Professional Documents

Culture Documents

Welder Qualification Report

Uploaded by

Aries Marte0 ratings0% found this document useful (0 votes)

54 views17 pagesThis document summarizes welder qualification test results for an individual with the name provided. It includes the welding process used, materials welded, welding variables, test methods, and results. The welder was qualified to welding procedure WPS-P1P1-01 using SMAW on SA-106 Grade B steel in the 6G position with uphill progression. All test results including visual examination, macro examination and bend tests were satisfactory.

Original Description:

Original Title

Machote WPQ Soldadores.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes welder qualification test results for an individual with the name provided. It includes the welding process used, materials welded, welding variables, test methods, and results. The welder was qualified to welding procedure WPS-P1P1-01 using SMAW on SA-106 Grade B steel in the 6G position with uphill progression. All test results including visual examination, macro examination and bend tests were satisfactory.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

54 views17 pagesWelder Qualification Report

Uploaded by

Aries MarteThis document summarizes welder qualification test results for an individual with the name provided. It includes the welding process used, materials welded, welding variables, test methods, and results. The welder was qualified to welding procedure WPS-P1P1-01 using SMAW on SA-106 Grade B steel in the 6G position with uphill progression. All test results including visual examination, macro examination and bend tests were satisfactory.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 17

Welder's name

Identification of WPS followed

Specification of base metal(s)

Welding Variables (QW-350)

Welding process(es)

Type (ie; manual, semi-auto) used

Backing (metal, weld metal, double-welded, etc.)

Plate Pipe (enter diameter if pipe or tube)

Base metal P- or S-Number to P- or S-Number

Filler metal or electrode specification(s) (SFA) (info. only)

Filler metal or electrode classification(s) (info. only)

Filler metal F-Number(s)

Consumable insert (GTAW or PAW)

Filler type (solid/metal or flux cored/powder) (GTAW or PAW)

Deposit thickness for each process

Process 1: SMAW 3 layers minimum Yes No

Process 2: 3 layers minimum Yes No

Position qualified (2G, 6G, 3F, etc.)

Vertical progression (uphill or downhill)

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW currenttype/polarity (AC, DCEP, DCEN)

Visual Examination of Completed WeId (QW-302.4) SATISFACTORIO (Satisfactory)

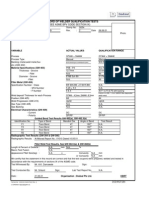

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

NOMBRE DEL SOLDADOR

Test Description

WPS-P1P1-01

SA- 106 Gr. B

Testing Conditions and Qualification Limts

Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; Plate bend specimen, corrosion-resistant overlay IQW-462.5(d)];

Macro test for fusion [QW-462.5(b)]; Macro test for fusion [QW-462.5(e)]

RESULTS

Bend test; Transverse root and face [QW-462.3(a); Longitudinal root and face [QW-462.3)b); Side (OW-462.2);

x

Alternative radiographic examination results (QW-191)

Fillet weld - fracture test (QW-180)

NONE

Macro examination (QW-184) ___________________________

NONE

Other tests

Film or specimens evaluated by NOMBRE TEC. NIVEL II RT

Mechanical tests conducted by N/A

Welding supervised by

Date

Thisiorm4E000SALmay*e.Qbta1 LLd?rom the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

Type Result Type

NOMBRE DE QUIEN SUPERVISO LA PRUEBA HOSTO

----------------- ----------------- -----------------

FECHA DEL REPORTE DE RT

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and testad in accordance with the requirements of Section IX of the ASME Boiler

and Pressure Vessel Code.

