Professional Documents

Culture Documents

TM 9 2320 387 24 1 Mantainance UpArmor HumVee Vol 1 Dec97

Uploaded by

Thoukididis ThoukididouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TM 9 2320 387 24 1 Mantainance UpArmor HumVee Vol 1 Dec97

Uploaded by

Thoukididis ThoukididouCopyright:

Available Formats

Volume No.

1

ARMY TM 9-2320-387-24- 1

AIR FORCE TO 36A12- 1 A-3052- 1

TECHNICAL MANUAL

UNIT, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE

FOR

TRUCK, UTIUM: S250 SHELTER

CARRIER, 4X4, Ml 113

(2320-01-412-0143) (EIC: 868)

TRUCK, UTlun: UP-ARMORED

CARRIER, 4X4, Ml 114

(2320-01-413-3739) (EIC: B6C)

HOW TO USE

nil.5 MANUAL

SERVICE AND

TROUBlESHOOllNG

(UNItI INSlRUCDONS

ENGINE !mlEMS

[UNill MAlNlENAME

TRAN!iMwON

ANDTRANMIRCASE 5-l

wm MAtNlENANQ

FlK4EUERSHAFB.

AXLES, AND SU.%MSlON

wNnlM4lNlENANcE

RRAuESYSlEM

@NlqMAlNlEw

FRAME (UNbT)MMENANCE

Appmved for public release; dishibuh is unlimited.

HEADQUARTERS, DEPARTMENTS OF THE ARMY

AN-b THE AIR FORCE

DECEMBER 1997

ARMY TM 9-2320-387-24-1

AIR FORCE TO 36A12-1A-3052-1

TECHNICAL MANUAL HEADQUARTERS

NO. 9-2320-387-24-1 DEPARTMENTS OF THE ARMY AND THE AIR FORCE

WASHINGTON, D.C., 31 December 1997

TECHNICAL ORDER

NO. 36A12-1A-3052-1

TECHNICAL MANUAL

VOLUME 1 OF 2

UNIT, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE

FOR

TRUCK, UTILITY: S250 SHELTER CARRIER,

4X4, M1113

(2320-01-412-0143) (EIC: B6B)

TRUCK, UTILITY: UP-ARMORED CARRIER,

4X4, M1114

(2320-01-413-3739) (EIC: B6C)

Thi s manual i s publ i shed i n two parts. TM 9-2320-387-24-1 contai ns chapters 1 through 9, and

TM 9-2320-387-24-2 contai ns chapters 10 through 33 and appendi ces A through H.

Thi s manual contai ns a tabl e of contents and al phabeti cal i ndex for both vol umes 1 and 2.

Change 1 i

Approved for public release; distribution is unlimited.

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can hel p i mprove thi s publ i cati on. I f you fi nd any mi stakes or i f you know of a way to i mprove the

procedures, pl ease l et us know. Submi t your DA Form 2028 (Recommended Changes to Equi pment

Techni cal Publ i cati ons), through the I nternet, on the Army El ectroni c Product Support (AEPS) websi te.

The I nternet address i s http://aeps.ri a.army.mi l . I f you need a password, scrol l down and cl i ck on

ACCESS REQUEST FORM. The DA Form 2028 i s l ocated i n the ONLI NE FORMS PROCESSI NG

secti on of the AEPS. Fi l l out the form and cl i ck on SUBMI T. Usi ng thi s form on the AEPS wi l l enabl e us

to respond qui cker to your comments and better manage the DA Form 2028 program. You may al so mai l ,

fax or emai l your l etter or DA Form 2028 di rect to: AMSTA-LC-CI Tech Pubs, TACOM-RI , 1 Rock I sl and

Arsenal , Rock I sl and, I L 61299-7630. The emai l address i s TACOM-TECH-PUBS@ri a.army.mi l . The fax

number i s DSN 793-0726 or Commerci al (309) 782-0726.

TM9- 2320- 387- 24- 1

CHAPTER 1

Section I.

II.

III.

CHAPTER 2

Section I.

II.

III.

Iv.

v.

CHAPTER 3

Section I.

