Professional Documents

Culture Documents

Costing of Joining Methods - Arc Welding Costs

Uploaded by

TasmanijskaNema0 ratings0% found this document useful (0 votes)

22 views27 pagesCosting of Joining Methods -

Arc Welding Costs

Original Title

Arc Costs

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCosting of Joining Methods -

Arc Welding Costs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views27 pagesCosting of Joining Methods - Arc Welding Costs

Uploaded by

TasmanijskaNemaCosting of Joining Methods -

Arc Welding Costs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 27

Costing of J oining Methods -

Arc Welding Costs

ver. 1

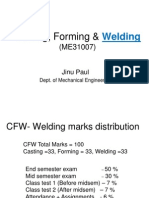

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

1

Overview Overview

Cost components

Estimation of costs Estimation of costs

Examples

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

2

Cost Components Cost Components

Materials

Labor Labor

Overhead

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

3

Materials Costs Materials Costs

Electrodes Electrodes

Some electrode sticks contain flux

Amount of electrode times electrode cost Amount of electrode times electrode cost

per unit weight gives electrode cost

Fluxes / Shielding gases Fluxes / Shielding gases

Quantity of flux and/or shielding gas

required times unit costs gives flux/gas required times unit costs gives flux/gas

cost

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

4

Material Costs Material Costs

Other consumables

may include cost of electricity, if not in may include cost of electricity, if not in

overhead

rags, files, blades, chisels. g , , ,

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

5

Labor Labor

Di t ti f ldi Direct time of welding

time to produce a length of weld

labor rate

multiplication gives labor cost per length

Set-up time, etc.

Personal time Personal time

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

6

Overhead Rate Overhead Rate

Usually a percentage of direct labor rate

Ranges from50 - 400% Ranges from 50 400%

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

7

Deposition Efficiency Deposition Efficiency

N t ll l t d i d it d ld Not all electrode is deposited as weld

lost as splatter, vaporization

stub ends left

Stick-electrode welding - 65%

Self-shielded, flux-cored welding - 82%

Arc welding with shielding gas - 92% Arc welding with shielding gas 92%

Submerged arc welding - 100%

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

8

Operator Efficiency Operator Efficiency

Welding time

Personal time

Set-up time

Electrode changing time g g

Slag chipping time (for subsequent passes)

poor weld quality increases time p q y

Time to beat weld to remove residual

stresses

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

9

Manual Operator Efficiency Manual Operator Efficiency

10 - 45%

65% is extreme of human achievement

Personal breaks

Set-up

Change position

Change electrodes g

De-slagging

Removing residual stresses

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

10

Removing residual stresses

Semi automatic Efficiency Semi-automatic Efficiency

25 - 60%

no need to change electrodes no need to change electrodes

wire used

higher currents speeds higher currents, speeds

some processes require no de-slagging

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

11

Automatic Efficiency Automatic Efficiency

Over 90%

if small set-up time, de-slagging time if small set up time, de slagging time

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

12

Cost Components Cost Components

Cost of electrode/length of weld

=(WE)(CE) (WE)(CE)

Cost of flux/length of weld

=(WF)(CF) =(WF)(CF)

Cost of gas/length of weld

(VG)(CG) =(VG)(CG)

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

13

Materials Cost/ Length (CM) Materials Cost/ Length (CM)

CM=(WE)(CE)+(WF)(CF)+(VG)(CG) CM (WE)(CE) (WF)(CF) (VG)(CG)

WE =weight of electrode WE = weight of electrode

CE = cost of electrode ($/wt)

WF weight of flux WF = weight of flux

CF = cost of flux ($/wt)

VG l f VG = volume of gas

CG = cost of gas ($/vol)

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

14

Labor Cost (CL) Labor Cost (CL)

CL = (t) (CR) / (OF)

t = time / length of weld

CR t f l b h d ($/ti ) CR = cost of labor + overhead ($/time)

OF = operating factor (efficiency)

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

15

Labor Cost (CL) Labor Cost (CL)

Alternatively Alternatively,

t = 1/S

S d f ld S = speed of weld

CL = (CR) / S (OF)

1 1 1

note

...

