Professional Documents

Culture Documents

Tender B - Architectural Specfications

Uploaded by

Je M'appelle NofreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tender B - Architectural Specfications

Uploaded by

Je M'appelle NofreCopyright:

Available Formats

KAY NGEE TAN ARCHITECTS

02 MAY 2012

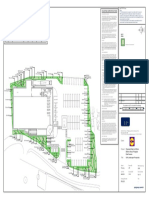

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

PROPOSED DEVELOPMENT OF FUNTASY ISLAND RESORT AT PULAU

MANIS, BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA (PACKAGE B)

CONSTRUCTION OF 40 UNITS OF OCEANFRONT VILLA AT PULAU 2, SERVICE

ANNEX WITH JETTY AT PULAU 4 & WAVE DEVELOPMENT (PHASE 1)

COMPRISING OF FERRY TERMINAL, WAVE PROMENADE 1, CLUB HOUSE 1,

PARTIAL 2F BROADWALK & 1F SERVICE CORRIDOR.

ARCHITECTURALSPECIFICATIONS

ARCHITECTURALSPECIFICATIONS

1

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

TABLEOFCONTENTS

A GENERALCONDITIONS 57

B DEMOLITIONS&ALTERATIONS 812

ExistingServices

Materials

Workmanship

SiteSafety

ScaffoldingandScreens

DustandNoiseControl

DamagetoAdjacentProperties

C MANSORY 1318

MaterialsGenerally

Bricks

ConcreteBlocks

MeshReinforcement

DampProofCourse

Mortar

SettingOut

Bonding

Laying

Holdfasts

ReinforcedBrickworkandBlockwork

Wallsbuiltfairorinfacingbricks

Layingdampproofcourse

WatertightnessTest

Accuracy

Lintels

Jointing

Accessiblejointsnotexposedtoview

Appearance

Cleanliness

Reinforcing/FixingAccessories

Joints

D WATERPROOFING 1927

Liquidappliedtanking/dampproofing

Liquidappliedroofcoatings

Fiberglasswaterproofing

WaterproofingMembrane

E FLOOR/SURFACEFINISH 2874

Cementbasedleveling/wearingscreeds

ARCHITECTURALSPECIFICATIONS

2

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

InSituFinishings

TileFinishing

TimberFlooring

ExternalRaisedTimberDeckSystem

Carpeting

Access/RaisedFloor

Sundries

F WALL/CEILING 7588

Cementboarddrywallsystem

Plasterboarddrywalllining

Plasterboardpanelpartitions

Precastlightweighthollowconcretepanel

Suspendedceilingandsupportworks

G METALWORKS 8996

Steel

StainlessSteel

Aluminium

Galvanizing

Sherardizing

ChromiumPlating

Anodizing

Flurocarboncoating

Powdercoating

Fasterners

Workmanship

Welding&brazing

Fixing

Components

Adjustablesteellouverwindows

Aluminiumwindow,door,sunshadefins&panels

Demountablepartitions

H PAINTINGWORKS/CLEARFINISH 97102

CoatingSystems

General

Preparation

Application

ARCHITECTURALSPECIFICATIONS

3

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

I GLAZING 103106

Glass

Glazingcomponents

Accessories

Glazinggenerally

Compoundglazing

Beadglazing

Gasketglazing

MirrorFixing

CleaningandProtection

J DOORS/WINDOWS/STAIRS 107118

WindowsGenerally

WindowProducts

DoorsGenerally

DoorProducts

Stairs

K BUILDINGFABRICSUNDRIES 119128

FireStoppingSystems

Sundryinsulation/proofingwork

Unframedisolatedtrims/skirtings/sundryitems

Door/WindowIronmongery

L FURNITURE/EQUIPMENT 129136

Generalfixtures/furnishings/equipment

Sanitaryappliancesandfittings

M BUILDINGFABRICREFERENCESPECIFICATION 137144

Purposemadejoinery

Preservative/fireretardanttreatment

Sealants

ARCHITECTURALSPECIFICATIONS

4

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

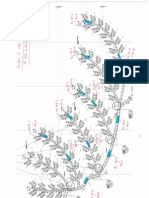

N EXTERNALWORKS 145172

CuttingDownTrees

Treeprotection

Bulkfiling

Premixroadsurfacing

Precastconcreteunits

Precastconcreteslabpaving

Precastconcretedrains

Turfing&plantermix

IrrigationSystem

AntitermiteTreatment

Vapour/MoistureBarrier

O ANNEX 173

Chapter4:SanitaryProvisions

ARCHITECTURALSPECIFICATIONS

5

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

A

GENERALCONDITIONS

ARCHITECTURALSPECIFICATIONS

6

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

1. These Architectural Specifications set out the basic standard or quality of materials and

workmanship required by the Works regardless of the trade headings under which they have

been described and shall be read in conjunction with the other Technical specifications

prepared separately by respective Consultants, the Contract Drawings, the Conditions of

Contract and all other documents in respect of the Contract.

2. The Contract Drawings may contain particular details / information / additional clauses which

