Professional Documents

Culture Documents

Sealent

Uploaded by

eraman_meOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sealent

Uploaded by

eraman_meCopyright:

Available Formats

Welcome to Choksey Chemicals

PRODUCTS>> Sealants

TECHSEAL RDL 940/941 are two component

sealant based on 'THIOKOL' - Polysulphide liquid polymer. It

consists of a 'Base' compound and 'accelerator' (Curing

Agent). When the two components are mixed together prior

to application, a chemical reaction is initiated which cures

'insitu' to a firm, flexible rubber like seal with excellent

adhesion to concrete, masonry, wood, glass, acrylic and PVC

plastics. It is capable of withstanding repeated extension,

compression & cyclic movements without loss of adhesion

and resists deterioration by weathering, sunlight, ozone,

water, salt, oils and fuels.

It is far superior to all the conventional joint sealing material

like bitumen, mastics, metallic channels and expansion

sheets. RDL-940 (Gun Grade) is a non-sag material used for

sealing of horizontal, vertical & ceiling joints. RDL-941 (Pour

Grade) is a pourable & self leveling material used for sealing

of horizontal joints only.

G Futura Sealar Coat

G Primers RDL-942 & RDL-

947

G Techseal RDL-940- GUN

GRADE

Techseal RDL- 941- POUR

GRADE

G Tech Seal CTPS

G Techseal PU-603 - GUN

GRADE

G Tech Seal CT PU -603

Pour Grade

G Techseal 1PPS

Technical Information

Characteristics

Nature : : Two Component

Mixing Ratio :

Base : Accelerator

92 : 8 parts by weight

Consistency after mixing, RDL 940

RDL 941

:

:

Thick, non-sag paste

Thick, flowing paste

Application time (pot life) at 30C

Initial setting time at 30C

:

:

2 to 3 hours

24hours

Complete curing time, at 5C

at 15C

at 25C

at 30C to 35C

:

:

:

:

8 weeks

4 weeks

2 weeks

1 weeks

Colour-Base compound

Accelerator (curing agent)

Mixed compound

:

:

:

Off, White

Dark brown to black

Grey

Sump (sag) resistance of RDL 940 : No Sagging

http://www.chokseychem.com/products/SEALANTS/rdl940_941.htm (1 of 4)6/15/2010 12:45:59 PM

Welcome to Choksey Chemicals

Features / Advantages

G Cures at ambient temperatures to a tough, elastic and flexible rubber like material.

G Bonds strongly to most of the building materials with the use of recommended primers.

G Durable, remains unaffected by UV rays, ozone and weathering conditions.

G Resistant to water, salt water, 10% dil. acids except nitric acids, 10% alkalies, most of

the common chemicals, vegetable, lubricating oils and fuels.

G Performs well in a temperature ranging from -40C to +80C and +100C intermittent.

G Resistent to biodegradation, prevents growth of fungus & micro-organism.

G Slip resistant (sag) can be applied in a horizontal joints.

G Movement capability - Provides satisfactory hermatic sealing of the joint subjected to

expansion, contraction, vibration and cyclic movement within the following limits.

- Movement joints upto + 25% of the width.

G Slip resistant (non-sag) can be applied in vertical & ceiling joints.

G Self leveling, after pouring in horizontal joint levels itself.

G Resilient recovers the original width after expansion & contraction without the loosing

the surface bond.

G Excellent repairability property.

G It can be overcoated by waterproofing compounds.

G Non-toxic.

G Sealant will not cause staining to concrete masonry or stones.

Application

G Sealing of expansion, contraction & construction joints in building structure such as

Basements, subways, retaining walls, floors, external walls and claddings of high-rise

buildings, roof terraces & ceilings especially structural expansion joint running through

the ceiling.

G Sealing of dynamic structural cracks

G Glazing joints of window, door frame and curtain walls.

G Joints & 'J' bolts of asbestos sheet roofing.

