Professional Documents

Culture Documents

BMS Method Statement

Uploaded by

engin_eer0 ratings0% found this document useful (0 votes)

231 views9 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

231 views9 pagesBMS Method Statement

Uploaded by

engin_eerCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 9

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

1

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

Certifications

Testing & Commissioning

Procedure of Building

Management System(BMS)

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

2

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

Table of Contents

Contents Page No.

1. Purpose ................................................................................................................................... 3

2. Scope ...................................................................................................................................... 3

3. References .............................................................................................................................. 3

4. Instruments ............................................................................................................................ 3

5. Preliminary Check ................................................................................................................... 3

6. Testing Procedure .................................................................................................................. 4

7. Testing Forms ........................................................................................................................ 5

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

3

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

1. Purpose

This procedure prescribes a uniform set of methods for conducting

commissioning verification checks and functional tests of HVAC DDC Systems

(BMS).

2. Scope

1. definitions and terminology

2. a general description of method(s) provided

3. required information and conditions for initiating a check or test

4. recommendations for applying general protocols specific applications

5. uniform method(s) including identification of test equipment and

measurement points for performing such checks or tests

6. identification of requirements for acceptance

3. Reference

1. Project Specifications.

2. NEEB.

3. Manufacturer test sheet.

4. Instruments

1. Multi meter including AC/DC.

2. Clamp meters.

3. Thermometer.

4. Humidity meter.

5. Flow hood.

6. Flow-meter.

5. Preliminary Checks

The following general check list must be done before starting the test:

1. Proper pneumatic pressures and conditions

2. Proper electric voltage and amperages, and all circuits are free from

grounds or faults.

3. Integrity/safety of all electrical [and pneumatic] connections

4. Proper interface with fire and life safety systems

5. Identification of all necessary control settings determined from balancing

procedures including:

Optimum VAV duct pressure set points

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

4

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

VAV fan VFD minimum and maximum speed settings

VAV Return fan volume tracking settings

Minimum outside air damper settings for air handling units.

VAV box minimum and maximum volume settings.

Optimum differential pressure set points for variable speed

pumping.

Variable volume pumps VFD minimum and maximum speed

settings.

Verification of air-handler maximum design flow.

6. Testing, calibration, and setting of all digital and analog sensing and

actuating devices.

7. Checking and setting zero and span adjustments for all actuating devices.

8. Checking of each digital control point.

9. Programming and testing of all sequences of operation, schedules and set

points.

10. Proper tuning of all control loops.

6. Testing Procedure

6.1 Verification checks:

Those full range of physical inspections and checks that are conducted to

verify that specific components, equipment, systems, and interfaces between

systems conform to a given criteria. These checks typically verify proper

installation, start-up and initial contractor checkout, prior to equipment being

functionally tested.

Documentation checks: verify specifications, submittals, TAB report, pre-

commissioning report, as-built drawings, and training implementation.

Hardware/software installation checks: verify nameplate data, verify

installed characteristics, and verify system is operational.

Software implementation checks: verify AI, AO, DI/DO I/O points, verify

sensor calibrations; demonstrate offline setpoints, control sequence logic,

graphics, alarm codes and standard reports.

6.2 functional tests:

Those full range of tests that are conducted to verify that specific

components, equipment, systems, and interfaces between systems conform to a

given criteria. These tests are typically used to verify that a sequence of operation

is correctly implemented or that a design intent criterion has been met. They

typically are done after equipment is placed in full operation. Performance tests,

which include efficiency, capacity, load, monitoring and M&V or savings protocols,

are considered a subset of functional tests.

Software functionality tests.

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

5

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

Operational trend tests: observed range of control; can be used to verify

many control sequences.

Control sequence tests. Possible tests include: start/stop (on/off);

schedule (scheduled start/stop, optimum start/stop [includes warm-up and

cool-down], unoccupied setback [includes night purge], sweep); lead/lag

(includes runtime and equipment failure); staging; reset (including setpoint

change, control by flow and speed control); safeties; economizer; life

safety interface; power failure.

