Professional Documents

Culture Documents

Iso 9001 2008 Checklist Sample Rev 2-20-09us

Uploaded by

RonaldSincheCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso 9001 2008 Checklist Sample Rev 2-20-09us

Uploaded by

RonaldSincheCopyright:

Available Formats

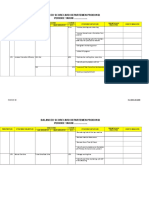

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 1 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

Contents of the ISO 9001:2008 Quality System Checklist

Page Hyperlinks (click underlines)

This SAMPLE document includes 4 clauses of the standard.

You receive the Windows .doc file (with hyperlinks). You may edit this document.

For: Windows 2000 and higher, XP, Vista and Microsoft Word 2000 and later versions.

4 Quality management system (title only)

2 4.1 General requirements

4.2 Documentation requirements (title only)

4 4.2.1 Documentation requirements General

8 4.2.2 Quality manual

9 4.2.3 Control of documents Click here to see sample

10 4.2.4 Control of records

5 Management responsibility (title only)

13 5.1 Management commitment

14 5.2 Customer focus Click here to see sample

15 5.3 Quality policy

5.4 Planning (title only)

17 5.4.1 Quality objectives

18 5.4.2 Quality management system planning

5.5 Responsibility, authority and communication (title only)

19 5.5.1 Responsibility and authority

20 5.5.2 Management representative

20 5.5.3 Internal communication

5.6 Management review (title only)

23 5.6.1 Management review General

23 5.6.2 Review input

23 5.6.3 Review output

6 Resource management (title only)

24 6.1 Provision of resources

6.2 Human resources (title only)

24 6.2.1 General

24 6.2.2 Competence, training and awareness

26 6.3 Infrastructure

26 6.4 Work environment

The Checklist may be placed on a network system for access by auditors.

This Checklist is included in the ISO 9001:2008 Auditor Training Course and Forms.

Page Hyperlinks (click underlines) All links are active on the final product.

7 Product realization (title only)

27 7.1 Planning of product realization

7.2 Customer-related processes (title only)

28 7.2.1 Determination of requirements related to the product

28 7.2.2 Review of requirements related to the product

29 7.2.3 Customer communication

7.3 Design and development (title only)

30 7.3.1 Design and development planning

31 7.3.2 Design and development inputs

31 7.3.3 Design and development outputs

33 7.3.4 Design and development review

33 7.3.5 Design and development verification

34 7.3.6 Design and development validation

34 7.3.7 Control of design and development changes

7.4 Purchasing (title only)

35 7.4.1 Purchasing process

36 7.4.2 Purchasing information

36 7.4.3 Verification of purchased product

7.5 Production and service provision (title only)

38 7.5.1 Control of production and service provision

40 7.5.2 Validation of processes for production and service provision

41 7.5.3 Identification and traceability

42 7.5.4 Customer property

43 7.5.5 Preservation of product

44 7.6 Control of monitoring and measuring equipment

8 Measurement, analysis and improvement (title only)

47 8.1 General

8.2 Monitoring and measurement (title only)

48 8.2.1 Customer satisfaction

49 8.2.2 Internal audit

51 8.2.3 Monitoring and measurement of processes

52 8.2.4 Monitoring and measurement of product Click here

55 8.3 Control of nonconforming product

57 8.4 Analysis of data

8.5 Improvement (title only)

59 8.5.1 Continual improvement

60 8.5.2 Corrective action Click here to see sample

61 8.5.3 Preventive action

62 Instructions for adding a page and text to the Checklist

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 2 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

4.2.3 Quality management system Documentation requirements Control of documents Clause 4.2.3

4.2.3 Control of documents

____ Is there a documented procedure for

document control?

Does the procedure define the controls needed to:

__ a) approve documents for adequacy before they

are issued

__ b) review, update and re-approve documents, as

necessary,

__ c) ensure that the current revision status of

documents and document changes are identified

__ d) ensure that relevant versions of documents

are made available at points of use

<The relevant version of a document is the version

that should be used for a task. The current revision of

the document may not be the right one for the task.>

__ e) ensure that documents remain legible and

easy to identify

__ f) ensure that documents that originate from out-

side the organization are identified and the

distribution of these documents is controlled

(applies to documents necessary for the planning and

operation of the quality management system)

__ g) prevent the unintentional use of obsolete

documents, and to clearly mark them with suitable

identification if they are kept for any purpose?

