Professional Documents

Culture Documents

Ch8 Steady Incompressible Flow in Pressure Conduits (PartB)

Uploaded by

avinash_friends21Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ch8 Steady Incompressible Flow in Pressure Conduits (PartB)

Uploaded by

avinash_friends21Copyright:

Available Formats

Chapter 8 Steady Incompressible Flow

in Pressure Conduits (Part B)

8.8 Head loss during turbulent flow in a pipe

8.9 Solution of Single Pipe Flows

8. 10 Local Head Losses

8.10.1 Losses at Sudden Enlargement

8.10.2 Losses at Sudden Contraction

Outline

We will be looking here at the flow of real

fluid in pipes real meaning a fluid that

looses energy due to friction as it

interacts with the pipe wall as it flows.

Head loss (Review)

Re

8 . 32

0

d

=

vd

= Re

Viscous sublayer

8.8 Head loss in Turbulent Flow

When flow is turbulent, the viscous dissipation effects cannot

be derived explicitly as in laminar flow, but the following

relation is still valid.

g

V

d

l

f h

f

2

2

=

l = pipe length

d= pipe diameter

V = pipe velocity

f = friction factor

8.8.1 Nikuradses Experiment

Nikuradsemade a great contribution to the theory of pipe

flow by differentiating between rough and smooth pipes.

A rough pipe is one where the mean height of roughness is

greater than the thickness of the laminar sub-layer. Nikuradse

artificially roughened pipe by coating them with sand. He

defined a relative roughness value k

s

/d (mean height of

roughness over pipe diameter) and produced graphs of

against Re for a range of relative roughness 1/30 to 1/1014.

d /2k

s

Figure : Regions on plot of Nikuradessdata

d /2k

s

d /2k

s

d /2k

s

Figure : Regions on plot of Nikuradessdata

0.0

0.2

0.4

0.6

0.8

1.0

1.2

2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0 5.2 5.4 5.6 5.8

lg (Re )

l

g

(

1

0

0

)

15

30.6

60

126

252

507

d /2k

s

Laminar

Transition Turbulent

0.0

0.2

0.4

0.6

0.8

1.0

1.2

2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0 5.2 5.4 5.6 5.8

lg (Re )

l

g

(

1

0

0

)

15

30.6

60

126

252

507

ks

d /2k

s

Laminar flowRe < 2000 (lg Re = 3.30)fRe

64 /Re

0.0

0.2

0.4

0.6

0.8

1.0

1.2

2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0 5.2 5.4 5.6 5.8

lg (Re)

l

g

(

1

0

0

)

15

30.6

60

126

252

507

d /2k

s

Transition from laminar to turbulent: 2300< Re < 4000

(3.3 < lgRe < 3.6)Pipe flow normally lies outside this region.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0 5.2 5.4 5.6 5.8

lg (Re)

l

g

(

1

0

0

)

15

30.6

60

126

252

507

d /2k

s

Smooth turbulent The limiting line of turbulent flow.

All value of relative roughness tend toward this as Re decreases.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0 5.2 5.4 5.6 5.8

lg (Re)

l

g

(

1

0

0

)

15

30.6

60

126

252

507

d /2k

s

Transitional turbulentThe region which ssvaries with

both Re and relative roughness. Most pipes lie in this region.

) (Re,

d

k

f

s

=

0.0

0.2

0.4

0.6

0.8

1.0

1.2

2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0 5.2 5.4 5.6 5.8

lg (Re)

l

g

(

1

0

0

)

15

30.6

60

126

252

507

d /2k

s

Rough turbulent. remains constant for a given relative

roughness. It is independent of Re.

Nikuradses Experiments

In general, friction factor

Function of Re and

roughness

Laminar region

Independent of roughness

Turbulent region

Smooth pipe curve

All curves coincide @

~Re=2300

Rough pipe zone

All rough pipe curves

flatten out and

become independent

of Re

Re

64

=

( )

Blausius

Re

4 / 1

k

=

Rough

Smooth

Laminar Transition Turbulent

BlausiusOK for smooth pipe

)

k

(Re,

s

D

F =

Re

64

=

2

74 . 5

log

25 . 0

+

=

e

9 . 0

10

Re 7 . 3

D

Regions on plot of Nikuradessdata

Turbulent flow in a circular pipe may be classified

as: smooth pipe region, rough pipe region and

transition region.

8.8.2 Moody chart

The Moody chart is a graphical method to find the friction factor

in pipes.