6.2 Networks (LAN/WAN):

The media that connects multiple intelligent devices. LAN (local area

network) implies a network over small geographic area. A building may have two

LANs, one for the building computer network and one for the DDC system. WAN

(wide area network) implies data transfer through a router. The most basic task of

the network is to connect the DDC controllers so that information can be shared

between them.

6.3 user interface devices:

Operator workstation (desktop computer with necessary software to

provide full access and operational capabilities to the entire DDC system); remote

workstation, also known as a portable terminal (laptop computer with necessary

software to provide full access and operational capabilities to the entire DDC

system from a remote location); mobile terminal station, also known as a hand-

held terminal (typically supplied and programmed by the vendor for specific set-up

tasks); smart stats (thermostats that allow a multiple hierarchy of user entered

offsets and adjustments); web browser (an internet based device with limited

software that provides some level of access and operational capabilities).

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

6

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

7. Test Forms.

Field device installation check form: (Sensors and Controlled Devices)

Device Name Installation Wiring Operation

Tem. sensor

Humidity sensor

Differential

pressure switch

Flow switch

Valves

Actuators

Dampers

Pressure sensor

Velocity sensor

Direct Digital Control (DDC) Panel Check form:

Panel

Name

Installation

verification

I/O points

setup check

Program

dawn

loaded

Network

operation

Stand alone

operation

DDC1

DDC2

DDC3

DDC4

DDC5

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

7

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

DDC6

Software and Graphical interface:

Software name:

System

name

Graphic

assembly

test

Commands

assembly test

Feedback

assembly

test

Alarm and

Alarm history

test

Time/

Date

Look Sound

Chiller

Boiler

AHU1

AHU2

Fire Fighting

Pump

Lighting

Transformer

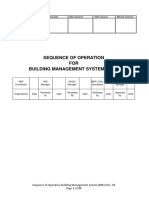

Sequence of Operation:

Controlled / Monitored

System

Sequence Of Operation

Acceptance

Remarks

Yes No

Chiller

Filled when final

sequence is approved

Boiler

Filled when final

sequence is approved

AHU1

Filled when final

sequence is approved

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

8

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

AHU2

Filled when final

sequence is approved

FCU

Filled when final

sequence is approved

Lighting

Filled when final

sequence is approved

Pumps

Filled when final

sequence is approved

Interface with other systems:

System Name Description of interface

Acceptance

Remarks

Yes No

Elevators

Fire Alarm

Access Door

Security

Power system

Generators

Transformers

Network test form:

Network

No.

Processor type Media Type Connection to

work station

Remarks

Commissioning, Testing & Balancing Procedure

For BMS System

P-511B Project

9

AMER BIN MALEK STREET- KHALDA -P.O.BOX 928497 AMMAN 11190 JORDAN

TEL.: 962-6-5346435 FAX: 962-6-5346435 WEB SITE: www.ees-jo.com

CERTIFIED COMMISSIONING, TESTING AND BALANCING OF HVAC SYSTEMS

You might also like

- DDC System Test Procedure-0831Document20 pagesDDC System Test Procedure-0831Abdul Mohid SheikhNo ratings yet

- BMS Method StatementDocument8 pagesBMS Method StatementIbrahim A. Hajjaj80% (5)

- IO Summary For IBMS Service PDFDocument348 pagesIO Summary For IBMS Service PDFpratimNo ratings yet

- QQ BMS Commissioning Method Statement-DraftDocument84 pagesQQ BMS Commissioning Method Statement-DraftAnonymous ixIhrPM271% (7)

- IBMS & HVAC SpecsDocument156 pagesIBMS & HVAC SpecsHumaid ShaikhNo ratings yet

- BMS Sequence of OperationDocument29 pagesBMS Sequence of Operationmohmmad alam Khan100% (1)

- M&E Works Risk MGMTDocument8 pagesM&E Works Risk MGMTSyaFiq MansoorNo ratings yet