are applicable to the Contract. If any parts of these Specifications contradict the Contract

Drawings, the latter shall take precedence. In the event of discrepancies found between the

Contract Drawings, the Architectural Contract Drawings shall take precedence over drawings

from other disciplines. In this respect, the Contractor shall carry out construction works following

the Architectural Contract Drawings and all cost incurred thereof including adopting the design

from other Contract Drawings to the Architectural Contract Drawings and additional labour,

materials, plant and equipment shall be deemed to have been included in the Contract Sum.

3. Where trade names or catalogue numbers are mentioned in the Contract Drawings, the

Technical Specifications, the Schedule of Works or Works Sections and all other documents in

the Contract, the reference is intended only as a guide to the type of article quoted or material

required, subject to the approval of the Engineer, the Contractor may substitute any article or

material similar and equal to those described by reference to trade names or catalogue

numbers. All proprietary materials or processes are to be used or carried out strictly in

accordance with the manufacturers instructions and recommendations. In the event of

discrepancies found between the Specifications and/or Contract Drawings with the appropriate

or relevant Code of Practice or Singapore/British Standards, the more stringent requirements

shown on the above documents shall deem to have been included in the Contract Sum and

form the basis of the Contract.

4. The Contractor shall ensure that these requirements are strictly adhered to when carrying out

the works, unless otherwise instructed, specified, etc. If the content of any item in the

Specifications, Contract Drawings appear to contravene the appropriate or relevant Code of

Practice or Singapore/British Standards, or is repugnant to the Contractors specialized

knowledge of good practice, it will be the Contractors express responsibility to bring this matter

to the attention of the Architect.

5. All proprietary materials or processes specified in this Specification or the Bills of Quantities are

to be used or carried out strictly in accordance with the manufacturer's instructions and

recommendations. Inform the Architect if such instructions and recommendations conflict with

any other specified requirements. Prior to incorporation into the Works, obtain confirmation from

the manufacturers and carry out all necessary tests to ascertain the adequacy, suitability and

compatibility of such proprietary materials or processes.

6. The Contractor is allowed to propose an alternative product or manufacturer of equivalent

specifications as specified in this documents and the Contract Drawings to all specified trades

with manufacturers, subject to the approval of the Architect.

7. All drawings and works from the Contractors consultants are to be done in accordance with the

submitted and approved authorities documents as informed by the Architect, All drawings are

subjected to changes due to requirements by Authorities, as informed by the Architect.

ARCHITECTURALSPECIFICATIONS

7

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

8. STANDARDS AND CODES OF PRACTICE

The standards and codes of practice referenced below and elsewhere in this Specification shall

establish the minimum but not to be construed as a limit on the standard of quality and

workmanship for the Works. They shall also serve as a basis for approval of such minimum

standards applicable thereto:

(1) Singapore Standards

(2) Singapore Standard Codes of Practice

(3) British Standards

(4) British Standard Codes of Practice

In case of conflict between any of the Standards and Codes of Practice and the drawings, this

Specification or any of the other Contract Documents in relation to the standard of quality and

workmanship, the Standard and/or Code of Practice having the more stringent requirement

shall govern unless otherwise notified by the Architect.

9. The Architect reserves the right to select and/or accept the level of standard and workmanship

which in his opinion will provide finished work that is to his satisfaction.