Colebrook and White proposed the following general equation

after studying flow in real pipes:

)

Re

51 . 2

7 . 3

lg( 2

1

f

d

e

f

+ =

The values of friction factor obtained from the equation are

plotted on a Moody diagram, which shows a family of curves

for f plotted against the relative roughness and Reynolds

number.

Colebrook-White Equation

A good approximate equation for the turbulent region

of the Moody chart is given by Haalands equation:

Haalandsequation is valid for turbulent

flow (Re > 2300)

Pipe roughness

pipe material pipe roughness

e (mm)

glass, drawn brass, copper 0.0015

commercial steel or wrought iron 0.045

asphalted cast iron 0.12

galvanized iron 0.15

cast iron 0.26

concrete 0.18-0.6

rivet steel 0.9-9.0

corrugated metal

45

PVC

0.12

8.24

Question

If the flow is in turbulent transition region, the Frictional

factor f of the industrial pipes _____ with the increase of the

Reynolds number

A increases B reduces C keeps constant.

Question

There are two pipes, one transports oil and the other transports

water. If diameter d ,length l and roughness coefficient of the

two pipes are all the same, kinematicviscosity

oil

is bigger

than

water

, the Reynolds Numbers are equal, then the

Frictional Loss______

A. h

fo

=h

fw

B. h

fo

>h

fw

C. h

fo

<h

fw

D.uncertain.

8.9 Single Pipe Flowssolution basics

2

4

D

Q

V

=

VD VD

= = Re

g

V

D

L

f h

L

2

2

=

Re

64 64

= =

DV

f

=

Re

9 . 6

7 . 3

log 8 . 1

1

11 . 1

D e

f

Four simultaneous equations:

continuity

energy loss

Reynolds

number

) / (Re, D e f f =

For

ColebrookWhite

)

Re

51 . 2

7 . 3

/

lg( 2

1

f

d

D e

f

+ =

Haaland

3 types of pipe flow problems:

1. Head loss (find h

L

given D, Q or V)

2. Discharge (find Q given D and h

L

)

3. Sizing problem (Find D given Q and h

L

)

Example ( Laminar flow):

Water, 20

o

C flows through a 0.6 cm tube, 30 m long, at a

flow rate of 0.34 liters/min. If the pipe discharges to the

atmosphere, determine the supply pressure if the tube is

inclined 10

o

above the horizontal in the flow direction.

10

L =30 m

D =.6 cm

1

2

Water Properties:

= 998 kg/m

3

g = 9790 N/m

3

= 1.005 E-6 m

2

/s

Energy Equation (neglecting )

P

2

= 0

P

1

g

= Z

2

Z

1

+ h

f

= L sin 10

o

+ h

f

V =

Q

A

=

0.34E

3

m

3

/ min*1min/ 60s

0.3/100 ( )

2

m

2

= 0.2m/ s

Re=

V D

=

0.2*0.006

1.005E

6

=1197 laminar flow

P

1

= 9790 N/m

3

*5.75 m = 56.34 kN/m

2

(kPa)

Example (turbulent flow):

Oil, = 900 kg/m

3

, = 1 E-5 m

2

/s, flows at 0.2 m

3

/s

through a 500 m length of 200 mm diameter, cast

iron pipe. If the pipe slopes downward 10

o

in the

flow direction, compute h

f

, pressure drop.

L

10

o

L =500 m

D =200 mm

1

2

The energy equation for = 1 can be written as follows

V =

Q

A

=

0.2m

3

/ s

.1 ( )

2

m

2

= 6.4m/ s

cast iron, ks= 0.26 mm

Re=

V D

=

6.4*.2

1E

5

= 128,000turbulent flow

Since flow is turbulent, use Haalandsequation to determine

friction factor (check your work using the Moody chart).

Z

2

Z

1

+ h

f

= - 500 sin 10 + 116.6 = - 86.8 + 116.6 = 29.8 m

Solution Summary

To solve basic pipe flow frictional head loss problem, use the

following procedure:

1. Use known flow rate to determine Reynolds number.

2. Identify whether flow is laminar or turbulent.

3. Use correct expression to determine friction factor (with

ks/dif necessary).

4. Use definition of h

f

to determine friction head loss.

5. Use general energy equation to determine total pressure drop.

8.10 Minor Losses in Turbulent Flow

Where K is minor loss coefficient

Transitions in pipe systems, such as bends, valves, changes in

diameter, entrances and exits, cause head losses in the system.