Verify that the documented

Document Control

procedure contains the

requirements a-g for

controlling:

__ Quality Manual

__ Documented

Procedures

__ Work Instructions

__ Product documentation

(including drawings,

specifications, bills of

material, parts lists,

production plans, control

plans, etc.)

__ External documents

__ Other required QMS

documents

Document

Control

procedure

Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID.

The Instructions Sample explains how to enter audit evidence on the Checklist.

4.2.3. ___ Are required QMS documents controlled as

defined in the document control procedure?

a) and b): Are new and revised documents:

___ reviewed for adequacy, and

___ approved by authorized personnel prior to issue?

___ Review a sampling of

new and revised

documents for evidence

that the requirements for

the review and approval of

documents are followed as

defined in the procedure.

All new and

revised

documents.

4.2.3 Are documents:

__ c) identified by their current revision status,

__ d) the relevant version for the task and available

at locations where they are needed

__ e) legible, readily identifiable and

retrievable?

(continued)

___ Ask a sampling of

employees how they know

they are using the right

document for the task.

___ Test the document

distribution system at

several locations: Ask for a

document used in the

department and check if it

is the current revision, is

retrievable and available.

All controlled

documents,

Master lists,

Distribution

lists, etc.

Return to Contents page.

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 3 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

4.2.3 Quality management system Documentation requirements Control of documents Clause 4.2.3 (continued)

4.2.3 Control of documents (continued)

4.2.3 f) Are external documents

____ identified, and their

____ distribution controlled?

(applies only to external documents that the

organization determines are necessary for the

planning and operation of the quality mgt. system)

(External documents are those that originate from

outside the organization.)

___ Review external

documents (identified in

clause 4.2.1.d) for proper

identification and control.

__ Do a sampling to

determine that documents

of external origin are

current at multiple

distribution points.

All

standards,

customer

documents,&

statutory/

regulatory

documents

Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID.

4.2.3 g) Are obsolete documents:

____ identified and removed from places of use to

prevent their use

____ identified to prevent their use, if they are kept

for any purpose?

___ Verify g)

___ Review retained

obsolete documents for

proper identification.

Identify any obsolete

documents not removed

from place of use.

All obsolete

documents

Return to Contents page.

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 4 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

5.2 Management responsibility Customer focus Clause 5.2

5.2 Customer focus

__ Does top management ensure that customer

requirements are determined and met with the aim of

enhancing customer satisfaction? (see 7.2.1 and

8.2.1)

<7.2.1 and 8.2.1 are listed below for reference: >

7.2.1 Determination of requirements related to the

product. The organization shall determine:

a) customer-specified requirements, including

requirements for delivery and post-delivery activities

Person(s) responsible for this activity:

___________________________________

b) requirements not stated by the customer but

necessary for stated use or known and intended use

Person(s) responsible for activity:

__________________________________

c) statutory and regulatory requirements related to

the product

Person(s) responsible for activity:

___________________________________

d) any additional requirements determined by the

organization?

Person(s) responsible for activity

___________________________________

8.2.1 Customer satisfaction

Does the organization monitor information relating to

customer perception as to whether the organization

has met customer requirements?

Person(s) responsible for activity

___________________________________

___ What methods has management determined for

obtaining information related to customer perception

as to whether product requirements have been met

and how this information will be used?

Person(s) responsible for activity ______________

___ Are those who are assigned responsibilities

(listed in 7.2.1 and 8.2.1) provided with adequate

resources to accomplish the assigned tasks?

(Resources means people, time and money.)

___ Interview those

responsible for managing

customer-related process-

es to access the organiza-

tion's strategy for determin-

ing customer requirements

and that they are met with

the aim of enhancing

customer satisfaction. Are

strategies used getting the

needed information?

Examples of customer-

related processes are:

Sales_________________

Marketing _____________

Contract Admin. ________

Customer Service_______

Product Repair ________

___ Is data concerning

customer needs and

expectations collected and

analyzed?

Collect customer

satisfaction analysis

reports. By interview,

or other means, determine:

__ if action was taken to

resolve problems

__ improvements or

changes have been

made and are now part

of the product or service

__ improvements or

changes are planned for

incorporation into the

product or service

Review any evidence of

customer dissatisfaction to

determine if customer

requirements are unknown

or not being met.

