Professional Documents

Culture Documents

Wet Air Oxidation System The Cleanest Way

Uploaded by

Sandro Goisis0 ratings0% found this document useful (0 votes)

44 views8 pagesSiemens Zimpro Wet Oxidation

Original Title

Wet Air Oxidation System the Cleanest Way

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSiemens Zimpro Wet Oxidation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views8 pagesWet Air Oxidation System The Cleanest Way

Uploaded by

Sandro GoisisSiemens Zimpro Wet Oxidation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

1

Answers for industry.

Zimpro Wet Air

Oxidation Systems:

The cleanest way to treat the dirtiest water

Can you treat the most

difficult wastewater with

only air?

The wet air oxidation process can be traced back to the 1930s in

Rothschild, Wisconsin, USA. F.J. Zimmermann developed the wet air

oxidation process and became founder and namesake of the company

Zimpro (now Siemens Water Technologies).

Zimmermann and his staff used spent pulping liquor from a local paper

mill to produce artificial vanilla flavoring (vanillin) by partial wet air

oxidation of ligno-sulphonic acids. Zimmermann and his colleagues

perfected the wet air oxidation process (or the Zimmermann Process

as it was known), and expanded it to other applications, including

wastewater treatment. Since then, applications for the wet air oxidation

process have become as varied as its history is long.

Zimpro Wet Air Oxidation

System: Innovative

Technologies for Difficult

Waste Treatment Problems

F.J. Zimmermann,

founder of the

Zimpro wet air

oxidation system.

3

The Process

The wet air oxidation process is the oxidation of soluble or suspended

components in an aqueous environment using oxygen as the oxidizing

agent. When air is used as the source of oxygen the process is referred to

as the wet air oxidation (WAO) process. The oxidation reactions occur at

temperatures of 150 C to 320 C (275 F to 608 F), and at pressures from

10 to 220 Bar (150 to 3200 psi). The required operating temperature is

determined by the treatment objectives. Higher temperatures require

higher pressure to maintain a liquid phase in the system.

The typical wet air oxidation system uses rotating equipment to raise the

feed stream and air (or oxygen) to the required operating pressure. Heat

exchangers are routinely employed to recover energy from the reactor

effluent and use it to preheat the feed/air mixture entering the reactor.

Auxiliary energy, usually steam, is necessary for startup and can provide

trim heat if required. The reactor vessel provides residence time at a

temperature which enables the oxidation reactions to proceed towards

completion. Since the oxidation reactions are exothermic, sufficient energy

may be released in the reactor to allow the wet air oxidation system to

operate without any additional heat input.

Wet Air Oxidation or Hydrolysis?

Hydrolysis is a process similar to the wet air oxidation process for the

treatment of wastewaters when oxygen is not a necessary reactant. In

hydrolysis, certain constituents of wastewaters and sludges can react

directly with water at elevated temperatures and pressures to yield a

treated effluent that is detoxified or meets the desired treatment objective.

What is the Zimpro WAO System?

Is there a specific Zimpro wet air oxidation system

design? No.

A broad range of both industrial and municipal

application experience allows us to custom design a

wet air oxidation system based on the specific

application and objectives. Our experience runs from

extensive R&D projects to the design and

construction of more than 150 systems worldwide.

Applications have involved:

n

A wide range of temperatures and pressures

n

The use of air, oxygen, or simply hydrolysis in

the absence of oxygen

n

A multitude of reactor designs and flow

configurations, including the use of catalyst

This diverse capability has led to our most recent

projects involving the co-development of

applications and designs for major industrial clients.

Some of the new industrial applications being

developed go beyond wastewater treatment, where

wet air oxidation or hydrolysis is applied for

inprocess recycle or end product recovery.

The process can convert organic contaminants

to carbon dioxide, water and biodegradable

short chain organic acids. Inorganic

constituents such as sulfides and cyanides

can also be oxidized. The wet air oxidation

process can involve any or all of the following

reactions:

Organics + O

2

CO

2

+ H

2

O + RCOOH*

Sulfur Species + O

2

SO

4

-2

Organic Cl + O

2

Cl

-1

+ CO

2

+ RCOOH*

Organic N + O

2

NH

3

+ CO

2

+ RCOOH*

Phosphorus + O

2

PO

4

-3

*Short chain organic acids such as acetic

acid make up the major fraction of residual

organic compounds.

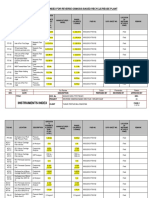

Wet Air Oxidation - Process Flow Diagram Typical WAO Process Reactions

4

Industrial Applications

A Zimpro wet air

oxidation system treats

industrial waste at

Atofina Italias methyl

methacrylate production

facility in Rhoo, Italy.

