Professional Documents

Culture Documents

infoPLC Net L02 Advanced Micro800 PPT PDF

Uploaded by

Alaa Ramadan0 ratings0% found this document useful (0 votes)

92 views19 pagesOriginal Title

infoPLC_net_L02_advanced_micro800_ppt.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

92 views19 pagesinfoPLC Net L02 Advanced Micro800 PPT PDF

Uploaded by

Alaa RamadanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 19

Advanced PLC Topics

for Micro controllers for Micro controllers

Copyright 2011 Rockwell Automation, Inc. All rights reserved.

www.infoPLC.net

Agenda

1 C t d C t U d t 1. Connected Components Update

2. How to quickly develop machine 2. How to quickly develop machine

3. Hand-on lab

4. Wrap-up

Copyright 2011 Rockwell Automation, Inc. All rights reserved. 2

www.infoPLC.net

Outline

1. Introduction

Present CC and brief product update, sample code website

Present problem(s) to be solved in lab conveyor app

Show how you might approach using OOB software (demo/presentation)

Communicate to drives using Modbus g

2. Comms portion

Show how we can make better using RA application aids (demo)

Sh h k b tt ti UDFB (h d ) Show how user can make better creating a UDFB. (hands-on)

3. Easier approach to doing math via Structured Text UDFB

Event interrupt to improve response time p p p

Copyright 2011 Rockwell Automation, Inc. All rights reserved. 3

www.infoPLC.net

Demo and Lab

What will you know after completing the lab

Be able to quickly configure a drive for speed control

Be able to quickly configure the PLC

What is the best way to control the drive using the PLC

How you can handle interruption of machine operation y

Copyright 2011 Rockwell Automation, Inc. All rights reserved. 4

www.infoPLC.net

Innovation

Micro800 & Connected Components Workbench

Just enough control Just enough control

Part of Connected

Components Bundle

Part of Connected

Components Bundle Components Bundle Components Bundle

Unified Software Unified Software

Convenience and

connectivity

Convenience and

connectivity

Unified Software Unified Software

yy

Easy to Install and Maintain Easy to Install and Maintain

(Confidential For Internal Use Only) 5

www.infoPLC.net

Innovation

Micro800 PLC Family

Micro810: Price of a smart

relay with the functionality

f Mi PLC

4Ch 10bit analog

input

4Ch 10bit analog

input

Build-In

Motion

Build-In

Motion

of a Micro PLC

Micro830: Economical PLC

Motion Motion

Plug-In Plug-In

Micro830: Economical PLC

with Plug-In customization

and PLOpen motion

Optional LCD Optional LCD

Serial Serial

Plug-In Plug-In

Ethernet Ethernet

Serial Serial

Micro850: Adds EtherNet/IP

and more I/O expansion to

USB USB

Expansion Expansion

and more I/O expansion to

Micro830 24 And 48 point

PLCs (4Q2012)

USB

(adapter)

USB

(adapter)

USB USB

(Confidential For Internal Use Only) 6

www.infoPLC.net

Connected Components Workbench Software

Easy to Acquire/Install

Free Internet download

Easy to Configure Easy to Configure

Single software for component

class products

G hi l D i C fi ti Graphical Device Configuration

Easy to Program

Extensive use of Microsoft

and IEC-61131 standards

Symbolic Programming

Rockwell Automation and Rockwell Automation and

user-defined function blocks

Easy to Update

S ft d t il bl Software updates available

via Internet

RAS1

www.infoPLC.net

Slide 7

RAS1 updated screenshot.

Rick Sykora, 9/1/2010

www.infoPLC.net

Innovation

Micro800 Plug-In Modules

Allows for highly customizable hardware

configurations by extending the

t ll I/O d i ti controllers I/O and communications

Plugs into front of controller without

increasing panel space increasing panel space

Wide range of plug-Ins available such as

analog I/O, serial ports, motion,

D i N t GPRS d t DeviceNet scanner, GPRS modem, etc.