G Sealing of water retaining structure joints such as Water tank, reservoir, dams,

aquaducts, canals, culverts and water treatment plant.

G Sealing of joints in traffic areas such as Bridges, roads and car parking areas.

Joint design

In building structures various (different) types of joints are designed such as Butt joints, Lap

joints, Fillets Joints, Expansion joints, Control joints and Glazing joints.

As the joint expand, contract or experience a shear movement, cyclic movements, sealant

changes the shape accordingly, but the volume of sealant remains same. Hence, in designing

the joints, it is vital that the proper width-to-depth ratio is specified so that the width of the

joint is consistent with the capability of sealant to endure daily and seasonal cycles for

prolonged periods.

The amount of movement in a joint is dependent on the length (span), the coefficient of linear

expansion of a panel section and the temperature differential of the substrate. To achieve the

long-tem, effective performance the established width-to-depth ratios are determined and are

given below:-

Fillet Joint

Expansion

Joint

Glazing

Joint

Control Joint

http://www.chokseychem.com/products/SEALANTS/rdl940_941.htm (2 of 4)6/15/2010 12:45:59 PM

Welcome to Choksey Chemicals

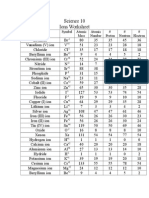

Joint Width Depth of sealant joint

Concrete & Masonry Metal & Glass

" to " (6.4mm to 12.5mm) " minimum (6.4mm)

" minimum

(6.4mm)

" to 1" (12.5mm to 25.4mm)

Width

2

Width

2

Over 1"

(25.4mm & above)

" maximum

(12.5 mm)

" maximum

(12.5 mm)

Direction for use

Surface Preparation

1. Surface preparation is the most important step before application of sealant to get best

results and to avoid failure.

2. The Joint surface must be dry, free from dust, coatings, bituminous mastics, concrete curing

agents, mould release agents, oils, greases and loose particles.

3. Clean the joint surface by wire brush and sanding with emery paper.

4. Remove dust by compressed air or paint brush.

5. Wipe out oil and grease by solvent soaked cloth (such as Xylene, Toluene or Acetone.)

Back up materials

Insert compressible polyethylene, polyurethane, thermocolfoam neoprene, polyethylene butyl

rods as back-up material to control depth of sealant in the joint and to provide support for

tooling of the sealant.

Priming

Select a primer suitable to the substrate and apply two coats by brush on the sides of the joints

surface at an interval of 30 minutes.

G Primer RDL 942 : For porous substrate such as concentrate, wood etc.

G Primer RDL 947 : For non-porous substrate such as metals, glass etc.

G Primer RDL 952 : For acrylic glass

G Primer RDL 948 : For PVC plastic & rubber

Bond breaker

Fix bond breaker tape such as self adhesive polyethylene tape on back-up material to avoid

adhesion of sealant to the third surface.

Masking tape

Apply masking tape such as self-adhesive polyethylene, cellophane or cloth tape on both edges

of the joint. It is used to improve the neatness of the finished seal by protecting the face edges

of the joint. It may be removed immediately after tooling of the sealant.

Mixing

The base and accelerator compounds supplied are packed in pre-weighed quantity as per the

mixing ratio. After the application of primer, mix the material of individual container. Transfer

entire quantity of accelerator to the base compound tin and mix it thoroughly to a uniform,

homogenous grey colour. Mixing can be done manually with spatula / palette knife or special

flat stirrer attached to a low speed electric mixer less than 500 r.p.m.

Application

Apply the mixed Gun grade compound by means of a spatula or by filling into a plastic

cartridge which is then placed into the hand held caulking gun into the joint.

Tooling and finishing

It is desirable that a smooth surface is obtained. Tool the sealant by pressing the puffy knife or

flat tool against the sealant surface, moving along the length of the joint. Tooling breaks air

bubbles and exposes any air pockets present. Tooling compresses the sealant, thus promoting

adhesion to the joint sides. After tooling the masking tape should be removed immediately.