Zimpro wet air oxidation

system uses oxygen to

treat high strength styrene

monomer and polyol

wastewater at Repsol YPF,

Tarragona, Spain.

Zimpro wet air oxidation

system treats the spent

caustic effluent generated

by the worlds largest

naphtha steam cracker a

the BASF ethylene facility,

Port Arthur, Texas.

Wastewater and In-process Treatment

Typical industrial applications for the wet air oxidation process

have a feed flow rate of 1 to 50 m

3

/h (4 to 220 gpm) per train,

with a Chemical Oxygen Demand (COD) from 10,000 to 150,000

mg/l (higher CODs with dilution). Objectives for industrial

applications can include pretreatment of difficult wastewater

streams to make them suitable for conventional treatment such

as biological polishing, or as treatment for product recovery. The

process can be applied to treat difficult process or wastewater

streams to satisfy a variety of objectives, such as:

n

Destruction of specific compounds

n

Elimination of toxicity or reactivity

n

Pretreatment to produce readily biodegradable

residual organics

n

Process liquor treatment for recycle/recovery

n

Gross reduction in COD

Spent Caustic Treatment

A common industrial application for the wet air oxidation

process is treatment of spent caustic wastewater streams

generated by ethylene plants and refineries. The process is

used for complete oxidation of reduced sulfur species such as

sulfides and mercaptides. By increasing temperature and

pressure, complex organic contaminants such as phenols can

also be broken down to either carbon dioxide and water, or

biodegradable short chain organics.

By applying the wet air oxidation process, odor associated with

sulfides and mercaptides will be eliminated and the treated

spent caustic is suitable for discharge to a conventional

biological treatment process.

5

Sludge Applications

The wet air oxidation

process is used to destroy

biological solids and

regenerate carbon at a

Tosco refinery. In this

application, the wet air

oxidation process

is referred to as the wet

air regeneration process.

In this application, at a

Tosco refinery, the wet

air oxidation process is

referred to as the wet air

regeneration process.

The Passaic Valley,

New Jersey, municipal

treatment plant uses

twelve Zimpro wet air

oxidation systems for

municipal sludge

treatment, each with a

capacity of over 60 m

3

per hour.

Sludge Treatment and Destruction

Another widespread application of the wet air oxidation process

has been for treatment of municipal sludge. The majority of

these systems are low temperature and low pressure designs,

commonly referred to as low pressure oxidation (LPO). An LPO

system uses temperatures and pressures of less than 220 C

(425 F) and 35 Bar (500 psig), respectively. Under these

conditions, sludge is broken down to enhance dewaterability.

When higher temperatures and pressures are applied, destruction

of volatile solids occurs and wet air oxidation can be used for

sludge destruction, a possible alternative to incineration.

Zimpro Wet Air Regeneration System

Biological treatment can be enhanced by incorporating

powdered activated carbon, known as the PACT system. A

specialized wet air oxidation design referred to as the Zimpro

wet air regeneration system is applied to sludge generated

by the PACT biological treatment system. The wet air

regeneration process will simultaneously destroy organic solids

and regenerate powdered carbon for reuse in the PACT system.

The wet air regeneration process has been used for municipal

and large industrial PACT systems.

6

Bench-scale Testing

We have the most extensive wet air oxidation process test

facilities in the world, capable of conducting bench-scale as

well as continuous flow pilot-scale studies. Bench-scale

autoclave testing is used to establish preliminary design criteria

for a full-scale design, allowing for evaluation of process

economics.

Materials-of-construction testing is also conducted to identify

suitable alloys for the application. Studies can involve the wet

air oxidation process and other treatment processes, like

biological treatment, that can be coupled with the wet air

oxidation process for effluent polishing. Our Enviroscan

Analytical nationally accredited analytical laboratory is used to

support in-house test work.

World-class Pilot Plant Facilities

Our wet air oxidation pilot system facilities are unparalleled.

The facilities include various pilot systems housed in a 930 m

2

(10,000 ft

2

) pilot plant that is RCRA Part B permitted by the U.S.

Environmental Protection Agency and the Wisconsin

Department of Natural Resources.

Continuous flow pilot studies can be performed under a wide

range of operating conditions. Pilot plant studies are performed

to optimize the design conditions for custom applications. Pilot

testing produces representative treated product for evaluation

and testing, giving the customer a better understanding of the

operating characteristics of the wet air oxidation process. Pilot

systems are constructed of many alloys, including titanium,

high-nickel and stainless alloys. The wet air oxidation or

hydrothermal system configurations are highly customized

based on the specific process approach.