1 1

2 1

+ +

=

S S

n

S

n

S S S

t

1

...

1 1

2 1

+ + + =

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

16

2 1

S S

Metal Deposition vs Labor Cost Metal Deposition vs. Labor Cost

1 1

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

17

Labor cost $/ ft of weld

Estimated Cost of Consumables Estimated Cost of Consumables

gas = 25-45 ft

3

/hr, solid flux = wt of deposited metal, 1973 prices

Process Type of

Electrode

Electrode

Cost ($/lb)

Deposition

Efficiency

Cost of

Deposited

(%) Metal

$/lb $/ft

Shielded

metal arc

E7024 0.191 65 0.29 0.045

metal arc

Self-shielded,

flux-cored

E70T-G 0.315 82 0.38 0.059

Submerged EL12 0.199 +flux 100 0.34 0.053 Sub eged

arc

0. 99 u 00 0.3 0.053

Gas metal-arc E70S-3 0.243 +flux 92 0.31 0.048

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

18

Estimated Costs Estimated Costs

All about 5/ft.

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

19

Trade-off Example p

1/4 fillet weld, 3/32 E7024 electrode,

85 ft/hr, operating factor 30%, labor +

overhead $7/hr

CL = (CR)/S(OF)

CL=(7)/85(0 3) =$0 275/ft CL=(7)/85(0.3) = $0.275/ft

Can you increase efficiency somehow?

40% -> $0.206/ft

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

20

Comparative Costs Comparative Costs

Factor E8018 Electrode and

Manual Welding

9000C-1 Wire and

Semi-automatic

W ldi Welding

Labor and overhead rate (CL) $20/hr $20/hr

Deposition rate (D) 3.11 lb/hr 5 lb/hr

Operating factor (OF) 0.3 0.45 p g ( )

Cost of labor and overhead to

deposit weld

$21.43/lb of weld $8.88/lb of weld

Electrode cost (CE) $0.667/lb $1.019/lb

Depositionefficiency(DE) 068 078 Deposition efficiency (DE) 0.68 0.78

Cost of deposited metal $0.98/lb $1.31/lb

Shielding gas flow rate (VG) none 40 ft

3

/hr

Cost of shielding gas (CG) $0.72/lb dep. metal gg ( ) p

Cost of welding $22.41/lb dep. metal $10.91/lb dep. metal

Labor cost seriously offsets cheap stick cost

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

21

Costs of Various Processes

(relative for guidance)

P A d O ti L b d W ldC t Process Arc speed

(ft/hr)

Operating

Factor

Labor and

Overhead ($/hr)

Weld Cost

($/ft)

Shielded metal-

arc

85 0.3 7 0.274

Shielded metal-

arc

85 0.4 7 0.206

Gas metal-arc

i t ti

80 0.5 7 0.175

semi-automatic

Self-shielded

flux-cored, semi-

auto

100 0.5 7 0.140

Submerged arc

semi-auto

110 0.5 7 0.127

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

22

Weld Comparison for Mild Steel

b c a

d

f e

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

23

Weld Comparison Example p p

1/4 diameter, manual metal-arc electrode

with solid flux attached 320 A (a) with solid flux attached, 320 A (a)

Deposition rate 6.25 lb/arc-hr (b)

Weld required 0.6 lb of weld metal/ft (c)

Welding speed 2 in/min (5.75 arc-

minutes/ft) (d)

Operating factor 20%(e) Operating factor 20% (e)

Time is 28.75 minutes/ft, labor cost at

$8/hr is $3 83/ft of weld (f)

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

24

$8/hr is $3.83/ft of weld (f)

Other Issues Other Issues

Calculations show what can happen, if

you have the correct equipment. y q p

Other costs

depreciation taxes etc depreciation, taxes, etc.

