Professional Documents

Culture Documents

04 053 063 Grooved Gaskets

Uploaded by

arianaseriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 053 063 Grooved Gaskets

Uploaded by

arianaseriCopyright:

Available Formats

Grooved gaskets

Types of gaskets

Grooved gaskets have proven extremely useful in all areas

of industry, including the most demanding sealing tasks.

Our grooved gaskets can be found in conventional power

plants as well as in the primary circuit of nuclear power plants.

In nuclear power plants, they are used e.g. as a heat exchanger gasket, as a valve cap gasket or as a manhole

cover gasket on steam generators or pressurisers.

Grooved gaskets have also been used to great success in

the chemical and petrochemical industries. Particularly in

places where there are high pressures and temperatures,

and therefore high bolt loads, to contend with. In order to

avoid damage to the flanges by the metal core, grooved gaskets are generally used with layers of PTFE, graphite, aluminium or silver. This gives total protection to the flanges, as

the profile geometry has been specifically adjusted to suit

the thickness of the layer.

We have developed a range of profiles to suit the various

properties of the layer materials.

The principal purpose of the soft layers is not however to

protect the flanges, but to provide a secure seal even at low

minimum surface pressures. A triaxial stress is created in

the profiling of the metallic carrier which has been filled with

the layer material. The load capacity is limited by the breaking point of the gasket and/or flange material. The stability of

this combination is therefore significantly higher than with a

pure PTFE, graphite, aluminium or silver seal.

Grooved gaskets be produced in sizes ranging from a few

millimetres to a diameter of 4,500 mm on our lathes. The

possibility of producing gaskets with greater diameters or

one-off production from drawings, such as oval gaskets,

can be examined in individual cases. For gaskets in heat

exchangers with partitions, it is necessary to insert partitions

with grooves of the same profile.

Gaskets for flanges with raised face or for smooth flanges

are supplied with a centring ring, so that the gasket is centred on the bolts. If the width of the centring ring is <= 10 mm,

then this ring is a part of the gasket (fixed central frame). At

greater widths, the integrated has a stress-relieving groove

(illustration 1). A loose centring ring should be used with

gaseous media. The loose centring ring is also advantageous where there are large differences in temperatures

between internal and external diameters. The loose centring ring is fitted in a groove (illustration 2 and 3).

04

The illustrations show the layout for a nominal thickness of

the metal core of 4 mm.

Illustration 1

Illustration 2

Illustration 3

Grooved gaskets are available that conform to works standards WN 100, WN 101, WN 136, WN145 (DINEN 1514-6),

WN 146 and WN 147. Works standards 100 and 101 only

contain a sealing width for all nominal pressure levels.

The sealing width bG = (d2 - d1)/2 should always increase as

the nominal pressure level increases. Due to the extremely

large difference between and V, in grooved gaskets, as

expressed in the application security SB = /V , works

standards 100 and 101 can be simplified.

55

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

Grooved gaskets

53

Grooved gaskets

Materials for the layers

Sealing thickness and groove pitch

PTFE, graphite and in certain cases silver or aluminium.

For flanges with tongue and groove faces and flanges with

male and female faces.

Condition as delivered

Soft-material layers are generally

supplied glued to the gasket.

When putting the gasket into

Condition during use

use, it should be noted that the

gasket is thicker around the layers.

04

In accordance with works standard 123

DN

NPS

to

100 to

350 to

900

ab

ab

over

We recommend PTFE or graphite as layers for pipelines,

apparatus parts or valves made from austenitic materials.

The layers should be either attached without glue or a lowchloride adhesive should be used.

In metal casings in narrow gaskets

where bD < 0,5 d1, single-part casings are used and in wide gaskets

with bD > 0,5 d1 [mm] twopart

casings are used.

80

300

900

resp.

to

3

resp. 4 to 12

resp. 14 to 36

36

with B7A, B9A, B15A =

with B27A, B29A, B25A =

Groove pitch t:

s

1,5

2,0

2,5

3,0

1,0 mm

1,5 mm

Profiles

Grooved gaskets with standard profiling

In the standard profile, the peaks of the groove are on one

level and the troughs are parallel to them. This profiling is

designed in accordance with DINEN 1514-6. The layer thickness for graphite, aluminium and silver should be 0.5 mm

and for PTFE 0.35 mm.

The B7A profile is for use with flange connections with tongue

and groove and male and female faces. The Profile B9A with

integrated centring ring should be selected for use with

smooth flanges and flanges with raised face. With gaseous

media, or where there are large differences in temperature

between internal and external diameters, the Profile B15A

with loose sheet metal centring ring should be used. The

grooved insert ring conforming to E7A is for groove-on-groove

flange connections.

Gasket profiles

Profile

Cross-section

B7A

This profiling should be used with gaskets for flange connections with male or female faces or tongue and groove

flanges. The minimum requirements are set out in our works

standard WN 123.

B9A

B15A

Gasket limiting values

Profiles

1.7335

grahpite

1.7335

PTFE*

1.4541

grahpite

1.4541

PTFE*

1.4541

aluminium

1.4541

silver

B7A, B9A, B15A, E7A

Recommended max. roughness

m

of the flange surfaces

from

to

25

50

50

100

25

50

50

100

12,5

25

12,5

25

Surface pressure

limits for 20 C

N/mm2

15

450

15

450

15

500

15

500

80

500

125

500

Surface pressure

limits for 300 C

N/mm2

30

390

301)

3901)

30

420

301)

4201)

95

420

140

420

Materials

1)

*

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

54

Grooved gaskets

Groove gaskets with PTFE layers are only suitable

for use at 280C to a limited extent.

