Professional Documents

Culture Documents

Macro and Micro Hardness Testing: A.R.G Sreekar, M M 1 2 B 0 0 2

Uploaded by

Arg SreekarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Macro and Micro Hardness Testing: A.R.G Sreekar, M M 1 2 B 0 0 2

Uploaded by

Arg SreekarCopyright:

Available Formats

MACRO AND MICRO

HARDNESS TESTING

A. R. G S r e e k a r ,

MM1 2 B0 0 2 .

1

Aim:

To measure the hardness of Tool steel, Fractured Mild steel, SS304L-Stealite welded samples.

Apparatus:

Brinell hardness machine, Vickers micro hardness machine, Rockwell hardness machine.

Theory:

Hardness is the measure of a materials resistance to localized plastic deformation (e.g., a small

dent or scratch). The depth or size of the resulting indentations is measure, which in turn is

related to a hardness number; the softer is the material, the larger and deeper is the

indentation, and lower the hardness index number. Measured hardness is only relative and

care should be taken when comparing value determined by various techniques. Some of the

techniques to find macro hardness are Brinell test, Rockwell test; and for very low loads Vickers

micro hardness test is used.

Macro Hardness Tests:

In Brinell tests, as in Rockwell measurements, a hard, spherical indenter is forced into the

surface of the metal to be tested. The diameter of the hardened

steel indenter is 10.00mm. Standard loads range between 500

and 3000 kg in 500-kg increments; during a test, the load is

maintained constant for specified time. The brinell hardness

number, HB, is a function of both the magnitude of the load and

the diameter of the resulting indentation. This diameter is

measured with a special low-power microscope, utilizing a scale

that is etched on the eyepiece. The measured diameter is then

converted to appropriate HB number using a chart; only one

scale is employed with this technique. For this technique, surface

finish should be smooth and flat where the indentation is to be

made.

Steel sphere is pressed against a metal surface for a

specified period of time (10 to 15 s, according to the ASTM), and

the surface of the indentation is measured. The load (in kgf)

divided bythe area (in mm

2

) of the curved surface gives the

hardness HB. Figure 1: Brinells Machine.

P 2P

HB = =

D Depth D

2

(D (D

2

-d

2

))

2

Where D and d are the diameters of the sphere and impression, respectively. The parameters

are indicated. Since d = D sin , we have

2P

HB =

D

2

(1 cos )

Rockwell Hardness Test:

Rockwell test constitute the most common method used to measure the hardness because they

are simple to perform and it also fetch results in a very short time. Different indenters are used

based on the material to which the hardness has to be found out. Indenters include spherical

and hardened steel balls having diameters 1/16, 1/8, , inch, and a conical diamond (BRALE)

indenter, which is used for the hardest materials. In this test hardness is determined by

difference in the depth of penetration resulting from the application of an initial minor load

followed by a larger major load; utilization of a minor load enhances test accuracy. For Rockwell

the minor load is load 10 kg , whereas major load is 150 kg. Each is represented by a letter of

the alphabet.

When specifying Rockwell hardness, both hardness number and scale symbol must be

indicated. The scale is designated by the symbol HR followed by the appropriate scale

identifications. For each scale, hardness may range up to

130; however, as hardness values rise above 100 or drop

below 20 on any scale, they become inaccurate; and

because the scales , have some overlap, in such a situation

it is best to utilize the next harder or softer scale.

Inaccuracies also result if the test specimen is too thin, if

an indentation is made too near a specimen edge, or if two

indentations are made too close to one another.

Specimens thickness should be at least 10 times the

indentation depth. Furthermore, testing of specimens

stacked one on top of another is not recommended. Also,

accuracy is dependent on the indentation made into a

smooth flat surface. Each measurement takes only few

seconds. Usually, the C scale is used for harder steels an

the B scale for softer steels; the A scale covers a wider

range of hardness.

Figure 2: Rockwell Hardness machine.

3

Rockwell Hardness Scales:

Scale Symbol Indenter Major Load (Kg)

A Diamond 60

B 1/16 inch ball 100

C Diamond 150

D Diamond 100

E 1/8 inch ball 100

The following precautions are recommended for reproducible results in Rockwell testing.

1. The indenter and anvil should be clean and well seated.

2. The surface to be tested should be clean, dry, smooth, and free from oxide. A rough-

ground surface is usually adequate for the Rockwell test.

3. The surface should be flat and perpendicular to the indenter.

4. Tests on cylindrical surfaces will give low readings, the error depending on the

curvature, load, indenter, and hardness of the material.