. .. -----------------

-----------------------------------------------------------------------

Test coupon Production weld

Thickness

Yes No

Yes No

SATISFACTORIO (Satisfactory)

Actual Values Range Qualified

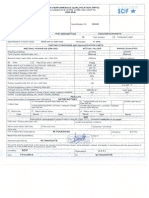

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

NOMBRE DEL SOLDADOR Identification No. S-XX

Test Description

WPS-P1P1-01

SA- 106 Gr. B 0.280" 6" 0.322" 8"

Testing Conditions and Qualification Limts

SMAW SMAW

Manual Manual

CON / SIN (with/without) CON / SIN (with/without)

6" u 8" O.D. > 2-7/8"

P1 P1 A P11 (P1 thru P11)

5.1

E6010 / E7018

F3 SIN RESPALDO, F4 CON RESPALDO

(F3 without backing / F4 with backing)

-------------------------- --------------------------

-------------------------- --------------------------

F3 SIN RESPALDO, F4 CON RESPALDO

(F3 without backing / F4 with backing)

F1=0.125" ; F4=0.155" o 0.197" F3=0.250" ; F4=ILIMITADO

-------------------------- --------------------------

6G F, H, V, O

ASCENDENTE (uphill) ASCENDENTE (uphill)

-------------------------- --------------------------

-------------------------- --------------------------

-------------------------- --------------------------

-------------------------- --------------------------

Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; Plate bend specimen, corrosion-resistant overlay IQW-462.5(d)];

Macro test for fusion [QW-462.5(b)]; Macro test for fusion [QW-462.5(e)]

RESULTS

Bend test; Transverse root and face [QW-462.3(a); Longitudinal root and face [QW-462.3)b); Side (OW-462.2);

X

x

ACEPTABLE (acceptable)

Fillet size (in.)__________NONE______________ Concavity/convexity (in.) _______OK_______

Company NOMBRE EMPRESA RT

By

Thisiorm4E000SALmay*e.Qbta1 LLd?rom the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

Type Result Type Result

No. REPORTE DE RT

------------------ -----------------

NOMBRE DE QUIEN SUPERVISO LA PRUEBA HOSTO

----------------- -----------------

Length and percent of defects

FECHA DEL REPORTE DE RT

-----------------

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and testad in accordance with the requirements of Section IX of the ASME Boiler

and Pressure Vessel Code.

Organization CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

----------------- ----------------- ------------------

NONE

-----------------------------------------------------------------------

Laboratory test no.

Production weld

Range Qualified

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

Test Description

0.280" 6" 0.322" 8"

Testing Conditions and Qualification Limts

SMAW

Manual

CON / SIN (with/without)

O.D. > 2-7/8"

P1 A P11 (P1 thru P11)

--------------------------

--------------------------

F3 SIN RESPALDO, F4 CON RESPALDO

(F3 without backing / F4 with backing)

F3=0.250" ; F4=ILIMITADO

--------------------------

F, H, V, O

ASCENDENTE (uphill)

--------------------------

--------------------------

--------------------------

--------------------------

Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; Plate bend specimen, corrosion-resistant overlay IQW-462.5(d)];

Macro test for fusion [QW-462.5(b)]; Macro test for fusion [QW-462.5(e)]

RESULTS

Bend test; Transverse root and face [QW-462.3(a); Longitudinal root and face [QW-462.3)b); Side (OW-462.2);

Result

No. REPORTE DE RT

-----------------

-----------------

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and testad in accordance with the requirements of Section IX of the ASME Boiler

and Pressure Vessel Code.

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

-----------------------------------------------------------------------

Nombre del operador

Welding operator's name

No. WPS utilizado

Identification of WPS followed

Especificacin del metal base

Specification of base metal(s)

Welding Variables (QW-361.1)

Tipo de soldadura

Type of welding (ie; manual, semi-auto) used

Welding process(es)

Filler metal used (Yes/No) (EBW o LBW)

Type of laser for LBW (CO2 to YAG, etc.)

Continuous drive or inertia welding (FW)

Vacuum or out of vacuum (EBW)

Type of welding (Machine)

Welding process

Direct or remote visual control

Automatic arc voltage control (GTAW)

Automatic joint tracking

Position qualified (2G, 6G, 3F, ETC.)

