Professional Documents

Culture Documents

The Power of Wear Rings

Uploaded by

Vinh Do Thanh0 ratings0% found this document useful (0 votes)

89 views18 pagesThe Power of Wear Rings

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Power of Wear Rings

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

89 views18 pagesThe Power of Wear Rings

Uploaded by

Vinh Do ThanhThe Power of Wear Rings

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 18

The Power of Wear Rings, Part 1

Written by Robert Aronen, Boulden International

Understand the Lomakin Effect

Reliability leaders view every repair as an opportunity for improvement. After all, most process

plants in Europe and North America are more than 20 years old. It makes little sense to assume

that the original equipment supplied in the 1970s is up to the task of increasing requirements for

reliability, efficiency, environmental protection and safety.

One simple upgrade that can be performed at the time of repair is the installation of nonmetallic

wear rings with reduced clearance. With modern composite materials, wear ring clearance can be

reduced to 50 percent of the API recommended minimum standard. This change increases pump

reliability, efficiency and safety.

Part 1 of this series will address the reliability benefits. Part 2 will address efficiency gains, and

Part 3 will address safety. This upgrade is not new, but during the past few years, installing

nonmetallic wear rings has become a standard upgrade for many process plants. After nearly two

decades of field experience, nonmetallic wear rings have become part of the industry standard.

API 610 11th Edition (ISO13709:2009), Centrifugal Pumps for Petroleum, Petrochemical, and

Natural Gas Industries, recognizes the use of nonmetallic wear rings with reduced clearance.

Figure 1a. (right) Concentric rotor end view

The Lomakin Effect

Reducing the wear ring clearance in a centrifugal pump is a significant reliability upgrade

because it increases rotor damping and stiffness in the pump. In more practical terms, reducing

wear ring clearance decreases vibration and shaft deflection.

The relationship between shaft deflection and reliability is clearly known. Unfortunately, that

wasnt always true. The pump designs of the 1960s, 1970s and 1980s did not anticipate current

standards for reliability and mechanical seal performance. The main problem with these older

pumps is that the shafts are typically too long, too thin and

too flexible. This results in excessive shaft deflection and inadequate mechanical seal life.

The members of the API 610 committee recognized the flaws of older designs and from API 610

7th Edition onward have implemented design requirements to minimize shaft deflection. For new

single and two-stage pumps, API 610 11th Edition recommends: To obtain satisfactory seal

performance, the shaft stiffness shall limit total deflectionto under 0.05 millimeters (0.002

inches) at the primary seal faces. (American Petroleum Institute)

Figure 2. (below) The airplane wing. Higher velocity over the top of the wing results in an

area of relatively lower pressure. Lower velocity under the wing results in a relatively

higher pressure. The result is upwards force (lift) that allows the airplane to fly.

For older pumps, the major pump manufacturers sell upgrade packages that replace the bearing

housing, seal chamber and shaft of the pump. The marketing material for these products

inevitably touts increased shaft stiffness and improved mechanical seal life as advantages.

Certainly, both new pumps and retrofits are excellent solutions to the problem of excessive shaft

deflection. Unfortunately, most process plants have hundreds of older pumps that would benefit

from an upgrade, and these options are often economically viable for only a small segment of the

pump population.

Figure 1b. (right) Concentric rotor side view. Differential pressure from discharge pressure

(Pd) to suction pressure (Ps) produces an axial flow of liquid across the wear rings.

The good news is that shaft stiffness comes from two factorsrotor design and wear rings. An

older plant can use the power of the wear rings to increase the shaft stiffness for hundreds of

pumps.

The stability generated by the wear rings is generally referred to as the Lomakin Effect, which is

driven by the differential pressure across the rings. The wear ring is a barrier between discharge

pressure (Pd) and suction pressure (Ps). The differential pressure across this interface creates an

axial flow velocity as shown in Figures 1a and 1b.

The Lomakin Effect can sometimes be confusing because it encompasses two separate

phenomena that occur at the wear rings: damping and stiffness. Damping does not directly

prevent shaft deflection, but minimizes rotor response to excitation forcesmuch in the same

way that shock absorbers result in a smooth ride in a car. Reduced clearance increases damping

and results in a more stable rotor (Mancini).

Reduced clearance also increases shaft stiffness. The additional stiffness is derived from a

positive corrective force which occurs whenever the rotor becomes eccentric. It works similar to

an airplane wing (Figure 2), where the difference in relative velocities creates a force due to

differential pressure.

A similar situation occurs when a centrifugal pump experiences shaft deflection. The pump rotor

is exposed to multiple loads such as the weight of the rotor, hydraulic forces and unbalance to

name a few. The result is shaft deflection and a rotor that runs off-center (Figure 3a and 3b).

When this happens, the axial flow across the wear ring changes, with higher flow and velocity on

the side with larger clearance and lower flow and velocity on the side with less clearance. The

stiffness generated from these forces is known as the Lomakin Effect.

Perhaps most important, the stiffness and damping are located at the impeller where the pump

has no bearing support. This strategic location gives the Lomakin Effect a great

deal of power in minimizing shaft deflection (Figure 5).

Combine the increased damping and stiffness, and a pump with reduced clearance runs with

lower vibration, less shaft deflection and a longer life than a pump with standard

clearance.