Soap solution can be used to smoothen the sealant surface.

Coverage

Sealant : To estimate the quantity of TECHSEAL required to seal the joint can be very easily

estimated by using the following formula :

i) RDL-940-L = 650

(W X D)

ii) RDL-941-L = 625

(W X D)

http://www.chokseychem.com/products/SEALANTS/rdl940_941.htm (3 of 4)6/15/2010 12:45:59 PM

Welcome to Choksey Chemicals

Where,

L = Length of the joint in linear running meter

W = Width of the joint in mm.

D = Depth of the joint in mm.

Primer : 1 lit. of primer is required per 15kgs. of Techseal.

Cleaning of tools & equipment

Tools and equipments can be easily cleaned with solvent such as Xylene, Toulene, Methyl,

Ethyl, Ketone and Acetone.

Storage and shelf life

Store the material at cool and dry place ( at 25C temp. & 50% RH). Shelf life is one year in

unopened containers.

Packing

Techseal : 1 kg, 4 kgs.

Primer : 100 ml, litre 1 litre

Specification Complies

BS 4254-1983 : British Standard Specification

TT-S-00227E : National Bureau of Standard (GSA)

C-920-87 : American Society for Testing & materials (ASTM)

DIN-18549 : German Standard Specification.

Precautions

G Some people are sensitive to resins, hardeners, solvent and its vapours so it is

advisable to use hand gloves and goggles.

G Avoid application below 10C temperatures.

G Avoid application and damp or moist substrate.

G Storage - store at cool & dry place.

G Ensure that two coats of primer are applied on the jointing surfaces

Home l Profile l Projects l Products l Services l Branches l Credentials l Recognition l R&D l Clients l Global Partners l Exports l Contact us

Choksey Chemicals Pvt. Ltd. - Corporate Communication. All rights reserved

http://www.chokseychem.com/products/SEALANTS/rdl940_941.htm (4 of 4)6/15/2010 12:45:59 PM

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 2 Ion Worksheet - AnswersDocument1 page2 Ion Worksheet - Answersapi-272986951No ratings yet

- Durability of ConcreteDocument74 pagesDurability of ConcreteSalman KhanNo ratings yet

- Iso 8501Document4 pagesIso 8501cisar0007100% (2)

- Techanical Specification of Hydraulic PressDocument10 pagesTechanical Specification of Hydraulic Presseraman_me0% (1)

- Glafkides Photographic Chemistry Vol 1 Compressed PDFDocument509 pagesGlafkides Photographic Chemistry Vol 1 Compressed PDFArena Wessel100% (1)

- Using of Borosilicate Glass Waste As A Cement AdditiveDocument5 pagesUsing of Borosilicate Glass Waste As A Cement AdditiveMateriales FicNo ratings yet

- Coconut Coir Dust Conversion to Ethyl LevulinateDocument6 pagesCoconut Coir Dust Conversion to Ethyl LevulinateAli DandamunNo ratings yet

- Refracta Presentation (Refractory)Document73 pagesRefracta Presentation (Refractory)Nael90% (10)

- Is 1580 1991Document8 pagesIs 1580 1991eraman_meNo ratings yet

- 16MnCr5 IMDocument3 pages16MnCr5 IMeraman_meNo ratings yet

- Disinfectant Fluids, Phenolic Type - Specification: (Fourth Revision)Document14 pagesDisinfectant Fluids, Phenolic Type - Specification: (Fourth Revision)eraman_meNo ratings yet

- Disinfectant Fluids, Phenolic Type - Specification: (Fourth Revision)Document14 pagesDisinfectant Fluids, Phenolic Type - Specification: (Fourth Revision)eraman_meNo ratings yet

- 16MnCr5 IMDocument3 pages16MnCr5 IMeraman_meNo ratings yet

- 48RDocument14 pages48RSesh JayasuriyaNo ratings yet

- IS2002 Steel SpecDocument2 pagesIS2002 Steel Speceraman_meNo ratings yet

- Electro-Motive Standard Welding Symbols AI01046Document9 pagesElectro-Motive Standard Welding Symbols AI01046eraman_meNo ratings yet

