Professional Documents

Culture Documents

Monitoring and Control of Hydro Power Plant

Uploaded by

João Pedro Reis LopesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monitoring and Control of Hydro Power Plant

Uploaded by

João Pedro Reis LopesCopyright:

Available Formats

MONITORING AND CONTROL OF HYDRO POWER PLANT

Matei Vinatoru

University of Craiova, Faculty of Automation, Computers and Electronics

Str. A. I. Cuza Nr. 13, Craiova, RO 200396

Abstract: In hydro power plants from Romania, there is a major interest for the

implementation of digital systems for monitoring and control replacing the conventional

control systems for power, frequency and voltage. Therefore is necessary to develop

mathematical models capable to accurately describe both dynamic and stationary

behaviour of the hydro units, in order to be able to implement digital control algorithms.

Moreover, it is necessary to implement systems for monitoring and control of hydro

power plants in a cascade system along a river, in order to optimize the use of the river

resources. This paper presents the possibilities of modelling and simulation of the hydro

power plants and performs an analysis of different control structures and algorithms.

Keywords: Hydro power plant, Control system, Digital Control Algorithms.

1. INTRODUCTION

This paper discusses the aspects of modelling and

design of hydro power plants and control of hydro

power groups. There are presented computing

methods for pressure losses on the water intake pipes

from the reservoir to the turbine, aspects regarding

the energy transformations for different turbine types

(Pelton, Francis, and Kaplan) in order to determine

the net hydraulic power of the plant and to determine

the control options for the turbines.

Also, are presented different control structures for

the power groups and hydro power plants. In this

case, are analyzed different SCADA monitoring and

control systems, for an assemble of hydro power

plants on the same water stream as well as SCADA

system for high-energy power plants with Kaplan

turbines, and the case studies for the modelling,

design and study of the power groups, with and

without water towers.

This paper will present several possibilities for the

modelling of the hydraulic systems and the design of

the control system.

2. THE DESIGN OF CONTROL SYSTEMS FOR

KAPLAN HYDRAULIC TURBINES

2.1. Introduction

Different construction of hydropower systems and

different operating principles of hydraulic turbines

make difficult to develop mathematical models for

dynamic regime, in order to design the automatic

control systems. Also, there are major differences in

the structure of these models. Moreover, there are

major differences due to the storage capacity of the

reservoir and the water supply system from the

reservoir to the turbine (with or without surge

chamber). The dynamic model of the plants with

penstock and surge chamber is more complicated

than the run-of-the-river plants, since the water feed

system is a distributed parameters system.

2.2. Modelling of the hydraulic system for run-of-

the-river hydropower plants

These types of hydropower plants have a low water

storage capacity in the reservoir; therefore the plant

operation requires a permanent balance between the

water flow through turbines and the river flow in

IFAC Workshop ICPS'07

2007, July 09-11

Cluj-Napoca, Romania

-44-

order to maximize the water level in the reservoir for

a maximum efficiency of water use. Next, we will

determine the mathematical model for each

component of the hydropower system.

A. Hydraulic turbine. The hydraulic turbine can be

considered as an element without memory since the

time constants of the turbine are less smaller than the

time constants of the reservoir, penstock, and surge

chamber, if exists, which are series connected

elements in the system.

As parameters describing the mass transfer and

energy transfer in the turbine we will consider the

water flow through the turbine Q and the moment M

generated by the turbine and that is transmitted to the

electrical generator. These variables can be

expressed as non-linear functions of the turbine

rotational speed N, the turbine gate position Z, and

the net head H of the hydro system.

Q = Q(H, N, Z) (1)

M = M(H, N, Z) (2)

Through linearization of the equations (1) and (2)

around the steady state values, we obtain:

z a n a h a q

Z

Z

Q

N

N

Q

H

H

Q

Q

. . .

13 12 11

+ + =

=

(3)

z a n a h a m

Z

Z

M

N

N

M

H

H

M

M

. . .

23 22 21

+ + =

=

(4)

where the following notations were used:

0

Q

Q

= q ,

0

N

N

= n ,

0

M

M

= m ,

0

H

H

= h ,

0

Z

Z

= z which

represent the non-dimensional variations of the

parameters around the steady state values.

B. The hydraulic feed system. The hydraulic feed

system has a complex geometrical configuration,

consisting of pipes or canals with different shapes

and cross-sections. Therefore, the feed system will

be considered as a pipe with a constant cross-section

and the length equal with real length of the studied

system. In order to consider this, it is necessary that

the real system and the equivalent system to contain

the same water mass. Let consider m

1

, m

2

... m

n

the

water masses in the pipe zones having the lengths l

1

,

l

2

,...,l

n

and cross-sections A

1

, A

2

,...,A

n

of the real feed

system. The equivalent system will have the length

L=l

1

+l

2

+...+l

n

and cross-section A, conveniently

chosen. In this case, the mass conservation law in

both systems will lead to the equation:

= =

=

n

i

i i

n

i

i

A l l A

1 1

. (5)

Since the water can be considered incompressible,

the flow Q

i

through each pipe segment with cross-

section A

i

is identical and equal with the flow Q

through the equivalent pipe

Q=v.A=Q

i

=v

i

.A

i

for i=1, 2,...,n (6)

Where v is the water speed in the equivalent pipe,

and v

i

is the speed in each segment of the real pipe.

From the mass conservation law it results:

Q

A l

l

A l

l Q

A

Q

v

i i

i

i i

i i

.

. .

= = = (7)

The dynamic pressure loss can be computed

considering the inertia force of the water exerted on

the cross-section of the pipe:

dt

dv

g

L

A a A L a m F

i

.

.

. . . .

= = =

(8)

Where L is the length of the penstock or the feed

canal, A is the cross-section of the penstock, is the

specific gravity of water (1000Kgf/m

3

), a is the water

acceleration in the equivalent pipe, and g=9,81 m/s

2

is the gravitational acceleration.

The dynamic pressure loss can be expressed as:

dt

dQ

A l

l

g

L

dt

dv

g

L

A

F

H

i i

i i

d

= = =

.

. .

(9)

Using non-dimensional variations, from (9) it results:

dt

Q

Q

d

A l

l L

H

Q

H

H

i i

i

d d

d

|

|

.

|

\

|

0

0

0

0

(10)

Or in non-dimensional form:

dt

dq

T h

w d

= (11)

Where T

W

is the integration constant of the

hydropower system and the variables have the

following meaning:

=

i i

i

d

w

d

d

d

A l

l L

H

Q

T

Q

Q

q

H

H

h

0

0

0 0

, , (12)

It must be noted that this is a simplified method to

compute the hydraulic pressure loss, which can be

used for run-of-the-river hydropower plants, with

small water head. If an exact value of the dynamic

pressure is required, then the formulas presented in

[8], sub-chapter 8.4 The calculation of hydro energy

potential shall be used.