Additional modules in future from

Encompass partners Encompass partners

(Confidential For Internal Use Only) 8 (Confidential For Internal Use Only) Copyright 2010 Rockwell Automation, Inc. All rights reserved. 8

Changes the Personality of the Base Unit Controller

www.infoPLC.net

Connected Components Release 1.1

PanelView Component

RACD

Serial (run-time)

p

With Design Station 2.0

RACD

USB/CIP or USB w/adapter (Micro810)

Hardwired

Micro830

p ( )

Hardwired

or

DSI/Modbus

USB to DSI/RS485 R1.1

LD, FBD and ST languages

= Temporary connection

g g

User Defined FB

IEC 61131 compatibility

Micro810, 830 and PF4

class drives support

PVc design station

Windows 7 64-bit support

o

f

t

w

a

r

e

o

f

t

w

a

r

e

(Confidential For Internal Use Only) 9

PowerFlex 4

Strengthening the Foundation Strengthening the Foundation

9

Windows 7 64-bit support

Chinese, English and

French localization

More robust

S

o

S

o

Kinetix 3

www.infoPLC.net

R1.1 Features (AFC December 2011)

Windows 7 64-bit support

Chinese and French localization

English user manuals

Smaller download footprint for R1 upgrade

(Global) variable export (Global) variable export

User-defined function block debugging

Improved download infrastructure (potentially improved speeds) Improved download infrastructure (potentially improved speeds)

Major R1 Anomalies Fixed

Ladder editor copy/paste

Debug view stays in frame

Fewer errors/steps to get into debug

Improved Save-As Improved Save As

Fewer exception faults

10 Copyright 2011 Rockwell

www.infoPLC.net

Current Micro800 Motion Support

Discrete I/O

Discrete I/O interface to one or more

Kinetix 3 servo drives

Micro800 user application sets digital I/O to start,

stop and set index positions

Refer to Kinetix 3 Component Servo

Drives manual

Kinetix 3 configured via Ultraware

Map digital inputs to index positions Map digital inputs to index positions

Define index positions

Modbus

(Confidential For Internal Use Only) Copyright 2010 Rockwell Automation, Inc. All rights reserved. 11

Digital I/O

www.infoPLC.net

Current Micro830 Motion Support - Modbus

Modbus communications to one or more Kinetix 3 servo drives

Micro830 user application uses MSG_MODBUS instructions or K3-specific UDFBs

(a ailable from Sample Code ebsite) to control ser o dri es in inde ing mode (available from Sample Code website) to control servo drives in indexing mode.

Refer to Kinetix 3 Host Commands for Serial Communication manual for Modbus

commands and parameters.

Micro830 controller requires serial port plug-in configured as Modbus

RTU Master

Kinetix 3 drives configured via Ultraware using 2090-CCMPDS cable Kinetix 3 drives configured via Ultraware using 2090-CCMPDS cable

Modbus

(Confidential For Internal Use Only) Copyright 2010 Rockwell Automation, Inc. All rights reserved. 12

Modbus

Modbus

www.infoPLC.net

Available K3 UDFBs from Sample Code Website

RA_K3_MBUS_OperationMode Reads the operation mode of the drive and change it if the

input is different. This function block continuously updates the output values on a 10 second

cycle, but will only write the new mode to the drive when triggered. y y gg

RA_K3_MBUS_IndexControl Provides simple index control and status for the drive. The

default operation runs continuously with a 100 millisecond cycle time.

RA_K3_MBUS_WriteIndex Provides simple index configuration for one index at a time in _ _ _ p g

the drive. This function block operates on a trigger, but will take more than one scan to complete.

RA_K3_MBUS_ReadIndex Reads the current index configuration for one index at a time in

the drive. This function block operates on a trigger, but will take more than one scan to complete.

RA_K3_MBUS_VelocityControl Provides simple velocity control and status for the drive.

The default operation runs continuously with a 100 millisecond cycle time.