Gaskets that are electrically isolated from the usual

pipelines by two PTFE layers can become

electrostatically charged. Appropriate measures

must be taken to discharge any electrical charge

that may arise depending on the medium.

Grooved gaskets

The convex grooved gasket

The convex grooved gaskets in Profile B27A, B29A and B25A

exhibit improved sealing properties compared to standard

grooved profiles.

04

The improvement is achieved by the decreasing depth of the

groove troughs towards the midpoint of the profile. The profiling is created as a step profile.

The sealing layer made from soft, plastic deformable material creates a thicker padding at the profile centre line than in

the internal and external zones. The layer thickness for graphite, aluminium and silver should be 0.5 mm and for PTFE

0.35 mm.

The specific surface pressure is greatest at the profile centre line, causing the sealing layers to flow well into the unavoidable irregularities and roughness on the flange surface.

Grooved gaskets in Profile B27A, B29A and B25A reduce

edge pressure.

The increased surface pressure at the profile centre line

has a positive effect on the sealing properties in tilted flanges.

With ordinary gaskets, when a flange is strongly tilted ( ~ 1)

it causes a raising of the internal diameter of the gasket to be

observed, as the flange is now loading the seal more on the

outer diameter. But with Profile B27A, B29A and B25A the

contact diameter is kept at dG. These gaskets are therefore

particularly suitable for flange connections where the pressures and temperatures are constantly fluctuating.

Profiles

The B27A profile is for use with flange connections with

tongue and groove and male and female faces. The Profile

B29A with integrated centring ring should be selected for

use with smooth flanges and flanges with raised face.

With gaseous media or large differences in temperature

between the internal and external diameters, Profile B25A

with loose sheet metal central edge should be used.

Gasket profiles

Profile

Cross-section

B27A

B29A

B25A

Surface pressures

The minimum surface pressure v is determined by the layer

material used with the convex grooved gasket.

The highest permissible surface pressure at a temperature

of is and this determines the allowable gasket load

reaction. The maximum allowable surface pressure is

determined by the material used in the metal core.

1)

*

Groove gaskets with PTFE layers are only suitable for use at 280C to a limited extent.

Gaskets that are electrically isolated from the usual pipelines by two PTFE layers can

become electro-statically charged. Appropriate measures must be taken to discharge

any electrical charge that may arise depending on the medium.

Gasket limiting values

Profiles

B27A, B29A, B25A

1.5415

PTFE*

1.4541

grahpite

1.4541

PTFE*

1.4828

grahpite

1.4541

aluminium

1.4541

silver

1.4828

silver

from

m to

1.5415

grahpite

Recommended max. roughness

of the flange surfaces

1.0038

grahpite

Materials

25

50

25

50

50

100

25

50

50

100

25

50

12,5

25

12,5

25

12,5

25

Surface pressure

limits for 20 C

N/mm2

15

350

15

450

15

450

15

500

15

500

15

500

70

500

100

500

100

500

Surface pressure

limits for 300 C

N/mm2 v

20

210

20

330

201)

3301)

20

420

201)

4201)

20

420

80

420

110

420

110

500

55

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

Grooved gaskets

55

Grooved gaskets

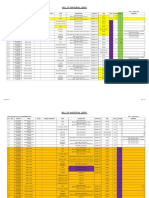

Works standard 145 = DIN EN 1514-6 for DIN flanges

Ordering example for a grooved gasket with layers, Profile

B29A, DN 100, PN 40, works standard 145, made of ... 1):

Grooved gasket B29A, DN 100, PN 40, works standard 145,

1.4541/PTFE

04

1) Specify material when placing order

2) Please arrange other thicknesses when ordering.