Using the Laplace transform in relation (11), it

results:

h

d

(s) = - sT

w

.q(s), and, ) (

1

) ( s h

sT

s q

d

w

= (13)

Replacing (13) in (3) and (4) and doing some simple

calculations, we obtain:

) (

1

) (

1

) (

11

13

11

12

s z

s T a

a

s n

s T a

a

s q

w w

+

+

+

= (14)

) (

1

) (

1

) (

11

13

11

12

s z

s T a

s T a

s n

s T a

s T a

s h

w

w

w

w

d

+

+

=

(15)

) (

1

) (

1

) (

11

13

23

11

12

21

s z

s T a

s T a

a s n

s T a

s T a

a s m

w

w

w

w

|

|

.

|

\

|

+

+

|

|

.

|

\

|

+

=

(16)

The mechanical power generated by the turbine can

be calculated with the relation P=..Q.H (see [8]

sub-chapter 8.5 Hydraulic turbines), which can be

used to obtain the linearized relations for variations

of these values around the steady state values:

p = .g.Q

o

.h + .g.H

o

.q (17)

-45-

Where is the turbine efficiency, and , Q, and H

were defined previously.

On the other hand, the mechanical power can be

determined using the relation P=M.=2.M.N,

which can be used to obtain the linearized relations

for variations of these values around the steady state

values:

( )

m

P

N

p

P

N

n

o

o

o

o

2

2 2

= (18)

Where P

0

=M

0

.

0

is the steady state power generated

by the turbine for a given steady state flow Q

0

and a

steady state head H

0

, and N

0

is the steady state

rotational speed.

Using these relations, the block diagram of the

hydraulic turbine, for small variation operation

around the steady state point, can be determined and

is presented in figure 1, where the transfer functions

for different modules are given by the following

relation:

|

|

.

|

\

|

+

=

|

|

.

|

\

|

+

=

+

=

+

=

+

=

+

=

s T a

s T a

a s H

s T a

s T a

a s H

s T a

s T a

H

s T a

s T a

s H

s T a

a

s H

s T a

a

s H

w

w

mz

w

w

mn

w

w

hz

w

w

hn

w

qz

w

qn

11

13

23

11

12

21

11

13

11

12

11

13

11

12

1

) ( ,

1

) ( ,

1

,

1

) ( ,

1

) ( ,

1

) (

(19)

For an ideal turbine, without losses, the coefficients

a

ij

resulted from the partial derivatives in equations

(12 - 16) have the following values: a

11

=0,5;

a

12

=a

13

=1; a

21

=1,5; a

23

=1. In this case, the transfer

functions in the block diagram are given by the

following relation:

s T . ,

s T

H ,

s T . ,

H H

w

w

hn

w

qz qn

5 0 1 5 0 1

1

+

=

+

= = (20)

|

|

.

|

\

|

+

=

+

=

s T . ,

s T

, H ,

s T . ,

s T

H

w

w

mn

w

w

hz

5 0 1

5 1

5 0 1

(21)

s T . ,

s T . .

s T . ,

s T

) s ( H

w

w

w

w

mz

5 0 1

5 0 1

5 0 1

1

+

=

|

|

.

|

\

|

+

= (46)

2.3. Simulation results

Example. Let consider a hydroelectric power system

with the following parameters:

-Water flow (turbines): Q(5001000) m

3

/s, Q

N

=725

m

3

/s;

-Water level in the reservoir: H(1738) m, H

N

=30

m;

-The equivalent cross-section of the penstock

A=60m

2

;

-Nominal power of the turbine

P

N

=178MW=178.000kW;

-Turbine efficiency =0,94;

-Nominal rotational speed of the turbine N=71,43

rot/min;

-The length of the penstock l=l

i

=20m;

It shall be determined the variation of the time

constant T

W

for the hydro power system.

For the nominal regime, using relation (12), where

l

i

=20m, the time constant of the system is:

s T

w

82 , 0

60 81 , 9

20

30

725

=

= (47)

Next we will study the variation of the time constant

due to the variation of the water flow through the

turbine for a constant water level in the reservoir,

H=30m, as well as the variation due to the variable

water level in the reservoir for a constant flow

Q=725 m

3

/s.

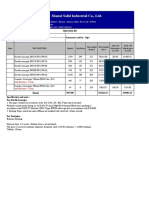

In table I, column 3 and figure 2 a) are presented the

values and the graphical variation of the time

constant T

W

for the variation of the water flow

between 500 m

3

/s and 110 m

3

/s, for a constant water

level in the reservoir, H=30m. In table 8.12 column 4

and figure 2 b) are presented the values and the

graphical variation of the time constant T

W

for the

variation of the water level in the reservoir, for a

constant water flow, Q=725m

3

/s.

It can be seen from the table or from the graphs that

the time constant changes more than 50% for the

entire operational range of the water flow through the

turbine or if the water level in the reservoir varies.

These variations will create huge problems during

the design of the control system for the turbine, and

robust control algorithms are recommended.

gQ

o

gH

o

H

qn

(s)

H

qz

(s)

H

hn

(s)

H

hz

(s)

H

mn

(s)

H

mz

(s)

2N

o

/P

o

(2N

o

)

2

/P

o

p

n p

n

n

n

z

z

z

z

m

h

q

+

Fig. 1. The block diagram of the hydraulic turbine.

-46-

Table I. Variations of the time constant of the hydro

system

H Q Tw(H=30m) Tw(Q=725mc/s

17 1135,46 1,286065 1,449101

20 965,14 1,093155 1,231736

23 839,25 0,950569 1,071075

26 742,42 0,8408882 0,947489

29 665,62 0,7538998 0,849473

32 603,21 0,6832217 0,769835

35 551,51 0,6246598 0,703849

38 507,97 0,5753446 0,648282

In figure 3 is presented the block diagram of the

turbines power control system, using a secondary

feedback from the rotational speed of the turbine. It

can be seen from this figure that a dead-zone element

was inserted in series with the rotational speed sensor

in order to eliminate the feedback for 0,5%

variation of the rotational speed around the

synchronous value.

The constants of the transfer functions had been

computed for a nominal regime T

W

=0,8s. The

optimal parameters for a PI controller are: K

R

=10,

T

I

=0,02s. The results of the turbine simulation for

different operational regimes are presented in figure

4, for a control system using feedbacks from the

turbine power and rotational speed, with a dead-zone

on the rotational speed channel for 0,5% variation

of the rotational speed around the synchronous value

(a) Power variation with 10% around nominal value,

b) Rotational speed variation for power control).

Figure 3. Block Diagram of the control system for hydraulic turbines

n p

0.0389

0.0016

s 4 , 0 1

1

+

0.0025

1.1305

p

n

n

n

z

z

z

z

m

h

q

+

s 4 , 0 1

1

+

s

s

4 , 0 1

8 , 0

+

s

s

4 , 0 1

2 , 0 5 , 1

+

s

s

4 , 0 1

8 , 0 1

+

s

s

4 , 0 1

8 , 0

+

|

|

.

|

\

|

+

s T

K

I

R

1

1

-

-

+

P

*

0,6

0,7

0,8

0,9

1

1,1

1,2

1,3

1,4

1,5

15 20 25 30 35 40

[s]

[m]

H

T

w

b)

0,5

0,6

0,7

0,8

0,9

1

1,1

1,2

1,3

1,4

500 600 700 800 900 1000 1100 1200

T

w

Q

[s]

[mc/s] a)

Figure 2 Variation of the integral time constant T

W

: a) by the flow Q, b) by the water level H

-47-

Fig. 4. Turbine Control simulations with feedbacks

from turbine power and rotational speed

Fig. 5 Control structure with only power feedback,

a) Power variation with 10% around nominal value,

b) Rotational speed variation for power control

In figure 5 are presented the variations of the turbine

power (graph a) and rotational speed (graph b) for

the control system using a feedback from the turbine

power but no feedback from the rotational speed .