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

25

Summary Summary

Costs of arc welding can be calculated

Calculations give you guidance on: Calculations give you guidance on:

process selection

operating condition targets operating condition targets

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

26

ME 6222: Manufacturing Processes and Systems

Prof. J .S. Colton GIT 2009

27

You might also like

- Productivity and EcononyDocument69 pagesProductivity and EcononyVijayan MunuswamyNo ratings yet

- Welding Cost Estimating: Lecture No 3 DR Arwa HusseinDocument42 pagesWelding Cost Estimating: Lecture No 3 DR Arwa HusseinArwa HusseinNo ratings yet

- Casting Defects and Design Issues: ME 6222: Manufacturing Processes and Systems Prof. J.S. Colton © GIT 2009 1Document37 pagesCasting Defects and Design Issues: ME 6222: Manufacturing Processes and Systems Prof. J.S. Colton © GIT 2009 1heart1985No ratings yet

- Welding Cost Estimation For 12 Joints in 8 NPS Sch. 80Document1 pageWelding Cost Estimation For 12 Joints in 8 NPS Sch. 80WeldPulse100% (2)

- Fusion ProcDocument26 pagesFusion Procdip_maanNo ratings yet

- Price Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost ItemDocument11 pagesPrice Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost Itemchompink6900No ratings yet

- Teknik Las: Dr. Ario Sunar Baskoro, ST, MT, MengDocument29 pagesTeknik Las: Dr. Ario Sunar Baskoro, ST, MT, MengMuhammadRiadyNo ratings yet

- Information About Welding Method and Joint Configuration:: Project: Test, Weld Number: Test 1Document1 pageInformation About Welding Method and Joint Configuration:: Project: Test, Weld Number: Test 1carrotironNo ratings yet

- Weld Cost CalculationDocument30 pagesWeld Cost CalculationDenial BasanovicNo ratings yet

- Handbook - Calculations0Document10 pagesHandbook - Calculations0paimpillyNo ratings yet

- GMAW Butt Joint Project ReportDocument43 pagesGMAW Butt Joint Project ReportahmedNo ratings yet

- Welding Rods InfoDocument9 pagesWelding Rods InfoSeju CherianNo ratings yet

- Flux Cored WireDocument38 pagesFlux Cored WireKentDemeterioNo ratings yet

- Welding Economy and ProductivityDocument29 pagesWelding Economy and Productivitykmas1612100% (4)

- Lesson 9Document23 pagesLesson 9Huynh Thanh TamNo ratings yet

- Fabrication Methods (Welding)Document84 pagesFabrication Methods (Welding)Karthikeyan MurugananthanNo ratings yet

- Practice 01 3.1document1Document11 pagesPractice 01 3.1document1Rob WillestoneNo ratings yet

- Weld Cost1Document25 pagesWeld Cost1Denis Hinojosa ZeballosNo ratings yet

- Everything You Need to Know About WeldingDocument49 pagesEverything You Need to Know About WeldingproxywarNo ratings yet

- Welding Questionaire: Duties and Responsibilities of Welding InspectorDocument32 pagesWelding Questionaire: Duties and Responsibilities of Welding Inspectorshaynad binsharafNo ratings yet

- Arc Welding, Shielded Metal Arc Welding, Metal Inert Gas WeldingDocument44 pagesArc Welding, Shielded Metal Arc Welding, Metal Inert Gas WeldingDinesh InavoluNo ratings yet

- Weld CalculationDocument13 pagesWeld CalculationAdnan RanaNo ratings yet

- ESAB Calculating Filler Metal Consumption PDFDocument10 pagesESAB Calculating Filler Metal Consumption PDFRuben Cruz S0% (2)

- WeldingDocument52 pagesWeldingPhani Sridhar ChNo ratings yet

- Workshop Case StudyDocument13 pagesWorkshop Case Study1071Vishal kumarNo ratings yet