II.

III.

Iv.

v.

CHAPTER 4

Section I.

II.

III.

n?

V.

VI.

VOLUME 1 OF 2

1 HOWTOUSETHISMANUAL 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 INTRODUCTION I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information ...........................................

Equipment Description and Data ..................................

Principles of Operation ..........................................

SERVICE AND TROUBLESHOOTING (UNIT) INSTRUCTIONS .........

Repair Parts, Special Tools, Test, Measurement, Diagnostic

Equipment (TMDE), and Support Equipment .........................

Service Upon Receipt ...........................................

Preventive Maintenance Checks and Services (PMCS) ...................

General Maintenance Instructions .................................

Electrical/Mechanical Systems Troubleshooting ........................

ENGINE SYSTEMS (UNIT) MAINTENANCE .......................

Lubrication System Maintenance ..................................

Fuel System Maintenance ........................................

Accelerator System Maintenance ..................................

Exhaust System Maintenance .....................................

Cooling System Maintenance .....................................

ELECTRICAL SYSTEM (UNIT) MAINTENANCE . . . . . . . . . . . . . . . . . . . .

Generating and Protective Control Box System Maintenance ..............

Starter and Starting Control System Maintenance ......................

Instruments, Sending Units, Switches, and Horn Maintenance .............

Transfer Case and Transmission Electrical Maintenance .................

Lighting System Maintenance ....................................

Battery System Maintenance .....................................

Page

vii

1-l

l-1

l-2

l-23

2-1

2-l

2-l

2-2

2-30

2-33

3-l

3-l

3-21

3-81

3-90

3-109

4-l

4-1

4-20

4-29

4-65

4-81

4-107

ii

TM9- 2320- 387- 24- l

Page

CHAPTER 5

Section I.

II.

TRANSMISSION AND TRANSFER CASE (UNIT) MAINTENANCE . . . . . . .

Transmission hlaintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-l

5-l

5-31

CHAPTER 6

Section I.

II.

III.

PROPELLER SHAFTS, AXLES, AND SUSPENSION (UNIT) MAINTENANCE

Propeller Shafts hlaintenance .....................................

Front and Rear Axles hlaintenance. .................................

Suspension Maintenance .........................................

6-l

6-l

6-12

6-48

CHAPTER 7

I.

II.

1 BRAKE SYSTEM (UNIT) MAINTENANCq. . . . . . . . . . . . . . . . . . . . . . . . .

I I

Service Brake System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Dual Service/Parking Brake System Maintenance . . . . . . . . . . . . . . . . . . .

7-l

7-l

7-37

CHAPTER 8

Section I.

II.

WHEELS AND STEERING (UNIT) MAINTENANCE ..................

Wheel and Runflat System Maintenance .............................

Steering Components hlaintenance .................................

8-l

8-l

8-35

CHAPTER 9 1 FRAME (UNIT) hlAINTENANCE I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-l

. . .

III

CHAPTER 12 . . . . . . . . . . . . . . . . . . . . . . . 12-1

Secti on I . Engi ne/Crew Compartment Heater Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . 12-1

I I . Communi cati ons Ki ts Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-25

I I I . Wi nch Ki t Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-49

SPECI AL PURPOSE KI TS (UNI T) MAI NTENANCE

CHAPTER 13 . . . . . . . . . . . . . . . . . . . . 13-1

Secti on I . General I nstructi ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

I I . Preparati on for Storage and Shi pment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

PREPARATI ON FOR STORAGE OR SHI PMENT

CHAPTER 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Secti on I . Mechani cal Troubl eshooti ng. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

I I . Ai r Condi ti oni ng Troubl eshooti ng. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

TROUBLESHOOTI NG (DS)/(GS)

CHAPTER 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Secti on I . General Engi ne Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

I I . Engi ne Repl acement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-47

ENGI NE (DS) MAI NTENANCE

CHAPTER 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1 FUEL SYSTEM (DS) MAI NTENANCE

CHAPTER 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1 COOLI NG SYSTEM (DS) MAI NTENANCE