This oscillation has no significant influence on the

performance of the system but would have lead to

permanent perturbation of the command sent to the

turbine gate.

2.4. Conclusions

The possibility of implementation of digital systems

for monitoring and control for power, frequency and

voltage in the cascade hydro power plant was

discussed. The simplified mathematical models,

capable to accurately describe dynamic and

stationary behaviour of the hydro units have been

developed and simulated. These aspects are

compared with experimental results. Finally, a

practical example was used to illustrate the design of

controller and to study the system stability.

3. IMPLEMENTATION OF DIGITAL SYSTEMS

FOR MONITORING AND CONTROL IN

CASCADE POWER PLANTS

3.1. Introduction

A series of hydro power plant systems in Romania

are capturing the river water in a geographical area

and store it in reservoirs connected through transport

pipes. Every lake has its own hydro power plant and

the water used through the turbines of one plant is

sent to the next reservoir, thus using the entire

hydraulic potential offered by the geographical area.

A similar hydro power system is built in the north-

west part of Oltenia region, in the south-west part of

Romania. The hydraulic profile of this cascade

system is presented in figure 6.

As it can be seen in this figure, there are two hydro

power plants, CH1 and CH2, with reservoirs and

surge tanks and one run-of-the-river power plant, CH

3, with a reservoir providing only a net head.

In this type of hydropower systems, provided with

small power units connected to the grid, the dynamic

of the hydraulic system has a great importance in the

stability of the system. The dynamics of the turbine

and electric generator have a very small influence

since the power grid has a great influence and will

maintain the generator rotational speed at a value

synchronized with the electrical frequency of the grid

and the generated power is dependent of the existing

unbalance. Therefore, this paper will try to study the

stability of the hydraulic system of the hydropower

system and the achievement of a maximum

efficiency of the water usage in the system.

0 0.5 1 1.5 2 2.5 3

-0.02

0

0.02

0.04

0.06

0.08

0.1

0.12

0 0.5 1 1.5 2 2.5 3

-2

-1

0

1

2

3

4

5

P[%]

a)

b)

t [s]

t [s]

0 0.5 1 1.5 2 2.5 3

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

P[%]

0 0.5 1 1.5 2 2.5 3

-4

-2

0

2

4

6

8

10

12

t [s]

t [s]

a)

b)

n[%]

-48-

3.2. The design of control systems for hydro power

plants with reservoir and surge tank.

Different construction of hydropower systems and

different operating principles of hydraulic turbines

make difficult to develop mathematical models for

dynamic regime, in order to design the automatic

control systems [1,2,5,6]. Also, there are major

differences in the structure of these models.

Moreover, there are major differences due to the

storage capacity of the reservoir and the water supply

system from the reservoir to the turbine (with or

without surge tank). The dynamic model of the

plants with penstock and surge tank is more

complicated than the run-of-the-river plants, since

the water feed system is a distributed parameters

system. This paper presents a solution for the

modelling of the hydraulic systems and the design of

the control system.

As it is know, the hydraulic power available at the

turbine is a function of the water flow trough the

turbine Q

t

and the net head H

n

.

P

h

= Q

t

H

n

(25)

In the long run operation of the hydro power plants

with reservoir and surge tank, it results from the

relation (25) that the power generated by the turbine

is maximum when the head H

n

is maintained at

maximum value, for variations of the river flow due

to meteorological conditions. In this case, the power

generated by the turbine will be only a function of

the water flow trough the turbine. In this case, the

controller is controlling the flow Q

t

in order to

maintain constant the water level in the reservoir,

thus the main feedback will be from the reservoirs

water level sensors.

There are cases when the hydro power plants with

high capacity reservoirs are used as peak load plants.

In these cases, the power dispatcher will impose the

plant generating power and the plant dispatcher or

the automatic control system will distribute the

required load over the operational power units and

the water level in the reservoir can vary between the

admissible maximum and minimum limits with an

admissible rate of variation. The set-point for the

water level controller is generated by the monitoring

system, has a certain variation profile and is a

function of the required power:

t

n

n

Q

P

H

*

*

= (26)

In figure 7 is presented the simplified hydraulic

diagram of a hydropower plant with reservoir and

surge tank. Using this structure, a case study is

presented, regarding the modelling, simulation and

the stability of the of the control structure.

3.2.1 Mathematical modelling of the control system

This control system is opening and closing the

control gates for the turbines in order to assure an

optimal operation and in the same time to maintain a

constant water level in the reservoir. In a similar

mode, a control system may be used for two plants in

a cascade system to maintain the water flows

between the plants.

In order to design the control system, there is

necessary to obtain a mathematical model of the

plant, which contains the water tunnel between the

reservoir and the surge tank, the surge tank itself, the

penstock and the hydraulic turbine[4,5,6]. We will

analyze every component of the plant in order to

determine the model, using the energy balance

equations and the continuity equations for the water

flows, in dynamic regime.

For the hydropower plant we will consider the

simplified diagram in figure 7.

a) The continuity equation for the water in the

reservoir

w t r

B

L

Q Q Q

dt

dH

A = (27)

Where: -A

L

is the area of the horizontal surface of the

equivalent reservoir considered as having a constant

depth H

L

. H

L

.A

L

=V

real

, Q

r

is the water flow entering

the reservoir, Q

W

is the discharging water flow

(through the emptying channel or overspill).

b) The energy balance equation for the water tunnel

between the reservoir and the surge tank:

Surge Tank

Penstok

Generator

Water tunnel

Overspill

Figure 7. Simplified model of the hydropower plant

Turbine

Controller

H

n

*

Level

transducer

Q

t

Echivalent

reservoir

H

B

H

C

Q

cf

Q

B

L

t

Q

e

Q

r

Q

c

Turbine

Gate

H

L

-49-

c

H

B

H

c

Q

c

Q

C

c t

Q

t

Q

t

C

dt

t

dQ

gA

L

t

t

= + + (28)

Where: -L

t

is the length of the tunnel between the

reservoir and the surge tank, A

t

is the cross-section

of the tunnel, Q

t

is the water flow in the tunnel, Q

c

is

the water flow entering the surge tank, H

B

is the

water height in the reservoir, H

C

is the water height

in the surge tank,

dt

dv

g

L

dt

A Q d

g

L

dt

dQ

gA

L

t t t t t t

t

t

= =

) / (

is the

inertial force of the water mass in the tunnel

expressed in hydrostatic units (meters of water

column), C

t

/Q

t

/Q

t

is the hydraulic pressure loss due

to friction with the tunnel walls; the flow Q

t

is

considered positive if the water flows from the

reservoir to the surge tank and the loss coefficient C

t

will be positive in this case, C

t

/Q

c

/Q

c

is the hydraulic

pressure loss due to the cross-section reduction at the

entrance in the surge tank installed to avoid the

pressure shocks, -H

B

-H

C

is the driving force that

moves the water in the tunnel and the surge tank.

c) The continuity equation for the surge tank

cf t c c

Q Q Q

dt

dHc

A = = (29)

Where: A

C

is the cross-section of the surge tank, Q

C

is the water flow at the entrance of the surge tank

(we assume that there is no water flow through the

top of the surge tank), Q

cf

is the water flow through

the penstock.

d) The energy balance equation for the penstock and

the turbine

Considering the low water volume existing in these

two elements we can neglect the water mass

accumulation (water is considered incompressible).