PN 250PN 400

PN 63PN 160

DN

PN 10PN 40

For DIN flanges

d3

d1

d2

d2

d2

PN 10

PN 16

PN 25

PN 40

10

15

20

22

26

31

36

42

47

36

42

47

36

42

47

46

51

61

46

51

61

46

51

61

46

51

61

PN 63 PN 100 PN 160 PN 250 PN 320 PN 400

56

61

72

56

61

72

56

61

-

67

72

-

67

72

-

67

78*

-

25

32

40

36

46

53

52

62

69

52

62

69

52

66

73

71

82

92

71

82

92

71

82

92

71

82

92

82

103

82

103

82

103

83

109

92

119

104

135

50

65

80

65

81

95

81

100

115

81

100

115

87

103

121

107

127

142

107

127

142

107

127

142

107

127

142

113

137

148

119

143

154

119

143

154

124

153

170

134

170

190

150

192

207

100

125

150

118

142

170

138

162

190

138

162

190

146

178

212

162

192

217

162

192

217

168

194

224

168

194

224

174

210

247

180

217

257

180

217

257

202

242

284

229

274

311

256

301

348

175

200

250

195

220

270

215

240

290

215

248

300

245

280

340

247

272

327

247

272

328

254

284

340

265

290

352

277

309

364

287

324

391

284

324

388

316

358

442

358

398

488

402

442

-

300

350

400

320

375

426

340

395

450

356

415

474

400

-

377

437

489

383

443

495

400

457

514

417

474

546

424

486

543

458

512

572

458

-

536

-

450

500

600

480

530

630

506

560

664

588

700

539

594

695

555

617

734

624

731

571

628

747

657

764

704

813

700

800

900

730

830

930

770

876

982

812

886

994

810

917

1017

804

911

1011

833

942

1042

852

974

1084

879

988

1108

950

-

1000

1200

1400

1040

1250

1440

1098

1320

1522

1110

1334

-

1124

1341

1548

1128

1342

1542

1154

1364

1578

1194

1398

1618

1220

1452

-

1600

1800

2000

1650

1850

2050

1742

1914

2120

1772

1972

2182

1764

1964

2168

1798

2000

2230

1830

-

2200

2400

2600

2250

2460

2670

2328

2512

2728

2384

2594

2794

2378

-

2800

3000

2890

3100

2952

3166

3014

3228

- Flanges compliant with the standard not available

* WN 145

Dimensions in mm

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

56

Grooved gaskets

Grooved gaskets

Works standard 146 for flanges in accordance with ANSI

B16.5

Ordering example for a grooved gasket with layers, Profile

B9A, NPS 5, for ANSI flanges, Class 600, works standard

146, made of ... 1):

04

Grooved gasket B9A, NPS 5, Class 600, works standard

146, 1.4541/graphite

1) Specify material when placing order

Class

150

d3

NPS

d1

d2

20

25

32

30

35

42

30

35

42

30

35

42

44,4

53,9

63,5

50,8

63,5

69,8

50,8

63,5

69,8

50,8

63,5

69,8

60,3

66,7

76,2

60,3

66,7

76,2

66,7

73,0

82,5

1

1

2

40

45

60

56

61

80

56

61

80

56

61

80

73,0

82,5

101,6

79,4

92,1

108,0

79,4

92,1

108,0

79,4

92,1

108,0

85,7

95,2

139,7

85,7

95,2

139,7

101,6

114,3

142,8

2

3

3

70

85

100

90

105

120

90

105

120

90

110

-

120,6

133,4

158,8

127,0

146,1

161,9

127,0

146,1

158,7

127,0

146,1

158,7

161,9

165,1

-

161,9

171,5

-

165,1

193,7

-

4

5

6

110

135

160

130

155

180

130

155

180

135

165

195

171,5

193,7

219,1

177,8

212,7

247,7

174,6

209,5

244,5

190,5

238,1

263,5

203,2

244,5

285,8

206,4

250,8

279,4

231,7

276,2

314,3

8

10

12

210

265

315

230

285

335

230

295

350

250

315

375

276,2

336,5

406,4

304,8

358,8

419,1

301,6

355,6

415,9

317,5

396,9

454,0

355,6

431,8

495,3

349,3

431,8

517,5

384,1

473,0

546,1

14

16

18

350

400

450

370

425

480

390

445

500

405

460

525

447,7

511,2

546,1

482,6

536,6

593,7

479,4

533,4

590,5

488,9

561,9

609,6

517,5

571,5

635,0

574,7

638,1

701,7

20

24

500

600

535

640

555

665

575

685

603,2

714,4

650,9

771,5

644,5

765,2

679,5

787,4

695,3

835,0

752,4

898,5

- Flanges compliant with the standard not available

d2

Class

900-2500

d2

Class

400-600

Class

150-300

For flanges in accordance with ANSI B16.5

300

400

600

900

1500

2500

Dimensions in mm

55

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

Grooved gaskets

57

Grooved gaskets

Works standard 147 for flanges in accordance with ASME

B16.47 Series A

Ordering example for a grooved gasket with layers, Profile

B9A, NPS 30, for flanges in accordance with ASME B16.47,

Series A, Class 600, works standard 147, made of ... 1):

04

Grooved gasket B9A, NPS 30, Class 600, works standard

147, 1.4541/graphite

1) Specify material when placing order

d1

d2

d2

26

28

30

650

705

755

685

745

795

705

765

820

32

34

36

805

855

905

850

900

955

38

40

42

960

1010

1060

44

46

48

d2

Class

900-2500

NPS

Class

400-600

Class

150-300

For flanges in accordance with ASME B16.47 Series A

Class

d3

150

300

400

600

900

725

785

840

772

829

880

832

895

949

829

889

943

864

911

968

880

943

1007

875

930

985

895

950

1005

937

987

1045

1003

1054

1114

1000

1051

1114

1019

1070

1127

1070

1134

1197

1015

1065

1120

1030

1085

1135

1065

1120

1175

1108

1159

1216

1051

1111

1162

1070

1124

1175

1102

1153

1216

1197

1248

1299

1110

1160

1210

1170

1225

1275

1190

1250

1300

1230

1285

1340

1273

1324

1381

1216

1270

1321

1229

1286

1343

1267

1324

1388

1365

1432

1483

50

52

54

1260

1310

1360

1330

1385

1435

1355

1405

1460

1432

1489

1546

1375

1426

1489

1400

1451

1515

1445

1495

1553

56

58

60

1410

1460

1510

1490

1540

1595

1515

1565

1625

1603

1661

1711

1540

1591

1742

1565

1616

1680

1610

1661

1730

- Flanges compliant with the standard not available

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

58

Grooved gaskets

Dimensions in mm

Grooved gaskets

Works standard 101* for DIN flanges

Ordering example for a grooved gasket with layers, Profile

B29A, DN 100, PN 40, works standard 101, made of ...1):