- QQ BMS Commissioning Method Statement-DraftDocument84 pagesQQ BMS Commissioning Method Statement-DraftAbdelrahim Hussam Moubayed100% (1)

- The Central Business District: New Administrative CapitalDocument18 pagesThe Central Business District: New Administrative CapitalAbanoub HakeemNo ratings yet

- 23 3400 - Hvac Fans PDFDocument4 pages23 3400 - Hvac Fans PDFMohamed FawzyNo ratings yet

- Method Statement Submittal FOR Start-Up Commissioning of Air Cooled ChillersDocument14 pagesMethod Statement Submittal FOR Start-Up Commissioning of Air Cooled ChillersSamboy Dionisio100% (1)

- Lonix IBMS SpecificationDocument23 pagesLonix IBMS Specificationkakyo29433No ratings yet

- BMS SpecificationDocument10 pagesBMS SpecificationsharafanyNo ratings yet

- T&C of Pressurization UnitDocument6 pagesT&C of Pressurization UnitMohamed YousufNo ratings yet

- MVAC SpecificationDocument185 pagesMVAC Specificationhdung0375% (4)

- BMS Commissining ChecklistDocument52 pagesBMS Commissining ChecklistAnvay Patil100% (1)

- Ibms Design Based ReportDocument67 pagesIbms Design Based ReportShameel PtNo ratings yet

- AHU Operational Control Spreadsheet TrainingDocument17 pagesAHU Operational Control Spreadsheet Trainingniti860No ratings yet

- MEPF-Testing and Commissioning ChecklistDocument90 pagesMEPF-Testing and Commissioning ChecklistADEN LIUNo ratings yet

- Testing & Commissioning of Telephone Data SystemDocument1 pageTesting & Commissioning of Telephone Data Systemhaytham65No ratings yet

- Tech Spec - IbmsDocument128 pagesTech Spec - IbmsAnonymous NcB95G6XwNo ratings yet

- BMS Sequence of OperationsDocument18 pagesBMS Sequence of OperationsRa Ar100% (2)

- "Air Handling Unit": Testing and Commissioning Method Statement ForDocument15 pages"Air Handling Unit": Testing and Commissioning Method Statement Forselcuk pekenNo ratings yet

- Installation of AHUDocument4 pagesInstallation of AHUamg007No ratings yet

- AV SystemsCommissioningTestsChecklistDocument17 pagesAV SystemsCommissioningTestsChecklistKhaja Muqeem UddinNo ratings yet

- MS - BMSDocument19 pagesMS - BMSarun kurlanNo ratings yet

- DG BMSDocument12 pagesDG BMSatramanathanNo ratings yet

- BMS T&C ManualDocument25 pagesBMS T&C ManualRini Puspitasari100% (1)

- Vesdsa System Method StatementDocument39 pagesVesdsa System Method StatementNideesh RobertNo ratings yet

- MS For The Access Control System Installation and TerminationDocument21 pagesMS For The Access Control System Installation and Terminationwaaji snapNo ratings yet

- FAT HVAC, Acceptance RequirementsDocument120 pagesFAT HVAC, Acceptance RequirementsSalley Bukhari100% (2)

- Method Statement For Installation FAHUDocument10 pagesMethod Statement For Installation FAHUfidgetyNo ratings yet

- Section 26 08 00 - Electrical Systems Commissioning GeneralDocument6 pagesSection 26 08 00 - Electrical Systems Commissioning GeneralRenan Verolli Dal'AvaNo ratings yet

- Automation BuildingDocument32 pagesAutomation BuildingmohyousifNo ratings yet

- Plumbing CommissioningDocument5 pagesPlumbing CommissioningZineddine ALICHENo ratings yet

- Bms Tender SpecificationDocument19 pagesBms Tender SpecificationharishupretiNo ratings yet

- 26 09 43 - Lighting Control SystemDocument11 pages26 09 43 - Lighting Control Systemfahimyaseen8175No ratings yet