Therefore, from the energy balance equation, the

behaviour of the penstock and the turbine can be

described by the water flow computed from the

following relation:

o

c c c c

o v

H

Q Q C H

Q x Q

+

= , (30)

Where: H

0

is the water level in the surge tank when

the gate is completely open, Q

0

is the water flow for

a completely open gate and -0 x 1 is the opening

factor for the gate.

We choose this form of the expression in order to use

non-dimensional values for the gate opening and to

avoid some very complex equations describing the

water flow through the gate. Therefore are necessary

some experiments to measure the values of H

0

and

Q

0

. The gate is open completely and the flow Q

0

in

steady conditions is measured. After the flow

stabilizes, the water height in the surge tank, H

0

, is

measured. It must be mentioned that in steady state

conditions (H

L

=constant, H

C

=constant,

Q

cf

=constant), the water flow into the surge tank

Q

C

=0.

e) The equation of the controller

The control system structure for the water level in the

reservoir is presented in figure 7. It is recommended

to use a PI controller if the gate servomotor is a

system with its own position controller (proportional

actuator) or a PD controller if the actuator is of the

integrating type (without its own position controller).

In our case we will use a PI controller.

In this control system, the water level in the reservoir

is compared with a set-point determined by the

operational conditions. If the level is different than

the set-point, the error is processed by the turbine

controller which will open or close the gates in order

to maintain the water level at the prescribed value.

The equation of the PI controller can be written in

differential form:

dt

H H d

K H H

T

K

dt

dx ref f

R ref f

i

R

) (

) (

+ = (31)

Where: H

ref

is the set-point level, H

f

is the water level

in the reservoir, K

R

, T

i

are the proportional constant

and the integral constant of the PI controller.

This equation is not considering some factors such

as: delays due to the servomotor and the controller,

and minimum and maximum variation rates for the

gates.

3.2.2 Stability analysis

The equations (27)-(31), which describe the dynamic

behaviour of the control system for the hydropower

unit, are strongly non-linear. Moreover, some

parameters such as loss coefficients C

t

and C

c

can

change due to different flow regimes and due to

building parameters of the feeding system. Therefore

is necessary to study the system stability in the

operation point (small stability in Lyapunov way)

and to determine the stability domain in the

operational parameters plane.

a) Small stability of the control system

Equations (27)-(31) will be linearized around the

operation point. For simplicity, it is preferable to use

non-dimensional variables as follows: q

t

is the

relative variation of the flow through the penstock, h

B

is the relative variation of the water level in the

reservoir, h

c

is the relative variation of the water level

in the surge tank, is the relative variation of the

controller output and q

r

is the relative variation of the

river flow around the steady state value for constant

water level (Q

r0

=Q

t0

).

0

0

0

0

0

0

0

0

0

0

r

r r

r

c

c c

c

B

B B

B

t

t t

t

Q

Q Q

q ;

x

x x

;

H

H H

h

;

H

H H

h ;

Q

Q Q

q

=

(32)

We will introduce the following supplementary

reference parameters,

0

2

0 0

;

c

t

t

ref

i

H

Q C

p

H

T x

= = ,

where characterize the statism of the integral

-50-

controller (the slope of the controller output for a

step variation of the error) and p characterize the

ratio between the losses on the feeding pipes and the

hydraulic pressure at the base of the surge tank.

In steady state regime, H

B

=const., H

c

=const.,

Q

t0

=Q

cf

=const. and from equations (27)-(31) it

results that:

0

2

0

0 0

) 1 (

c

t

t c ref B

H p C H H H Q + = + = =

0

0

0

0

0

c

t

H

H

Q

Q

x = .

According with the previous relations and

considering that the spillover flow is zero (Q

B

=0),

following linearization of equations (27)-(31), the

linear state equations, expressed with non-

dimensional variables defined in (32), can be written

as:

-from (27) it results:

r t

B

t

ref L

q q

dt

dh

Q

H A

+ =

0

(33)

-from (28) it results:

c B

c

ref

c

c

c

c

t

c

t

t

t

c t

t t

h h

H

H

q

H

C

q

H

C

dt

dq

H gA

L Q

Q

Q

= +

+ +

0 0

2

0

0

2

0

0

0

2

2

(34)

It can be considered that the level control system

works with a zero steady state error, H

B0

=H

ref

and

Q

c0

=0 and from equation (28), written for steady

state, it results:

1 1

0

2

0

0

0 0 0

2

0

+ = + =

= =

p

H

C

H

H

or

H H H H C

c

t

t

c

ref

c ref c B

t

t

Q

Q

In this case, equation (34) becomes:

c B t

t

c t

t t

h h p q p

dt

dq

H gA

L Q

+ + = ) 1 ( 2

0

0

(35)

From the linearization of equation (29) it results:

0 0

0

t

cf

t

c

t

c c

Q

Q

q

dt

dh

Q

H A

= (36)

Where the variation of the water flow through the

penstock Q

cf

can be obtain from the linearization of

the equation (30) around the steady state values:

c

t

t

c

c c

cf

h

Q

Q

h

H

H Q x

H

H

Q x Q

+ =

= + =

2

2

0

0

0

0 0 0

0

0

0 0

In this case, equation (29) becomes:

=

c t

c

t

c c

h q

dt

dh

Q

H A

2

1

0

0

(37)

The equation system (33 -37) can be expressed in

canonical matrix-vectorial form:

Bu Ax

dt

dx

+ = or Bu Ax x + =

Where the following notations were used:

0 0

0

0

0

, ,

t

L ref

L

t

c c

c

t s

t t

t

Q

A H

T

Q

A H

T

A H g

Q L

T

=

=

.

And

(

(

(

=

c

B

t

h

h

q

x ;

(

(

(

(

=

1

1

0

L

T

B ;

(

(

(

(

(

(

(

=

c c

f

w w w

T T

T

T T

p

T

p

2

1

0

1

0 0

1

1 1 2

A ; | |

r

q 0 = u .

(39)

The block diagram of the installation is presented in

figure 8.