Grooved gasket B29A, DN 100, PN 40, works standard 101,

1.4541/PTFE

04

Grooved gaskets can also be manufactured with a sealing

width optimised to the nominal pressure in accordance with

works standard 145

1) Specify material when placing order

2) The thickness of the metal part 3.8+0.2 mm at a nominal size of

4. Please arrange other thicknesses when ordering.

For DIN flanges

d3

DN

d1

d2

PN 10

PN 16

PN 25

PN 40

PN 63

PN 100

PN 160

PN 250

PN 320

PN 400

10

15

20

22

26

31

36

42

47

46

51

61

46

51

61

46

51

61

46

51

61

56

61

-

56

61

-

56

61

-

67

72

-

67

72

-

67

78

-

25

32

40

36

46

53

52

66

73

71

82

92

71

82

92

71

82

92

71

82

92

82

103

82

103

82

103

83

109

92

119

104

135

50

65

80

65

81

95

87

103

121

107

127

142

107

127

142

107

127

142

107

127

142

113

137

148

119

143

154

119

143

154

124

153

170

134

170

190

150

192

207

100

125

150

118

142

170

144

176

204

162

192

217

162

192

217

168

194

224

168

194

224

174

210

247

180

217

257

180

217

257

202

242

284

229

274

311

256

301

348

175

200

250

195

224

275

229

258

315

247

272

327

247

272

328

254

284

340

265

290

352

277

309

364

287

324

391

284

324

388

316

358

442

358

398

488

402

442

-

300

350

400

325

375

426

365

420

474

377

437

489

383

443

495

400

457

514

417

474

546

424

486

543

458

512

572

458

-

536

-

450

500

600

480

530

630

528

578

680

539

594

695

555

617

734

624

731

571

628

747

657

764

704

813

700

800

900

730

830

930

780

880

980

810

917

1017

804

911

1011

833

942

1042

852

974

1084

879

988

1108

950

1000

1200

1400

1040

1250

1440

1090

1310

1510

1124

1341

1548

1128

1342

1542

1154

1364

1578

1194

1398

1618

1220

1452

-

1600

1800

2000

1650

1850

2050

1730

1930

2130

1772

1972

2182

1764

1964

2168

1798

2000

2230

1830

-

2200

2400

2600

2250

2460

2670

2340

2550

2760

2384

2594

2794

2378

-

2800

3000

2890

3100

2980

3190

3014

3228

- Flanges compliant with the standard not available

55

Dimensions in mm

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

Grooved gaskets

59

Grooved gaskets

Works standard 100* = EN 12560-6 for flanges in accordance with ANSI B 16.5

Ordering example for a grooved gasket with layers, Profile

B9A, NPS 5, for ANSI flanges, Class 600, works standard

100, made of ...1):

04

Grooved gasket B9A, NPS 5, Class 600, works standard

100, 1.4541/graphite

*

Grooved gaskets can also be manufactured with a sealing

width optimised to the nominal pressure in accordance with

works standard 146

For flanges in accordance with ANSI B16.5

Class

NPS

150

d3

d1

d2

23,0

28,6

36,5

33,3

39,7

47,6

44,4

53,9

63,5

300

50,8

63,5

69,8

400

50,8

63,5

69,8

600

50,8

63,5

69,8

900

60,3

66,7

76,2

60,3

66,7

76,2

66,7

73,0

82,5

1

1

2

44,4

52,4

69,8

60,3

69,8

88,9

73,0

82,5

101,8

79,4

92,1

108,0

79,4

92,1

108,0

79,4

92,1

108,0

85,7

95,2

139,7

85,7

95,2

139,7

101,6

114,3

142,8

2

3

3

82,5

98,4

111,1

101,6

123,8

136,5

120,6

133,4

158,8

127,0

146,1

161,9

127,0

146,1

158,7

127,0

146,1

158,7

161,9

165,1

-

161,9

171,5

-

165,1

193,7

-

4

5

6

123,8

150,8

177,8

154,0

182,6

212,7

171,5

193,7

219,1

177,8

212,7

247,7

174,6

209,5

244,5

190,5

238,1

263,5

203,2

244,5

285,8

206,4

250,8

279,4

231,7

276,2

314,3

8

10

12

228,6

282,6

339,7

266,7

320,7

377,8

276,2

336,5

406,4

304,8

358,8

419,1

301,6

355,6

415,9

317,5

396,9

454,0

355,6

431,8

495,3

349,3

431,8

517,5

384,1

473,0

546,1

14

16

18

371,5

422,3

479,4

409,6

466,7

530,2

447,7

511,2

546,1

482,6

536,6

593,7

479,4

533,4

590,5

488,9

561,9

609,6

517,5

571,5

635,0

574,7

638,1

701,7

20

22

24

530,2

581,0

631,8

581,0

631,8

682,6

603,2

657,2

714,4

650,9

701,7

771,5

644,5

698,5

765,2

679,5

730,3

787,4

695,3

835,0

752,4

898,5

- Flanges compliant with the standard not available

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

60

Grooved gaskets

1500

2500

Dimensions in mm

Grooved gaskets

Works standard 136* for flanges in accordance with ASME

B16.47 Series A

Ordering example for a grooved gasket with layers, Profile

B9A, NPS 30, for flanges in accordance with ASME B16.47,

Series A, Class 600, works standard 136, made of ...1):