- CIGWELD DEPOSITION DATADocument7 pagesCIGWELD DEPOSITION DATAgitaNo ratings yet

- Module - IIDocument48 pagesModule - IIsivasaNo ratings yet

- Introduction To Cost EstimatingDocument22 pagesIntroduction To Cost EstimatingArwa HusseinNo ratings yet

- Weld Cost CalculationDocument27 pagesWeld Cost Calculation-Abdul Khodir Van Java-100% (7)

- Machining Economics 1Document8 pagesMachining Economics 1Yosef Mario KNo ratings yet

- FLUX CORED WIRES FOR SHIPBUILDING AND STRUCTURESDocument1 pageFLUX CORED WIRES FOR SHIPBUILDING AND STRUCTUREScamelod555No ratings yet

- Chapter 22: Materials Selection: Economic, Environ., & Design IssuesDocument17 pagesChapter 22: Materials Selection: Economic, Environ., & Design Issuesanton_deocampoNo ratings yet

- HVDC Transmission Line DesignDocument55 pagesHVDC Transmission Line DesignJamal khanNo ratings yet

- Wielding Process Jayme 2 FinalDocument28 pagesWielding Process Jayme 2 FinalJAYME JOSWANo ratings yet

- MIG Welding ProcessDocument12 pagesMIG Welding ProcessHimanshu RaoNo ratings yet

- Overview of EurocodesDocument27 pagesOverview of EurocodesbsitlerNo ratings yet

- Current Transformer Rev1Document26 pagesCurrent Transformer Rev1adi_sofa100% (1)

- Document 19394 Section 13214Document6 pagesDocument 19394 Section 13214Brian LukeNo ratings yet

- Duties of Welding InspectorDocument11 pagesDuties of Welding Inspectormuhammadazhar50% (2)

- Selected Welding Application in Offshore IndustryDocument38 pagesSelected Welding Application in Offshore IndustryzuudeeNo ratings yet

- Determining The Cost of WeldingDocument22 pagesDetermining The Cost of WeldingSanjay J NNo ratings yet

- Casting Defects and Design Issues PDFDocument39 pagesCasting Defects and Design Issues PDFPANKAJ kUMARNo ratings yet

- Casting, Forming & WeldingDocument90 pagesCasting, Forming & WeldingmahdiNo ratings yet

- Dieless Wire DrawingDocument8 pagesDieless Wire DrawingRohit GothwalNo ratings yet

- SEO Busbar Welding Code GuideDocument28 pagesSEO Busbar Welding Code GuideCourage MurevesiNo ratings yet

- Estimation of Welding CostDocument41 pagesEstimation of Welding CostAnkur2592% (13)

- Weld Metal Cost Calculator 3Document1 pageWeld Metal Cost Calculator 3Naresh Tammineedi100% (1)

- AWSPipeWeld - American Welding SocietyDocument2 pagesAWSPipeWeld - American Welding Societybarukomkss100% (1)

- 2 Joining ProcessDocument54 pages2 Joining ProcessIzzah Suhair Binti Sa'AbanNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- MJ-WG-8 Cam Weld Gauge Measures WeldsDocument1 pageMJ-WG-8 Cam Weld Gauge Measures WeldsTasmanijskaNemaNo ratings yet

- ISO 15614-1 - 2004 - Red Corr 2008-6Document5 pagesISO 15614-1 - 2004 - Red Corr 2008-6TasmanijskaNemaNo ratings yet

- SCC 9 PDFDocument1 pageSCC 9 PDFTasmanijskaNemaNo ratings yet

- Control of Stress Corrosion CrackingDocument1 pageControl of Stress Corrosion CrackingTasmanijskaNemaNo ratings yet

- Binder9 PDFDocument10 pagesBinder9 PDFTasmanijskaNemaNo ratings yet

- Stress Corrosion Cracking Mechanisms and PreventionDocument1 pageStress Corrosion Cracking Mechanisms and PreventionTasmanijskaNemaNo ratings yet