For the controller, from (7) and noting:

H

H

H H

h

ref

ref ref

r

0

0

= ,

0

0

x T

H K

K

i

ref R

I

= , (integral

constant of the controller

rationalized),

0

0

x

H K

K

ref R

P

= , the proportional

constant (rationalized) and e(t)=(h

r

-h

BT

), we obtain:

dt

t de

K t e K

dt

d

P I

) (

) ( + =

(40)

Adding equations (33), (35), and (37) and using the

notations from (14), we obtain the complete equation

system for the controller in figure 7:

H

R

(s) H

IT

(s)

H

p

(s)

h

B

*

h

B

(s) (s) e(s)

q

r

(s)

q

t

(s)

-

+

+

-

Figure 8. The block diagram of level controller

Notes: H

R

(s)-controller transfer function;

H

IT

(s)-the transfer function on the direct channel

H

P

(s)-transfer function on the perturbation channel

-51-

r

L

t

L

B

q

T

q

T dt

dh

+ =

1 1

(41)

c

t

B

t

t

t

t

h

T

h

T

p

q

T

p

dt

dq

|

|

.

|

\

| +

+ =

1 1 2

(42)

=

c

c

c

t

c

c

T

h

T

q

T dt

dh 1

2

1 1

(43)

Using Laplace transform, for zero initial conditions,

from equations (40) to (43) it results:

) s ( h

sT

) s ( h

sT

p

) s ( q

sT

p

) s ( q

); s ( q

sT

) s ( q

sT

) s ( h

c

t

B

t

t

t

t

r

L

t

L

B

|

|

.

|

\

| +

+ =

+ =

1 1 2

1 1

(44)

) s ( e K ) s ( e

s

K

) s (

) s (

sT

) s ( h

sT

) s ( q

sT

) s ( h

P

I

c

c

c

t

c

c

+ =

=

1

2

1 1

(46)

These equations can be processed to obtain the

transfer functions on the direct channel and on the

perturbation channel. From (45), the flow q

t

can be

expressed as:

) (

2

1

) (

2

) 1 (

) ( s h

p s T

s h

p s T

p

s q

c

t

B

t

t

+

+

+

= (48)

This will be used in equation (46):

) s ( ) s ( h ) s ( h

p s T

) s ( h

p s T

) p (

) s ( h sT

c c

t

B

t

c c

+

+

+

=

2

1

2

1

2

1

(49)

And the variation of the water level in the surge tank

can be determined as:

) s (

) p ( s ) T pT ( s T T

p s T

) s ( h

) p ( s ) T pT ( s T T

) p (

) s ( h

t c t c

t

B

t c t c

c

+ + + +

+

+ + + +

+

=

1 2 4 2

2

1 2 4 2

1

2

2

(50)

Let note H

n

(s)=2T

c

T

t

s+(4pT

c

+T

t

)s+2(p+1) to

simplify the calculations and let use (50) in (48) to

determine the water flow through the penstock,

which is equal with the flow through turbine.

1 2 4 2 : where

1

2

1

2

+ + + + =

+

+

+

=

p s ) T pT ( s T T ) s ( H

), s (

) s ( H

) s ( h

) s ( H

) s ( H

p s T

) p (

) s ( q

t c t c m

n

B

n

m

t

t

(51)

And after simple processing from (51) and (44) it

results:

( )

) (

) (

) ( 2

) (

) (

2

) ( s q

s P

s H p s T

s

s P

p s T

s h

r

n t t

B

+

+

+

=

(52)

Where the characteristic polynomial of the open-loop

system is:

( )

| |

| | ) p p ( s T ) p ( ) T T )( p ( p

s T T ) p ( T T ) p ( T T p

s T pT T T s T T ) s ( P

t c L

t c t L L c

t c t L t c L T

1 3 2 1 1 4

1 2 1 2 2 8

8 2

2

2 2

3 4 2

+ + + + + + + +

+ + + + +

+ + + =

(53)

From (52), the two transfer functions in the block

diagram of the control system presented in figure 2

can be calculated:

) (

2

) (

s P

p s T

s H

t

IT

+

= and

( )

) (

) ( 2

) (

s P

s H p s T

s H

n t

P

+

=

(54)

From (47), using the Laplace transform, we get:

) ( ) ( ) ( s h

s

s K K

s h

s

s K K

s

BT

R I

r

R I

+

+

= (55)

Replacing (55) in (52), after several simple

transforms, it results:

) s ( q

) s K K )( p s T ( ) s ( P s

) s ( H ) p s T ( s

) s ( h

) s K K )( p s T ( ) s ( P s

) s K K )( p s T (

) s ( h

r

R I t

n t

r

R I t

R I t

B

+ + +

+

+

+

+ + +

+ +

=

2

2

2

2

(56)

Where the characteristic polynomial of the closed-

loop system is:

( )

| |

| |

I R I t

R t t c L

t c t L L c

t c t L

t c L R I t

pK s ) p p pK K T (

s K T T ) p ( ) T T )( p ( p

s T T ) p ( T T ) p ( T T p

s T pT T T

s T T ) s K K )( p s T ( ) s ( P s ) s ( L

T

2 1 3 2 2

1 1 4

1 2 1 2 2 8

8

2 2

2

2

3 2

4

5 2

+ + + + + +

+ + + + + + +

+ + + + + +

+ + +

+ = + + + =

For an exact analysis of the hydropower unit

dynamic behaviour it can be considered the example

of a hydropower plant with reservoir and surge tank

having a low installed power but a high storage

capacity in the reservoir.

Experiment. It is considered a hydropower system

with the following parameters:

The water volume in the reservoir V

L

=4,8.10

6

m

3

;

-The equivalent depth of the reservoir (considered

constant) H

L

=60m; The equivalent reservoir surface

area is A

L

4,8.10

6

/60=8.10

4

m

2

; The length of the pipe

between the reservoir and the surge tank L

t

=9650m,

the diameter of the pipe D

t

=3,6m and the cross-

section A

t

=10m

2

; The surge tank has a diameter

D

c

=5,4m with a cross-section A

c

=23m

2

; The gross

nominal head H

B

=260m, H

Bmax

=266m, H

Bmin

=245m;

The gross nominal head at the surge tank H

c0

=230m;

The nominal flow through the penstock Q

t0

=36m

3

/s;

The length of the penstock L

cf

=205m.

-52-

Using the previous data, the time constants and

equations coefficients can be determined using

relation (14):

s .

.

T

;

.

T ;

,

T

L

c t

5

10 6

36

80000 260

150

36

23 234

15

10 230 81 9

36 9560

= =

= = =

=

023 0

36 36

230 13 0

13 0

230

230 260

2

0

0

0

0

0

2

,

.

. , pH

C

; ,

H

H H

H

C

p

Q

Q

t

c

t

c

c ref

c

t

t

= =

=

= =

(56)

34 2

230

36

0

0

0

0 0

0

0

0 0 0 0

,

c

H

t

Q

H

Q x

;

H

c

H

Q x

t

Q

v

Q = = = = =

The steady state value for the controller output x

0

is

determined using the maximum flow through the

penstock Q

vmax

=56m

3

/s and is obtained for x

0

=1:

7 3

64 0

374 2

iar 64 0

56

36

0

0

0

,

,

,

; , x

H

Q

= = = =

Replacing these values in equations (48) and (50),

we obtain the operational expressions for the flow q

t

and the level in the surge tank:

) s ( h

s

,

) s ( h

s

.