04

Grooved gasket B9A, NPS 30, Class 600, works standard

136, 1.4541/graphite

*

Grooved gaskets can also be manufactured with a sealing width

optimised to the nominal pressure in accordance with works

standard 147

1) Specify material when placing order

For flanges in accordance with ASME B16.47 Series A

Class

2) The thickness of the metal part 3.8+0.2 mm at a nominal size of 4.

Please arrange other thicknesses when ordering.

d3

NPS

d1

d2

150

300

400

600

900

26

28

30

690

740

800

740

790

850

772

829

880

832

895

949

829

889

943

864

911

968

880

943

1007

32

34

36

845

895

950

905

955

1010

937

987

1045

1003

1054

1114

1000

1051

1114

1019

1070

1127

1070

1134

1197

38

40

42

960

1015

1065

1020

1075

1125

1108

1159

1216

1051

1111

1162

1070

1124

1175

1102

1153

1216

1197

1248

1299

44

46

48

1125

1175

1220

1185

1235

1290

1273

1324

1381

1216

1270

1321

1229

1286

1343

1267

1324

1388

1365

1432

1483

50

52

54

1270

1320

1375

1350

1400

1455

1432

1489

1546

1375

1426

1489

1400

1451

1515

1445

1495

1553

56

58

60

1430

1485

1535

1510

1565

1615

1603

1661

1711

1540

1591

1742

1565

1616

1680

1610

1661

1730

- Flanges compliant with the standard not available

Dimensions in mm

55

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

Grooved gaskets

61

Grooved gaskets

04

The gasket thickness is ever smaller than the groove depth

For flanges with tongue and groove

In accordance with ANSI B 16.21 (150 to 1500)

Conforms to DIN 2691 edition 11.71 (PN 10 to PN 160)

Ordering example for a grooved gasket with layers, Profile

B7A, NPS 5, wide model, made of ...1):

Ordering example for a grooved gasket with layers, Profile

B7A, DN 100, made of ...1):

Grooved gasket, B7A, DN 100, DIN 2691, 1.4571/graphite

Grooved gasket, B7A, NPS 5, ANSI B 16.5 wide, tongue and

groove, 1.4541/graphite

For flanges in accordance with ASME/

ANSI B16.5

For DIN flanges

DN

d1

d2

4-62)

82)

10

20

22

24

30

32

34

15

20

25

29

36

43

39

50

57

32

40

50

51

61

73

65

75

87

65

80

100

95

106

129

109

120

149

125

150

175

155

183

213

175

203

233

200

250

300

239

292

343

259

312

363

350

400

500

395

447

549

421

473

575

600

700

800

649

751

856

675

777

882

900

1000

961

10623)

987

10923)

narrow

wide

DN

d1

d2

d2

25

33

38

35

43

48

35

43

51

1

1

2

48

54

73

57

64

83

64

73

92

2

3

3

86

108

121

95

117

130

105

127

140

4

5

6

132

160

191

145

173

203

157

186

216

8

10

12

238

286

343

254

305

362

270

324

381

14

16

18

375

425

489

394

448

511

413

470

533

20

24

533

641

559

667

584

692

Dimensions in mm

Dimensions in mm

1) Specify material when placing order

2) Only for flanges in refrigeration engineering

3) Dimensions in accordance with DIN 2512

1) Specify material when placing order

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

62

Grooved gaskets

Grooved gaskets

04

For flanges with male and female

In accordance with ANSI B 16.21 (150 to 1500)

Conforms to DIN 2692 edition 5.66 (PN 10 to PN 100)

Ordering example for a grooved gasket with layers, Profile

B7A, NPS 5, wide model, made of ...1):

Ordering example for a grooved gasket with layers, Profile

B7A, DN 100, made of ...1):

Grooved gasket, B7A, NPS 5, ANSI B 16.21 wide, male and

female, 1.4541/graphite

Grooved gasket, B7A, DN 100, DIN 2692, 1.4541/graphite

For flanges in accordance with ASME/ANSI

B16.5

narrow

wide

For DIN flanges

d1

d2

NPS

d2

d1

d2

10

15

20

18

22

28

34

39

50

d1

18

24

30

21

27

34

35

43

51

25

32

40

35

43

49

57

65

75

1

1

2

38

44

57

42

48

60

64

73

92

50

65

80

61

77

90

87

109

120

2

3

3

68

84

97

73

89

102

105

127

140

100

125

150

115

141

169

149

175

203

4

5

6

109

137

162

114

141

168

157

186

216

175

200

250

195

220

274

233

259

312

8

10

12

213

267

318

219

273

324

270

324

381

300

350

400

325

368

420

363

421

473

14

16

18

349

400

451

356

406

457

413

470

533

500

600

700

520

620

720

575

675

777

20

24

502

603

508

610

584

692

800

900

1000

820

920

1020

882

987

1091

to be specified by user

DN

Dimensions in mm

Dimensions in mm

1) Specify material when placing order

2) The gasket thickness is always less than the female face depth

55

Kempchen Dichtungstechnik GmbH Tel. +49 (0)208 8482 0 Fax. +49 (0)208 8482 285 info@kempchen.de www.kempchen.de