Page

TM 9-2320-387-24-1

iv Change 1

CHAPTER 11 . . . . . . . . . . . . . . . . . . . . . . . 11-1

Secti on I . Weapon Carri er Body Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

I I . Shel ter Carri er Body Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-139

I I I . Ai r Condi ti oni ng Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-151

I V. Rear Cargo Door Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-165

SPECI AL PURPOSE BODI ES (UNI T) MAI NTENANCE

VOLUME 2 OF 2

CHAPTER 10 . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Secti on I . Body Mai ntenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

I I . Body Accessori es Mai ntenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-100

BODY AND ACCESSORI ES (UNI T) MAI NTENANCE

TM 9- 2320- 387- 24- l

CHAPTER 18 ELECTRICAL SYSTEM (DS) MAINTENANCE . . . . . . . . . . . . .

CHAPTER 19 1 TRANSRIISSION (DS) hlAINTENANCE I. . . . . . . . . . . . . . . . . .

CHAPTER 20 1 TRANSFER CASE CDS) RfAINTENANCE I. . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 21

CHAPTER 22

CHAPTER 23

CHAPTER 24

CHAPTER 25

Section I.

II.

CHAPTER 26

CHAPTER 27

CHAPTER 28 TRANSMISSION (GS) REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 PROPELLER SHAFTS, AXLES, AND SUSPENSION CDS) hfAINTENANCE 21-l

I

1

I

1 SERVICE BRAKE SYSTEhl (DS) RIAINTENANCE I. . . . . . . . . . . . . . . . . . . 22-l

1 STEERING SYSTEhl CDS) hlAINTENANCE I. . . . . . . . . . . . . . . . . . . . . . . . 23-l

FRAhIE (DS) MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-l

SPECIAL PURPOSE BODIES CDS) hI.AINTENANCE . .................

Armament Carrier Maintenance ...................................

Air Conditioning Maintenance .....................................

SPECIAL PURPOSE KITS (DS) hfAINTENANCE I. . . . . . . . . . . . . . . . . . . . 26-1

ELECTRICAL SYSTEhf (GS) REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-l

Page

18-l

19-l

20-l

25-l

25-l

25-37

28-l

V

TM 9-2320-387-24-l

CHAPTER 29

CHAPTER 30

CHAPTER 31

CHAPTER 32

CHAPTER 33

CHAPTER 34

APPENDIX A

APPENDIX B

APPENDIX C

APPENDIX D

APPENDIX E

APPENDIX F

APPENDIX G

APPENDIX H

INDEX

1 TRANSFER CASE (GS) REPAIR 1 . . . . . . . . . . .

1 DIFFERENTIAL (GS) REPAIR I. . . . . . . . . . . .

. ,...................

. . . . . . . . . . . . . . . . . . . .

STEERING SYSTEM (GS) REPAIR . . . . . . . . . .

. . . . .

1 FRAME (GS) REPAIR I. . . . . . . . . . . . . . . . . . . . . . . . . .

1 BODY(GS) REPAIR 1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1 SUSPENSION (GS) hZAINTENANCE 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFERENCES ................................................

MAINTENANCE ALLOCATION CHART ..............................

EXPENDABLE/DURABLE SUPPLIES AND hIATERIALS LIST ............

ILLUSTRATED LIST OF hI.ANUFACTURED ITEMS ....................

TORQUELIMITS ..............................................

BODY REPAIR MATERIALS. .....................................

MANDATORY REPIACEMEhT PARTS. .............................

WIRING DIAGRAMS AND SCHEMATICS. ...........................

Page

29-l

30-l

32-1

33-1

34-1

A-l

B-l

C-l

D-l

E-l

F-l

G-l

H-l

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INDEX 1

vi

TM 9-2320-387-24-1

Change 1 1-1

CHAPTER 1

INTRODUCTION

Section I. GENERAL INFORMATION

a. Thi s techni cal manual contai ns i nstr ucti ons for uni t, di r ect, and gener al suppor t mai ntenance of

the 4x4, M1113 and M1114 vehi cl es.

b. Model s i ncl uded ar e:

(1) M1113, S250 Shel ter Car r i er

(2) M1114, Up-Ar mor ed

Depar tment of the Ar my for ms and pr ocedur es used for equi pment mai ntenance wi l l be those pr escr i bed

by DA Pam 738-750, The Ar my Mai ntenance Management System (TAMMS).