Figure 3a. (below left) Non-concentric rotor end view. Higher axial flow will occur in areas

with more clearance; lower axial flow will occur in areas with less clearance.

Figure 3b. (above right) Non-concentric rotor side view. The relative difference in velocity

(V1 > V2) results in a net corrective force on the rotor--i.e. The Lomakin Effect.

Case Studies

The reliability impact from reduced wear ring clearance has been documented in numerous case

studies during the past two decades. A recent study looked at repair data, vibration data and seal

leakage data for 61 pumps installed in a North American refinery. The data was compiled for

several years before the installation of composite wear rings with reduced clearance and for an

equal period after the conversion (Aronen, Boulden, Russek). The results are shown in Table 1.

Figure 4. Inverse relationship of Lomakin stiffness coefficient to wear ring clearance.

After the conversion to composite wear rings with reduced clearances, the pumps were

significantly more reliable, ran with lower vibration and experienced fewer seal leaks. Several

other individual case studies have shown similar results. Studies of older pumps have shown

overall vibration levels reduced by as much as 90 percent (Komin, 1985). Other studies have

shown increased life and/or reduced vibrations in hydrocarbon (Pledger), boiler feed water

(Aronen, Plaizier, Sinclair) and condensate services (DuPont).

This upgrade can be of particular benefit with older designs. A 1997 paper highlighted the

upgrade of several two-stage overhung pumps. The results from these upgrades showed

increased performance, reduced vibration and increased mean time between repair (MTBR)

(Pumps and Systems). Even though the two-stage overhung

design is now considere obsolete, many of these pumps continue to operate because replacement

with a betweenbearings design is cost prohibitive.

Figure 5. Lomakin-induced stiffness is located at the impeller where the pump needs it.

Cost of Upgrade

Upgrading with composite wear rings is possibly the most costeffective way to improve the

reliability of existing pumps. The upgrade can be performed as part of a standard repair, does not

typically require additional machinery modifications and should not add substantial time or

complexity to the repair.

Factor Considered Change

Annual Repairs

45 percent decrease in

repairs

Average Overall

Vibration Level

25 percent decrease in

overal vibration

Annual seal leaks (VOC

services)

67 percent decrease in

recorded seal leaks

Table 1. Results from Refinery Study of 61 Pumps

The upgrade cost of composite wear rings is primarily the added expense of an advanced

composite material in place of a traditional material, such as 400 series stainless steel, cast iron

or bronze. The cost varies widely based on the type and size of the pump. For example, the

added cost of composite material for a small, singlestage pump should be less than $1,000.

Whereas, for a large, multi-stage pump, a composite material upgrade can cost more than

$15,000.

Keeping in mind this huge variation, experience suggests that the average cost of a composite

wear ring upgrade is in the range of $3,000. At this price, a large process facility, such as a

refinery or petrochemical plant, could upgrade 50 pumps per year for about $150,000. After a

few years, the facility will have upgraded several hundred pumps and have much more reliable

pumping capability.

Compare this to the price of the other upgrade options that can increase shaft stiffness, new

pumps or major mechanical retrofits (typically provided by the OEM or a qualified independent

pump shop). These other alternatives can substantially increase pump reliability and in certain

situations they are absolutely necessary. Unfortunately, they cost much more than an upgrade

with composite wear rings, limiting the number of services where these upgrades are justified.

Conclusions

Upgrading centrifugal pumps to composite wear rings with reduced clearance is a major

reliability upgrade that can be executed at the time a pump is repaired. The reduction in

clearance results in increased shaft stiffnessaddressing one of the major problems with many

pumps, particularly older designs. Case studies have shown this upgrade to result in fewer

repairs, lower vibration and fewer mechanical seal leaks.

Compared to other upgrade methods that improve rotor stiffness, composite wear rings offer a

cost-effective method of improving reliability for a large population of pumps. Furthermore, this

investment pays off not only in terms of reliability but in reduced energy consumption. The

efficiency benefits of this upgrade will be the topic of Part 2.

References

American Petroleum Institute. API Standard 610 11th Edition, (ISO13709). Centrifugal Pumps for Petroleum, Petrochemical, and Natural Gas

Industries. September 2010

Aronen, R., Boulden, B., and Russek, M., 2007, Driving Pump Reliability Forward with Advanced Composite Wear Rings," Proceedings of the

23rd International Pump

Users Symposium, Turbomachinery Laboratory, Texas A&M University, College Station, Texas, p. 15-19.

Aronen, R., Plaizier, D., and Sinclair, D., 2007, Building a Better Boiler Feed Pump, Pumps and Systems, November 2007.

DuPont, Tough Composite Bearings Prove Their Value at Power Plant, E.I. du Pont de Nemours & Co., 2008.

Flowserve, 2005, How to Ensure Old Pumps Help the Environment," Pump Insight, News on Pump Technology, Systems and Services, First

Quarter 2005.

Komin, R. P., 1990, Improving Pump Reliability in Light Hydrocarbon and Condensate Service With Metal Filled Graphite Wear

Parts," Proceedings of the Seventh International

Pump Users Symposium, Turbomachinery Laboratory, Texas A&M University, College Station, Texas, p. 49-54.

Mancini, M., 2009, Increasing Pump Reliability and Life (Part 2) Pumps and Systems, January 2009.