Consumable inserts (GATW or PAW)

Backing (with/without)

Single or multiple pass per side

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

WELDER OPERATOR PERFORMANCE QUALIFICATIONS (WPQ)

NOMBRE DEL SOLDADOR

Test Description

WPS-P1P1-11

SA-516-70

Testing Variables and Qualification Limts When Using Automatic Welding Equipment

Testing Variables and Qualification Limts When Using Machine Welding Equipment

Visual Examination of Completed WeId (QW-302.4) SATISFACTORIO (Satisfactory)

Plate specimen, macro test for fusion [QW-462.5(b)]

Alternative radiographic examination results (QW-191)

Fillet weld - fracture test (QW-181.2)

NONE

Fillet welds in plate [QW-462.4 (b)]

Macro examination(QW-184) Fillet size (in)

Other tests

Film or specimens evaluated by NOMBRE TEC. NIVEL II RT

Mechanical tests conducted by N/A

Welding supervised by

Date

RESULTS

Transverse root and face bends [QW-462.3(a)] Longitudinal bends [QW-462.3(b) Side bends (QW-462.2);

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)]

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d)]

Type Result Type

. .. -----------------

----------------- ----------------- -----------------

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and testad in accordance with the requirements of Section IX of the ASME Boiler

and Pressure Vessel Code.

FECHA DEL REPORTE DE RT

-----------------------------------------------------------------------

NOMBRE DE QUIEN SUPERVISO LA PRUEBA HOSTO

Probeta Soldadura de produccin

Test coupon Production weld

Espesor

Thickness

Actual Values Range Qualified

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

WELDER OPERATOR PERFORMANCE QUALIFICATIONS (WPQ)

NOMBRE DEL SOLDADOR Identificacin No. A-6

Test Description

WPS-P1P1-11

SA-516-70 0.280" 6" 0.322" 8"

Testing Variables and Qualification Limts When Using Automatic Welding Equipment

-------------------------- --------------------------

SAW SAW

Semiautomatic Semiautomatic

-------------------------- --------------------------

ASCENDENTE (uphill) ASCENDENTE (uphill)

-------------------------- --------------------------

F1=0.125" ; F4=0.155" o 0.197" F3=0.250" ; F4=ILIMITADO

-------------------------- --------------------------

-------------------------- --------------------------

Identification No.

Testing Variables and Qualification Limts When Using Machine Welding Equipment

X

SATISFACTORIO (Satisfactory)

Plate specimen, macro test for fusion [QW-462.5(e)]

ACEPTABLE (acceptable)

Fillet welds in pipe [QW-462.4 (c)]

x Concavity/convexity (in.)

Company NOMBRE EMPRESA RT

Certified by:

-------------------------- --------------------------

-------------------------- --------------------------

RESULTS

Transverse root and face bends [QW-462.3(a)] Longitudinal bends [QW-462.3(b) Side bends (QW-462.2);

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)]

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d)]

Type Result Type Result

-----------------

----------------- ----------------- ------------------ -----------------

----------------- ----------------- ------------------

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and testad in accordance with the requirements of Section IX of the ASME Boiler

and Pressure Vessel Code.

Organization CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

FECHA DEL REPORTE DE RT

Length and percent of defects

NONE

-----------------------------------------------------------------------

Laboratory test no. No. REPORTE DE RT

NOMBRE DE QUIEN SUPERVISO LA PRUEBA HOSTO

Soldadura de produccin

Production weld

Range Qualified

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

WELDER OPERATOR PERFORMANCE QUALIFICATIONS (WPQ)

Test Description

0.280" 6" 0.322" 8"

Testing Variables and Qualification Limts When Using Automatic Welding Equipment

--------------------------

SAW

Semiautomatic

--------------------------

ASCENDENTE (uphill)

--------------------------

F3=0.250" ; F4=ILIMITADO

--------------------------

--------------------------

Testing Variables and Qualification Limts When Using Machine Welding Equipment

--------------------------

--------------------------

RESULTS

Transverse root and face bends [QW-462.3(a)] Longitudinal bends [QW-462.3(b) Side bends (QW-462.2);

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)]

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d)]

Result

-----------------

-----------------

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and testad in accordance with the requirements of Section IX of the ASME Boiler

and Pressure Vessel Code.