Head losses at transition points are called minor losses. A minor

loss is usually a function of the velocity head as follows:

g

V

k h

Minor L

2

2

) (

=

Sources of minor losses

Additional pressure (energy) losses

due to:

Fittings, bends, orifice plates, and valves

Losses due to physics

Vena contracta

Abrupt changes in flow area

Losses due to piping networks for fluid distribution

Typical piping elements with minor losses

Minor losses in piping networks

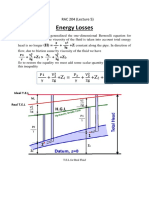

8.10.1 Sudden Enlargement

)

2 2

( ) ( ) (

2

2 2

2

1 1 2 1

2 1

g g g

p

g

p

z z h

j

+ + =

Momentum equation:

) ( ) (

1 1 2 2 2 1 2 2 2 2 1

v v Q z z gA A p A p = +

g

v v v

g

p

g

p

z z

2 1 1 2 2 2 1

2 1

) (

= +

g

v v

g

v v v

h

j

2

) (

2

2 2

2

1 1 2 1 1 2 2

+

=

( )

2

1

2

2

2

2

2

2

2

2

1

2

2

1 2

2

2

1

1

2

1

1

2

1

2

2

1

2

1 2

) 1 (

2 2

) 1 (

2

) (

) 1 (

2 2

) 1 (

2

= = =

=

= = =

=

A

A

K

g

V

K

g

v

A

A

g

v v

h

A

A

K

g

V

K

g

v

A

A

g

v v

h

j

j

g

v

K h

A

A

K

j

2

1 5 . 0

2

2

2

=

1

2

A

1

A

2

v

1

v

2

A

1

8.10.2 Sudden Contraction

8.10.3 Gradual Expansion (Diffusor)

( )

g

V V

K h

E E

2

2

2 1

=

diffusor angle ( )

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0 20 40 60 80

K

E

2

1

2

2

2

1

2

=

A

A

g

V

K h

E E

Loss due to gradual enlargement

g

V

K h

e e

2

2

=

0 . 1

e

K

5 . 0

e

K

04 . 0

e

K

8.10.4 Entrance Losses

Losses can be

reduced by

accelerating the

flow gradually and

eliminating the

8.10.5 Head Loss in Valves

Function of valve type and valve

position

The complex flow path through valves

can result in high head loss (of course,

one of the purposes of a valve is to

create head loss when it is not fully

open)

g

V

K h

v v

2

2

=

In a sudden expansion pipe shown in figure, velocity is v

1

and v

2

respectively. A middle diameter pipe is connected between the

two pipes to form a two-sudden-expansion pipe. The interaction

of minor resistances is negligible. That is, superposition method

can be applied here. Determine: (1) the velocity of the middle

pipe when the total minor head loss of the pipe is the least. (2)

the total minor head loss, and the comparison with the one

sudden expansion pipe.

Example

Solution: (1) The minor head loss of the two-sudden-expansion

pipe.

Assume the velocity of middle pipe is v, and make the total

minor head loss be the least, so

2The total minor head loss is

the minor head loss of the one sudden

expansion pipe is

the total minor head loss of the two-sudden-expansion pipe is

half of the minor head loss of the one sudden expansion pipe.

8.11 Branching Pipes

Branching pipe systems, such as the one shown by Figure

8.27, can be solved using the following:

1. Q

1

= Q

2

+ Q

3

.

2 The elevation of P is common to all pipes.

Branching pipe systems

8.12 Pipes in Series

Pipes in series, as shown by Figure 8.29, can be solved as

follows:

Q = Q

1

= Q

2

= Q

3

h

L

= h

L1

+ h

L2

+ h

L3

Fig. Pipes in series

The pipe elements of the pipes in series have:

A.the same head loss

B. the same total head loss

C. the same hydraulic slope

D. the same discharge through them

Consider the two reservoirs shown in figure, connected by a single

pipe that changes diameter over its length. The surfaces of the two

reservoirs have a difference in level of 9m. The pipe has a diameter

of 200mm for the first 15m (from A to C) then a diameter of

250mm for the remaining 45m (from C to B).

Example

For the entrance use k

L

= 0.5 and the exit k

L

=1.0. The join at C is sudden.

For both pipes use = 0.04.