Is this done?

__Do Mgt. Review minutes

discuss how to improve

products and/or services?

Product

information

brochures,

customer

information,

contracts,

quality plans

Note to Lead

Auditor:

This clause

can be

audited with

7.2.1 & 8.2.1

They use

same

information.

Customer

complaints

and/or

satisfaction

survey

results.

Internal

customer

complaints.

Results of

management

reviews.

Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID.

Return to Contents page.

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 5 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

8.2 Measurement, analysis and improvement Monitoring and measurement

8.2.4 Monitoring and measurement of product

Clause 8.2.4

8.2.4 Monitoring and measurement of product

product characteristics the distinguishing

features of the product or service

___ Are product characteristics monitored and

measured at appropriate stages of product realization

to verify that requirements for the product are met in

accordance with the quality plan (traveler/work

order)? (see clause 7.1)

____ Are records of product conformity with

acceptance criteria maintained, and

customer the person or organization that receives

a product.

internal customer the next process that will

perform a work or service activity

____ do records indicate the person(s) who

authorized the release of product for delivery

to the customer? (see clause 4.2.4)

<Guideline: When auditing any process, you

check to see that defined monitoring and

measurement activities are taking place, and that

records with authorized release signatures are

present.>

Note: Monitoring and

measurement activities

required to determine

product or service

conformance to require-

ments are identified during

planning activities. (a

requirement of 7.1 c.)

Review several quality

plans for work in

progress and their

associated test / inspection

instructions.

__ Does the quality plan

indicate where monitoring

and measuring should take

place?

__ Is acceptance criteria

clearly defined?

__ Are the required

inspection and tests

performed and the results

recorded?

___ Do records indicate

who released the product?

__ Is the product or service

monitored and measured

at the stages indicated in

the quality plan?

Quality plan

for product,

Traveler

Inspection

and Test

procedures

and

instructions

Quality

control plans

and related

records

Get a list of

who is

qualified to

perform audit

monitoring,

inspection

and

measuring

activities in

all process

areas.

Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID.

Verify as applies to in-process inspection

(continued)

Observe in-process

inspection operations.

____ Is uninspected or

nonconforming product

prevented from being used

in the next processing

stage?

___ Is the inspection status

of the product maintained

throughout all stages of

production?

___ Are inspection

personnel trained?

___ Are inspection

procedures available and

followed?

Quality

plans,

checklists,

or traveler

In-process

inspection

process,

procedures

and/or

relevant work

instructions

Qualified

inspector list

Return to Contents page.

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 6 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

8.2.4 Measurement, analysis and improvement Monitoring and measurement of product Clause 8.2.4 (continued)

8.2.4 Monitoring and measurement of product

(continued)

All questions on this page

apply to final inspection area

___ Is the release of product and delivery of service

to the customer held until the planned arrangements

(including inspections, tests, and measurements)

have been satisfactorily completed, unless otherwise

approved by an appropriate authority and, where

applies, by the customer?

objective evidence information based on facts

acquired through measurement, test, observation, or

some other means that can be proven to be true.

RE: Final inspection

Observe final inspection

___ Are instructions for

final inspection available?

___ Are all activities in the

final inspection instructions

completed before product

is released?

___ Is there is objective

evidence that all the

acceptance criteria for the

product have been met

before release?

___ Do records show the

person(s) who authorized

the release of product or

delivery of service to the

customer?

___ Verify that inspectors

in the final inspection

area are qualified.

Review a sample of

completed order records.

____ Do the completed

orders/records show that

all final inspection activities

stated in the quality plan /

procedures were

completed and that the

requirements for the

product were met?

___ Do the records show

the person(s) who

authorized release of the

product?

___ If records show a

situation where all

specified activities were

not performed before

release of product or

service delivery, did a

relevant authority (or, as

appropriate, the customer)

approve the product

release?

Quality

plans,

final audit

checklists,

or traveler

Final

inspection

process,

procedures

and/or

relevant work

instructions

Employee

records or

list of

qualified

inspectors

Records of

completed

work.

Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID.

Return to Contents page.