5. The thickness of the specimen should be such that a mark or bulge is not produced on

the reverse side of the piece. It is recommended that the thickness be at least 10 times

the depth of the indentation. Tests should be made on only a single thickness of

material.

6. The spacing between indentations should be three to five times the diameter of the

indentation.

7. The speed of application of the load should be standardized. This is done by adjusting

the dashpot on the Rockwell tester. Variations in hardness can be appreciable in very

soft materials, unless the rate of application of the load is carefully controlled. For such

materials, the operating handle of the Rockwell tester should be brought back as soon

as the major load has been fully applied.

Figure 3: Image of the tool sample. Figure 4: Image of the fractured mild steel.

4

Vickers Micro-Indentation Hardness:

Vickers micro hardness test uses 136 angled diamond pyramid. For each test a very small

diamond indenter having a pyramidal geometry is forced into the surface of the specimen.

Applied loads are very small; they are of the order 1 gram to 1Kg. The resulting indentation is

observed under a microscope and measured; this measurement is automatically converted into

a hardness number. Careful specimen surface preparation may be necessary to ensure a well-

defined indentation that may be accurately measured. They are referred to as micro

indentation-testing methods based on the indenter size.

Modern micro indentation hardness-testing equipment has been automated by

coupling the indenter apparatus to an image analyzer that incorporates a computer and

software package. The software controls important system functions to include indent location,

indent spacing, computation of hardness values, and plotting of data.

Figure 5: Image of the SS304L-Stealite welded sample. Figure 6: Image of Vickers Micro-hardness machine.

Results:

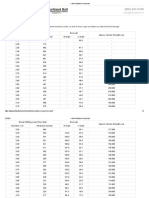

Table showing Hardness vs Distance of SS304L-Stealite welded sample.

Distance (mm) Hardness(HV)

0 235

1 216

2 225

4 249

5

Figure 7: Hardness vs Distance graph of the welded sample.

From the above figure, hardness is first decreasing up to a distance of 1mm, and increasing

after with distance. Hardness is low at the weld joint because of the brittle weld metal, as it is a

micro indenter the indentation might have happened at the area where Heat affected zone is

present, due to the presence of coarse grains; and the hardness again increases with increase in

distance from the HAZ due to fine grains according to Hall-Petch relationship which states that

hardness increases with decrease in grain size but up to a critical grain size.

The hardness of the tool steel measured by Rockwell hardness equipment is 55 HRC,

very close to real value 60 HRC from [3] by using a load of 150 Kg.

The hardness of the Fractured Mild steel is around 85 HRB by using a load of 31.25 Kg

obtained from Rockwell test.

References:

1.

You might also like

- Aluminium AlloysDocument43 pagesAluminium AlloysArg SreekarNo ratings yet

- Matlab TutorialDocument173 pagesMatlab TutorialSaurabh Tiwari100% (8)

- Ordertracking: Users ManualDocument38 pagesOrdertracking: Users Manualbinh buiNo ratings yet

- Seismic Simulator Biaxial Dev - 003372Document2 pagesSeismic Simulator Biaxial Dev - 003372EZIO AUDITORENo ratings yet

- Hardness Testing Methods GuideDocument33 pagesHardness Testing Methods Guideamol1321No ratings yet

- Chapter-4: 4.1 Matrix MaterialsDocument17 pagesChapter-4: 4.1 Matrix MaterialsSasiKumar PetchiappanNo ratings yet

- Earthquake Resistant Architecture BasicsDocument15 pagesEarthquake Resistant Architecture BasicsAr Shubham JaiswalNo ratings yet

- Principles of Continuum Mechanics: A Study of Conservation PrinciplesDocument10 pagesPrinciples of Continuum Mechanics: A Study of Conservation PrinciplesYsharath ChandramouliNo ratings yet

- Hardness TestingDocument10 pagesHardness TestingMekhmanNo ratings yet

- Hardness TestingDocument10 pagesHardness TestingMekhmanNo ratings yet

- Fast-Track Troubleshooter Quick Reference GuideDocument15 pagesFast-Track Troubleshooter Quick Reference GuideScott BobarinoNo ratings yet

- Linear Variable Differential Transformer (LVDT)Document21 pagesLinear Variable Differential Transformer (LVDT)kanchi100% (1)

- Electrical DictionaryDocument91 pagesElectrical DictionaryQudratullah EhsanNo ratings yet