Total head loss for the system H =height difference of reservoirs

and solve for Q, to give Q =

0.158 m

3

/s

8.13 Pipes in Parallel

Parallel pipes, as shown by Figure 8.30, can be solved as

follows:

Q = Q

1

+ Q

2

+ Q

3

h

L

= h

L1

= h

L2

= h

L3

Pipes in parallel

Question

From the figure, we can see that the relationship among the

head losses from A to B in the pipes in parallel 1, 2, 3 is:

A. h

fAB

h

fl

+h

f2

+h

f3

B. h

fAB

h

fl

+h

f2

C. h

fAB

h

f2

+h

f3

D. h

fAB

h

fl

=h

f2

=h

f3

.

Example

Two pipes connect two reservoirs (A and B) which have a height difference

of 10m. Pipe 1 has diameter 50mm and length 100m. Pipe 2 has diameter

100mm and length 100m. Both have entry loss k

L

= 0.5 and exit loss k

L

=1.0

and Darcy f of 0.008.

Calculate:

a) rate of flow for each pipe

b) the diameter D of a pipe 100m long that could replace the two pipes

and provide the same flow.

You might also like

- Elementary Mechanics of Fluids ExplainedDocument23 pagesElementary Mechanics of Fluids ExplainedAndre Amba MatarruNo ratings yet

- Viscous Flow in Pipes: OverviewDocument40 pagesViscous Flow in Pipes: OverviewPaulo BuenoNo ratings yet

- Lecture 5 2Document15 pagesLecture 5 2IbrahimDewaliNo ratings yet

- 10 Analysis of Pipe Flows: The Moody ChartDocument8 pages10 Analysis of Pipe Flows: The Moody ChartMiguel Angel Alvarez BoreaNo ratings yet

- Summary of Drinking Water Supply System: Chapter 2. Basic Principles of Pipe FlowDocument20 pagesSummary of Drinking Water Supply System: Chapter 2. Basic Principles of Pipe Flowaidah maqbulahNo ratings yet

- 4th Sem - Mech Engg - Fluid Mechanics-P-1Document29 pages4th Sem - Mech Engg - Fluid Mechanics-P-1Narinder SharmaNo ratings yet

- 9 Flow in Pipes - With FiguresDocument59 pages9 Flow in Pipes - With FiguresCarlos SerranoNo ratings yet

- Student Handout 20 2014Document20 pagesStudent Handout 20 2014kietniNo ratings yet

- FLUMECHDocument4 pagesFLUMECHniel senNo ratings yet

- Lab Experiments Losses in PipeDocument14 pagesLab Experiments Losses in Pipesawmag123No ratings yet

- Flow Regimes and Pressure Losses in Closed ConduitsDocument18 pagesFlow Regimes and Pressure Losses in Closed ConduitsJay Wilmer RoqueroNo ratings yet

- Flow Through PipesDocument29 pagesFlow Through PipesMichael TinambunanNo ratings yet

- Chapter-12 PumpDocument39 pagesChapter-12 PumpSalehin AnamNo ratings yet

- HW 10Document7 pagesHW 10mahrbhojiaNo ratings yet

- PS9Soln 2014Document13 pagesPS9Soln 2014Eddz Del Rosario RodriguezNo ratings yet

- Flow in Pipes Faculty - Washington.eduDocument18 pagesFlow in Pipes Faculty - Washington.eduils411No ratings yet

- 2 - Flow in Pipes Closed Conduits (Compatibility Mode)Document28 pages2 - Flow in Pipes Closed Conduits (Compatibility Mode)Eddy BongNo ratings yet

- Hydraulic TransientsDocument58 pagesHydraulic TransientsjulianvillajosNo ratings yet

- Expt 1 - Friction Loses in PipesDocument20 pagesExpt 1 - Friction Loses in PipesFauzi Helmi67% (6)

- Indo 1Document29 pagesIndo 1Michael TinambunanNo ratings yet

- Fluids - IIIDocument9 pagesFluids - IIIPOONAM RANINo ratings yet

- MP 211 Fluid Mechanics Test at University of Dodoma Covers Key ConceptsDocument5 pagesMP 211 Fluid Mechanics Test at University of Dodoma Covers Key ConceptsJanuaryNo ratings yet

- Pipe FlowDocument6 pagesPipe FlowManu K VasudevanNo ratings yet

- GR 3Document28 pagesGR 3Dale BelchesNo ratings yet

- Experiment 1 - Friction Losses in PipesDocument34 pagesExperiment 1 - Friction Losses in PipesKhairil Ikram33% (3)