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 7 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

8.2.4 Measurement, analysis and improvement Monitoring and measurement of product Clause 8.2.4 (continued)

8.2.4 Monitoring and measurement of product

(continued)

Verify as applies to service organizations

Verify as applies to product servicing and repair

inspection

___ Is the release of product and delivery of service

to the customer held until the planned arrangements

(including inspections, tests, and measurements)

have been satisfactorily completed, unless otherwise

approved by an appropriate authority and, where

applies, by the customer?

verification activities checks to make sure all

requirements for the product were met.

objective evidence information based on facts

acquired through measurement, test, observation, or

some other means that can be proven to be true.

For services and repair:

Observe services/repair:

___ Are all verification

activities specified in the

quality plan / procedures

completed before the

service or product is

released?

___ Is there is objective

evidence that all product

(or service) acceptance

criteria have been met?

___ Do records show the

person(s) who authorized

the release of the product /

or delivery of the service to

the customer?

___ Verify that inspectors

involved in service / repair

are qualified.

Review a sample of

service or repair completed

orders and:

____ Verify that all

activities specified in the

quality plan / procedures

were completed and

requirements for

service/repair were met.

___ Do final inspection

records indicate the

person(s) who authorized

release of service/repair?

___ If records show a

situation where all

specified activities were

not performed before

release of product or

service delivery, did a

relevant authority (or as

appropriate, the customer)

approve the product/

service release?

Quality

plans,

final audit

checklists,

or traveler

Employee

records or

list of

qualified

inspectors

Service

repair

inspection

and final

inspection

process,

procedures

and/or

relevant work

instructions

Records of

completed

work.

Return to Contents page.

The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited:

Questions

(those relating to new/ revised requirements are in

italics and underlined) <Guideline statements>

Guidelines for

Auditing

Documents

/ Where to

Look

Documented? Need to be? Y or N

Interaction considered? Y or N

(cite source - give comments)

Implemented? Y or N

In Use? Effective?

Y or N (comments)

Auditor Name:

Date:

Audit Ref.

Page 8 of 8

file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms 2009 ISO 9000 Checklist Audit page ___ of ___ pages

8.5.2 Measurement, analysis and improvement Improvement Corrective action Clause 8.5.2

8.5.2 Corrective action

___ Is there a documented corrective action

procedure that defines the requirements for:

___ a) reviewing nonconformities (including

customer complaints)

___ b) determining the root cause(s) of

nonconformities

___ c) evaluating the need for action to prevent

recurrence of the nonconformities

___ d) determining the action needed and

implementing the action

___ e) recording the results of action taken

(see clause 4.2.4)

___ f) reviewing the corrective actions taken

to verify their effectiveness

____ Does the procedure require that the action

taken on nonconformities must be appropriate

to the effects of the nonconformities found?

____ Does the organization take corrective

action to eliminate the causes of

nonconformities in order to prevent their

recurrence?

<The following is a guidance note and not included in

the text of the standard.

Note: When the nonconformity is minor and isolated,

the risks or cost associated with taking

corrective action may not be justified.>

Verify that the documented

procedure clearly defines

___ requirements for

(a through f).

___ a) Is there evidence

that the types of

nonconformities in the

far right column are

reviewed and evaluated

to determine if action is

needed to prevent the

specific problems found

from occurring again?

__ Do plans for corrective

action include considera-

ation of:

__ action to remove the

nonconformity and prevent

recurrence in the short

term

__ action to determine if

other product (or similar

product) is affected that is

in production, in stock or

being designed

__ action to determine if

the nonconformity applies

to product or service

delivered in the past, and

is action needed to

minimize the impact of the

defect on these customers

__ action to prevent the

problem in the future.

___ e) Are there records

of the results of the

corrective action taken?

___ f) Are corrective

actions taken reviewed to

verify effectiveness?

Documented

Corrective

Action

procedure

Customer

complaints,

Internal audit

reports,

data

analysis,

minutes of

management

reviews

Corrective

action

records

Management

review

action

records/

minutes of

management

reviews

Completed

Corrective

Action

Request

Forms

CPAR Log

Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID.

a) Does the documented procedure state who is responsible for reviewing nonconformities

that originate from the sources listed here? The procedure may make reference to other

procedures or documents with this information. (as applies)

__ incoming materials

__ incoming subcontracted product

__ in-process/final inspection or test

__ nonconforming material review

__ sales or service concessions

__ audit nonconformity

__ customer complaints

__ product returns

__ warranty repairs

__ process related nonconformities

__ system related nonconformities

Also see the instructions sample of how to enter audit evidence on the Checklist.