RA_K3_MBUS_ChangeVelocity Updates the Preset Velocity values for the drive. This

function block continuously updates the output values on a 10 second cycle, but will only write the

input values to the drive when triggered.

RA_K3_MBUS_Jog Assuming that the drive is ready but not enabled, this function block will

ll th t j th d i f d d b k d t th d f lt j d ith t h i allow the user to jog the drive forward and backward at the default jog speed, without changing

the operation mode of the drive.

(Confidential For Internal Use Only) Copyright 2010 Rockwell Automation, Inc. All rights reserved. 13

www.infoPLC.net

RA_K3_MBUS_IndexControl UDFB

(Confidential For Internal Use Only) Copyright 2010 Rockwell Automation, Inc. All rights reserved. 14

http://samplecode.rockwellautomation.com

www.infoPLC.net

Whats new in R2?

PanelView Component

Micro850

Kinetix Servo

USB (programming)

Micro850

Stratix 2000

Ethernet switch

PTO

USB (programming)

Micro850 support (24 or 48 point base with Ethernet)

o

f

t

w

a

r

e

o

f

t

w

a

r

e

Micro850 support (24 or 48 point base with Ethernet)

Controller password

2085 I/O support

PLC i (Mi 830 d 8 0)

(Confidential For Internal Use Only) 15 15

S

o

S

o

PLCopen motion (Micro830 and 850)

PowerFlex 7 drives and support

www.infoPLC.net

Conveyor application example for the lab

Now lets take a look at a simple program for a conveyor application for

loading freight. A motor drives the conveyor belt moves the item(s) until

the item can be unloaded Depending on the type of freight the speed of the item can be unloaded. Depending on the type of freight, the speed of

the conveyor is adjusted

Copyright 2006 Rockwell

www.infoPLC.net

What controls do I need for this application?

A motor

A drive controller for the motor

A small PLC to coordinate the start/stop/speed change of the conveyor

An HMI may be a simple switch(es) or touchscreen display.

Copyright 2011 Rockwell Automation, Inc. All rights reserved. 17

www.infoPLC.net

Copyright 2011 Rockwell Automation, Inc. All rights reserved.

www.infoPLC.net

You might also like

- MicroLogix1400 Series B Launch OverviewDocument50 pagesMicroLogix1400 Series B Launch OverviewRicardo FuentesNo ratings yet

- Poweflex 400 User Manual PDFDocument218 pagesPoweflex 400 User Manual PDFRichie ChicolNo ratings yet

- Import A PanelView Component - PanelView 800 .Cha File Into Connected Components WorkbenchDocument3 pagesImport A PanelView Component - PanelView 800 .Cha File Into Connected Components WorkbenchNicolásColomberoNo ratings yet

- 1756-GuardLogix Controller SystemsDocument160 pages1756-GuardLogix Controller SystemsMohammad OkourNo ratings yet

- LAB 10 Introduction To Ladder Logic ProgrammingDocument10 pagesLAB 10 Introduction To Ladder Logic ProgrammingNyanphyo AungNo ratings yet

- PLC Exercises Ladder Diagram ProgrammingDocument27 pagesPLC Exercises Ladder Diagram Programmingمحمد سليمانNo ratings yet

- E Learning Rockwell AutomationDocument2 pagesE Learning Rockwell AutomationAsian SinabutarNo ratings yet

- User Manual ControlLogix 5580Document164 pagesUser Manual ControlLogix 5580Nixius0% (1)

- Manual MotomanXRC BasicDocument12 pagesManual MotomanXRC BasicNGUYỄN HOÀNG LINHNo ratings yet

- B&R DeviceNetDocument92 pagesB&R DeviceNetanon_493710115No ratings yet

- 12 TwinCAT PLC ControlDocument81 pages12 TwinCAT PLC ControlFrilya Andarni Saragih SumbayakNo ratings yet

- Micrologix 1400 IntroductionDocument7 pagesMicrologix 1400 IntroductionsayedmhNo ratings yet