ARCHITECTURALSPECIFICATIONS

8

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

B

DEMOLITIONS&ALTERATIONS

ARCHITECTURALSPECIFICATIONS

9

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

1 EXISTING SERVICES

The Contractor shall comply with all requirements of the various statutory Authorities and

Government Departments in respect of the existing services at and in the vicinity of the Site.

The Contractor shall also inform and liaise with the Authority/Department concerned should

he encounter any services at the Site, and arrange with and offer them all necessary

assistance in ensuring the timely diversion, disconnection, termination, or capping off of all

utility services.

The Contractor shall also engage licensed cable detection workers to ascertain and confirm

that there are no live services cables before carrying out any excavation/demolition works.

2 MATERIALS

Unless otherwise specified in the Bills of Quantities, all materials arising out of the

demolitions and alterations work shall become the property of the Contractor who shall

allow credit for the full value to him of all materials salvaged.

Where provision is made in the Bills of Quantities for the value of credits to be shown

separately, the Employer shall be entitled to purchase salvaged materials from the

Contractor upon payment to the Contractor of the credit value (if any) shown in the Bills.

Remove from the Site materials which are not required by the Employer. Unwanted

materials shall not be permitted to accumulate or become a health or fire risk.

3 WORKMANSHIP

(1) Method and Procedure for Demolitions

The building shall be demolished progressively from the roofs down to the

foundations on a storey-by-storey and bay-by-bay basis, and/or on whatever other

basis deemed expedient and safe by the Contractor and to the approval of the

Architect.

The Contractor shall employ methods that cause no shock or vibration likely to

damage surrounding properties, plant or equipment or buried services. The use of

explosives will not be permitted.

The Contractor shall be responsible for the full protection and stability of those

parts of the buildings which are to remain as shown on the drawings.

The Contractor's method of demolition must comply strictly with SS CP 11.

The demolition of one part of the structure may result in other parts becoming

unsafe or unstable. The Contractor is required to study and predetermine where

temporary supports, etc will be required. Provisions shall be made for adequate

shoring, strutting and bracing designed by the Contractor's Professional Engineer.

The Contractor shall submit with his tender for consideration of the Architect, a

detailed statement with regard to the method, procedure, plant, tools and

equipment which he intends to follow and/or use.

(2) Method and Procedure for Alterations Work

ARCHITECTURALSPECIFICATIONS

10

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

The Contractor shall sequence his works to the existing building in such a manner

so that all work to the roofs and drainage installation can be commenced and

completed as soon as possible and the building made weathertight in advance of

other internal restoration/fitting-out works. Work which exposes the building to

weather shall be undertaken during favourable weather conditions.

Provide tarpaulins, weatherproof coverings and the like to the satisfaction of the

Architect for the full protection of the internal parts of the existing building so long

as the building is not weathertight.

Alterations shall be carried out with the minimum amount of disturbance to those

parts of the building which are to remain. Provide all temporary shoring, needling,

strutting, scaffolding, dustproof screens, tarpaulins, dust sheets and the like and

other temporary works incidental to alterations. Execute the alterations work in

phases as may be directed by the Architect.

New work associated with the alterations shall be as specified in the appropriate

trade sections. The Contractor shall be responsible for all making good in its fullest

sense to match all aspects of the existing works and through, around, into, over

and up to new items, openings and the like and the proper jointing to existing, all to

the approval of the Architect.

4 SITE SAFETY

The Contractor shall comply with the Workplace Safety and Health Act 2006 (hereinafter

referred to as 'the Act') and the provisions of the Factories (Building Operations and Works

of Engineering Construction) Regulations (hereinafter referred to as 'the Regulations') and

any amendment or re-enactment thereto particularly with regard to Part XI (Demolition) of

the Regulations. Prior to commencement of the Works, the Contractor shall obtain a

Certificate of Registration under the Workplace Safety and Health (Registration of

Factories) Regulations.

It shall be the duty of the Contractor to comply with all requirements of the Act and

Regulations, as will affect him or any person or persons employed by him, and as related to

any work, act or operation performed or about to be performed by him.