- Commissioning Mission Critical Facilities, HH Angus - 1445909328Document7 pagesCommissioning Mission Critical Facilities, HH Angus - 1445909328SargurusivaNo ratings yet

- Data Point Summary For Building Management SystemDocument3 pagesData Point Summary For Building Management SystemBasil Oguaka100% (2)

- Itcc Bms Io HvacDocument40 pagesItcc Bms Io Hvacuddinnadeem0% (1)

- Design Criteria MechanicalDocument35 pagesDesign Criteria MechanicalNoushad P HamsaNo ratings yet

- HVAC Commissioning Report PDFDocument117 pagesHVAC Commissioning Report PDFbambang sudarsono100% (1)

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- Quy Trinh T&C BMS Cho MVAC - Tham KhaoDocument79 pagesQuy Trinh T&C BMS Cho MVAC - Tham Khaovin ssNo ratings yet

- Sequence of OperationsDocument12 pagesSequence of Operationseyad100% (2)

- BMS Single Line Diagram Schedule of Points PDFDocument11 pagesBMS Single Line Diagram Schedule of Points PDFcalidad67% (3)

- 1.method of Statement - BMS - R0Document2 pages1.method of Statement - BMS - R0JaveedMdJaveedNo ratings yet

- DD Electric Driven Fire Pump SpecificationDocument16 pagesDD Electric Driven Fire Pump SpecificationNurcahyo Djati WNo ratings yet

- MST Installation of Pressurization UnitDocument10 pagesMST Installation of Pressurization Unitvictor100% (1)

- Standard: Building Management SystemsDocument64 pagesStandard: Building Management Systemssriteja79No ratings yet

- QQ BMS Commissioning Method Statement-DraftDocument83 pagesQQ BMS Commissioning Method Statement-DraftLarryBea100% (1)

- NT-Series UPS Installation and Commissioning Check ListDocument20 pagesNT-Series UPS Installation and Commissioning Check ListWalter AchayaNo ratings yet

- BMSDocument44 pagesBMSHari Krishna100% (5)

- BMS UbcDocument94 pagesBMS Ubcamhosny64No ratings yet

- BMS Sequence of OperationDocument2 pagesBMS Sequence of OperationRaja AntonyNo ratings yet

- Bms Proposal StepsDocument2 pagesBms Proposal StepsArman Ul NasarNo ratings yet

- Enterprise Buildings Integrator R500Document42 pagesEnterprise Buildings Integrator R500Danijel VucickiNo ratings yet

- Video Intercom Solution and Cabling SpecificationsDocument20 pagesVideo Intercom Solution and Cabling SpecificationsSaid GedeonNo ratings yet

- Testing & Commissioning of VAV (Variable Air Volume) Method Statement HQDocument4 pagesTesting & Commissioning of VAV (Variable Air Volume) Method Statement HQTerrence Gil Pamienta Buenaflor33% (3)

- Testing and Commissioning Procedure For Building Management SystemDocument8 pagesTesting and Commissioning Procedure For Building Management SystemJane NixonNo ratings yet

- 8e294532 24Document96 pages8e294532 24Ignacio MarínNo ratings yet

- HIF HS81 Brochure 4-2015Document8 pagesHIF HS81 Brochure 4-2015pvalverdea2014No ratings yet

- Sap On Aws OverviewDocument22 pagesSap On Aws OverviewTushil KumarNo ratings yet

- Ba2374092 04 en Tapcon260 BPL Iec61850Document168 pagesBa2374092 04 en Tapcon260 BPL Iec61850Eric DondebzangaNo ratings yet

- SCCM 2012 Part 1 NotesDocument50 pagesSCCM 2012 Part 1 NotesShivakumar S KadakalNo ratings yet

- Azure Top 20 Most Helpful InformationDocument183 pagesAzure Top 20 Most Helpful InformationSpl FriendsNo ratings yet