- ME 498 - 6 - Nanoindentation and NanoscratchDocument23 pagesME 498 - 6 - Nanoindentation and NanoscratchTt OwnsqqNo ratings yet

- 493 07 Pump InterDocument11 pages493 07 Pump InterAnonymous 4yJ6kHP1100% (1)

- KLA AppNote StrainRateDocument6 pagesKLA AppNote StrainRatep dNo ratings yet

- University of Anbar College of Engineering Petrochemical Engineering ReportDocument10 pagesUniversity of Anbar College of Engineering Petrochemical Engineering Reportprince amerNo ratings yet

- Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical OverviewDocument19 pagesIndentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical OverviewAmarjit KumarNo ratings yet

- Hardness Experiment ReportDocument15 pagesHardness Experiment ReportsinabirecikNo ratings yet

- Mts 010184Document56 pagesMts 010184mecambNo ratings yet

- Strain hardening exponent materials constant n value stress-strain behavior metalsDocument1 pageStrain hardening exponent materials constant n value stress-strain behavior metalsdr_kh_ahmedNo ratings yet

- ENGR 244: Brinell hardness test resultsDocument10 pagesENGR 244: Brinell hardness test resultsSamuelNo ratings yet

- Astm E140-97Document21 pagesAstm E140-97Ivan AlanizNo ratings yet

- Fluids and Conditions Unit3l2Document17 pagesFluids and Conditions Unit3l2KJDNKJZEFNo ratings yet

- Cast IronDocument9 pagesCast IronArg Sreekar100% (1)

- Hardness Testing Methods ExplainedDocument9 pagesHardness Testing Methods ExplainedMohan S kumarNo ratings yet

- Tensile Testing Basics Tips TrendsDocument5 pagesTensile Testing Basics Tips TrendsJonathan Elias MoralesNo ratings yet

- Rotary ActuatorsDocument11 pagesRotary Actuatorskadir kayaNo ratings yet

- Evaluating Bond of Individual Steel Wire, Indented or Plain, For Concrete ReinforcementDocument7 pagesEvaluating Bond of Individual Steel Wire, Indented or Plain, For Concrete Reinforcementmohammed karasnehNo ratings yet

- Microindentation Hardness Testing: A Valuable Tool for Materials EngineersDocument7 pagesMicroindentation Hardness Testing: A Valuable Tool for Materials EngineersAida LizethNo ratings yet

- MTS Spiral WashersDocument1 pageMTS Spiral WashersAlphamanNo ratings yet

- Friction and Wear of Ptfe Comp at Cry TempDocument10 pagesFriction and Wear of Ptfe Comp at Cry Tempa100acomNo ratings yet

- Structural ExamplesDocument85 pagesStructural ExamplesfariasgarciarojasNo ratings yet

- Bohler M398.Ru - enDocument16 pagesBohler M398.Ru - enAnonymous 5A0DsVMTNo ratings yet

- Testing of MaterialsDocument18 pagesTesting of MaterialsMike SinghNo ratings yet

- Shaking Table Model Test and Numerical Analysis of A Complex High-Rise Building - Xilin Lu, Yin Zhou, Wensheng Lu - 2007Document34 pagesShaking Table Model Test and Numerical Analysis of A Complex High-Rise Building - Xilin Lu, Yin Zhou, Wensheng Lu - 2007Martin Dario Mazo QuingrejoNo ratings yet

- Civil Engineering Material TestingDocument8 pagesCivil Engineering Material TestingprashmceNo ratings yet

- Hardness Testing Machine Selection GuideDocument15 pagesHardness Testing Machine Selection GuideSanjay Kumar RanaNo ratings yet

- Seismic Dampers and The Factors Affecting Its Efficacy A Review PaperDocument5 pagesSeismic Dampers and The Factors Affecting Its Efficacy A Review PaperInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- FFF SolutionsDocument152 pagesFFF SolutionsMohammedAL-AthariNo ratings yet

- SSAB - 912 en Bending of High Strength Steel PDFDocument8 pagesSSAB - 912 en Bending of High Strength Steel PDFchristos032No ratings yet

- Planck (1900), Distribution LawDocument8 pagesPlanck (1900), Distribution LawDavid VandermeerNo ratings yet

- Unit IIDocument23 pagesUnit IIvizhideepaNo ratings yet

- TOM Unit 2 PDFDocument23 pagesTOM Unit 2 PDFNikhil NagarajanNo ratings yet

- Hardness Test: A Guide to Macro and Micro Hardness Measurement MethodsDocument6 pagesHardness Test: A Guide to Macro and Micro Hardness Measurement MethodsApril FlowerNo ratings yet