- GuardLogix Safety Application Instruction SetDocument398 pagesGuardLogix Safety Application Instruction SetGerardo Alejandro Peña GonzálezNo ratings yet

- D027B OmronDocument141 pagesD027B OmronirfanWPKNo ratings yet

- Module 07 - Ethernet - IPDocument56 pagesModule 07 - Ethernet - IPGabriel David Paez CamposNo ratings yet

- 3HAC032104-En (Robot Studio Manual)Document594 pages3HAC032104-En (Robot Studio Manual)jaschaNo ratings yet

- FATEC Mitsubishi QD77 PositiotingDocument342 pagesFATEC Mitsubishi QD77 PositiotingMichealNo ratings yet

- FANUC Software WeldPRODocument2 pagesFANUC Software WeldPROMihail AvramovNo ratings yet

- What Is FactoryTalk Activation Video ScriptDocument5 pagesWhat Is FactoryTalk Activation Video ScriptEletrica ManutNo ratings yet

- Aaa2 PDFDocument561 pagesAaa2 PDFjosmera88No ratings yet

- 1400 Programmers ManualDocument694 pages1400 Programmers ManualangelNo ratings yet

- InfoPLC Net PowerFlex 525 AC DrivesDocument34 pagesInfoPLC Net PowerFlex 525 AC DrivesgodoyunipNo ratings yet

- Product Profile - Kinetix® 6500 - 2094-pp005 - En-P PDFDocument4 pagesProduct Profile - Kinetix® 6500 - 2094-pp005 - En-P PDFNicolás A. SelvaggioNo ratings yet

- PLC-controlled Stepper Motor Drive For NC PositionDocument10 pagesPLC-controlled Stepper Motor Drive For NC PositiondeoarshiNo ratings yet

- 10 Competitive Advantages Through EtherCAT 1609Document102 pages10 Competitive Advantages Through EtherCAT 1609Khaled OuniNo ratings yet

- EtherCAT Device Protocol PosterDocument1 pageEtherCAT Device Protocol Posterkroenen SSNo ratings yet

- Beckhoff and TwinCAT GuideDocument17 pagesBeckhoff and TwinCAT Guidevoltus88No ratings yet

- Servo Control AdvanceDocument105 pagesServo Control Advancemangoody207901No ratings yet

- FanucDocument2 pagesFanucdanielNo ratings yet

- Sigrok - Using Logic To Debug LogicDocument34 pagesSigrok - Using Logic To Debug Logicebbys89No ratings yet

- 1783-Um007 - En-P - Statrix 5700Document528 pages1783-Um007 - En-P - Statrix 5700Nguyễn SangNo ratings yet

- PLC Siemens S7-300 Cpu 312C ManualDocument176 pagesPLC Siemens S7-300 Cpu 312C ManualKique KiNo ratings yet

- Rev 1 Module2 PLCDocument293 pagesRev 1 Module2 PLCMuhd IzzatNo ratings yet

- FANUC's Standard Manual Handling Programming (Version 5.0)Document29 pagesFANUC's Standard Manual Handling Programming (Version 5.0)EngChengLengNo ratings yet

- Manual Rs Logix 5000: DownloadDocument2 pagesManual Rs Logix 5000: DownloadRenanNo ratings yet

- Roboguide Ohjekirja SV V8 EngDocument109 pagesRoboguide Ohjekirja SV V8 EngMorteza85No ratings yet

- Drive Field KCL 20181004ESAGIntegrated Motion Update October 2018Document54 pagesDrive Field KCL 20181004ESAGIntegrated Motion Update October 2018vuNo ratings yet

- MicroLogix 1400 Programmable Controllers PDFDocument42 pagesMicroLogix 1400 Programmable Controllers PDFPablo ToscanoNo ratings yet

- Introduction To Control Systems: Ece-FcsDocument71 pagesIntroduction To Control Systems: Ece-FcsBUENAOBRA VASHNo ratings yet