Return to Contents page.

Click Browser back button (in top left corner) to Return

You might also like

- QMS Doc Req.01Document10 pagesQMS Doc Req.01AliNo ratings yet

- How To Build An Effective Competency Matrix Competency-Matrix/)Document4 pagesHow To Build An Effective Competency Matrix Competency-Matrix/)Anonymous VPJkWfcOQNo ratings yet

- Lean: Focus On Products: Cause of Instability Improve Productivity Poor Delivery To Customer Employees Operator MANDocument3 pagesLean: Focus On Products: Cause of Instability Improve Productivity Poor Delivery To Customer Employees Operator MANwaseef4mvsNo ratings yet

- List of Production ReportsDocument12 pagesList of Production ReportsSangeeth BhoopaalanNo ratings yet

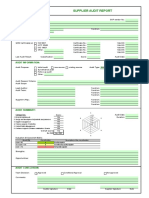

- HIL-MM-SEF-01 - Supplier Assessment Form ReviewDocument6 pagesHIL-MM-SEF-01 - Supplier Assessment Form ReviewNaveen GuptaNo ratings yet

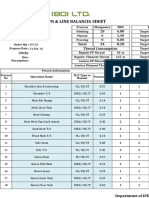

- Balanced Scorecard Departemen Produksi PERIODE TAHUN .Document7 pagesBalanced Scorecard Departemen Produksi PERIODE TAHUN .mr mrNo ratings yet

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocument3 pagesSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapNo ratings yet

- Supplier Audit ChecklistDocument12 pagesSupplier Audit ChecklistRildo Alves0% (1)

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- Why analysis root cause manufacturing defectsDocument4 pagesWhy analysis root cause manufacturing defectsmaulikgadaraNo ratings yet

- ISO/TS 14969 Diagram SystemDocument8 pagesISO/TS 14969 Diagram SystemAyuNo ratings yet

- Audit ComplianceDocument1 pageAudit ComplianceNitin SharmaNo ratings yet

- Capa - 2Document1 pageCapa - 2Quality DWINo ratings yet

- VDA FMEA Process AnalysisDocument54 pagesVDA FMEA Process Analysishmp90No ratings yet

- Change Management C Pillar Stacking Reduced From 1+4 To 1+2Document18 pagesChange Management C Pillar Stacking Reduced From 1+4 To 1+2shobha shelarNo ratings yet

- PDCA Instructional TemplateDocument2 pagesPDCA Instructional TemplatevinayNo ratings yet

- Time Study SheetDocument29 pagesTime Study SheetJahidul IslamNo ratings yet

- Manufacturing Readiness ChecklistDocument5 pagesManufacturing Readiness Checklistkhmorteza100% (1)

- Supplier Audit Checklist Optimizes Risk ManagementDocument13 pagesSupplier Audit Checklist Optimizes Risk ManagementPrakash kumarTripathiNo ratings yet

- New Staff Induction Training PlanDocument5 pagesNew Staff Induction Training PlanJohnNo ratings yet

- Customer Survey Form T2m 2009Document1 pageCustomer Survey Form T2m 2009Peracha EngineeringNo ratings yet

- ISO management review report for USPLDocument1 pageISO management review report for USPLChintala YesukiranNo ratings yet

- CUSTOMER EVENTS BY MODEL AND MONTHDocument29 pagesCUSTOMER EVENTS BY MODEL AND MONTHBiswaranjan SahooNo ratings yet

- Template - Management Review ReportDocument2 pagesTemplate - Management Review ReportIslam WayNo ratings yet

- Industrial Pipe Marking GuideDocument2 pagesIndustrial Pipe Marking GuideArun KumarNo ratings yet

- 10-Part Air Gauge Measurement AnalysisDocument4 pages10-Part Air Gauge Measurement AnalysisSaurabh PhandNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Statistical Process Control For Attribute Data (SPC)Document45 pagesStatistical Process Control For Attribute Data (SPC)RajanishshettyNo ratings yet

- KEPL MR 06 - Management Review MeetingDocument2 pagesKEPL MR 06 - Management Review MeetingAvijit SenNo ratings yet