Refer to TM 750-244-6, Pr ocedur es for Destr ucti on of Ar my Tank-automoti ve Equi pment to Pr event

Enemy Use.

Refer to TM 740-90-1, Admi ni str ati ve Stor age of Equi pment and TM 746-10, Mar ki ng, Packagi ng, and

Shi pment of Suppl i es and Equi pment: Gener al Packagi ng I nstr ucti ons for Fi el d Use.

I f your vehi cl e needs i mprovement, l et us know. Send us an EI R. You, the user, are the onl y one who can tel l

us what you dont l i ke about your equi pment. Let us know why you dont l i ke the desi gn or performance. The

preferred method for submi tti ng QDRs i s through the Army El ectroni c Product Support (AEPS) websi te

under the El ectroni c Defi ci ency Reporti ng System (EDRS). The web address i s: https://aeps.ri a.army.mi l .

Thi s i s a secured si te requi ri ng a password whi ch can be appl i ed for on the front page of the websi te. I f the

above method i s not avai l abl e to you, put i t on an SF 368, Product Qual i ty Defi ci ency Report (PQDR), and

mai l i t to us at: U.S. Army Tank-automoti ve and Armaments Command, ATTN: AMSTA-TR-E/PQDR MS

267, 6501 E. 11 Mi l e Road, Warren, MI 48397-5000. Wel l send you a repl y.

The quar ter l y Equi pment I mpr ovement Repor t and Mai ntenance Di gest, TB 43-0001-62 ser i es,

contai ns val uabl e fi el d i nfor mati on on the equi pment cover ed i n thi s manual . The i nfor mati on i n the

TB 43-0001-62 ser i es i s compi l ed fr om some of the Equi pment I mpr ovement Repor ts that you pr epar ed

on the vehi cl es cover ed i n thi s manual . Many of these ar ti cl es r esul ted fr om comments, suggesti ons,

and i mpr ovement r ecommendati ons that you submi tted to the EI R pr ogr am. The TB 43-0001-62 ser i es

contai ns i nfor mati on on equi pment i mpr ovements, mi nor al ter ati ons, pr oposed Modi fi cati on Wor k Or der s

(MWOs), war r anti es (i f appl i cabl e), acti ons taken on some of your DA For m 2028s (Recommended

Changes to Publ i cati ons), and advance i nfor mati on on pr oposed changes that may affect thi s manual .

The i nfor mati on wi l l hel p you i n doi ng your job better and wi l l hel p i n keepi ng you advi sed of the l atest

changes to thi s manual . Al so r efer to DA Pam 25-30, Consol i dated I ndex of Ar my Publ i cati ons and Bl ank

For ms and appendi x A, Refer ences, of thi s manual .

1-6. EQUIPMENT IMPROVEMENT REPORT AND MAINTENANCE DIGEST (EIR MD)

1-5. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR)

1-4. PREPARATION FOR STORAGE AND SHIPMENT

1-3. DESTRUCTION OF ARMY EQUIPMENT TO PREVENT ENEMY USE

1-2. MAINTENANCE FORMS, RECORDS, AND REPORTS

1-1. SCOPE

TM 9- 2320- 387- 24- l

1-7. METRIC SYSTEM

The equipment described herein contains metric components and requires metric common and special

tools; therefore, metric units in addition to standard units will be used throughout this publication.

In addition, a metric conversion table is located on the inside back cover of this publication.

l-8. MANDATORY REPLACEMENT PARTS

The maintenance instructions contained herein make reference to removing and discarding piece

parts such as: gaskets, lockwashers, cotter pins, O-rings, seals, etc.; these items should be considered

mandatory replacement items and replaced with new parts during assembly/installation.

l-9. BREAK-IN PROCEDURE

Upon receipt of vehicles, or after engine replacement, break-in procedures must be observed during the

first 500 miles (804 kilometers) of operation. For break-in procedure, refer to TM 9-2320-387-10.