Marscher, W.D., 2007, An End Users Guide to Pump Rotordynamics, Proceedings of the 23rd International Pump Users Symposium,

Turbomachinery Laboratory, Texas A&M

University, College Station, Texas, p. 69-83.

Pledger, J. P., 2001, Improving Pump Performance & Efficiency with Composite Wear Components, World Pumps, Number 420. Pumps and

Systems, New Life for Old Pumps,

May 1997.

Pumps & Systems, March 2011

Robert Aronen is managing director for Boulden International in Europe and the Middle East.

He has worked with nonmetallic wear rings since 1998, first as a rotating equipment engineer in

a California refinery and for the past several years representing DuPont Vespel CR-6100.

He has a BSME, 1991, from Rose-Hulman Institute of Technology.

The Power of Wear Rings Part Two: Efficiency

Written by Robert Aronen, Boulden International

With a 50 percent decrease in clearance, efficiency is increased by 2 to 4 percent.

Part One of this series discussed how wear rings impact pump reliability by increasing rotor

stabilityreducing vibration and shaft deflectionthereby increasing the life of the mechanical

seals. Part Two examines the impact of pump wear ring clearance on pump efficiency.

For decades, pump designers have known that increasing wear ring clearance leads to a loss of

efficiency. However, with metal wear rings, even the minimum clearance as specified by API610

is substantial. Because the clearance cannot be reduced between two metal rings without an

increased risk of pump seizure, metal wear rings limit pump efficiency.

Using non-metallic wear rings, the metal-to-metal interfaces within the pump can be eliminated,

and wear ring clearance can generally be reduced by 50 percent. This change produces a

significant improvement in pump efficiency.

Figure 1. Leakage across wear rings back into the impeller

Pump Efficiency Impact

Wear rings act as a seal between the high-pressure and low-pressure regions within a pump.

Leakage past the wear rings (QL) recirculates within the impeller as shown in Figure 1. The

operators only see the flow coming out of the pump (Q). The total energy consumption of the

pump, however, is a function of Q + QLthe total flow through the impeller (Lobanoff, Ross).

Obviously, if we reduce the wear ring clearance, we reduce QL and therefore reduce the power

required to obtain the same flow (Q) from the pump. As we will see, QL is often a substantial

percentage of the total flow within the impeller.

The relationship between Q and QL is a function of the pump specific speed (NS), which

describes the hydraulic performance of a pump. The calculation is:

N

s

= (RPM GPM)/H^

(.75)

Where:

RPM = rotations per minute

GPM = gallons per minute flow at best efficiency point (BEP)

H = Pump head in feet at BEP

Pumps with low specific speed values are said to have radial flow impellers. These pumps put

up high heads at relatively low flow ratessuch as boiler feed water pumps. Conversely, pumps

with high specific speed values are said to have axial flow impellers. These pumps put up low

heads with large flow ratesfor example, cooling water pumps.

The relationship between efficiency, wear ring clearance and specific speed has been well

documented. In 1946, Stepanoff published a chart showing the efficiency loss for a single-stage,

double-suction pump with a doubling of wear ring clearance as a function of specific speed. In

1985, Bloch published a similar chart for a single-suction pump showing the efficiency loss

when wear ring clearance increased for pumps of various specific speeds.

If we take this data and use it to estimate the efficiency gain from a 50 percent reduction in

clearance, we can plot the data on a curve (Figure 2).

Figure 2: Efficiency Gain from 50% Reduction in Wear Ring Clearance

Table 1. Field studies and test stand data of efficiency gain versus wear ring clearance

Next, we can compare test data and field studies to the chart. Several studies provide enough

information to calculate the pump specific speed, show the degree to which the clearance was

reduced and quantify the efficiency gain. Some of these studies are field case studies, and some

are from pump test stands. The data is shown in Table 1.

To compare this data to the plot shown in Figure 2, the last three values must be adjusted to

approximate what would occur with a 50 percent reduction in clearance. Because leakage flow is

mostly linear with clearance, we can approximate the efficiency gain at a 50 percent reduction in

clearance by using a linear extrapolation of the efficiency gain. For example for the data point

Test Stand 2, a 50 percent reduction in clearance should produce nearly double the efficiency

gain of the 27 percent reduction in clearance which was used in the actual test. Making these

adjustments, the curve from Figure 2 matches quite well with the field and test stand data (Figure

3).

Figure 3. Efficiency gain from 50 percent reduction in wear ring clearance

Bear in mind that Figure 3 shows the efficiency gain from a 50 percent reduction in wear ring

clearance compared to the API minimum clearance for a pump running at BEP. Several other

situations exist in which efficiency gains will be substantially larger, such as:

Multistage pumps, which have multiple leak paths in addition to the wear rings, and

closing the clearance at all of the leakage paths will increase the efficiency gain

Pumps for which the wear ring clearance can be reduced by more than 50 percent

Pumps for which reducing the clearance also mitigates cavitation

Savings

Reducing the wear ring clearance to 50 percent of the API standard will save a plant a substantial

amount of money. Consider a population of pumps with total online horsepower of 25,000

horsepowertypical for a 100,000-barrels-per-day refinery. A 3 percent efficiency gain over the

entire pump population will decrease power usage by 4.9 million kilowatt hours. Annual savings

will be a function of the local cost of power (Table 2).