Full Spectrum of

Testing Capabilities

Our Enviroscan Services in-house

analytical laboratories are an integral

part of the Rothschild, Wisconsin, test

facilities.

Our pilot testing facility is the largest

of its kind in the world with numerous

pilot units constructed of various alloy

materials.

We offer extensive wet air oxidation

bench-scale and materials-of-

construction testing.

7

Full Scale Systems

Our in-house engineering staff provides complete engineering

and design for full scale wet air oxidation systems. Certified

welders and electricians work in our 2300 m

2

(25,000 ft

2

),

ASME-certified manufacturing facility, which specializes in high

alloy welding. This includes certifications for a variety of alloys,

including nickel and titanium. We can supply wet air oxidation

or hydrolysis systems as modular skid- and tower-mounted

equipment packages. Custom engineered system modules are

piped and wired to the greatest practical extent, incorporating

customer specifications and vendor preferences.

Our manufacturing group holds the ASME PP (Power Piping)

and U (Unfired Pressure Vessel) stamps, NBIC R (Repair) stamp,

and are UL Listed. We are also Manufacturers License (ML)

certified in the Peoples Republic of China. And in 2008, we

achieved ISO 9001:2008 registration.

In addition, we realize that safety and quality go hand in hand.

Our Rothschild, Wisconsin, facility has an exemplary safety

record, reaching 16 years without a lost time accident in 2010.

We were awarded the Wisconsin Corporate Safety Award in

2000, 2004 and 2008.

Engineering, Design, Construction

and Manufacturing

We use state-of-the-art 3D software

for the design of modular wet air

oxidation systems.

Zimpro wet air oxidation skids in our

manufacturing area.

www.siemens.com/wetox

Siemens

Water Technologies

+1.715.359.7211

zimpro.water@siemens.com

2011 Siemens Water Technologies Corp

GIS-WAO-BR-0111

Subject to change without prior notice.

Enviroscan Services, Enviroscan Analytical, PACT and Zimpro are

trademarks of Siemens, its subsidiaries or affiliates.

ASME is a trademark of the American Society of Mechanical Engineers.

UL is a trademark of Underwriters Laboratories, Inc.

The information provided in this literature contains merely general

descriptions or characteristics of performance which in actual case

of use do not always apply as described or which may change as a

result of further development of the products. An obligation to

provide the respective characteristics shall only exist if expressly

agreed in the terms of the contract.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Solubility of Chlorine in BrineDocument3 pagesSolubility of Chlorine in BrineSandro Goisis0% (1)

- Bariumcarbonat PropertiesDocument2 pagesBariumcarbonat PropertiesSandro GoisisNo ratings yet

- Motiva Final ReportDocument93 pagesMotiva Final ReportTC Cüneyt ŞanNo ratings yet

- Range of Utilization - PlasticsDocument2 pagesRange of Utilization - PlasticsSandro GoisisNo ratings yet

- Pump Handbook by GrundfossDocument156 pagesPump Handbook by GrundfossSyam TawakkalNo ratings yet

- Flow pattern based two-phase frictional pressure drop modelDocument13 pagesFlow pattern based two-phase frictional pressure drop modelSandro Goisis100% (1)

- Polymer Chemical ResistanceDocument47 pagesPolymer Chemical ResistanceRoo FaNo ratings yet

- Materials For Wet Oxidation Processing EquipmentDocument101 pagesMaterials For Wet Oxidation Processing EquipmentSandro GoisisNo ratings yet

- PSV Sizing ChemEngDocument5 pagesPSV Sizing ChemEngSandro GoisisNo ratings yet

- Brochure - On-Site Nitrogen MembraneDocument2 pagesBrochure - On-Site Nitrogen MembraneSandro GoisisNo ratings yet

- Materials For Wet Oxidation Processing EquipmentDocument101 pagesMaterials For Wet Oxidation Processing EquipmentSandro GoisisNo ratings yet

- Example 5.2 2Document4 pagesExample 5.2 2Pritam RoyNo ratings yet

- Example 5.2 2Document4 pagesExample 5.2 2Pritam RoyNo ratings yet

- AspenCOMThermoV7 3 RefDocument359 pagesAspenCOMThermoV7 3 RefSandro GoisisNo ratings yet

- Curve Fitting Ammonia-Water Mixture PropertiesDocument18 pagesCurve Fitting Ammonia-Water Mixture PropertiesSandro GoisisNo ratings yet