) s ( q

) s ( q

s

. ,

) s ( q

s

. ,

) s ( h

c B t

r t B

1 58

92 1

1 58

35 4

10 166 0 10 166 0

5 5

+

+

=

+ =

(57)

) s (

s s

) s ( ,

) s ( h

s s

,

) s ( h

B c

+ +

+

+ +

=

1 41 1991

1 58 26 0

1 41 1991

5 0

2

2

(58)

( )

| |

| |

I R I t

R t t c L

t c t L L c

t c t L t c L

R I t

pK s ) p p pK K T (

s K T T ) p ( ) T T )( p ( p

s T T ) p ( T T ) p ( T T p

s T pT T T s T T

) s K K )( p s T ( ) s ( P s ) s ( L

T

2 1 3 2 2

1 1 4

1 2 1 2 2 8

8 2

2

2

2

3 2

4 5 2

+ + + + + +

+ + + + + + +

+ + + + + +

+ + + =

= + + + =

L(s) = 405.10

8

. s

5

+ 153.10

7

.s

4

+ 348,53.10

5

.s

3

+

(35,27.10

4

+15.K

R

).s

2

+ (15.K

I

+0,26.K

R

+4238).s +

0,26.K

I

(59)

Using the stability criteria Routh-Hurwitz for the

characteristic polynomial (59) we obtain a series of

inequalities for the tuning parameters K

i

and K

R

as

follows:

-from the block diagram of the control system

presented in figure 8, it can be seen that the transfer

coefficient on the direct channel is negative,

therefore the controller shall have inverse output and

therefore K

R

<0;

-from the inequality a

0

=0,26.K

I

>0 it results that the

integral parameter shall be positive;

-from the Hurwitz determinant of second order

results:

a

0

. a

1

= 0,26 K

I

.( 15 K

I

+ 0,26 K

R

+ 4238) > 0

16300 69 , 57 + <

I R

K K

this gives us a very large range for the tuning

parameters of the controller;

-from the Hurwitz determinant of third order results:

K

I

< (14950000000 + 152270* K

R

+3,9*

K

R

2

)/(3072000 - 225* K

R

)

Solving previous inequality graphically, we obtain

K

R

(0 -100), 0<K

i

<(4866 -4826) and again, the

range for the tuning parameters is large.

During the real operation of the hydropower unit,

even if the control system remains stable, the

oscillations in the hydraulic unit shall be avoided

since they can generate huge over pressure in the

penstock. In order to highlight these oscillations, a

simulation of the hydropower unit was performed

using different values for the tuning parameters.

The block diagram in figure 9 was used for

simulation. The transfer functions in the diagram

were computed using the equations (57)-(58).

Notes: |

.

|

\

|

+ =

s

K

K s H

I

R R

1 ) ( ,

1 58

92 . 1

+

=

s

H

Qt

s

s

s H

qth

5 10 . 166 . 0

) (

= ,

1 58

35 . 4

+

=

s

H

hqt

,

1 41 1991

5 . 0

) (

2

+ +

=

s s

s H

hhc

,

1 41 1991

1 58

) (

2

+ +

+

=

s s

s

s H

C

s

5

10 . 166 , 0

h

B

(s)

q

r

(s)

q

t

(s)

-

+

Figure 9. The block diagram of the level control system, used for simulation

H

R

(s)

h

B

*

(s)

e(s)

+

-

H

C

(s)

H

hhc

(s)

H

hqt

(s)

H

qth

(s)

H

Qt

(s)

h

c

(s)

-

-

+ +

-53-

This diagram was preferred for simulation since it

allows highlighting the variation of some specific

parameters of the system, such as the level in the

surge tank and the flow variation in the penstock Q

t

.

The simulation results are represented in the figures

10 and 11.

In figure 10 is presented the system output for a 10%

variation of the set-point for the reservoir water

level, with no limitation on the flow control channel.

Oscillations of the flow can be observed, due to the

big differences between the time constants in the

simulation scheme.

To avoid these flow oscillations, the variation of the

flow control output is limited in order to avoid big

differences between the subsequent commands sent

to the gate. The simulation results are presented in

figure 11.

3.3. Conclusions

Specifically, a hydropower plant may be composed

of several turbine-generator units, referred to in this

paper as groups. Each hydropower plant must be

controlled by a local SCADA system that will be

connected at the Central SCADA system, which

performs the control of the plants from the hydro-

valley, for optimal generation scheduling and control

for the reservoir stream-flows.

4. MONITORING SYSTEM FOR CASCADE

HYDRO POWER PLANTS.

The optimal generation scheduling is an important

daily activity for hydroelectric power generation

companies. The goals are to determine which

hydropower groups are to be used in order to

generate enough power to satisfy demand

requirements, with various technological constraints

and with minimum operating cost. In the same time

hydropower systems must consider the stream-flow

equations for reservoirs that couple all reservoirs

along a hydro-valley, because the amount of outflow

water released by one of hydropower plant affects

water volumes in all the plants downstream.

Furthermore, other conditions must be imposed as:

water travel times, alternative uses (irrigation, flood

control, navigation). To solve the optimal scheduling

of hydropower plants, a highly sophisticated

modelling for the operation is required.

In the figure 12 is presented the SCADA system

architecture for monitoring and control of hydro

power plants in a cascade system along a river,

implemented in order to optimize the use of the river

resources [7]. This structure is implemented at the

central dispatcher. At the level of hydro power plant

there is a local monitoring and control system,

interconnected with central dispatcher via modems

and radio communication buses.

0 2000 4000 6000 8000 10000

-2.5

-2

-1.5

-1

-0.5

0

0.5

1

0 2 0 0 0 4 0 0 0 6 0 0 0 8 0 0 0 1 0 0 0 0

-0 .0 2

0

0 .0 2

0 .0 4

0 .0 6

0 .0 8

0 .1

0 .1 2

0 .1 4

t [s]

h

B

[%]

Figure 10. The response of the control system for a 10% variation of the set-point

t [s]

q

t

[%]

0 2000 4000 6000 8000 10000

-0.02

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

Figure 11. The response of the control system with flow limitation

0 2000 4000 6000 8000 10000

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

t t

h

B

[%] q

t

-54-

The monitoring system presented above is

performing the following functions:

-Data acquisition from the local monitoring systems

installed in each power plant, using routers

connected to telephone lines or radio

communications; the data is sent tot the SCADA

server for processing, monitoring and optimization;

-The optimal load distribution between the

operational units in the power plants, depending of

the available water flow, in order to ensure an

efficient usage of the water for the required system

power;

-Monitoring of the water levels in the reservoirs and

water flow control in order to maintain the maximum

water level in the reservoirs;

-In the case of extreme rain conditions, control the

water flows in order to avoid flooding of the areas

neighbouring the plants.

5. CONCLUSIONS

The possibility of implementation of digital systems

for monitoring and control for power, frequency and

voltage in the cascade hydro power plant was

discussed. The simplified mathematical models,

capable to accurately describe dynamic and

stationary behaviour of the hydro units were

developed and simulated and these results were

compared with the experimental results. Finally, a

practical example was used to illustrate the design of

controller and to study the system stability.

REFERENCES

[1] G., D Ferrari-Trecate, Mignone, D. Castagnoli, M.

Morari, Hybrid Modeling and Control of a

Hydroelectric Power Plant, CH 0802, Institut fur

Automatik, ETH- Zurich, (2003).

[2] C. Henderson, Yue Yang Power Station The

Implementation of the Distributed Control System,

GEC Alsthom Technical Review, Nr. 10, 1992.