- Fx3u Enet Adp FlyerDocument4 pagesFx3u Enet Adp FlyerAlvaro Villalba TorresNo ratings yet

- 01-05 Best Practice For The Enterprise Multi-DC + Branch Solution (Multi-Hub Networking)Document192 pages01-05 Best Practice For The Enterprise Multi-DC + Branch Solution (Multi-Hub Networking)prasanthaf077No ratings yet

- HF LPB100 User Manual V1.5120140122Document76 pagesHF LPB100 User Manual V1.5120140122Claudiu PascuNo ratings yet

- Final Computer Architecture Individual AssignmentDocument33 pagesFinal Computer Architecture Individual AssignmentMichelle FernandoNo ratings yet

- A+ Core 2 220-1002Document61 pagesA+ Core 2 220-1002Angel Gabriel De la CruzNo ratings yet

- Documentation: Original: H:/Dokumentation/Rsv-PCX/Word - Dokumente/RRTN - 1200 - GBDocument38 pagesDocumentation: Original: H:/Dokumentation/Rsv-PCX/Word - Dokumente/RRTN - 1200 - GBwilliam_malonzoNo ratings yet

- Learning Material - System Analysis and DesignDocument697 pagesLearning Material - System Analysis and Designtaurus_vadivelNo ratings yet

- MSC CA&It Syllabus 7to10 NoncbcsDocument59 pagesMSC CA&It Syllabus 7to10 NoncbcsRaj AkhaniNo ratings yet

- MTechDocument11 pagesMTechtamleduc1810dnNo ratings yet

- DGS F1018P E - DsDocument3 pagesDGS F1018P E - DsferdyhernawanNo ratings yet

- Microsoft 365 Communityver1fromMSDocument741 pagesMicrosoft 365 Communityver1fromMSbachankNo ratings yet

- EduCloud Pte LTDDocument17 pagesEduCloud Pte LTDMurtuzaNo ratings yet

- OV 2500 NMS-E 4.4R2 Installation and Upgrade Guide - RevDDocument178 pagesOV 2500 NMS-E 4.4R2 Installation and Upgrade Guide - RevDamel632No ratings yet

- Technical Seminar Documentation On 3D Internet: M.Grace Beryl 10RG1A0571 C.S.EDocument20 pagesTechnical Seminar Documentation On 3D Internet: M.Grace Beryl 10RG1A0571 C.S.EAman SharmaNo ratings yet

- Redtacton IEEE ReportDocument9 pagesRedtacton IEEE ReportBhavikk Kotadia86% (7)

- Ethernet I/O Modules: ADAM-6000: Communication Controller Wireless LAN Input/Output Ethernet NetworkingDocument18 pagesEthernet I/O Modules: ADAM-6000: Communication Controller Wireless LAN Input/Output Ethernet NetworkingMarcello LechterNo ratings yet

- Wireless Communications and Security Issues Associated With The Wireless Application Protocol (WAP)Document13 pagesWireless Communications and Security Issues Associated With The Wireless Application Protocol (WAP)decentankiNo ratings yet

- Vance Jensen Resume 10Document2 pagesVance Jensen Resume 10api-509258897No ratings yet

- Assessment of Cybercrime Governance in EthiopiaDocument8 pagesAssessment of Cybercrime Governance in Ethiopiadevid mandefroNo ratings yet

- MIS Chapter 1Document56 pagesMIS Chapter 1Robeir AmirNo ratings yet

- Chapter4 - Network AssuranceDocument17 pagesChapter4 - Network AssuranceBeza GetachewNo ratings yet

- Web 3Document4 pagesWeb 3priyanka MORENo ratings yet

- Tron 40VDR Float Free Capsule Inst & Tech ManualDocument16 pagesTron 40VDR Float Free Capsule Inst & Tech Manualleo.wainer50% (2)

- ALU IP Products-Oct-2009 2Document60 pagesALU IP Products-Oct-2009 2Assoumane IssoufouNo ratings yet