CONSTRUCTORA HOSTOTIPAQUILLO S.A. DE C.V.

-----------------------------------------------------------------------

No. REPORTE DE RT

Plate

Pipe (enter

6" u 8"

Base metal P-

or S-Number

P1

Filler metal

or electrode

5.1

Filler metal or electrode classification(s) (info. only)

E6010 / E7018

O.D. > 2-7/8"

P1 A P11 (P1

thru P11)

E6010 / E7018

You might also like

- WPQ Format Sec IxDocument2 pagesWPQ Format Sec IxParminder SinghNo ratings yet

- QW484BDocument1 pageQW484BMohamed Ahmed MaherNo ratings yet

- Welders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionDocument8 pagesWelders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionGerardo Arispe AramayoNo ratings yet

- DQR Project Quality Control Form for Welder PerformanceDocument1 pageDQR Project Quality Control Form for Welder PerformanceminhnnNo ratings yet

- WQT 1236Document1 pageWQT 1236mir31721No ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSAlesol EquipmentNo ratings yet

- WPQ WELDER PERFORMANCE QUALIFICATIONDocument2 pagesWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSDocument1 pageWPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSMohamed Ahmed MaherNo ratings yet

- Qw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document7 pagesQw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Gerardo Arispe AramayoNo ratings yet

- Saravanan Wpq-5g 50nbDocument1 pageSaravanan Wpq-5g 50nbDeepakNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- FQ 069Document1 pageFQ 069Chava TejaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- FORM QW-484B WELDING OPERATOR QUALIFICATIONSDocument1 pageFORM QW-484B WELDING OPERATOR QUALIFICATIONSKautiilaNo ratings yet

- WPQ Welder Performance QualificationsDocument1 pageWPQ Welder Performance Qualificationsjoshrathburn1980No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- mohanWPQ-1G 40NBDocument1 pagemohanWPQ-1G 40NBDeepakNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- Asme Ix - : ProcedureDocument11 pagesAsme Ix - : ProcedureMohammed Elmodathir Ali100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Test Description (Information Only)Document2 pagesTest Description (Information Only)dayalramNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification Recordravi00098No ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Asme Sec Ix 2021: KG - Pandithan Iwe Technical AdviserDocument80 pagesAsme Sec Ix 2021: KG - Pandithan Iwe Technical AdviserjswldeepNo ratings yet

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification RecordproxywarNo ratings yet

- ASME SEC IX Welding Qualification GuideDocument79 pagesASME SEC IX Welding Qualification Guideabdelkader bensatal100% (1)

- Qualification Soudeur PDFDocument3 pagesQualification Soudeur PDFr_racNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPQTDocument1 pageWPQTyousab creator2No ratings yet

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocument1 pageWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Exhibit No. 28Document28 pagesExhibit No. 28caod1712No ratings yet

- Asme Section IxDocument71 pagesAsme Section Ixranjitkumar1977100% (1)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- PT ZUG WELDING QUALIFICATIONDocument1 pagePT ZUG WELDING QUALIFICATIONMuhammad Fitransyah Syamsuar Putra100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- BS en Iso 15614-1-2017Document50 pagesBS en Iso 15614-1-2017Aries Marte89% (28)

- How To Weld Duplex Stainless Steels PDFDocument20 pagesHow To Weld Duplex Stainless Steels PDFAries MarteNo ratings yet

- Manual-Standard WeldingDocument192 pagesManual-Standard WeldingkhalidmhNo ratings yet