Grooved gaskets

63

You might also like

- 04-053-063 Grooved GasketsDocument11 pages04-053-063 Grooved Gasketsritesh sharmaNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Garnituri DIN 2697Document12 pagesGarnituri DIN 2697Dumitru SorinaNo ratings yet

- GFCP Catalog Flange Insulation PDFDocument32 pagesGFCP Catalog Flange Insulation PDFSalmanNo ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring Gasketsopenid_ZrfbXb06No ratings yet

- Flexitallic Flexpro Brochure 11-30-2017Document8 pagesFlexitallic Flexpro Brochure 11-30-2017Imthiyaz HNo ratings yet

- Wound SpiralDocument2 pagesWound SpiralMircea Dan StanciuNo ratings yet

- PSI Casing End Seals For Carrier Pipe End SealDocument10 pagesPSI Casing End Seals For Carrier Pipe End SealvenkateshwaranNo ratings yet

- Profile SurveyDocument10 pagesProfile Surveygalici2002No ratings yet

- Psi Flange KitsDocument8 pagesPsi Flange Kitsdianudin safarudinNo ratings yet

- Corrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsDocument4 pagesCorrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsTaufiqTaufiqNo ratings yet

- GASKET - DESIGN - & - BOLTING Kamprofile PDFDocument77 pagesGASKET - DESIGN - & - BOLTING Kamprofile PDFPranpath NarupantawartNo ratings yet

- Corrugated and Grooved Gaskets - GrafexDocument3 pagesCorrugated and Grooved Gaskets - GrafexLupeteNo ratings yet

- Brett FillersDocument2 pagesBrett Fillerslokomoko1No ratings yet

- Spiralwound: Product InformationDocument2 pagesSpiralwound: Product InformationMohamed RaafatNo ratings yet

- Camprofile Gaskets PDFDocument4 pagesCamprofile Gaskets PDFLymeParkNo ratings yet

- Topspan 22 40Document6 pagesTopspan 22 40bradrimmNo ratings yet

- Valquatight Gasket: Valqua No. 6590 Product Name BLACKTIGHT (Basic Design)Document5 pagesValquatight Gasket: Valqua No. 6590 Product Name BLACKTIGHT (Basic Design)성수길No ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring GasketsRitesh VishambhariNo ratings yet

- Richpac® Spiral Wound Gask ETDocument13 pagesRichpac® Spiral Wound Gask ETIgor NircaNo ratings yet

- Absolutely leak proof gasket selectionDocument12 pagesAbsolutely leak proof gasket selectionbruteforce2000No ratings yet

- Spiral Wound GasketsDocument1 pageSpiral Wound Gasketsgalici2002No ratings yet

- Foxboro TX PresionDocument44 pagesFoxboro TX PresionRicardo Felipe Cortes MenayNo ratings yet

- Expamet Plastering AccessoriesDocument20 pagesExpamet Plastering Accessoriesapi-27549425100% (3)

- Multiple Distributor QSQ-6-4: Catalogue PageDocument4 pagesMultiple Distributor QSQ-6-4: Catalogue PagepauloNo ratings yet

- Wire Jacketing Nylon FirestoneDocument14 pagesWire Jacketing Nylon FirestoneAndres Valencia MiraNo ratings yet

- Lysaght Panelrib 18 Sept 2008Document4 pagesLysaght Panelrib 18 Sept 2008Daniel McCallumNo ratings yet

- English Torque ASAHIDocument1 pageEnglish Torque ASAHI1068181No ratings yet

- Wire and Cable Extrusion (Peek)Document3 pagesWire and Cable Extrusion (Peek)Sh.nasirpurNo ratings yet

- 04 044 052 Spiroflex Spiral Wound GasketsDocument9 pages04 044 052 Spiroflex Spiral Wound Gasketsgazwang478No ratings yet

- ES 49BranchConnections PDFDocument7 pagesES 49BranchConnections PDFprabuharan89No ratings yet

- Push-In/threaded L-Fitting QSML-M5-4: Catalogue PageDocument4 pagesPush-In/threaded L-Fitting QSML-M5-4: Catalogue Pageabrap_dNo ratings yet

- 102 EN Sealing Solutions For Offshore Industry PDFDocument20 pages102 EN Sealing Solutions For Offshore Industry PDFWiskusa NarudeanNo ratings yet

- 16 StaticgasketsDocument10 pages16 StaticgasketsRobinReyndersNo ratings yet

- Sa Tun en 2Document4 pagesSa Tun en 2a_salehiNo ratings yet

- Afico Pipe InsulaionDocument4 pagesAfico Pipe InsulaionProcurement Alamco100% (1)

- Push-In Bulkhead Connector QSS-4: Catalogue PageDocument4 pagesPush-In Bulkhead Connector QSS-4: Catalogue PagepauloNo ratings yet

- Bearing (N Mind: Precision Ball Bearing Basics: BearingsDocument16 pagesBearing (N Mind: Precision Ball Bearing Basics: Bearings唐波No ratings yet