- Chem Eng May 2014Document84 pagesChem Eng May 2014Sandro GoisisNo ratings yet

- Iapws95 RevDocument18 pagesIapws95 RevSandro GoisisNo ratings yet

- Thermodynamic Properties of Water and SteamDocument49 pagesThermodynamic Properties of Water and SteamBalthasar Sebastian LumbanTobingNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Definition of Terms:: Harvesting MethodsDocument5 pagesDefinition of Terms:: Harvesting MethodsHero DiasNo ratings yet

- LECTURE 5-Measurement of Water Yield From WatershedDocument23 pagesLECTURE 5-Measurement of Water Yield From WatershedChu DicksonNo ratings yet

- Instruments Index RO Plant YTMDocument8 pagesInstruments Index RO Plant YTMSswahyudiNo ratings yet

- How To Clean A BeachDocument3 pagesHow To Clean A BeachSara AguilarNo ratings yet

- British Council Library in Lahore awarded LEED GoldDocument1 pageBritish Council Library in Lahore awarded LEED GoldBoi 7No ratings yet

- Wartsila O E W 26 PG M.Document172 pagesWartsila O E W 26 PG M.Uhrin Imre100% (1)

- Jakarta - WikipediaDocument15 pagesJakarta - WikipediarizkisembiringNo ratings yet

- Hand Molding Demonstration ProcessDocument45 pagesHand Molding Demonstration ProcessqueenofthegypsiesNo ratings yet

- Ashford Gauge Manual PDFDocument20 pagesAshford Gauge Manual PDFJoe_Merchant100% (1)

- DM Plan Mohadevpur Upazila Sunamgonj District - English Version-2014Document101 pagesDM Plan Mohadevpur Upazila Sunamgonj District - English Version-2014CDMP BangladeshNo ratings yet

- HR POLICY All Pages - Final 11-05-2012 PDFDocument270 pagesHR POLICY All Pages - Final 11-05-2012 PDFVarun Guggilam100% (1)

- Spe 88491 MS PDFDocument7 pagesSpe 88491 MS PDFBruni MartinezNo ratings yet

- Types of PumpsDocument18 pagesTypes of PumpsAhmed Adel Ibrahim100% (1)

- Landslide: Parts of A Typical SlideDocument14 pagesLandslide: Parts of A Typical SlideShuvanjan Dahal100% (3)

- Achieving MDGs Sanitation Target Through CLTS. PERCIK. Indonesia Water and Sanitation Magazine. December 2008Document53 pagesAchieving MDGs Sanitation Target Through CLTS. PERCIK. Indonesia Water and Sanitation Magazine. December 2008Oswar MungkasaNo ratings yet

- Gate Valves in IndustryDocument3 pagesGate Valves in IndustryKogulan SubramaniamNo ratings yet

- Shifting and Tilting Occur Generally During The Sinking Phase of Well FoundationsDocument8 pagesShifting and Tilting Occur Generally During The Sinking Phase of Well FoundationsAble KuriakoseNo ratings yet

- Allday Item DBDocument30 pagesAllday Item DBGMA MIS-PROF-SHELL ALVIN DREONo ratings yet

- Are Golf Courses Bad For The EnvironmentDocument4 pagesAre Golf Courses Bad For The EnvironmentKyle M. SantosNo ratings yet

- (ACM) RG CatalogueDocument8 pages(ACM) RG Cataloguerazak shareefNo ratings yet

- New Method for Calculating Evaporation from Occupied PoolsDocument4 pagesNew Method for Calculating Evaporation from Occupied PoolsSarosh MohiyuddinNo ratings yet

- Toilet Specification Status Rev 2 2010Document4 pagesToilet Specification Status Rev 2 2010aprilmarieadeveraNo ratings yet

- Reducers Used in Piping Industry PDFDocument2 pagesReducers Used in Piping Industry PDFaap1100% (1)

- Presentation To Unconventional Gas Technical Forum Victoria, BC April 4, 2008Document35 pagesPresentation To Unconventional Gas Technical Forum Victoria, BC April 4, 2008Rafi Zafar100% (1)

- Asian Development BankDocument20 pagesAsian Development BankG. SASIDHARA KURUPNo ratings yet

- ISO TS 22002-2 Programa de Prerequisitos CateringDocument26 pagesISO TS 22002-2 Programa de Prerequisitos CateringRodrigo Díaz López80% (5)

- How To Raise Juvenile Discus by Willie LohDocument3 pagesHow To Raise Juvenile Discus by Willie Lohjim_corbet1211No ratings yet

- Brackish WaterDocument20 pagesBrackish WaterMarie PeneyraNo ratings yet

- Evs ProjectDocument11 pagesEvs ProjectUmesh TyagiNo ratings yet

- Kemper Arena CollapseDocument4 pagesKemper Arena Collapseapi-357035617No ratings yet