- TIA Portal Integration Guide for Cognex In-Sight & Dataman SensorsDocument8 pagesTIA Portal Integration Guide for Cognex In-Sight & Dataman SensorsDavid GarayNo ratings yet

- RSLogix 5000 Sample Projects GuideDocument5 pagesRSLogix 5000 Sample Projects GuidepmmdavidNo ratings yet

- Micro800 Programming Basics Tutorial 2: Variables, Instruction BlocksDocument23 pagesMicro800 Programming Basics Tutorial 2: Variables, Instruction BlocksTete GoriNo ratings yet

- TechED EMEA 2019 - VZ01 - Visualisation at Rockwell Automation - What's New and What's NextDocument47 pagesTechED EMEA 2019 - VZ01 - Visualisation at Rockwell Automation - What's New and What's Nextmrb20No ratings yet

- Motion - Kinetix Selection GuideDocument170 pagesMotion - Kinetix Selection GuideNicolás A. SelvaggioNo ratings yet

- Modern Electrical Drive Systems and Power Electronic ConvertersDocument9 pagesModern Electrical Drive Systems and Power Electronic ConvertersGthulasi78No ratings yet

- Servo Motor Guide: Types, Construction & ApplicationsDocument7 pagesServo Motor Guide: Types, Construction & ApplicationsAHMED YOUSEFNo ratings yet

- Guide Book Fatek Vol.1Document62 pagesGuide Book Fatek Vol.1PutraHarizalNo ratings yet

- 90203-1104DEC E Cont Operations PDFDocument414 pages90203-1104DEC E Cont Operations PDFelmacuarro5No ratings yet

- DeviceNet Troubleshooting GuideDocument28 pagesDeviceNet Troubleshooting GuidemdarwishbpNo ratings yet

- Stratix 8000 Hardware User ManualDocument92 pagesStratix 8000 Hardware User ManualJesus Rebaza RomanNo ratings yet

- Sequential Motion ControlDocument608 pagesSequential Motion Controltomjordan12321No ratings yet

- KST ConveyorTech 71 enDocument108 pagesKST ConveyorTech 71 enphong viNo ratings yet

- Process Control and Automation of a Batch Reactor: Modelling, Tuning and ImplementationDocument100 pagesProcess Control and Automation of a Batch Reactor: Modelling, Tuning and ImplementationMr.M. ArivalaganNo ratings yet

- 1756 rm006 - en P PDFDocument561 pages1756 rm006 - en P PDFAndrés LageNo ratings yet

- 840Dsl CNC Commiss Man en-USDocument374 pages840Dsl CNC Commiss Man en-USaaaaaaNo ratings yet

- Converting PLC-5 or SLC500 Logic To Logix Based LogicDocument80 pagesConverting PLC-5 or SLC500 Logic To Logix Based LogicChris BreedloveNo ratings yet

- Rockwel Micro 830 PDFDocument16 pagesRockwel Micro 830 PDFLuís Miguel Romão100% (1)

- Cabacitor Bank Sizing 1Document4 pagesCabacitor Bank Sizing 1Alaa RamadanNo ratings yet

- Am Tool 07 v1.1Document23 pagesAm Tool 07 v1.1Alaa RamadanNo ratings yet

- A.C. Motor and Its TypesDocument10 pagesA.C. Motor and Its TypessasidaranNo ratings yet

- Ds 266hsh Nsh-En 02 2011Document28 pagesDs 266hsh Nsh-En 02 2011Alaa RamadanNo ratings yet

- CalculationsDocument2 pagesCalculationskhialzadaNo ratings yet

- Calculation of Short-Circuit CurrentsDocument35 pagesCalculation of Short-Circuit CurrentsdaodoquangNo ratings yet

- Mosis Hdb3 ReportDocument98 pagesMosis Hdb3 ReportPaul CruzNo ratings yet

- Boolean AlgebraDocument25 pagesBoolean AlgebraTejas Bhandari100% (6)

- Nurmaliza Binti MD AliDocument39 pagesNurmaliza Binti MD AliAlaa RamadanNo ratings yet