- Problem Solving BoardDocument3 pagesProblem Solving Boardshiv jangaleNo ratings yet

- 7QC Tools GuideDocument51 pages7QC Tools GuideMonu SharmaNo ratings yet

- Links Between Quality StandardsDocument4 pagesLinks Between Quality StandardsToni HimawanNo ratings yet

- ISO 9001:2008 & ISO/TS 16949 Quality Management RequirementsDocument52 pagesISO 9001:2008 & ISO/TS 16949 Quality Management Requirementssupady5751No ratings yet

- MRM PlanDocument2 pagesMRM Plang.kannan100% (1)

- MRM Data For AugDocument2 pagesMRM Data For AugPrakash kumarTripathiNo ratings yet

- Standard Work For Leaders Daily Checklist SampleDocument2 pagesStandard Work For Leaders Daily Checklist SampleRanjeet DongreNo ratings yet

- TPM Pillar Basic Knowledge Improvement ExampleDocument1 pageTPM Pillar Basic Knowledge Improvement ExampleAnkurNo ratings yet

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueDocument4 pages43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarNo ratings yet

- Gauge Repeatability & Reproduceability Report (MSA Study)Document2 pagesGauge Repeatability & Reproduceability Report (MSA Study)Karan MalhiNo ratings yet

- Non Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLDocument1 pageNon Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLAyush NarangNo ratings yet

- Logo Perusahaan CAR ISO 9001Document2 pagesLogo Perusahaan CAR ISO 9001Yoepy WijayaNo ratings yet

- 4list of DocumentsDocument2 pages4list of Documentsrishi gautam100% (1)

- SOP Warranty RepairsDocument2 pagesSOP Warranty RepairsKristantyo PrasetyaNo ratings yet

- Quality Management System Checklist Iso 9001Document13 pagesQuality Management System Checklist Iso 9001Ayman Hamed MalahNo ratings yet

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNo ratings yet

- Appendix 10 Waste Matrix Attachment A 092203Document14 pagesAppendix 10 Waste Matrix Attachment A 092203droffilcz27No ratings yet

- Performance Management Plan (PMP)Document3 pagesPerformance Management Plan (PMP)Sephora DjenadiNo ratings yet

- Department Name: Production Department Name: Production: Material ResourcesDocument21 pagesDepartment Name: Production Department Name: Production: Material ResourcesLesly LesNo ratings yet

- DK Qap QHS 12-FR 03-R6 - CarDocument1 pageDK Qap QHS 12-FR 03-R6 - CarErlan Gus HermawanNo ratings yet

- IT Group Internal Audit Schedules and ReportsDocument11 pagesIT Group Internal Audit Schedules and ReportsBhavin SukhadiyaNo ratings yet

- Salary Formation: Basic HRA Allowances Tel. Expense Food All. Spl. All. Monthly Salary PF Bonus LTA Perks Gross SalaryDocument1 pageSalary Formation: Basic HRA Allowances Tel. Expense Food All. Spl. All. Monthly Salary PF Bonus LTA Perks Gross SalaryNikunj SavaniNo ratings yet

- TKW Fasteners ProfileDocument37 pagesTKW Fasteners ProfileRishi GautamNo ratings yet

- Vendor Selection Site Visit Checklist and QuestionnaireDocument4 pagesVendor Selection Site Visit Checklist and QuestionnaireAMIT HBNo ratings yet

- Checklist & Rating Sheet)Document26 pagesChecklist & Rating Sheet)Michel Bryan Semwo0% (1)

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- Quality: Prince 2 Approach To QualityDocument3 pagesQuality: Prince 2 Approach To Qualityquree25No ratings yet

- Process Validation Ensures Quality PartsDocument24 pagesProcess Validation Ensures Quality Partsshobha shelarNo ratings yet

- Audit Checklist 9001 13485 21 CFR 820Document66 pagesAudit Checklist 9001 13485 21 CFR 820Zoli0984100% (5)

- Quality System Manual ISO 9001:2008 Internal Audit Check ListDocument14 pagesQuality System Manual ISO 9001:2008 Internal Audit Check ListDivakar Panigrahi100% (1)

- ISO 9001 Gap Analysis Quick ReferenceDocument7 pagesISO 9001 Gap Analysis Quick ReferencecbNo ratings yet