These savings do not include local incentives for reducing power consumption or other savings,

such as avoiding the need for a new substation.

Table 2. Annual Savings from 3 percent efficiency gain on 25, 000 horsepower of pumping

capacity

Cavitation

Reducing the internal leakage within the pump also reduces the net positive suction head

required (NPSHR). Therefore, pumps with reduced wear ring clearance are less likely to cavitate.

This was the topic of an entire article in Pumps & Systems, July 2009, (Henshaw). The article

included a complete pump curve showing the impact of reduced clearance on all aspects of pump

performance (Figure 4).

At BEP, the NPSHR was almost 10 feet lower after the wear ring clearance was reduced. For

most pumping systems, the only other way to create such a large amount of additional NPSH

margin is to increase the height of the suction vessel.

Conclusions

For typical process pumps, reducing wear ring clearance by 50 percent will produce an

efficiency gain in the range of 2 to 4 percent. The exact gain will be related to the pumps

specific speed, the pump type, how much the clearance can be reduced and where the pump

operates on the curve. In addition to the efficiency gain, the pump will also have a lower NPSHR

at most flow rates, reducing the risk of cavitation, which will provide additional reliability and

efficiency improvement.

Figure 4. The impact of reduced wear ring clearance on pump performance Source: Pumps

and Systems, July 2009

So far, this series has explored the reliability and efficiency benefits of using non-metallic wear

rings with reduced clearance. Next month, Part Three (the last installment) will examine the

safety aspects of upgrading pumps with non-metallic wear rings.

Reference:

American Petroleum Institute, API Standard 610 11th Edition, (ISO13709), Centrifugal Pumps

for Petroleum, Petrochemical, and Natural Gas Industries, September 2010.

Aronen, R., Plaizier, D., and Sinclair, D., Building a Better Boiler Feed Pump, Pumps and

Systems, November 2007.

Bloch, H.P.; Geitner, F.K. Practical Machinery Management for Process Plants, Volume 4,

Major Process Equipment Maintenance and Repair, Gulf Publishing, Houston, 1985.

GreeneTweed, Ruhrpumpen, 2003, Case Study: Pump Solutions.

Henshaw, T., Effect of Internal Clearances on NPSHR Pumps and Systems, July 2009.

Komin, R. P., 1990, Improving Pump Reliability in Light Hydrocarbon and Condensate Service

With Metal Filled Graphite Wear Parts, Proceedings of the Seventh International Pump Users

Symposium, Turbomachinery Laboratory, Texas A&M University, College Station, Texas, pp. 49

54.

Lobanoff, V.S.; Ross, R.R. Centrifugal Pumps: Design and Application: Second Edition, Gulf

Publishing, Houston, 1992.

Mancini, M., 2009, Increasing Pump Reliability and Life (Part 2) Pumps and Systems, January

2009.

Pledger, J., Improving Pump Performance & Efficiency with Composite Wear Components

World Pumps, September 2001.

Pumps and Systems, New Life for Old Pumps, Pumps and Systems, May 1997.

Robert Aronen is managing director for Boulden International in Europe and the Middle East.

He has worked with nonmetallic wear rings since 1998, first as a rotating equipment engineer in

a California refinery and for the past several years representing DuPont Vespel CR-6100. He

has a BSME, 1991, from Rose-Hulman Institute of Technology.

Pumps & Systems, April 2011

The Power of Wear Rings Part Three: Safety

Written by Robert Aronen

Part One of this series addressed potential reliability improvements from using nonmetallic wear

rings with reduced clearance. Part Two evaluated the efficiency gains from reduced clearance.

In this final look at pump wear rings, the safety impact of nonmetallic rings with reduced

clearances is examined.

Whether a plant uses metal wear rings or nonmetallic wear rings, it has a responsibility to have

the necessary safeguards in place to ensure safe operation. This obligation does not go away with

nonmetallic wear rings. However, under certain circumstances, nonmetallic wear rings can

mitigate the damage from off-design events.

Pump Seizure

Wear rings are the primary interface between rotating and stationary parts in the pump. Under

normal operating conditions, little contact occurs at the wear rings. However, hard contact can

occur at the wear rings when the pump experiences off-design conditions such as dry running,

zero-flow operation or an external eventsuch as a failed bearing. These circumstances can

expose the difference between metal and nonmetallic wear rings. Metal With metal wear rings,

an inherent risk of seizure existshigh-speed contact between rotating and stationary parts,

welding the parts together. Seizure is an uncommon failure mode but is highly undesirable.

When a pump seizes, the rotor often stops abruptly. This can cause broken shafts, failed seals,

broken couplings, release of product to atmosphere and all the other negative consequences that

can stem from product release. To avoid seizure with metal wear rings, API610 recommends

minimum clearances and a difference in Brinell harness number of at least 50 unless both

[wear] rings have a Brinell hardness number of at least 400. These guidelines reduce but do not

eliminate the risk of seizure.

Nonmetallic

With the use of nonmetallic wear rings, the ordinary metal-to-metal interfaces within the pump

can be eliminated, and clearances can be reduced. Extensive industry experience has shown that

nonmetallic materials do not seize in the same manner as metal parts. Therefore, a rapid stopping

of the pump rotor is highly unlikely.