Section II. EQUIPMENT DESCRIPTION AND DATA

1-l 0. EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES

The 4x4, Ml113 and Ml114 vehicles are tactical vehicles designed for use over all types of roads, as well

as cross-country terrain, in all weather conditions. The vehicles have four driving wheels powered by a

V-8, liquid-cooled, turbocharged diesel engine. Four-wheel hydraulic service brakes and a mechanical

parking brake are common to all models. Ml113 and Ml114 vehicles are equipped with a pintle hook for

towing. Tiedown and lifting eyes are provided for air, rail, or sea shipment.

1- 2

TM 9-2320-387-24-l

1 l-1 0. EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES Kontdl

1

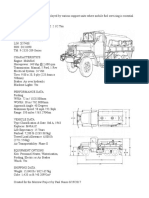

UP-ARMORED CARRIER, W/SUPPLEMENTAL ARMOR: Ml 114

PURPOSE: This model is used to transport, mount, and operate the M2 and M60 machine guns and

MKl9 automatic grenade launcher with armor protection for crew, weapons components, and

ammunition. The Ml114 model may have a optional rear winch which can be used for recovery operations.

Ml 114

1-3

TM9- 2320- 387- 24- l

l-1 0. EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES (Contd)

S250SHELl YERCARRI EkM1113

PURPOSE: This model is used for securing and transporting the S250 electrical equipment shelter. The

Ml113 model may have a optional front winch which can be used for recovery operations.

Ml 113

l - 4

TM 9- 2320- 387- 24- l

l- 11. LOCATION AND DESCRIPTION OF MAJOR

COMPONENTS

The exterior components described below are common to all vehicles covered in this manual. Special

differences are found in TM 9-2320-387-10 or table l-l, Differences Between Models, in this manual.

0

A

0

B

0

C

0

D

0

E

0

F

0

G

0

H

0

I

0

J

0

K

0

L

AIR CLEANER - Filters air before it enters intake manifold.

ENGINE - Provides power for the vehicle.

TRANSMISSION - Transmits engine power to transfer case at varying speeds.

FUEL TANK - Stores fuel.

GEARED I-IUB - Transfers turning action of halfshafts to wheels for vehicle motion.

PINTLE HOOK - Permits towing of vehicles or equipment.

REAR PROPELLER SHAFT - Transmits power from the transfer case to the rear differential.

TRANSFER CASE - Provides full-time four-wheel drive with three drive ranges.

FRONT PROPELLER SHAFT - Transmits power from the transfer case to the front differential.

MASTER CYLINDER AND HYDRO-BOOSTER - Provides hydraulic pressure and power assist

for vehicle stopping power.

DIFFERENTIAL - Transfers turning action of the propeller shaft to the geared hubs through the

halfshafts.

WINCH - 9,000 lb electrically powered to provide recovery capability. Located in front of vehicle on

Ml113 models (if equipped) and rear of vehicle on Ml114 models (if equipped).

m

/

7i-m

A

F _- - n n

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Military BlundersDocument381 pagesMilitary BlundersThoukididis Thoukididou100% (6)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm B221Document15 pagesAstm B221prakhar tandon67% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- TM 9-2815-202-34 Engine M 109Document670 pagesTM 9-2815-202-34 Engine M 109Thoukididis Thoukididou100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Unit, Direct Support and General Support Maintenance Repair Parts and Special Tools List (Including Depot Maintenance Repair Parts)Document611 pagesUnit, Direct Support and General Support Maintenance Repair Parts and Special Tools List (Including Depot Maintenance Repair Parts)tehFattManNo ratings yet

- Raiseboring Drill PipesDocument16 pagesRaiseboring Drill Pipesmanuel_plfNo ratings yet

- W3 - Basic Upstream Oil - Gas ProcessesDocument63 pagesW3 - Basic Upstream Oil - Gas ProcessesHidayah HumairaNo ratings yet

- 2nd Armor BattalionDocument36 pages2nd Armor BattalionThoukididis ThoukididouNo ratings yet