- Solutions of Optional AssignmentDocument4 pagesSolutions of Optional AssignmentVaibhav BacchavNo ratings yet

- Transport in plantsDocument7 pagesTransport in plantsTatiana Vardaramatou0% (1)

- Phase Transfer CatalystDocument6 pagesPhase Transfer CatalystPMH100% (3)

- Arihant 41 Years Chemistry (Crackjee - Xyz)Document497 pagesArihant 41 Years Chemistry (Crackjee - Xyz)KaushikNo ratings yet

- Properties of Matter: States, Bonding, CrystalsDocument40 pagesProperties of Matter: States, Bonding, CrystalsWong SunNo ratings yet

- Refrigerants: by Manoj.P.J Associate Prof (Mech)Document13 pagesRefrigerants: by Manoj.P.J Associate Prof (Mech)aggin maria jamesNo ratings yet

- Dissolved Oxygen (DO) in Water: Experiment 7Document12 pagesDissolved Oxygen (DO) in Water: Experiment 7marco asmarNo ratings yet

- MP Board Class 12 Chemistry Previous Year Paper 2018Document4 pagesMP Board Class 12 Chemistry Previous Year Paper 2018Varun PatidarNo ratings yet

- ASTM C125 15aDocument4 pagesASTM C125 15aOLOFINTUYI Ilesanmi OlanrewajuNo ratings yet

- HILCO Stick Electrodes at A GlanceDocument6 pagesHILCO Stick Electrodes at A Glanceziaee950No ratings yet

- A Study On Durability Properties of Geopolymer Concrete Made With 100% GGBSDocument5 pagesA Study On Durability Properties of Geopolymer Concrete Made With 100% GGBSMahmoud HakimNo ratings yet

- Cambridge IGCSE: Chemistry 0620/12Document16 pagesCambridge IGCSE: Chemistry 0620/12Mohammed khaled GhazalNo ratings yet

- Starch GranuleDocument9 pagesStarch GranuleKay Buchorchor JnrNo ratings yet

- Life Processes - CBSE Class 10 BiologyDocument7 pagesLife Processes - CBSE Class 10 BiologyGurukul24x775% (8)

- ChemDocument6 pagesChemRoselyn BunquinNo ratings yet

- Sulphur and its Compounds: Extraction and AllotropesDocument16 pagesSulphur and its Compounds: Extraction and AllotropesVaibhav TripathiNo ratings yet

- Process Heat Transfer TutorialDocument4 pagesProcess Heat Transfer TutorialSuraya JohariNo ratings yet

- Chapter 9 Carbon ChemistryDocument6 pagesChapter 9 Carbon Chemistryapi-30718309No ratings yet

- Fly Ash. Use of Secondary Additives in Fly Ash Based Soil Stabilization For Soft SubgradesDocument34 pagesFly Ash. Use of Secondary Additives in Fly Ash Based Soil Stabilization For Soft SubgradesjyjiaNo ratings yet

- Effect of Microbes On Drilling Fluid FormulationDocument8 pagesEffect of Microbes On Drilling Fluid FormulationIJAERS JOURNALNo ratings yet

- Design of A Wastewater Treatment Plant For Paint Factories-1Document7 pagesDesign of A Wastewater Treatment Plant For Paint Factories-1Bonny AsianzuNo ratings yet

- Experiment 5 Chem 26.1Document2 pagesExperiment 5 Chem 26.1Collin Reyes HuelgasNo ratings yet

- CHE 203 Thermodynamics Final ExamDocument5 pagesCHE 203 Thermodynamics Final ExamcessareNo ratings yet

- Mechanisms of Hormone Action NotesDocument3 pagesMechanisms of Hormone Action Notesapi-390361165No ratings yet