- Sol Celle PanelDocument1 pageSol Celle PanelTasmanijskaNemaNo ratings yet

- ISO 15614-1 - 2004 - Red Corr 2008-7Document3 pagesISO 15614-1 - 2004 - Red Corr 2008-7TasmanijskaNemaNo ratings yet

- Conclusions: Temperature (°C)Document1 pageConclusions: Temperature (°C)TasmanijskaNemaNo ratings yet

- Living With SCC: Stress CorrosionDocument1 pageLiving With SCC: Stress CorrosionTasmanijskaNemaNo ratings yet

- SCC 5Document1 pageSCC 5TasmanijskaNemaNo ratings yet

- SCC 7 PDFDocument1 pageSCC 7 PDFTasmanijskaNemaNo ratings yet

- SCC 1Document1 pageSCC 1TasmanijskaNemaNo ratings yet

- Stress Corrosion: CrackingDocument1 pageStress Corrosion: CrackingTasmanijskaNemaNo ratings yet

- ISO 15614-1 - 2004 - Red Corr 2008-2Document5 pagesISO 15614-1 - 2004 - Red Corr 2008-2TasmanijskaNemaNo ratings yet

- Uns S 32760 - 7&8 PDFDocument2 pagesUns S 32760 - 7&8 PDFTasmanijskaNemaNo ratings yet

- ISO 15614-1 - 2004 - Red Corr 2008-1Document5 pagesISO 15614-1 - 2004 - Red Corr 2008-1TasmanijskaNemaNo ratings yet

- Uns S 32760 - 1&2Document2 pagesUns S 32760 - 1&2TasmanijskaNemaNo ratings yet

- Uns S 32760 - 5&6Document2 pagesUns S 32760 - 5&6TasmanijskaNemaNo ratings yet

- Uns S 32760 - 6Document1 pageUns S 32760 - 6TasmanijskaNemaNo ratings yet

- Uns S 32760 - 6Document1 pageUns S 32760 - 6TasmanijskaNemaNo ratings yet

- Uns S 32760 - 6Document1 pageUns S 32760 - 6TasmanijskaNemaNo ratings yet

- Esab Storage HandlingDocument4 pagesEsab Storage HandlingTasmanijskaNema100% (1)

- Uns S 32760 - 3Document1 pageUns S 32760 - 3TasmanijskaNemaNo ratings yet

- Development of UNS S 32760Document8 pagesDevelopment of UNS S 32760TasmanijskaNemaNo ratings yet

- SCC 1Document1 pageSCC 1TasmanijskaNemaNo ratings yet

- Bohler Welding 1%nickel - CatalogueDocument8 pagesBohler Welding 1%nickel - CatalogueTasmanijskaNemaNo ratings yet

- Development of UNS S 32760Document8 pagesDevelopment of UNS S 32760TasmanijskaNemaNo ratings yet

- Stress Corrosion: CrackingDocument1 pageStress Corrosion: CrackingTasmanijskaNemaNo ratings yet

- Stress Corrosion Cracking Mechanisms and PreventionDocument1 pageStress Corrosion Cracking Mechanisms and PreventionTasmanijskaNemaNo ratings yet

- Measuring Principles Lecture on Sources of ErrorDocument18 pagesMeasuring Principles Lecture on Sources of ErrorAbhinav SinglaNo ratings yet

- Freesmachine Falcon HandleidingDocument198 pagesFreesmachine Falcon Handleidingmad zollaNo ratings yet

- Justification Proposed RecloserDocument3 pagesJustification Proposed Recloserjominique ferrerNo ratings yet

- Installation and user guide for PLATINUM invertersDocument90 pagesInstallation and user guide for PLATINUM invertersElyes MbarekNo ratings yet

- KOOV Educator Kit SONYDocument8 pagesKOOV Educator Kit SONYAlfonso CalderonNo ratings yet