- JanusDocument69 pagesJanusThoukididis ThoukididouNo ratings yet

- FM 3-21-8 The Infantry Rifle Platoon and Squad COMPLETEDocument602 pagesFM 3-21-8 The Infantry Rifle Platoon and Squad COMPLETECBDrucker100% (1)

- FM 3-21-8 The Infantry Rifle Platoon and Squad COMPLETEDocument602 pagesFM 3-21-8 The Infantry Rifle Platoon and Squad COMPLETECBDrucker100% (1)

- TM 9-2920-258-30&P Alternator M 109Document76 pagesTM 9-2920-258-30&P Alternator M 109Thoukididis ThoukididouNo ratings yet

- Technical Advice Sheet - 5 Dealing With Dampness in Old WallsDocument10 pagesTechnical Advice Sheet - 5 Dealing With Dampness in Old WallsLasha ShartavaNo ratings yet

- Compression MouldingDocument41 pagesCompression MouldingSuranjana Mandal100% (1)

- Summer Internship Report on Rejection Reduction in CPC Ring ManufacturingDocument33 pagesSummer Internship Report on Rejection Reduction in CPC Ring ManufacturingrenatoeliegeNo ratings yet

- M49A2CDocument2 pagesM49A2CArmySGTNo ratings yet

- JWFC Event Handbook 2010Document284 pagesJWFC Event Handbook 2010Thoukididis Thoukididou100% (1)

- TM 9-2350-314-34-2 Maintenance Manual M 109 A6Document660 pagesTM 9-2350-314-34-2 Maintenance Manual M 109 A6Thoukididis ThoukididouNo ratings yet

- Iraq Ordnance Identification Guide 2004Document653 pagesIraq Ordnance Identification Guide 2004Thoukididis Thoukididou100% (3)

- Janus 2Document6 pagesJanus 2Thoukididis ThoukididouNo ratings yet

- TM-9-2350-261-10 Μ113Α2Document765 pagesTM-9-2350-261-10 Μ113Α2Thoukididis ThoukididouNo ratings yet

- TM 9-1015-203-12 Howitzher Light Towed 105mm M101A1Document389 pagesTM 9-1015-203-12 Howitzher Light Towed 105mm M101A1sergey62No ratings yet

- Conectores Deutz - Cat Rehs0970Document104 pagesConectores Deutz - Cat Rehs0970Miguel Angel Martinez DominguezNo ratings yet

- Heat Treatment of MetalsDocument44 pagesHeat Treatment of Metalsikram7550100% (2)

- 202-24P EngDocument328 pages202-24P EngtehFattManNo ratings yet

- German Fighter Ace Hans Joachim MarseilleDocument234 pagesGerman Fighter Ace Hans Joachim MarseilleHamilton60100% (6)

- Cilindro Servo KONGSBERGDocument47 pagesCilindro Servo KONGSBERGAnonymous UjSbzQ100% (1)

- Welding Dissimilar MetalsDocument6 pagesWelding Dissimilar MetalsNitintak100% (1)

- Triumph Sprint ST 1050 Manual 2005pdfDocument441 pagesTriumph Sprint ST 1050 Manual 2005pdfweverton lenkerNo ratings yet

- German Guided Missiles PDFDocument52 pagesGerman Guided Missiles PDFThoukididis Thoukididou100% (7)

- German Half-Tracks of WWII PDFDocument74 pagesGerman Half-Tracks of WWII PDFThoukididis Thoukididou100% (6)

- German Gliders in WWII PDFDocument52 pagesGerman Gliders in WWII PDFThoukididis Thoukididou100% (5)

- German Headgear in World War II-VolI PDFDocument305 pagesGerman Headgear in World War II-VolI PDFThoukididis Thoukididou100% (2)

- German Fighters Over The Med-WWII Photo Album PDFDocument97 pagesGerman Fighters Over The Med-WWII Photo Album PDFThoukididis Thoukididou100% (1)