- Limestone - Slurry OptimizationDocument5 pagesLimestone - Slurry OptimizationSharif M Mizanur RahmanNo ratings yet

- Engineering Hydraulics/Pipeline CalculationsDocument29 pagesEngineering Hydraulics/Pipeline Calculationsbasher rajabNo ratings yet

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- Set8ans 12Document9 pagesSet8ans 12Teoh Tiong EeNo ratings yet

- Set8ans 12Document9 pagesSet8ans 12Teoh Tiong EeNo ratings yet

- Steady Conduit FlowDocument13 pagesSteady Conduit FlowEyuelAdamNo ratings yet

- Hydraulic cylinders, lines, and fittings explainedDocument8 pagesHydraulic cylinders, lines, and fittings explainedYudha PrastyaNo ratings yet

- Pipeline Flow Calculation Using Head Loss EquationsDocument3 pagesPipeline Flow Calculation Using Head Loss Equationsnanduslns07No ratings yet

- Hydraulics - Chapter 3Document8 pagesHydraulics - Chapter 3thuaiyaalhinaiNo ratings yet

- Review Notes on Pipes and HydraulicsDocument15 pagesReview Notes on Pipes and HydraulicsMelvin EsguerraNo ratings yet

- Pipe's Minor LossesDocument95 pagesPipe's Minor LossesJosept RevueltaNo ratings yet

- PipesDocument25 pagesPipesSidesway 26No ratings yet

- Topic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Document23 pagesTopic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Nor SyamimiNo ratings yet

- PlumbingDocument16 pagesPlumbingMelvin EsguerraNo ratings yet

- Chegg SolutionsDocument9 pagesChegg SolutionsRambabu R100% (1)

- Fluid Mechanics: University of LeedsDocument16 pagesFluid Mechanics: University of LeedsHasitha MadusankaNo ratings yet

- FM Minor Losses 1Document14 pagesFM Minor Losses 1mahesh100% (1)

- Chapter 4Document106 pagesChapter 4lockas222No ratings yet

- CCNY LabManualDocument29 pagesCCNY LabManualShady HegazyNo ratings yet

- Fluids - IIIDocument29 pagesFluids - IIINitin GandhareNo ratings yet

- The Effect of Geometric Parameters On The Head Loss Factor in HeadersDocument9 pagesThe Effect of Geometric Parameters On The Head Loss Factor in HeadersSudarshan GNo ratings yet

- FLUID MECHANICS D203 Otazky PDFDocument87 pagesFLUID MECHANICS D203 Otazky PDFKhoa NguyễnNo ratings yet

- Pipe System Analysis Using Hardy-Cross MethodDocument32 pagesPipe System Analysis Using Hardy-Cross MethodShida ShidotNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Modern Electrical Installation for Craft StudentsFrom EverandModern Electrical Installation for Craft StudentsRating: 4.5 out of 5 stars4.5/5 (4)

- Electronic Devices and Circuits: In Three VolumesFrom EverandElectronic Devices and Circuits: In Three VolumesRating: 3.5 out of 5 stars3.5/5 (2)

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1No ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Important Topics of Class 11Document1 pageImportant Topics of Class 11avinash_friends21No ratings yet

- NEET Electrostatics NotesDocument40 pagesNEET Electrostatics Notesavinash_friends21100% (1)

- Electromagnetic Induction and ACDocument7 pagesElectromagnetic Induction and ACavinash_friends21No ratings yet

- Class Table - Apps Script - Google DevelopersDocument19 pagesClass Table - Apps Script - Google Developersavinash_friends21No ratings yet

- Better Writing Right NowDocument239 pagesBetter Writing Right NowShabab Hyder100% (6)

- 2 Basic Working Principle, ConfigurationDocument17 pages2 Basic Working Principle, Configurationrichardcaroncstj100% (1)

- Marvels of Physics: Friction and Inclined PlanesDocument2 pagesMarvels of Physics: Friction and Inclined Planesavinash_friends21No ratings yet

- Chapter 4 of YogaDocument76 pagesChapter 4 of Yogaavinash_friends21No ratings yet

- 01 Introduction To Manufacturing and MachiningDocument10 pages01 Introduction To Manufacturing and MachiningTarun MehtaNo ratings yet