The Contractor shall ensure a safe working environment on the Site at all times. All safety

provisions shall be properly maintained. The Contractor shall ensure that his workmen take

all necessary precautions when safety measures are installed.

The Contractor shall submit a safety drawing, certified by his Professional Engineer to the

Ministry of Manpower (MOM) not later than one week after commencement of the Works.

The approval of the MOM for such safety drawing shall not relieve the Contractor and his

Professional Engineer of the need to ensure the adequacy and sufficiency of the safety

provisions.

The Contractor shall display warning signs of 900 x 600mm (minimum size) at strategic

positions along the perimeter of the Site to deter trespassing. Signs shall have the words

'Danger- Keep Out' in the four official languages painted red on a white background with

gloss finishing paint. Warning lights shall also be provided at similar positions and activated

at night.

Works carried out at or near the main roads shall also comply with the Land Transport

Authority's Recommendations on Temporary Road Signs.

ARCHITECTURALSPECIFICATIONS

11

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

The Contractor shall appoint a qualified and competent person to take charge of all matters

on site safety and to conduct regular safety meetings.

The Contractor shall employ only experienced and trained operators for his plant,

equipment and vehicles. The Contractor shall submit to the Architect and the relevant

Authorities, a list of the plant, equipment and vehicles to be used at the Site, together with

the names, identity card or passport numbers and years of experience of the operators not

later than one week after the commencement of the Works. The Contractor shall inform the

MOM within one week of any changes made. The list shall be displayed at the site office.

The Contractor is deemed to have allowed for costs and expenses of all safety provisions

including that which may arise from amendments to the Regulations and changes in the

requirements of MOM or other relevant Authorities.

Should the MOM order a total or partial stoppage of work due to safety violations, the

Contractor shall not be entitled to any claims for compensation or extension of time for

completion.

5 SCAFFOLDING AND SCREENS

Scaffolding shall be of a type approved by the MOM and shall comprise an independent

tied metal scaffold complying with the requirements of the Factories (Scaffolds) Regulations

2004 and Singapore Standard Code of Practice for Scaffolding, CP 14. The scaffold shall

be erected to roof level along the external perimeter of the building.

No loading of debris shall be placed on the scaffold, in excess of its design capacity.

Scaffolds shall be dismantled progressively as demolition progresses and shall not be left

projecting unnecessarily above the residual height of the building or structure. Scaffolds

shall be erected and dismantled by approved fixers under supervision, in accordance with

the relevant regulations and bye-laws and to the satisfaction of the Chief Inspector

(Factories) of the MOM.

The Contractor shall submit detailed drawings of the scaffolding system, its layout and/or

support cantilevers to the Chief Inspector (Factories), MOM for approval. The approval of

the MOM shall not relieve the Contractor and his Professional Engineer from any liability for

defective design and the erection of the metal scaffolds.

Dustproof canvas sheeting shall be securely fastened together, onto the outer face of metal

scaffolds to prevent drifting of dust and debris.

6 DUST AND NOISE CONTROL

The Contractor shall comply with the Environmental Pollution Control Act and is required to

take all proper and reasonable precautions to control the emission and escape of dust and

excessive noise.

All work to be demolished and debris shall be well watered to prevent dust rising.

The Contractor's attention is drawn to the provisions of the Environmental Pollution Control

(Control of Noise at Construction Sites) Regulations and Singapore Standard Code of

Practice for Noise Control on Construction and Demolition Sites, CP49 on noise control.

The Contractor shall ensure that the amount of noise is within the stipulated levels by

minimizing the number of plant and equipment working simultaneously or the number of

ARCHITECTURALSPECIFICATIONS

12

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

noise emitting activities being carried out simultaneously and restricting the hours of

working where excessive noise is emitted.

Should the amount of dust and the level of noise is such as to cause undue inconvenience

and nuisance, the Contractor shall be required to effect corrective measures at his own

expense to the satisfaction of the Architect and the relevant Authorities. Any delays or

slowdown due to stoppages arising from interim/permanent injunctions or from compliance

with any regulatory or mandatory requirement of the Authorities to abate the nuisance shall

be solely at the Contractor's cost.