- 28V, Low Iq, High Current, Fixed 3.3V-8A Synchronous Buck Converter With 100 Ma LDODocument18 pages28V, Low Iq, High Current, Fixed 3.3V-8A Synchronous Buck Converter With 100 Ma LDORonytec SuporteNo ratings yet

- Electrical System Design GuidelinesDocument125 pagesElectrical System Design Guidelinescarlosmarciosfreitas100% (1)

- RF Circuit Design Ludwig Solution Manual - Free PDF DownloadsDocument4 pagesRF Circuit Design Ludwig Solution Manual - Free PDF Downloadssree4790% (3)

- Leaflet UPS H 15 30kVA en UsDocument2 pagesLeaflet UPS H 15 30kVA en UsEmilio KowalskiNo ratings yet

- W005F.... W10F: 1.5 A 50 V To 1000 VDocument4 pagesW005F.... W10F: 1.5 A 50 V To 1000 VBraulio Manuel Trejo PerezNo ratings yet

- RF FiltersDocument10 pagesRF Filtersec academicNo ratings yet

- High performance BIT3713 PWM controller datasheetDocument11 pagesHigh performance BIT3713 PWM controller datasheetRodolfo CarruyoNo ratings yet

- An 931 Appnote Ad7689Document4 pagesAn 931 Appnote Ad7689Gunta AkhiriNo ratings yet

- Ultra Fast Avalanche Sinterglass Diode Specifications and Data SheetDocument7 pagesUltra Fast Avalanche Sinterglass Diode Specifications and Data SheetRey TiburonNo ratings yet

- 55 - B - 5 - Physics For VI CandidatesDocument27 pages55 - B - 5 - Physics For VI CandidatesOm TripathiNo ratings yet

- Section 13 BASIC PUMP SIZING FOR ESPDocument69 pagesSection 13 BASIC PUMP SIZING FOR ESPYassin MuhssenNo ratings yet

- Distribution Substation Manual IntroductionDocument18 pagesDistribution Substation Manual Introductionharisanju123No ratings yet

- Panasonic Tc-p55vt50 Chassis Gpf15duDocument108 pagesPanasonic Tc-p55vt50 Chassis Gpf15duOK100% (1)

- Thermoelectric Cooler2Document33 pagesThermoelectric Cooler2Ahmad ShujaNo ratings yet

- Lab 2 - Transistor BiasDocument12 pagesLab 2 - Transistor Biascrackintheshat100% (1)

- Physics ProjectDocument9 pagesPhysics ProjectAkshata AnkolekarNo ratings yet

- NA1 Air Circuit Breaker: Empower The WorldDocument56 pagesNA1 Air Circuit Breaker: Empower The WorldIbrahim Al-AssraNo ratings yet

- HBT-6200 Field TelephoneDocument2 pagesHBT-6200 Field TelephonePanglima EtwinNo ratings yet

- Datasheet M 2000ia 2300Document1 pageDatasheet M 2000ia 2300carlosdr.05.09.1993No ratings yet

- Arsenic For High Capacity Lithium and Sodium-Ion BatteriesDocument11 pagesArsenic For High Capacity Lithium and Sodium-Ion BatteriesLIZANA QUISPE ELMER ARSENIONo ratings yet

- Tesla Switch Solar Charger To Debut at Bedini ConferenceDocument8 pagesTesla Switch Solar Charger To Debut at Bedini Conferenceutorrent411No ratings yet

- Methods For Coordinating System Protective EquipmentDocument17 pagesMethods For Coordinating System Protective EquipmentMichael Parohinog GregasNo ratings yet

- TCM E80 M en 160520 E004Document116 pagesTCM E80 M en 160520 E004Eduardo ContrerasNo ratings yet

- WELDINGDocument51 pagesWELDINGStewart StevenNo ratings yet

- Ta 3404 8 60 PDFDocument1 pageTa 3404 8 60 PDFkapaiNo ratings yet