Example:

Consider the impeller shown in Figure 1 (below).

A foreign metal object entered the process stream and lodged itself inside the impeller. The event

created very high vibrations and extreme impact loads on the wear rings. Fortunately, this pump

was fitted with stationary composite wear rings as shown in Figure 2 (below).

The operators heard the noise, shut the pump down and put the spare pump into service without

incident. The pump did not seize. No damage to the major pump components occurred except for

the impeller, and hazardous product was not released to the atmosphere.

Wear Ring Clearance

With metal wear rings, a common practice when faced with pump seizure is to increase the wear

ring clearance. As discussed in the first two parts of this series, increased clearance reduces the

reliability and efficiency of the pump. Increased clearance can also lead to excessive vibration,

driver or pump bearing failure, shaft breakage, driver overloading and possible total pump

destruction. (Bloch & Geitner, p. 35) Conversely, with reduced wear ring clearance, as

discussed in Part One of this series, the pump rotor will benefit from additional stiffness and

damping, which can reduce vibration; shaft deflection; and the related loads on the critical pump

components such as the bearings, drivers and seals.

Material Selection

When selecting a nonmetallic wear ring material, users should consider what happens to the wear

rings during off-design operation. Heavily loaded contact between rotating and stationary parts is

likely. As in the example above, the rings could experience impact loading. If the pump runs dry,

heat will be generated, and potentially, thermal shock may occur when the liquid flow is

restored. To withstand these forces, some of the material properties to consider are wear

resistance, impact resistance, thermal shock resistance and the coefficient of thermal expansion.

No material is indestructible, but with consideration of the above factors, nonmetallic wear rings

should remain intact during all but the most extreme off-design events.

Conclusions

Centrifugal pumps are generally safe. However, off-design operation can sometimes lead to

extensive damage due to seizure at the metal wear rings. With metal wear rings, the traditional

solution has been to increase the clearance at the expense of reliability, efficiency and rotor

stability. Nonmetallic materials allow the user to eliminate the metal-to-metal interfaces within

the pump and reduce the clearance. This upgrade improves reliability and efficiency, while

minimizing the risk of seizure and mitigating damage to the pump during off-design events.

Conversely, if a plant avoids one major event through the use of nonmetallic wear rings, the

savings from that one event can easily justify the upgrade of hundreds of pumps.

References:

American Petroleum Institute, API Standard 610 11th Edition, (ISO13709), Centrifugal Pumps

for Petroleum, Petrochemical and Natural Gas Industries, September 2010.

Bloch, H.P. & Budris, A.R., Pump Users Handbook: Life Extension, The Fairmont Press, 2003.

Bloch, H.P. & Geitner, F.K., Practical Machinery Management for Process Plants, Volume 4,

Major Process Equipment Maintenance and Repair, Gulf Publishing, Houston, Texas, 1985.

Henshaw, T., Effect of Internal Clearances on NPSHR, Pumps and Systems, July 2009.

Mancini, M., Increasing Pump Reliability and Life (Part 2) Pumps and Systems, January 2009.

Marscher, W.D., An End Users Guide to Pump Rotordynamics, Proceedings of the 23rd

International Pump Users Symposium, Turbomachinery Laboratory, Texas A&M University,

College Station, Texas, pp. 69 83, 2007.

Pumps & Systems, May 2011

Robert Aronen is managing director for Boulden International in Europe and the Middle East.

He has worked with nonmetallic wear rings since 1998, first as a rotating equipment engineer in

a California refinery and for the past several years representing DuPont Vespel CR-6100. He

has a BSME, 1991, from Rose-Hulman Institute of Technology. He can be reached at

robert@bouldencompany.com.

You might also like

- Improving Reliability and Efficiency of Centrifugal PumpsDocument4 pagesImproving Reliability and Efficiency of Centrifugal PumpsHatem ShawkiNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- BR MiningDocument12 pagesBR MiningSteven TremolNo ratings yet

- Ms Megachem A2740 8e 3Document23 pagesMs Megachem A2740 8e 3nata siagianNo ratings yet

- Schroedahl ArvDocument19 pagesSchroedahl ArvfadzilharmanNo ratings yet

- Type OHH Pump API610 9 Ed. (ISO 13709) : File Name / OHH Sales Presentation - PPT 11/21/2001 1Document20 pagesType OHH Pump API610 9 Ed. (ISO 13709) : File Name / OHH Sales Presentation - PPT 11/21/2001 1Jorge OportoNo ratings yet

- 5275 PDFDocument28 pages5275 PDFLevi BriceñoNo ratings yet

- Bearing Isolator: Pump, Electric Motor and Split Pillow Block Interchange ManualDocument60 pagesBearing Isolator: Pump, Electric Motor and Split Pillow Block Interchange ManualSuresh Kumar MittapalliNo ratings yet

- ISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesDocument5 pagesISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesChandra SimanjuntakNo ratings yet

- Magnetic Drive Pumps Product GuideDocument32 pagesMagnetic Drive Pumps Product GuideJean-francois RosierNo ratings yet

- Thermostatic Bimetals PDFDocument4 pagesThermostatic Bimetals PDFoletta1944No ratings yet