- Astm A105-A105mDocument5 pagesAstm A105-A105mAries MarteNo ratings yet

- PND FolletoDocument29 pagesPND FolletoAries MarteNo ratings yet

- G1-03 (Reapproved 2017) E1Document9 pagesG1-03 (Reapproved 2017) E1Aries MarteNo ratings yet

- Conducting Corrosion Tests in Field Applications: Standard Guide ForDocument9 pagesConducting Corrosion Tests in Field Applications: Standard Guide ForAries MarteNo ratings yet

- Hobart Institute. Welding Procedures and Qualification Training Workbook (Inspection Academy)Document39 pagesHobart Institute. Welding Procedures and Qualification Training Workbook (Inspection Academy)Julio Bacilio Cruz100% (3)

- Portada ART-001-15-00036-1 - B PDFDocument1 pagePortada ART-001-15-00036-1 - B PDFAries MarteNo ratings yet

- Cpvm-Fcawgdi. 502Document3 pagesCpvm-Fcawgdi. 502Aries MarteNo ratings yet

- Cpvm-Fcawgdi. 511Document3 pagesCpvm-Fcawgdi. 511Aries MarteNo ratings yet

- Cpvm-Fcawgdi. 501Document3 pagesCpvm-Fcawgdi. 501Aries MarteNo ratings yet

- Portada ART-001-15-00036-1 - B PDFDocument1 pagePortada ART-001-15-00036-1 - B PDFAries MarteNo ratings yet

- QW-484 Weldwer Performanc E Qualificatio S (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code) Test DescriptionDocument2 pagesQW-484 Weldwer Performanc E Qualificatio S (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code) Test DescriptionAries MarteNo ratings yet

- Cpvm-Fcawgdi. 510Document3 pagesCpvm-Fcawgdi. 510Aries MarteNo ratings yet

- 000.100.0071 Instructions For Preparing A Project Scope of Work (SOW) PDFDocument9 pages000.100.0071 Instructions For Preparing A Project Scope of Work (SOW) PDFAries MarteNo ratings yet

- WPS-P1P8-02 R0 Smaw SawDocument3 pagesWPS-P1P8-02 R0 Smaw SawAries MarteNo ratings yet

- American AlloyDocument1 pageAmerican AlloyAries MarteNo ratings yet

- CharolasDocument12 pagesCharolasAries MarteNo ratings yet

- XD LolDocument1 pageXD LolAries MarteNo ratings yet

- Flux Lincoln 860Document2 pagesFlux Lincoln 860Aries MarteNo ratings yet

- Qw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Document8 pagesQw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Aries MarteNo ratings yet

- Presentacion Asme Seccion Viii Division 2-2013 (3) - 007Document1 pagePresentacion Asme Seccion Viii Division 2-2013 (3) - 007Aries MarteNo ratings yet

- How Trays Work Flooding PDFDocument20 pagesHow Trays Work Flooding PDFAries MarteNo ratings yet

- Date of IssuanceDocument1 pageDate of IssuanceAries MarteNo ratings yet

- WPS-P1P1-02 R0 Smaw Saw PWHTDocument3 pagesWPS-P1P1-02 R0 Smaw Saw PWHTAries MarteNo ratings yet

- Flux Lincoln 860Document2 pagesFlux Lincoln 860Aries MarteNo ratings yet

- Brochure Roll Bonded Clad Plates EDocument36 pagesBrochure Roll Bonded Clad Plates EAries MarteNo ratings yet

- SECCION 20 E1 Distribution LogDocument1 pageSECCION 20 E1 Distribution LogAries MarteNo ratings yet

- Welding Processes PDFDocument44 pagesWelding Processes PDFHusain AliNo ratings yet

- Manual SAE 400 G7Document60 pagesManual SAE 400 G7america1591No ratings yet

- SEO-Optimized Title for TIG Filler Rods Data SheetDocument1 pageSEO-Optimized Title for TIG Filler Rods Data SheetV U P RaoNo ratings yet

- 2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeDocument1 page2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeKARTICK PRASADNo ratings yet