- Hardness TestDocument9 pagesHardness Testshmosaali133No ratings yet

- Assignment 3 - POMDocument8 pagesAssignment 3 - POMMcDhanesh JiNo ratings yet

- Mechanical TestigDocument58 pagesMechanical TestigVishi SinghNo ratings yet

- MEC 2309 Hardness TestDocument8 pagesMEC 2309 Hardness TestBilly MulengaNo ratings yet

- Hardness Testing.pptDocument11 pagesHardness Testing.pptJeyakumar JamesNo ratings yet

- Me 212 Laboratory Experiment #3 Hardness Testing and Age HardeningDocument8 pagesMe 212 Laboratory Experiment #3 Hardness Testing and Age HardeningurwakhanNo ratings yet

- Hardness Tests ExplainedDocument15 pagesHardness Tests ExplainedHossam SallamNo ratings yet

- Hardness TestDocument13 pagesHardness TestMohammad FrehatNo ratings yet

- Hardness TestDocument6 pagesHardness Testnigoxiy168No ratings yet

- Hardness TestDocument8 pagesHardness Testعماد المعماريNo ratings yet

- Hardness Test MethodsDocument7 pagesHardness Test MethodsParveen (Atam Valves)No ratings yet

- Lab 1 Report: Brinell Hardness TestDocument3 pagesLab 1 Report: Brinell Hardness TestNoby BecheerNo ratings yet

- Brunel Hardness TestDocument8 pagesBrunel Hardness TestSalam AlbaradieNo ratings yet

- Lab ReportDocument21 pagesLab ReportMuhammad YasirNo ratings yet

- Hardness and Torsion LabDocument20 pagesHardness and Torsion LabRafi UdeenNo ratings yet

- What Is Hardness?: (Type Text)Document5 pagesWhat Is Hardness?: (Type Text)akif222999No ratings yet

- Hardness TestDocument5 pagesHardness TestJatinNo ratings yet

- BHT & VHTDocument8 pagesBHT & VHTMoHammadNashatSabbahNo ratings yet

- GENG 231 Materials Science2Document10 pagesGENG 231 Materials Science2JojoAl-mansouriNo ratings yet

- Section IIIDocument7 pagesSection IIIalaa12344.eslamNo ratings yet

- 穆賢 K1006117 HardnessTestDocument18 pages穆賢 K1006117 HardnessTestMuhammad AbizardNo ratings yet

- Mechanical Properties and Hardness TestsDocument15 pagesMechanical Properties and Hardness TestsMitzySolòrzanoNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Chapter 4 - PlanningDocument47 pagesChapter 4 - PlanningArg SreekarNo ratings yet

- CH 02 - The Evolution of ManagementDocument37 pagesCH 02 - The Evolution of ManagementArg SreekarNo ratings yet

- Ril SR2007 08Document99 pagesRil SR2007 08Arg SreekarNo ratings yet

- Ch. 3 - The Environmental Context of ManagementDocument24 pagesCh. 3 - The Environmental Context of ManagementArg SreekarNo ratings yet

- MM2030 July2012 Quiz2Document1 pageMM2030 July2012 Quiz2Arg SreekarNo ratings yet

- IIT MADRAS ACADEMIC CALENDARDocument2 pagesIIT MADRAS ACADEMIC CALENDARM036No ratings yet

- B.tech Welding LAb QuestionsDocument2 pagesB.tech Welding LAb QuestionsArg SreekarNo ratings yet

- Immerse 2015 CDocument77 pagesImmerse 2015 CArg SreekarNo ratings yet

- 14 Space Lattices & Pearson SymbolsDocument1 page14 Space Lattices & Pearson SymbolsArg SreekarNo ratings yet

- Lec 11Document35 pagesLec 11Arg SreekarNo ratings yet

- Solidification Processes PartIIDocument5 pagesSolidification Processes PartIIArg SreekarNo ratings yet

- Assignment 5Document11 pagesAssignment 5Arg SreekarNo ratings yet

- MM5017 Assignment1Document2 pagesMM5017 Assignment1Arg SreekarNo ratings yet

- MML2014 GA.R.G Sreekar REPCompressionDocument5 pagesMML2014 GA.R.G Sreekar REPCompressionArg SreekarNo ratings yet