- What Is The Zeitgeist - PART IDocument13 pagesWhat Is The Zeitgeist - PART IMalcolm Armstrong100% (1)

- Accomplishment in ScinceDocument21 pagesAccomplishment in ScinceChristine CanoyNo ratings yet

- Dry Docking Ships Training Course for DockmastersDocument7 pagesDry Docking Ships Training Course for DockmastersSunil Kumar P GNo ratings yet

- Material Safety Data Sheet: Section I - Chemical Product and Company IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - Chemical Product and Company IdentificationMu ClasNo ratings yet

- Qualitative Data AnalysisDocument62 pagesQualitative Data AnalysisCes Aria100% (2)

- SQL Server DBA Daily ChecklistDocument4 pagesSQL Server DBA Daily ChecklistLolaca DelocaNo ratings yet

- Curriculum VitaeDocument4 pagesCurriculum Vitaebtk_20No ratings yet

- K-12 Grade 9 Science Roll Roll AwayDocument20 pagesK-12 Grade 9 Science Roll Roll AwayMeya Jhana Navidad75% (8)

- List of indexed conferences from Sumatera UniversityDocument7 pagesList of indexed conferences from Sumatera UniversityRizky FernandaNo ratings yet

- 354 33 Powerpoint-Slides CH4Document52 pages354 33 Powerpoint-Slides CH4Saravanan JayabalanNo ratings yet

- Data Pre Processing in WEKADocument5 pagesData Pre Processing in WEKAPrashant SunejaNo ratings yet

- Manuel Quezon's First Inaugural AddressDocument3 pagesManuel Quezon's First Inaugural AddressFrancis PasionNo ratings yet

- Citizen Journalism Practice in Nigeria: Trends, Concerns, and BelievabilityDocument30 pagesCitizen Journalism Practice in Nigeria: Trends, Concerns, and BelievabilityJonathan Bishop100% (3)

- Curriculum Evaluation ModelsDocument2 pagesCurriculum Evaluation ModelsIrem biçerNo ratings yet

- Work From Home Policy LeadsquaredDocument5 pagesWork From Home Policy LeadsquaredAnthonyNo ratings yet

- 2 Reason Why I Like DoraemonDocument2 pages2 Reason Why I Like Doraemonpriyanka shafiraNo ratings yet

- Bilingual Language Development TypesDocument29 pagesBilingual Language Development Typesirish delacruzNo ratings yet

- Wjec A Level Maths SpecificationDocument50 pagesWjec A Level Maths SpecificationastargroupNo ratings yet

- INGLESDocument20 pagesINGLESNikollay PeñaNo ratings yet

- Basics of Excellence Service in The Hotel, Restaurant, and Catering IndustryDocument43 pagesBasics of Excellence Service in The Hotel, Restaurant, and Catering IndustryTrinitaaNo ratings yet

- 015-Using Tables in ANSYSDocument4 pages015-Using Tables in ANSYSmerlin1112255No ratings yet

- Computational Chunking in Chess PDFDocument211 pagesComputational Chunking in Chess PDFTran VuNo ratings yet

- Instructional Module Training PlanDocument5 pagesInstructional Module Training Planapi-246767803100% (1)

- The Confidence Myth and What It Means To Your Career: by Tara MohrDocument4 pagesThe Confidence Myth and What It Means To Your Career: by Tara MohrdargeniNo ratings yet

- AbDocument13 pagesAbSk.Abdul NaveedNo ratings yet

- Escaping The Digital Dark AgeDocument5 pagesEscaping The Digital Dark AgeKarlos lacalleNo ratings yet

- Biologicalisation - Biological Transformation in ManufacturingDocument32 pagesBiologicalisation - Biological Transformation in ManufacturingGuillermo AvilesNo ratings yet

- Space Systems and Space Subsystems Fundamentals Course Sampler 140211082630 Phpapp02Document42 pagesSpace Systems and Space Subsystems Fundamentals Course Sampler 140211082630 Phpapp02danielNo ratings yet

- ASVAB Arithmetic Reasoning Practice Test 1Document7 pagesASVAB Arithmetic Reasoning Practice Test 1ASVABTestBank100% (2)

- What Is A Political SubjectDocument7 pagesWhat Is A Political SubjectlukaNo ratings yet