- High Strength Steel Sheets for Structural ApplicationsDocument2 pagesHigh Strength Steel Sheets for Structural ApplicationsAnonymous AlhzFE9EVNNo ratings yet

- CAIRN TSG Q GUI 0005 B1 Guideline For Material Inspection RequirementsDocument47 pagesCAIRN TSG Q GUI 0005 B1 Guideline For Material Inspection RequirementsGOPINATH KRISHNAN NAIRNo ratings yet

- Sievert Global Cataloue 2016 - Web PDFDocument80 pagesSievert Global Cataloue 2016 - Web PDFBeto Pascual RoqueNo ratings yet

- Migman 385Document58 pagesMigman 385tyszruNo ratings yet

- Astm A217-A217m 2010Document4 pagesAstm A217-A217m 2010rcfrcf279No ratings yet

- Mos TPZB 260 PDFDocument16 pagesMos TPZB 260 PDFThanesh ManogaranNo ratings yet

- A540A540M-11 Standard Specification For Alloy-Steel Bolting For Special ApplicationsDocument8 pagesA540A540M-11 Standard Specification For Alloy-Steel Bolting For Special ApplicationsChuthaNo ratings yet

- Prochem 1100 Series ValvesDocument6 pagesProchem 1100 Series ValvesAnastasijaNo ratings yet

- BPW Original-Spare Parts. Mechanical SuspensionsDocument70 pagesBPW Original-Spare Parts. Mechanical SuspensionsMunzir HammamNo ratings yet

- 2850 L3 Diploma Qualification Handbook IVQ v1Document230 pages2850 L3 Diploma Qualification Handbook IVQ v1damnsexybeast100% (1)

- Nickel and HT Alloys For Petrochemical ApplicationsDocument39 pagesNickel and HT Alloys For Petrochemical ApplicationsDaniel Corella100% (1)

- Caustic SCCPaper 080 ACACorrosion Control 0072007 Sydney AustraliaDocument8 pagesCaustic SCCPaper 080 ACACorrosion Control 0072007 Sydney AustraliajaNo ratings yet

- Rehau - PPR Pipe and FittingDocument12 pagesRehau - PPR Pipe and FittingharefiezNo ratings yet

- KAHN-Louis 1944 MonumentalityDocument7 pagesKAHN-Louis 1944 MonumentalitywegenerNo ratings yet

- Selectwear 58: DescriptionDocument1 pageSelectwear 58: DescriptionEli FreemanNo ratings yet

- WIweld01 Co2 Welding Rev 01Document1 pageWIweld01 Co2 Welding Rev 01Gautam KumarNo ratings yet

- Manual Arc Welding of Titanium Alloy Hardware Process SpecificationDocument20 pagesManual Arc Welding of Titanium Alloy Hardware Process SpecificationFaiz NanafiNo ratings yet

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Splicing of Pipes - r1Document3 pagesSplicing of Pipes - r1Prakash RajNo ratings yet

- WT SyllabusDocument1 pageWT SyllabuschandrasekarcncetNo ratings yet

- Question BankDocument13 pagesQuestion BankAkshay Kumar100% (1)

- SA 980 P 11430 CS FGD Ball Valve Rev T02Document3 pagesSA 980 P 11430 CS FGD Ball Valve Rev T02altipatlarNo ratings yet

- Improvement of Multi-Purpose Hall Project Bill of MaterialsDocument21 pagesImprovement of Multi-Purpose Hall Project Bill of MaterialsVicent John ParedesNo ratings yet

- Centinela Flot Column Quality Plan WVendor AuditDocument15 pagesCentinela Flot Column Quality Plan WVendor AuditAndrés RodríguezNo ratings yet

- Guascor Siemens SLE Family - F & S (F - SF)Document441 pagesGuascor Siemens SLE Family - F & S (F - SF)Oleg GorlushinNo ratings yet

- Pec pdf1Document11 pagesPec pdf1Delmark Dionisio LusterioNo ratings yet