- Chapter 8Document16 pagesChapter 8Sharmi SanthakumarNo ratings yet

- Ammonia Absorption Downdraft Tropical Calc 1Document14 pagesAmmonia Absorption Downdraft Tropical Calc 1Alaa RamadanNo ratings yet

- Dsd213 Electrical Load Calculation WorksheetDocument1 pageDsd213 Electrical Load Calculation WorksheetAlaa RamadanNo ratings yet

- Per Unit Calculation MethodDocument3 pagesPer Unit Calculation Methodevonik123456No ratings yet

- Motor Feeder CT CalculationDocument12 pagesMotor Feeder CT Calculationjoydeep_d323250% (2)

- 03192005214235Document0 pages03192005214235Daniela Buse0% (2)

- Appendix A - Program Logic DiagramDocument1 pageAppendix A - Program Logic DiagramAlaa RamadanNo ratings yet

- Calculations For HV and LVDocument40 pagesCalculations For HV and LVAerwin BautistaNo ratings yet

- PLC 1Document27 pagesPLC 1Juan Sánchez LópezNo ratings yet

- Basic Network AnalysisDocument31 pagesBasic Network AnalysisdaodoquangNo ratings yet

- 1 Computer Organization and Logic Design ﻲﻘﻄﻨﻤﻟﺍ ﻢﻴﻤﺼﺘﻟﺍﻭ ﺔﺒﺳﺎﺤﻟﺍ ﺐﻴﻛﺮﺗ ﻩﺩﺎﻤﻟﺍ ﺫﺎﺘﺳﺍ: ﻡ. ﻡ. ﺮﻀﺧ ﻲﻠﻋ ﺪﺒﻋ ءﺎﺴﻴﻣDocument81 pages1 Computer Organization and Logic Design ﻲﻘﻄﻨﻤﻟﺍ ﻢﻴﻤﺼﺘﻟﺍﻭ ﺔﺒﺳﺎﺤﻟﺍ ﺐﻴﻛﺮﺗ ﻩﺩﺎﻤﻟﺍ ﺫﺎﺘﺳﺍ: ﻡ. ﻡ. ﺮﻀﺧ ﻲﻠﻋ ﺪﺒﻋ ءﺎﺴﻴﻣAshish KatochNo ratings yet

- Boat Calculation ExampleDocument2 pagesBoat Calculation ExampleAlaa RamadanNo ratings yet

- Logic GatesMdSaifAhmedDocument10 pagesLogic GatesMdSaifAhmedmdkaifahmedNo ratings yet

- 5.4. Electric Resistance ChartDocument1 page5.4. Electric Resistance ChartAlaa RamadanNo ratings yet

- Wiring and LLDocument10 pagesWiring and LLAlaa RamadanNo ratings yet

- 20 - How To Calculate Wire & Fuse Sizes For Electric MotorsDocument2 pages20 - How To Calculate Wire & Fuse Sizes For Electric MotorsLNo ratings yet

- 0 Electrical Load CalculationsDocument1 page0 Electrical Load CalculationsAlaa RamadanNo ratings yet

- Wire Sizing and Calculation MethodsDocument22 pagesWire Sizing and Calculation Methodspraveenbusa100% (1)

- TRILOGI 5.3 PLC Ladder Diagram Programmer and Simulator A TutorialDocument24 pagesTRILOGI 5.3 PLC Ladder Diagram Programmer and Simulator A Tutorialgopir28No ratings yet

- Calculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEDocument4 pagesCalculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEAlaa RamadanNo ratings yet

- XC Sun49Document4 pagesXC Sun49Alaa RamadanNo ratings yet

- Broadband Bill JuneDocument1 pageBroadband Bill JunekarthikNo ratings yet

- Efficient EGS generator sets for all your power needsDocument5 pagesEfficient EGS generator sets for all your power needsJohn GarnetNo ratings yet