- Battle of The Bulge 1944 (2) Bastogne (Campaign)Document91 pagesBattle of The Bulge 1944 (2) Bastogne (Campaign)Thoukididis Thoukididou100% (5)

- German Eastern Front-Focus On Armour Camouflage AndMarkings PDFDocument38 pagesGerman Eastern Front-Focus On Armour Camouflage AndMarkings PDFThoukididis Thoukididou100% (3)

- German Fighters Over The Med-WWII Photo Album PDFDocument97 pagesGerman Fighters Over The Med-WWII Photo Album PDFThoukididis Thoukididou100% (1)

- 086 - M109 155mm Self-Propelled Howitzer 1960-2005Document51 pages086 - M109 155mm Self-Propelled Howitzer 1960-2005Thoukididis Thoukididou86% (7)

- German Destroyers and Escorts-WW2 Photo Album PDFDocument98 pagesGerman Destroyers and Escorts-WW2 Photo Album PDFThoukididis Thoukididou100% (2)

- 1st Battal Action Iwo JimaDocument43 pages1st Battal Action Iwo JimadmanosNo ratings yet

- Army - FM 1 - The ArmyDocument75 pagesArmy - FM 1 - The ArmyMeowmix100% (1)

- FM 7-8 W CH 1Document410 pagesFM 7-8 W CH 1Thoukididis ThoukididouNo ratings yet

- FM 23-25 Light Antiarmor WeaponsDocument136 pagesFM 23-25 Light Antiarmor WeaponsThoukididis ThoukididouNo ratings yet

- Konnerup (2012) Design of Steel-Concrete Composite Structures For A High-Rise BuildingDocument185 pagesKonnerup (2012) Design of Steel-Concrete Composite Structures For A High-Rise Buildingint8No ratings yet

- Is 694Document30 pagesIs 694nm_rangaNo ratings yet

- Cement Practice QuestionsDocument2 pagesCement Practice QuestionsSureshKonamNo ratings yet

- Managing Hazardous Waste in IndiaDocument19 pagesManaging Hazardous Waste in IndiaKrishna Chandran PallippuramNo ratings yet

- Types of Bricks in Masonry Construction - Properties & Uses - The Constructor PDFDocument5 pagesTypes of Bricks in Masonry Construction - Properties & Uses - The Constructor PDFPrajith AdNo ratings yet

- E2 Gates Mectrol CatalogueDocument60 pagesE2 Gates Mectrol Cataloguepavli999No ratings yet

- Cnveyors ComponentsDocument16 pagesCnveyors ComponentsLizbeth AtamariNo ratings yet

- GMK4115Document28 pagesGMK4115SeksiNo ratings yet

- Manual STAHL Ex PZC Overpressure Monitoring SystemDocument18 pagesManual STAHL Ex PZC Overpressure Monitoring SystemEdel Weiss50% (2)

- Importing Mining Chemicals From ChinaDocument6 pagesImporting Mining Chemicals From Chinacalisto_rNo ratings yet

- Lecture 5 Shaft Design With SolutionsDocument38 pagesLecture 5 Shaft Design With Solutionsgatoradeqazwsx100% (2)

- Recent Innovations in Concrete and Foundations Lead to More Sustainable GrowthDocument49 pagesRecent Innovations in Concrete and Foundations Lead to More Sustainable Growthprakash.sharmaNo ratings yet

- Hawai Chappal: - SpecificationDocument28 pagesHawai Chappal: - SpecificationAvinash MishraNo ratings yet

- Hexion Starting Formulation 8014Document4 pagesHexion Starting Formulation 8014uzzy2No ratings yet

- APMRG1 Series: Packaged Air ConditionersDocument32 pagesAPMRG1 Series: Packaged Air Conditionerszaid jamaluNo ratings yet

- Sunsai Pharma Equipments Pvt. ltd-1Document2 pagesSunsai Pharma Equipments Pvt. ltd-1Sunsai VasaiNo ratings yet

- BVC BrochureDocument16 pagesBVC BrochureMOHSINNo ratings yet

- Introduction To HydraulicDocument28 pagesIntroduction To HydraulicMohamed ElmakkyNo ratings yet