- How's Steel Manufactured?: Raw Materials For IronmakingDocument6 pagesHow's Steel Manufactured?: Raw Materials For Ironmakingamitkhanna71No ratings yet

- 8-Bit Microprocessor Architecture and Instruction SetDocument3 pages8-Bit Microprocessor Architecture and Instruction SetArg SreekarNo ratings yet

- Lec 8 9 SlideDocument10 pagesLec 8 9 SlideArg SreekarNo ratings yet

- Dual PhaseDocument4 pagesDual PhaseArg SreekarNo ratings yet

- Gibbs TriangleDocument4 pagesGibbs TriangleArg SreekarNo ratings yet

- Vector and Tensor AnalysisDocument10 pagesVector and Tensor Analysisrammar147No ratings yet

- Academic Calendar Jul-Dec 2014 26.12.2013Document2 pagesAcademic Calendar Jul-Dec 2014 26.12.2013Arg SreekarNo ratings yet

- Energy Sources Supply Demand Lec1 4sep13Document43 pagesEnergy Sources Supply Demand Lec1 4sep13Arg SreekarNo ratings yet

- Brinell Hardness TestDocument6 pagesBrinell Hardness TestAnonymous 4APvkrc6No ratings yet

- Hardness ComparisonDocument4 pagesHardness Comparisonvendi supendiNo ratings yet

- Steel Hardness ConversionDocument4 pagesSteel Hardness ConversionMNo ratings yet

- Iso 4964 1984Document8 pagesIso 4964 1984xaxafagaNo ratings yet

- Mohs Hardness Scale Minerals TestDocument2 pagesMohs Hardness Scale Minerals Testnick210700% (1)

- Lab Report 12Document3 pagesLab Report 1221pwind0685No ratings yet

- ASTM E110 (2010) - Standard Test Method For Indentation Hardness of Metallic Materials by Portable Hardness TestersDocument3 pagesASTM E110 (2010) - Standard Test Method For Indentation Hardness of Metallic Materials by Portable Hardness TestersLalit PatelNo ratings yet

- ERNST Guide To Hardness TestingDocument25 pagesERNST Guide To Hardness TestingSalem OmriNo ratings yet

- Experiment 2Document3 pagesExperiment 2Apet GriffinNo ratings yet

- Micro/Vickers Hardness Test Results for Part f5Document3 pagesMicro/Vickers Hardness Test Results for Part f5Mohamed NasrNo ratings yet

- BHT & VHTDocument8 pagesBHT & VHTMoHammadNashatSabbahNo ratings yet

- E 140Document23 pagesE 140Luna Hernandez Ricardo100% (1)

- Astm-E140 Conversión de DurezasDocument25 pagesAstm-E140 Conversión de DurezasPablo PerdomoNo ratings yet

- Hardness ComparisonDocument7 pagesHardness ComparisonankurNo ratings yet

- Hardness Tests ExplainedDocument15 pagesHardness Tests ExplainedHossam SallamNo ratings yet

- ME2Document12 pagesME2MikeyNo ratings yet

- Astm E10-18Document33 pagesAstm E10-18Lucie DekanyNo ratings yet

- Materials Engg Hardness TestDocument8 pagesMaterials Engg Hardness TestSourav KayalNo ratings yet

- Sist en Iso 6506-1-2006Document23 pagesSist en Iso 6506-1-2006BorutKecelj100% (2)

- Vickers Test PresentationDocument21 pagesVickers Test PresentationnailamushNo ratings yet

- WILSON Hardness - Conversion - ChartDocument1 pageWILSON Hardness - Conversion - ChartKevin Wells0% (1)

- Mohs Scale of Mineral HardnessDocument3 pagesMohs Scale of Mineral HardnessDeep JoshiNo ratings yet

- Rockwell Hardness Test MaterialsDocument4 pagesRockwell Hardness Test MaterialsMir Md. Mofachel HossainNo ratings yet

- Brinell Hardness of Metallic Materials: Standard Test Method ForDocument9 pagesBrinell Hardness of Metallic Materials: Standard Test Method ForMughal DarbarNo ratings yet

- BRINELL HARDNESS TEST FinalizedDocument1 pageBRINELL HARDNESS TEST FinalizedMohsin QaziNo ratings yet

- Hardness: The Most Important Dates in The History of Hardness Testing Are As FollowsDocument4 pagesHardness: The Most Important Dates in The History of Hardness Testing Are As FollowsSanjay YadavNo ratings yet