- Dimension Tolerance For Shaft BasisDocument13 pagesDimension Tolerance For Shaft Basissafa shaikhNo ratings yet

- Arc Welding and Gas Welding Processes ExplainedDocument23 pagesArc Welding and Gas Welding Processes ExplainedRaghu ChowdaryNo ratings yet

- Influence of Anti Dive and Anti Squat Geometry in Combined Vehicle Bounce and Pitch DynamicsDocument12 pagesInfluence of Anti Dive and Anti Squat Geometry in Combined Vehicle Bounce and Pitch Dynamicslakshmanakumarr@gmail.comNo ratings yet

- Carter's Formula & Ker Wilson's FormulaDocument6 pagesCarter's Formula & Ker Wilson's FormulaChor FenolNo ratings yet

- Ku Reprint Ps April2007Document2 pagesKu Reprint Ps April2007keyur1109No ratings yet

- Minex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5Document20 pagesMinex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5HyungTae JangNo ratings yet

- Critical Speed Analysis of Centrifugal Pump PDFDocument8 pagesCritical Speed Analysis of Centrifugal Pump PDFPackage RotaryNo ratings yet

- 1 Magnetic-Drive-PumpsDocument19 pages1 Magnetic-Drive-PumpsMuzammil PiyarjiNo ratings yet

- Fristam pumps parts and data sheetsDocument16 pagesFristam pumps parts and data sheetsWinNo ratings yet

- Protech Bearing Isolator Seal TheoryDocument8 pagesProtech Bearing Isolator Seal TheorySanjoy Kr. DeyNo ratings yet

- Lesson Plan - Russian Alphabet Soup PDFDocument3 pagesLesson Plan - Russian Alphabet Soup PDFAnthonNo ratings yet

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezNo ratings yet

- Ms Hda A1826 8e 1 PDFDocument35 pagesMs Hda A1826 8e 1 PDFradanpetricaNo ratings yet

- Boiler Feed Pump - KSBDocument1 pageBoiler Feed Pump - KSBgulmal husainNo ratings yet

- Axial Flow or Propeller PumpDocument4 pagesAxial Flow or Propeller PumpTarunPatraNo ratings yet

- 7977 8cd2Document2 pages7977 8cd2Pete Pompes0% (1)

- Application of Composites For Centrifugal PumpsDocument4 pagesApplication of Composites For Centrifugal Pumpsravide76No ratings yet

- Bearing Technology For Pumps and CompressorsDocument12 pagesBearing Technology For Pumps and Compressorsmans2014No ratings yet

- Peerless Full Product Line B-1270 - BrochureDocument12 pagesPeerless Full Product Line B-1270 - BrochureHuilber MartínezNo ratings yet

- Listings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013Document116 pagesListings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013jehodgsonNo ratings yet

- Pump KnowledgeDocument17 pagesPump Knowledgesmupy_122No ratings yet

- Eccentric Reducers and Straight Runs of Pipe at Pump Suction - Hydrocarbon Processing - September 2010Document4 pagesEccentric Reducers and Straight Runs of Pipe at Pump Suction - Hydrocarbon Processing - September 2010kronafNo ratings yet

- Effects of Tribological Parameters on Slurry Erosion of MaterialsDocument13 pagesEffects of Tribological Parameters on Slurry Erosion of MaterialsGuru SamyNo ratings yet

- Hermetic Pump Designs for Oil and Gas IndustryDocument2 pagesHermetic Pump Designs for Oil and Gas IndustryYh LeongNo ratings yet

- Boletin Non ClogDocument12 pagesBoletin Non ClogulisesgeNo ratings yet

- Botros, Kamal Kamel - Mohitpour, Mo - Van Hardeveld, Thomas - Pipeline Pumping and Compression Systems - A Practical Approach (2013, ASME Press) - Libgen - lc-1Document615 pagesBotros, Kamal Kamel - Mohitpour, Mo - Van Hardeveld, Thomas - Pipeline Pumping and Compression Systems - A Practical Approach (2013, ASME Press) - Libgen - lc-1PGR ING.No ratings yet

- Pressure Dam Bearings USEFULDocument16 pagesPressure Dam Bearings USEFULAmna ChaudaryNo ratings yet

- Centrifugal Pumps Chapter OverviewDocument21 pagesCentrifugal Pumps Chapter Overviewmonjardin68No ratings yet

- Mechanical seal support systems ASME ANSI API specificationsDocument18 pagesMechanical seal support systems ASME ANSI API specificationsYang Gul LeeNo ratings yet

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhNo ratings yet

- Design of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFDocument11 pagesDesign of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFasrikalyanNo ratings yet

- Mathematical Modelling of Centrifugal Pump for Aircraft Fuel SystemDocument43 pagesMathematical Modelling of Centrifugal Pump for Aircraft Fuel SystemRakib KhanNo ratings yet

- Presentation of PumpDocument46 pagesPresentation of PumpArindam SamantaNo ratings yet

- 9 Centrifugal Pumps: Applications, Types, AdvantagesDocument24 pages9 Centrifugal Pumps: Applications, Types, Advantagesjosegabrielrosas100% (1)

- Hydraulic Pumps Lec NotesDocument30 pagesHydraulic Pumps Lec NotesDarsh MenonNo ratings yet