[3] G. I. Krivchenko, Hydraulic machines: Turbine and

Pumps,2nd ed. ISBN 1-56670-001-9, CRC Press,

London (1994).

[4] M. Vntoru, E. Iancu, C. Vntoru, Control,

Monitoring and Protection of the Turbine and

Generator System, International Symposium on System

Theory, Robotics, Computers and Process Informatics,

SINTES 9, Craiova , (1998).

[5] O. F. Jimenez, M. H. Chaudhry Water level Control in

Hydropower Plants, Journal of Energy Engineering,

Vol118, No. 3 Dec. 1992.

[6] H. Weber, V. Fustik, F. Prillwitz, A. Iliev, Practically

oriented simulation model for the Hydro Power Plant

Vrutok in Macedonia, Balkan Power Conference, 19.

21.06.2002, Belgrade

[7] I.C.E Felix -Bucharest S.A, Arhitectura sistemului de

control supervizor i achiziie de date (SCADA) al

cascadei de hidrocentrale de pe Oltul Mijlociu, http://

www.felix.ro/apl.html.

[8] M. Vinatoru, Conducerea automata a proceselor

industriale, vol. II, Editura Universitaria Craiova, 2005.

To CHE

System

ER

Radio

Engineering

Pules Message NMEA

Sincron

mGPS

Local Sincron

Server

Ethernet Switch

Pulse Message NMEA

Operator 1

Operator 2

Engineering Server

SCADA 1

Server

SCADA 2

Hist. Date

Server

Ethernet Bus

Ethernet Switch

Simulator CHE

Router

Asyncron 2

Router

Asyncron 1

- - - - - - Modem 10 Modem 1

Ethernet Bus

Sever Radio

comunication

Fig. 12. SCADA system architecture - Dispatcher

Hydro power plants

Wall Display (4 modules)

-55-

You might also like

- Hydro Electric Power Plant AutomationDocument39 pagesHydro Electric Power Plant AutomationMd Abdul RahemanNo ratings yet

- Network Code For Requirements For Grid Connection Applicable To All GeneratorsDocument85 pagesNetwork Code For Requirements For Grid Connection Applicable To All GeneratorsEliza Maria CloteaNo ratings yet

- An Improved Approach For Connecting VSD and Electric Motors PDFDocument8 pagesAn Improved Approach For Connecting VSD and Electric Motors PDFalbertofgvNo ratings yet

- Technical Specs For Power Supply SystemDocument120 pagesTechnical Specs For Power Supply SystemJoshua GarbinNo ratings yet

- Alarm Acknowledgment in The RTAC HMI - AG2014-35 - 20200807Document12 pagesAlarm Acknowledgment in The RTAC HMI - AG2014-35 - 20200807teodorojrNo ratings yet

- Experion PksDocument270 pagesExperion PksKalyanasundaram GNo ratings yet

- Digital Substation Deployment AjarbaizanDocument8 pagesDigital Substation Deployment AjarbaizanInayat HathiariNo ratings yet

- ATS Control Panel InstallDocument28 pagesATS Control Panel Installvijayakumar3661No ratings yet

- Nema Ics 1.3-1986 (R2020) Watermarked - 2021-12-02Document13 pagesNema Ics 1.3-1986 (R2020) Watermarked - 2021-12-02man_y2kNo ratings yet

- STN HiAv V2.0Document88 pagesSTN HiAv V2.0Sagar JadhavNo ratings yet

- CS400 Manual - EngDocument128 pagesCS400 Manual - Engrany_m75% (4)

- Role of SCADA in Hydro Power PlantDocument6 pagesRole of SCADA in Hydro Power PlantIndin HasanNo ratings yet

- Simaris Control SiemensDocument21 pagesSimaris Control SiemensKijo SupicNo ratings yet

- 6 Simple Rules To Ensure Substation SafetyDocument3 pages6 Simple Rules To Ensure Substation Safetyat35No ratings yet

- Transmissioncode 2007 EnglDocument79 pagesTransmissioncode 2007 EnglMichel Urra ValderramaNo ratings yet

- 1 2 3 4 5 CFC For S7 Continuous Function Chart Simatic: Appendices ManualDocument126 pages1 2 3 4 5 CFC For S7 Continuous Function Chart Simatic: Appendices ManualBatchmanNo ratings yet

- GCB Application GuideDocument61 pagesGCB Application GuideAnonymous fbeCwgBFYNo ratings yet

- Omicron PTL User Manual EnuDocument29 pagesOmicron PTL User Manual EnuimuNo ratings yet

- 3500 44 Aeroderivative Monitor 129774 01 Rev D PDFDocument87 pages3500 44 Aeroderivative Monitor 129774 01 Rev D PDFlancasaNo ratings yet

- Electrical SCADA System Remote Terminal Unit SpecificationDocument24 pagesElectrical SCADA System Remote Terminal Unit SpecificationhauheoNo ratings yet

- Testing A Metalenclosed Bus PDFDocument10 pagesTesting A Metalenclosed Bus PDFTunoNegro1No ratings yet

- Integrating IEC 61850 and DNPDocument10 pagesIntegrating IEC 61850 and DNPpainkiller000No ratings yet

- 850 Fast Secure Redundant CommunicationsDocument2 pages850 Fast Secure Redundant CommunicationsamruthkiranbabujiNo ratings yet

- EIG2010Document492 pagesEIG2010Ahmad AlsayedNo ratings yet

- 11 AC Induction Motor TestingDocument12 pages11 AC Induction Motor TestingrajNo ratings yet

- The Product Life Cycle Support Policy See Life Cycle Overview Is (1) ...Document4 pagesThe Product Life Cycle Support Policy See Life Cycle Overview Is (1) ...Pradeep KumarNo ratings yet

- Distribution Safety Rules 2016Document118 pagesDistribution Safety Rules 2016bxteoNo ratings yet

- Section 1 General Rules and InstructionsDocument2 pagesSection 1 General Rules and InstructionsDhebdjshdn ShxhshushdNo ratings yet

- MHI DEH Governor for Stable Steam Turbine OperationDocument2 pagesMHI DEH Governor for Stable Steam Turbine Operationhamidkatebi100% (1)

- Heavy Duty Rectifier Broschuere Chlor 020 FINALDocument6 pagesHeavy Duty Rectifier Broschuere Chlor 020 FINALdwijanuarpribadiNo ratings yet

- Arc Flash Analysis IEEE Method Versus THDocument11 pagesArc Flash Analysis IEEE Method Versus THByron CastanedaNo ratings yet

- ESB Networks Electrical Safety Rules 2006Document36 pagesESB Networks Electrical Safety Rules 2006bdiaconu20048672No ratings yet

- IEEE Recommended Practice For Exc. Sys Models 1Document9 pagesIEEE Recommended Practice For Exc. Sys Models 1Emmanuel Zamorano0% (1)

- Scada ReportDocument60 pagesScada ReportSudhir GargNo ratings yet

- Ieee Draft Recommended Practice For Excitation Sys PDFDocument202 pagesIeee Draft Recommended Practice For Excitation Sys PDFroyclhorNo ratings yet