- Fey Kolca KatalogDocument46 pagesFey Kolca KatalogВиталий БобуличNo ratings yet

- Jamesbury 4000Document12 pagesJamesbury 4000Dinesh ChouguleNo ratings yet

- Push-in fittings catalogueDocument4 pagesPush-in fittings catalogueRamon rodenciaNo ratings yet

- Fabrication of Thermal Insulating Fitting Covers For NPS Piping, and Vessel LaggingDocument3 pagesFabrication of Thermal Insulating Fitting Covers For NPS Piping, and Vessel Laggingnisha_khanNo ratings yet

- Flexpro™ Kammprofiles: Ideal For Shell and Tube Style Heat Exchanger FlangesDocument1 pageFlexpro™ Kammprofiles: Ideal For Shell and Tube Style Heat Exchanger FlangesTAHIR MAHMOODNo ratings yet

- Masonry Reinforcement and Windposts March 2015 V3Document14 pagesMasonry Reinforcement and Windposts March 2015 V3witwatersrandNo ratings yet

- KLAMFLEX Pipe Coupling Technical ManualDocument16 pagesKLAMFLEX Pipe Coupling Technical ManualDeepak JoyNo ratings yet

- 100059s Zvlnena Tesneni (W1A, W11A, W2A ... )Document4 pages100059s Zvlnena Tesneni (W1A, W11A, W2A ... )brkmechNo ratings yet

- ManguerasDocument2 pagesManguerasErick RiverosNo ratings yet

- Kimmco-Isover Rigid Pipe Covering (K450)Document8 pagesKimmco-Isover Rigid Pipe Covering (K450)amirNo ratings yet

- The F990 Has Smooth Flow Characteristics, Abrasion, Erosion and Corrosion Resistance With A Crevice Free Internal ContourDocument4 pagesThe F990 Has Smooth Flow Characteristics, Abrasion, Erosion and Corrosion Resistance With A Crevice Free Internal ContourRobi KeiNo ratings yet

- Sanitary Fittings (MS 02 124 E) R2Document4 pagesSanitary Fittings (MS 02 124 E) R2herysyam1980No ratings yet

- Catalog A9: Sealing Rings Retaining RingsDocument48 pagesCatalog A9: Sealing Rings Retaining Ringsshrikant mishraNo ratings yet

- Push-In/threaded L-Fitting QSL-G1/8-6: Catalogue PageDocument4 pagesPush-In/threaded L-Fitting QSL-G1/8-6: Catalogue Pageabrap_dNo ratings yet

- ESP Cables: Exploration & ProductionDocument2 pagesESP Cables: Exploration & ProductionHimawan Sigit NugrohoNo ratings yet

- Roof SealDocument2 pagesRoof Sealmk779900mkNo ratings yet

- Dek TiteDocument4 pagesDek TiteJackyNo ratings yet

- Best practice guidance for firestopping openingsDocument19 pagesBest practice guidance for firestopping openingsWAlly PerezNo ratings yet

- Mercer Expansion JointsDocument8 pagesMercer Expansion JointskuraimundNo ratings yet

- Expansion JointDocument10 pagesExpansion JointMohammed BaquarNo ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring GasketsRitesh VishambhariNo ratings yet

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- Pipe List Working LATESTDocument2 pagesPipe List Working LATESTAnonymous Iev5ggSRNo ratings yet

- DGN Status 16.Document2 pagesDGN Status 16.Anonymous Iev5ggSRNo ratings yet

- Gr91 - DS2a2009 - Released Version by ECCC April09Document3 pagesGr91 - DS2a2009 - Released Version by ECCC April09Anonymous Iev5ggSRNo ratings yet

- FGD Bill of Materials for 693MW Power ProjectDocument4 pagesFGD Bill of Materials for 693MW Power ProjectAnonymous Iev5ggSRNo ratings yet

- 04 044 052 Spiroflex Spiral Wound GasketsDocument9 pages04 044 052 Spiroflex Spiral Wound Gasketsgazwang478No ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring GasketsRitesh VishambhariNo ratings yet

- Stock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightDocument4 pagesStock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightAnonymous Iev5ggSRNo ratings yet

- Coade Piping Stress Analysis SeminarDocument66 pagesCoade Piping Stress Analysis SeminarAnonymous Iev5ggSRNo ratings yet

- Ami Product Guide CatalogDocument50 pagesAmi Product Guide CatalogAnonymous Iev5ggSRNo ratings yet

- Everything You Need to Know About GRP PipesDocument24 pagesEverything You Need to Know About GRP PipesmgjorNo ratings yet

- Support Span Calculation FRP.Document2 pagesSupport Span Calculation FRP.Anonymous Iev5ggSRNo ratings yet

- Pipe Dimension and Support Span TableDocument4 pagesPipe Dimension and Support Span TableAnonymous Iev5ggSRNo ratings yet

- Snow Load As Weight Per MM Calculation 330Document1 pageSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRNo ratings yet

- Structural Detailing in SteelDocument253 pagesStructural Detailing in Steelandrugrasu100% (27)

- Pipe Thickness Calculation AS Per ASME 31.3Document11 pagesPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNo ratings yet