- The Impact of Off BEP Pump Operation (CE)Document1 pageThe Impact of Off BEP Pump Operation (CE)jdgh1986No ratings yet

- Cavitation and PUmp NPSHRDocument39 pagesCavitation and PUmp NPSHRRaheel Sultan100% (1)

- Technical Torque: Suction Side Centrifugal PumpsDocument11 pagesTechnical Torque: Suction Side Centrifugal PumpsTanishk KumarNo ratings yet

- How To Read Pump CurveDocument4 pagesHow To Read Pump CurvenghiemvhNo ratings yet

- Positive Displacement Vs Centrifugal PumpDocument11 pagesPositive Displacement Vs Centrifugal PumpArslan BhattiNo ratings yet

- Positive Displacement PumpsDocument6 pagesPositive Displacement PumpsVignesh DuraiNo ratings yet

- Compressors: Me7313 Industrial Automation and ControlDocument13 pagesCompressors: Me7313 Industrial Automation and ControlNuwan DinushaNo ratings yet

- Mark 3 ASME Pumps PDFDocument94 pagesMark 3 ASME Pumps PDFInf IngNo ratings yet

- Operators Guide To Rotating Equipment PDFDocument11 pagesOperators Guide To Rotating Equipment PDFOlusegun Olugbade0% (1)

- Forces influencing hydraulic parameters on centrifugal impellersDocument12 pagesForces influencing hydraulic parameters on centrifugal impellersHosseinNo ratings yet

- Pump Notes PDFDocument25 pagesPump Notes PDFUsman KhalidNo ratings yet

- Studies On Drying Kinetics of Solids in A Rotary DryerDocument6 pagesStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNo ratings yet

- 4244 12672 1 PB PDFDocument15 pages4244 12672 1 PB PDFVinh Do ThanhNo ratings yet

- Proper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreDocument9 pagesProper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreVinh Do ThanhNo ratings yet

- Air-Fuel Ratio, Lambda and Engine Performance: AFR M MDocument12 pagesAir-Fuel Ratio, Lambda and Engine Performance: AFR M MVinh Do ThanhNo ratings yet

- 4244 12672 1 PB PDFDocument15 pages4244 12672 1 PB PDFVinh Do ThanhNo ratings yet

- NPK-15 8 15Document5 pagesNPK-15 8 15Vinh Do ThanhNo ratings yet

- Effects of Drying Parameters On Heat Transfer During DryingDocument13 pagesEffects of Drying Parameters On Heat Transfer During DryingVinh Do ThanhNo ratings yet

- Modeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsDocument8 pagesModeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsVinh Do ThanhNo ratings yet

- Modelling and Simulation of A Direct Contact Rotary DryerDocument16 pagesModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhNo ratings yet

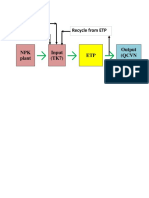

- Recycle From ETP Make Up H2O DAP, UreaDocument1 pageRecycle From ETP Make Up H2O DAP, UreaVinh Do ThanhNo ratings yet

- The Heart of Operations - World Cement - 02-2015Document4 pagesThe Heart of Operations - World Cement - 02-2015fetniNo ratings yet

- Tinh Luong Nuoc Bay HoiDocument22 pagesTinh Luong Nuoc Bay HoiVinh Do ThanhNo ratings yet

- Dryer CalculationsDocument4 pagesDryer CalculationsVinh Do Thanh0% (1)

- Ansi B16-104Document1 pageAnsi B16-104Monica Suarez100% (1)

- Aoac - Methods.1.1990. MoistureDocument2 pagesAoac - Methods.1.1990. MoistureVinh Do ThanhNo ratings yet

- Multi-Use Chair DesignDocument7 pagesMulti-Use Chair DesignVinh Do ThanhNo ratings yet

- Review On Development of Polypropylene Manufacturing ProcessDocument11 pagesReview On Development of Polypropylene Manufacturing ProcessShweta Yadav100% (1)

- PEP Report 267A: Ihs ChemicalDocument8 pagesPEP Report 267A: Ihs ChemicalVinh Do ThanhNo ratings yet

- 1 0ProjectManagementProceduresDocument8 pages1 0ProjectManagementProceduresRamiesRahmanNo ratings yet

- CRACKER A PC Based Simulator For Industr PDFDocument6 pagesCRACKER A PC Based Simulator For Industr PDFVinh Do ThanhNo ratings yet

- Equivalent Grades of Cast IronsDocument2 pagesEquivalent Grades of Cast IronsVinh Do ThanhNo ratings yet

- Natural Evaporation RateDocument16 pagesNatural Evaporation RateVinh Do ThanhNo ratings yet

- Metal Price IndexDocument1 pageMetal Price IndexVinh Do ThanhNo ratings yet

- Mau Giay Uy Quyen Bang Tieng AnhDocument3 pagesMau Giay Uy Quyen Bang Tieng AnhVinh Do ThanhNo ratings yet

- DRS 279-2015 Organic Fertilizer - SpecificationDocument17 pagesDRS 279-2015 Organic Fertilizer - SpecificationVinh Do ThanhNo ratings yet

- Estimating Evaporation From Water SurfacesDocument27 pagesEstimating Evaporation From Water SurfacesVinh Do ThanhNo ratings yet