- Siemens S7-300 - 400 CP-343-1 Ethernet Connection GuideDocument5 pagesSiemens S7-300 - 400 CP-343-1 Ethernet Connection GuideSandeep YadavNo ratings yet

- Bendix NA-R9A, B Stromberg Float Carburetor InstructionDocument12 pagesBendix NA-R9A, B Stromberg Float Carburetor InstructionWilfredo Díaz GonzalezNo ratings yet

- Cherry Picker ChecklistDocument2 pagesCherry Picker Checklistpatrick ruwonaNo ratings yet

- Unified Endpoint Management and Security 2022Document5 pagesUnified Endpoint Management and Security 2022Mathieu LEROYNo ratings yet

- Orion ZF 4HP22 24 4Spd 4solDocument10 pagesOrion ZF 4HP22 24 4Spd 4solEdwinNo ratings yet

- G1 Driving TestDocument14 pagesG1 Driving TestChandraVijayDubeyNo ratings yet

- Grand Project Report ON Bharti Airtel Limited: Submitted byDocument35 pagesGrand Project Report ON Bharti Airtel Limited: Submitted byMukesh ManwaniNo ratings yet

- Simplicity CO BrochureDocument6 pagesSimplicity CO BrochurerkssNo ratings yet

- Bim Module EpflDocument105 pagesBim Module EpflMúÑír PåhôrêNo ratings yet

- SOLIS RHI - (3-6) kW-48ES-5GDocument2 pagesSOLIS RHI - (3-6) kW-48ES-5GKatterinne PlataNo ratings yet

- SKKXDocument2 pagesSKKXBharath KumarNo ratings yet

- DN02 S09011 e XK 3131 01Document2 pagesDN02 S09011 e XK 3131 01ayemyothantNo ratings yet

- Motorola H550 ManualDocument5 pagesMotorola H550 ManualAnonymous w0egAgMouGNo ratings yet

- 05-NRI Chinese and Foreign Rank HoldersDocument2 pages05-NRI Chinese and Foreign Rank HolderspranavNo ratings yet

- Software Design and Architecture: Introduction LectureDocument21 pagesSoftware Design and Architecture: Introduction LectureM UsamaNo ratings yet

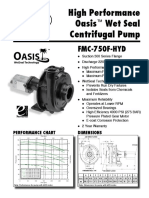

- FMC 750F HydDocument2 pagesFMC 750F HydСергей НоваковскийNo ratings yet

- Ethical Hacking Foundation Certification Training BrochureDocument8 pagesEthical Hacking Foundation Certification Training BrochureRogérs Rizzy MugangaNo ratings yet

- Carzoo IndiaDocument21 pagesCarzoo IndiaRomeshNo ratings yet

- WFP-TMP Iwp ElectricalDocument5 pagesWFP-TMP Iwp ElectricalMuthu KumaranNo ratings yet

- CSA CertificateDocument8 pagesCSA CertificateVaibhav PatilNo ratings yet

- Boot Sector GamesDocument100 pagesBoot Sector GamesIonas FNo ratings yet

- Lego Education Wedo 2.0Document29 pagesLego Education Wedo 2.0Hai LamNo ratings yet

- Java Virtual MachineDocument4 pagesJava Virtual Machinekurniawan-el-machi-199No ratings yet

- Ic m411 PDFDocument64 pagesIc m411 PDFmilen65No ratings yet

- 2023.05 Heat Pump Specs - SplitDocument4 pages2023.05 Heat Pump Specs - SplitPrabin BhattaraiNo ratings yet

- WARN 2597 Philips - Neurology Solutions 1.27.20Document4 pagesWARN 2597 Philips - Neurology Solutions 1.27.20Sinclair Broadcast Group - EugeneNo ratings yet

- Sylantech Electricals Rechargeable LED BulbsDocument9 pagesSylantech Electricals Rechargeable LED BulbsSylantech ElectricalsNo ratings yet

- Google Classroom PresentationDocument33 pagesGoogle Classroom PresentationSaqib RiazNo ratings yet