- Pipe Size CalculationDocument28 pagesPipe Size CalculationAnonymous Iev5ggSR100% (1)

- Senior Flexonics Expansion JointsDocument93 pagesSenior Flexonics Expansion JointssunethbabuNo ratings yet

- Tractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Document4 pagesTractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Anonymous Iev5ggSRNo ratings yet

- Diagrams Indicating Terminal PointsDocument6 pagesDiagrams Indicating Terminal PointsAnonymous Iev5ggSRNo ratings yet

- Bourdon Effect in CAESAR II: Intergraph CASDocument3 pagesBourdon Effect in CAESAR II: Intergraph CASAnonymous Iev5ggSR100% (1)

- En-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisDocument7 pagesEn-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisAnonymous Iev5ggSRNo ratings yet

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- STEAM TURBINE 3 Design and MaterialsDocument19 pagesSTEAM TURBINE 3 Design and MaterialsHandayani Kesumadewi100% (2)

- Turbocompressor For Aeration STC-GO - SiemensDocument6 pagesTurbocompressor For Aeration STC-GO - SiemensAnonymous Iev5ggSRNo ratings yet

- DM Water SystemDocument1 pageDM Water SystemAnonymous Iev5ggSRNo ratings yet

- LISEGA Catalog 2010Document7 pagesLISEGA Catalog 2010Olivier RioNo ratings yet

- PipeHanger DesignEngineering Catalog PDFDocument84 pagesPipeHanger DesignEngineering Catalog PDFRaheem_kaNo ratings yet

- 6303A HP Flare Drain DrumDocument16 pages6303A HP Flare Drain DrumMohammad MohseniNo ratings yet

- Oracle Database Question Bank 1Document5 pagesOracle Database Question Bank 1subbaraomca2010No ratings yet

- Adhokshaj Mishra: Thwarting The Surveillance in Online CommunicationDocument24 pagesAdhokshaj Mishra: Thwarting The Surveillance in Online CommunicationGauravRajNo ratings yet

- Application for Assistant Engineer PostDocument3 pagesApplication for Assistant Engineer PostKandasamy Pandian SNo ratings yet

- Air Pak SCBA Ordering Specifications (HS 6701)Document8 pagesAir Pak SCBA Ordering Specifications (HS 6701)QHSE ManagerNo ratings yet

- Cheat SheetDocument50 pagesCheat SheetAnubhav ChaturvediNo ratings yet

- Primary Mathematics Book 5Document87 pagesPrimary Mathematics Book 5joseph kunikina0% (1)

- A134 PDFDocument4 pagesA134 PDFJarbas MoraesNo ratings yet

- 3P61 Service Manual PDFDocument17 pages3P61 Service Manual PDFgulaab786No ratings yet

- Smart Payment MeterDocument2 pagesSmart Payment MeterJesus Castro OrozcoNo ratings yet

- Detector of FM SignalDocument4 pagesDetector of FM SignalR. JaNNaH100% (1)

- Trace MasterDocument29 pagesTrace Masterapi-3858801No ratings yet

- CHEST Workout Structure and Training Log PREVIEWDocument3 pagesCHEST Workout Structure and Training Log PREVIEWgaurav singhNo ratings yet

- GestioIP 3.0 Installation GuideDocument17 pagesGestioIP 3.0 Installation GuidepiterasNo ratings yet

- Battery Testing and MaintenanceDocument23 pagesBattery Testing and MaintenanceMormor Omerta0% (1)

- PERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedDocument4 pagesPERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedNadia KhanNo ratings yet

- Dealer FeedbackDocument3 pagesDealer FeedbackTarun BhatiNo ratings yet

- Cisco As5300 Voice GatewayDocument12 pagesCisco As5300 Voice GatewayAbderrahmane AbdmezianeNo ratings yet

- Tda 1526Document15 pagesTda 1526Adilcio Melo0% (1)

- Fundamentals 2014Document959 pagesFundamentals 2014Angelo Vittorio VettorazziNo ratings yet

- Dont CryDocument8 pagesDont CryIolanda Dolcet Ibars100% (1)

- Waukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsDocument6 pagesWaukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsLUISA FERNANDA TORRES MANOSALVANo ratings yet

- UFED Solutions Brochure WebDocument4 pagesUFED Solutions Brochure Webwilly irawanNo ratings yet

- Presentation On BAJAJDocument19 pagesPresentation On BAJAJVaibhav AgarwalNo ratings yet

- Abstracts Book Nanotech 2013Document151 pagesAbstracts Book Nanotech 2013felipe de jesus juarez torresNo ratings yet

- SEO ProposalDocument5 pagesSEO ProposalShivdev SaiNo ratings yet

- Cybersecurity-Student-Book Res Eng 1014Document38 pagesCybersecurity-Student-Book Res Eng 1014Nistor Andreea Maria100% (1)

- 1893 Shadow RunDocument6 pages1893 Shadow RungibbamonNo ratings yet

- Difference Between AND: Shahirah Nadhirah Madihah Suhana AtiqahDocument11 pagesDifference Between AND: Shahirah Nadhirah Madihah Suhana AtiqahShahirah ZafirahNo ratings yet

- Chapter 11B: Survey of Database SystemsDocument17 pagesChapter 11B: Survey of Database SystemsMurtaza MoizNo ratings yet