ratings yet

- Answer Sheet FINAL LipidDocument3 pagesAnswer Sheet FINAL LipidFaridah MagumparaNo ratings yet

- The Focus Shooting Method CourseDocument48 pagesThe Focus Shooting Method CourseKobiXDNo ratings yet

- 03-Mechanical Seal &seal System Basics-REV01Document39 pages03-Mechanical Seal &seal System Basics-REV01Fayez Al-ahmadiNo ratings yet

- Name: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2ADocument2 pagesName: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2AamirossaifuddinNo ratings yet

- Tenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionDocument4 pagesTenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionMostofa RubalNo ratings yet

- English Task Resumido 2Document12 pagesEnglish Task Resumido 2Luis ArmandoNo ratings yet

- Hart Transmitter Calibration: Application NoteDocument8 pagesHart Transmitter Calibration: Application NoteThulasi Raman KowsiganNo ratings yet

- Management of Septic Shock in An Intermediate Care UnitDocument20 pagesManagement of Septic Shock in An Intermediate Care UnitJHNo ratings yet

- Analytical Methods To Measure The Constants of Fats and OilsDocument5 pagesAnalytical Methods To Measure The Constants of Fats and OilsPenicillium Notatum67% (3)

- Prometheus BoundDocument10 pagesPrometheus BoundPhillip HosfeldtNo ratings yet

- Mahavir Glass Proforma InvoiceDocument2 pagesMahavir Glass Proforma Invoicemahendra patelNo ratings yet

- COMPRESSED AIR VALIDATION SYSTEMDocument13 pagesCOMPRESSED AIR VALIDATION SYSTEMbpharmba100% (5)

- Brosur Sy135cDocument9 pagesBrosur Sy135cDenny KurniawanNo ratings yet

- Blower Selection For Wastewater Aeration PDFDocument10 pagesBlower Selection For Wastewater Aeration PDFRobert MontoyaNo ratings yet

- Torn MeniscusDocument10 pagesTorn MeniscusKrystal Veverka100% (3)

- Design and Development of Manually Operated ReaperDocument8 pagesDesign and Development of Manually Operated ReaperIOSRjournalNo ratings yet

- Improving Students' Science Process SkillsDocument9 pagesImproving Students' Science Process SkillsNovia RahmawatiNo ratings yet

- Swami Brahmananda - The Spiritual Son of Sri RamakrishnaDocument7 pagesSwami Brahmananda - The Spiritual Son of Sri RamakrishnaEstudante da Vedanta100% (2)

- TacoDocument12 pagesTaconguyennhan2190No ratings yet

- Xoro Hrs 8540 HD Sat ReceiverDocument33 pagesXoro Hrs 8540 HD Sat ReceiverPinoNo ratings yet

- PCB Table of Contents GuideDocument3 pagesPCB Table of Contents GuidePreet ChahalNo ratings yet

- Malaria Epidemiology & PreventionDocument92 pagesMalaria Epidemiology & PreventionritikaritikaNo ratings yet

- Genius+ Ba Cu en 1113Document72 pagesGenius+ Ba Cu en 1113AlbertNo ratings yet

- Motherboards Tuf z270 Mark 2Document70 pagesMotherboards Tuf z270 Mark 2Jonah HexNo ratings yet

- Christmas Around the WorldDocument16 pagesChristmas Around the WorldVioleta Veljanovska100% (1)

- The M.T Taco Food Truck Business Plan Project Business Plan DraftDocument23 pagesThe M.T Taco Food Truck Business Plan Project Business Plan DraftAbhishek Prasad RoyNo ratings yet

- Stats Set-1Document4 pagesStats Set-1Harsha KSNo ratings yet

- Railway Electrification Projects Budget 2019-20Document9 pagesRailway Electrification Projects Budget 2019-20Muhammad Meraj AlamNo ratings yet