- Ieqa GN Section1Document3 pagesIeqa GN Section1avinash_friends21No ratings yet

- Convection 3Document26 pagesConvection 3avinash_friends21No ratings yet

- Convection 2Document64 pagesConvection 2avinash_friends21No ratings yet

- Cooling SystemDocument56 pagesCooling SystemajayranuatNo ratings yet

- Mean Deviation - Wolfram MathWorldDocument4 pagesMean Deviation - Wolfram MathWorldbraulio.dantas-1No ratings yet

- CH20005-Chemical Reaction Engineering:) C C CRDocument2 pagesCH20005-Chemical Reaction Engineering:) C C CRSunny KashyapNo ratings yet

- MCQ Electromagnetism Self-AssessmentDocument2 pagesMCQ Electromagnetism Self-AssessmentJunaidKhanNo ratings yet

- Maths IA IntroDocument20 pagesMaths IA Introshakthi aravinthNo ratings yet

- Heat of Hydration StressesDocument7 pagesHeat of Hydration StressesAnkur BarsainyaNo ratings yet

- Zetex HandbookDocument8 pagesZetex HandbookbolermNo ratings yet

- Instructivo Luxometro Steren Her-410 PDFDocument12 pagesInstructivo Luxometro Steren Her-410 PDFLuis CárdenasNo ratings yet

- L-3/T-2/CE Date: 07/08/2016Document30 pagesL-3/T-2/CE Date: 07/08/2016নীল জোছনা0% (1)

- Audio Processing Quiz 1Document2 pagesAudio Processing Quiz 1Tony BrooksNo ratings yet

- SRS 413Document158 pagesSRS 413edderguiNo ratings yet

- University of Engineering and Technology Peshawar, PakistanDocument54 pagesUniversity of Engineering and Technology Peshawar, PakistanJoachim GardNo ratings yet

- DARK ENERGY TECHNOLOGY - Theory and Science of The Rainbow BridgeDocument78 pagesDARK ENERGY TECHNOLOGY - Theory and Science of The Rainbow BridgeBoris Petrovic100% (4)

- 08 Energy 03 Complementary Strain Energy PDFDocument2 pages08 Energy 03 Complementary Strain Energy PDFjack_hero_56No ratings yet

- 53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions AnDocument7 pages53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions AnJohn Aries Almelor Sarza100% (1)

- Tutorial Chapter 1 2018Document3 pagesTutorial Chapter 1 2018Ain Syahira0% (1)

- Radar Systems Range Equation PDFDocument6 pagesRadar Systems Range Equation PDFSanjid ElahiNo ratings yet

- CFD and Experimental Study of Wetting of Structured Packing ElementsDocument139 pagesCFD and Experimental Study of Wetting of Structured Packing ElementsahmedsalemyNo ratings yet

- Jawaharlal Nehru Technological University KakinadaDocument4 pagesJawaharlal Nehru Technological University KakinadaVenkat ChadalavadaNo ratings yet

- 85 Describing Motion OrganizerDocument10 pages85 Describing Motion OrganizerFernando Sorto50% (2)

- Pages From Cinematography-Theory and PracticeDocument74 pagesPages From Cinematography-Theory and PracticeSalazar SliterinNo ratings yet

- IOE, TU Questions and Solutions: Engineering Physics (for BE first yearDocument235 pagesIOE, TU Questions and Solutions: Engineering Physics (for BE first yearRajeev PaudelNo ratings yet

- MIT Feedback Linearization LectureDocument5 pagesMIT Feedback Linearization LectureJosé Ignacio Fierro TravoNo ratings yet

- Jar TestDocument1 pageJar TestEduardo Tonino Chavez GaytanNo ratings yet

- Bearings ShaftsDocument74 pagesBearings ShaftsCik MinnNo ratings yet

- Love My LifeDocument5 pagesLove My LifeLinda Veronica0% (1)

- Approximations and Simplified Equations SPRING 2019Document12 pagesApproximations and Simplified Equations SPRING 2019Kula Segara PandiyanNo ratings yet

- Antimicrobial Properties of Silver NanoparticlesDocument37 pagesAntimicrobial Properties of Silver NanoparticlesbasavarajitnalNo ratings yet

- What Happens When Warm Air RisesDocument30 pagesWhat Happens When Warm Air RisesCriselAlamag100% (1)

- PFlow ScriptDocument6 pagesPFlow Scripttohu777No ratings yet

- WMM Plant CalibrationDocument5 pagesWMM Plant CalibrationAnonymous zyIPjL9vNo ratings yet