- Part 001 CNT Guide To Control Panel Cable Identification PDFDocument7 pagesPart 001 CNT Guide To Control Panel Cable Identification PDFDany ArriagadaNo ratings yet

- Fdocuments - in Is 8478Document11 pagesFdocuments - in Is 8478chandu1821No ratings yet

- IEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another LookDocument6 pagesIEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another Lookvenkat chakNo ratings yet

- 13849-1 AVENTICS Machine Safety PDFDocument59 pages13849-1 AVENTICS Machine Safety PDFpedro paivaNo ratings yet

- PowerSCADA Expert 7.30 Installation GuideDocument59 pagesPowerSCADA Expert 7.30 Installation GuideHuseyin Doga EmirogullariNo ratings yet

- Bus ArrangementDocument9 pagesBus ArrangementharimadhavareddyNo ratings yet

- Microgrids Black StartDocument7 pagesMicrogrids Black StartLalit ChoudharyNo ratings yet

- Zambian Grid CodeDocument174 pagesZambian Grid CodeNima Mahmoudpour100% (1)

- SCADA Standard FinalDocument46 pagesSCADA Standard Finalcatalin_juganaruNo ratings yet

- Trasformatori SGBDocument24 pagesTrasformatori SGBst_calvoNo ratings yet

- DNP3 Telecontrol v10 eDocument91 pagesDNP3 Telecontrol v10 eandrademaxNo ratings yet

- Scada Project 1326860164Document86 pagesScada Project 1326860164ddh3107No ratings yet

- A Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Document8 pagesA Standard Format For Power System Studies: Peter E. Sutherland (SM) R. Gerald Irvine (SM)Ritaban R. BanerjeeNo ratings yet

- CFC For Simatic s7 (v9.0 Sp2)Document448 pagesCFC For Simatic s7 (v9.0 Sp2)Dogan KarabulutNo ratings yet

- 2VAA005340 en D Symphony Plus Product Catalog PDFDocument148 pages2VAA005340 en D Symphony Plus Product Catalog PDFtt cheneyNo ratings yet

- Hy 250 Scala en DataDocument6 pagesHy 250 Scala en DataAhmed Bilal KhanNo ratings yet

- Pumps and Motors ManagementDocument80 pagesPumps and Motors ManagementMihai Constantinescu100% (1)

- MV Switchgear CT Inspection and Test Procedure: October 2019Document6 pagesMV Switchgear CT Inspection and Test Procedure: October 2019sabamalar100% (1)

- SDG Implementers GuideDocument260 pagesSDG Implementers GuideJeevanandhamNo ratings yet

- Scada System Software RequirementsDocument21 pagesScada System Software RequirementsadactivatorNo ratings yet

- 3451r 92 PDFDocument13 pages3451r 92 PDFFred PrzNo ratings yet

- The King Soldier Bream Auto Saved)Document8 pagesThe King Soldier Bream Auto Saved)tariqmaaniNo ratings yet

- KDF GAC Filters and HousingsDocument37 pagesKDF GAC Filters and HousingsGreen EnergyNo ratings yet

- WaterfloodingDocument4 pagesWaterfloodingjayeshepNo ratings yet

- Penetron Admix BrochureDocument16 pagesPenetron Admix BrochureTatamulia Bumi Raya MallNo ratings yet

- ANDRITZ Company Presentation eDocument6 pagesANDRITZ Company Presentation eAnonymous OuY6oAMggxNo ratings yet

- Comparision of Odour Control TechnologiesDocument2 pagesComparision of Odour Control TechnologiesRahmi ArslanNo ratings yet

- Arahan Makmal Sem 11718-NewDocument18 pagesArahan Makmal Sem 11718-NewAidaFarzanaNanaNo ratings yet

- Caltrans A1Document91 pagesCaltrans A1RubyNo ratings yet

- Eco-Friendly Home Cleaning Recipes and TipsDocument24 pagesEco-Friendly Home Cleaning Recipes and TipsAndrés PacompíaNo ratings yet

- Wonder 5 Unit 2 Test Preparation SheetDocument1 pageWonder 5 Unit 2 Test Preparation SheetAnkica AndrijevićNo ratings yet

- PipeDocument1 pagePipeJawad ChamsouNo ratings yet

- 04TRK S2 - Konversi Reaktor Non-IdealDocument10 pages04TRK S2 - Konversi Reaktor Non-IdealRachmad YogaswaraNo ratings yet

- Thermal Expansion, Calorimetry, Elasticity & ViscosityDocument45 pagesThermal Expansion, Calorimetry, Elasticity & ViscositygokulNo ratings yet

- Estimating Microbial Contamination in Water SamplesDocument5 pagesEstimating Microbial Contamination in Water SamplesAmraha NoorNo ratings yet

- Household ProductsDocument5 pagesHousehold Productsr'BrilePonjeNo ratings yet

- Introduction Project Proposal JuslDocument3 pagesIntroduction Project Proposal JuslJaslyn BautistaNo ratings yet

- Constructive concrete curing compoundDocument2 pagesConstructive concrete curing compoundAstc AfaqNo ratings yet

- Physics - An Introduction For Early Grades PDFDocument14 pagesPhysics - An Introduction For Early Grades PDFsadriddin ariayeeNo ratings yet

- Fall 2009 Michigan Trout Unlimited NewletterDocument28 pagesFall 2009 Michigan Trout Unlimited NewletterMichigan Trout UnlimitedNo ratings yet

- Chlorine Hand BookDocument32 pagesChlorine Hand BookGanesh RamaniNo ratings yet

- Mofad ProfileDocument30 pagesMofad ProfileSAMUEL KIMANINo ratings yet

- CambodiaDocument16 pagesCambodiaThach BunroeunNo ratings yet

- AQT35 ManualDocument282 pagesAQT35 Manualvasile madalinaNo ratings yet

- Rancang Bangun Sistem Irigasi Tetes Otomatis Berbasis Perubahan Kadar Air Tanah Dengan Menggunakan Mikrokontroler Arduino NanoDocument8 pagesRancang Bangun Sistem Irigasi Tetes Otomatis Berbasis Perubahan Kadar Air Tanah Dengan Menggunakan Mikrokontroler Arduino NanoAnde IsnendaNo ratings yet

- Fluvial Geomorphology PDFDocument84 pagesFluvial Geomorphology PDFNelson Edwin Huaman VillacortaNo ratings yet

- Mobile COBRA concrete mixing plantDocument7 pagesMobile COBRA concrete mixing plantAnonymous z4Fe39jNo ratings yet

- Mai Lan Hương G8 -Tập 2Document110 pagesMai Lan Hương G8 -Tập 2Tsuyuri RikaNo ratings yet

- WBGTDocument12 pagesWBGTNardi 1DideNo ratings yet

- LP For 24 17Document12 pagesLP For 24 17William BuquiaNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastFrom EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastRating: 4.5 out of 5 stars4.5/5 (76)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- How to Install & Design Solar Panels like a Professional: Save Thousands by Doing It Yourself: Power All Your Projects with the Power of the SunFrom EverandHow to Install & Design Solar Panels like a Professional: Save Thousands by Doing It Yourself: Power All Your Projects with the Power of the SunRating: 3 out of 5 stars3/5 (1)

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)