- How To Calculate Heat Load - 5 StepsDocument1 pageHow To Calculate Heat Load - 5 StepsVinh Do ThanhNo ratings yet

- Optimization of Wall Thickness For Minimum Heat LossesDocument9 pagesOptimization of Wall Thickness For Minimum Heat LossesVinh Do ThanhNo ratings yet

- How To Calculate Heat Load - 5 StepsDocument1 pageHow To Calculate Heat Load - 5 StepsVinh Do ThanhNo ratings yet

- Investigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyDocument5 pagesInvestigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyradanpetricaNo ratings yet

- Special Report PDM Guidebook2016Document44 pagesSpecial Report PDM Guidebook2016Vinoth KumarNo ratings yet

- Unit One: Wind LoadsDocument67 pagesUnit One: Wind Loadsabdu yimerNo ratings yet

- Ribe V D P Y I: Ibration Ampers Rotect Our NvestmentDocument8 pagesRibe V D P Y I: Ibration Ampers Rotect Our Nvestmentpisang123456100% (1)

- Experiment No6Document3 pagesExperiment No6TALHANo ratings yet

- Mechanical Vibrations in Spacecraft Design PDFDocument443 pagesMechanical Vibrations in Spacecraft Design PDFrrq100% (1)

- Order Tracking Program CAT-SAA1-ORDTRK Datasheet 1603-1Document2 pagesOrder Tracking Program CAT-SAA1-ORDTRK Datasheet 1603-1SamirNo ratings yet

- Chapter 4 Vibration and WaveDocument30 pagesChapter 4 Vibration and WavePrakash DuraisamyNo ratings yet

- Natural Frequencies of BeamsDocument10 pagesNatural Frequencies of BeamsPurwandy HasibuanNo ratings yet

- 9200 74712 SeismoprobeDocument15 pages9200 74712 SeismoprobekamranamvajNo ratings yet

- Introduction To Helicopter Aerodynamics and Dynamics Dr. C. Venkatesan. Department of Aerospace Engineering. Indian Institute of Technology, KanpurDocument22 pagesIntroduction To Helicopter Aerodynamics and Dynamics Dr. C. Venkatesan. Department of Aerospace Engineering. Indian Institute of Technology, KanpurAnonymous drYNHeNo ratings yet

- 03 Mathematical Modelling PrinciplesDocument40 pages03 Mathematical Modelling PrinciplesAnoop Kumar AllankiNo ratings yet

- VibrationDocument32 pagesVibrationpothusothuNo ratings yet

- CTS HandbookDocument786 pagesCTS HandbookRicky Vil100% (4)

- 1031 1192105937 02 202109 FGH ST Mad11 Tanacs For Cep - PDF 50996599 v1Document17 pages1031 1192105937 02 202109 FGH ST Mad11 Tanacs For Cep - PDF 50996599 v1Jesús SarriaNo ratings yet

- International Conference on Structural Stability and Dynamics: Non-Linear Behavior and Instability of Shallow ArchesDocument6 pagesInternational Conference on Structural Stability and Dynamics: Non-Linear Behavior and Instability of Shallow ArchesMazen Al-arsanNo ratings yet

- Engine VibrationDocument3 pagesEngine VibrationИлларион ПанасенкоNo ratings yet

- Rotor Balancing Simulator: Fourth Year Graduation ProjectDocument21 pagesRotor Balancing Simulator: Fourth Year Graduation ProjectMahmoud SamirNo ratings yet

- Control & Instrumentation 2Document0 pagesControl & Instrumentation 2SHIVAJI CHOUDHURY100% (3)

- Product Specification VIBROCONTROL 950/960: FeaturesDocument3 pagesProduct Specification VIBROCONTROL 950/960: FeaturesPedro RosaNo ratings yet

- ECSS E ST 10 03C (1june2012)Document128 pagesECSS E ST 10 03C (1june2012)jsadachiNo ratings yet

- Bilz - Vibration Isolation of Foundations & FrameworksDocument12 pagesBilz - Vibration Isolation of Foundations & FrameworksmikelotingaNo ratings yet

- Vibro Acoustic Analysis With Flux and Opti Struct FINALDocument31 pagesVibro Acoustic Analysis With Flux and Opti Struct FINALEnmel Martínez BejaranoNo ratings yet

- Simple Harmonic MotionDocument22 pagesSimple Harmonic Motionjear100% (1)

- Ch1 Introduction to VibrationDocument75 pagesCh1 Introduction to Vibrationhailegebreselassie24No ratings yet

- Response Effects of Guitar Pickup Position and WidthDocument16 pagesResponse Effects of Guitar Pickup Position and WidthRahmat SantosoNo ratings yet

- Calibrate Sensors Anywhere with Portable Vibration CalibratorDocument23 pagesCalibrate Sensors Anywhere with Portable Vibration CalibratorNovato300% (1)

- Mechanical VibrationDocument13 pagesMechanical VibrationKhalil Raza100% (1)

- ADR245B - New Catalogue - 25 Aug 2015Document26 pagesADR245B - New Catalogue - 25 Aug 2015MeghavahinaNo ratings yet

- 10.1007@978 3 030 47717 2Document413 pages10.1007@978 3 030 47717 2riadhNo ratings yet