7 DAMAGE TO ADJACENT PROPERTIES

The Contractor shall take proper precautions to ensure that no damage is caused to

adjacent structures. In the event damage does occur, it must be made good to the

satisfaction of the Architect. Any damage caused to the roads, whether public or private,

drains, kerbs, etc must be made good to the complete satisfaction of the Architect. The

Contractor shall bear all time and cost consequences in connection therewith.

ARCHITECTURALSPECIFICATIONS

13

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

C

MASONRY

ARCHITECTURALSPECIFICATIONS

14

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

1 MATERIALS GENERALLY

Submit samples of each type of brick and block and obtain approval before placing orders

with suppliers. If requested by the Architect, submit samples of the bricks and blocks to

PSB for testing and pay fees in connection therewith.

Stack bricks and blocks clear of the ground and protect from inclement weather, chipping or

damage.

2 BRICKS

Common bricks and facing bricks shall be of standard size 215 x 102.5 x 65mm of even

shape, hard, well burnt, machine made pressed bricks with true arrises complying with SS

103 Second Grade having a minimum compressive strength of 20 MN/m2.

Bricks for use in external walls shall be free from hairline cracks.

3 CONCRETE BLOCKS

Blocks shall be hard, even in shape, square with true arrises, well matured and of a dense,

well consolidated mixture.

Blocks for load bearing use shall be Class A with a minimum compressive strength of not

less than 5.6 MN/m2 and comply with SS 76(M).

Blocks for non-load bearing use shall comply with SS 271 and have a minimum

compressive strength of not less than 3.2 N/mm2.

4 MESH REINFORCEMENT

Mesh shall be 22 gauge expanded mild steel strip, 25mm narrower than the width of the

wall and galvanised after cutting.

5 DAMP PROOF COURSE

The damp proof course shall be bitumen with a fibre base complying with BS 6398 Class B.

6 MORTAR

Cement to be in accordance with BS 8204-1, clause 5.1.3.

Sand shall be clean natural sand of light colour free from organic matter and shall comply

with SS 31 and be washed and/or screened if required by the Architect.

Plasticisers shall be of approved manufacture.

Water shall be from the main supply, kept free from impurities.

Mix mortar in the ratio of 1:6 by volume and incorporate plasticiser in the proportion

recommended by the manufacturer.

Thoroughly mix mortar by mechanical mixer or by hand on a clean level timber platform and

use within two hours of mixing.

ARCHITECTURALSPECIFICATIONS

15

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

7 SETTING OUT

Provide proper setting out rods and set out all work showing openings, heights, sills and

lintels. No part of the walling shall be carried up more than 1000mm higher at one time

than any other part and in such cases the jointing shall be made in long steps, not toothed,

so as to prevent cracks arising. Walls shall be levelled around at floors and wall heads and

built in level courses.

Walls as built shall be within a tolerance of + 15mm of setting out dimensions.

8 BONDING

Half brick thick walls and block walls shall be built in stretcher bond. Brick walls of one

brick or greater thickness shall be built in English bond. Piers and angles shall be properly

bonded together and intersections of walls shall be cut, toothed and bonded together at

alternate courses.

9 LAYING

Before commencing laying, ascertain from other trades that all pipes, conduits, drains,

sleeves, bolts, hangers, door and window fixing lugs, timber pellets or any other materials

for which provision is required has been catered for.

Bricks and blocks shall be wetted before being laid and tops of walls where left off shall

likewise be wetted before recommending laying.

Lay bricks and blocks on a full bed of mortar and fill solid all joints. Bed and vertical joints

shall be of a uniform 10mm thickness. Bricks shall be laid frog uppermost and filled with

mortar.

Walls shall be built within a tolerance of + 15mm of plumb in any storey height. Perpends

and quoins shall be plumb and square.

Use templates for forming door and window openings where not built in and for forming lift

shafts accurately at each floor level.

Bed frames and plates, etc which are built in with cement mortar 10mm thick.

Cut and pin or build in ends of bars and the like and make good in cement mortar.

Cut or form all holes, mortices, chases and openings in walls for fittings, pipes, turn-in of

finishings and the like and subsequently make good in cement mortar.

Joints in walls to be plastered or rendered shall be raked out to a depth of 10mm whilst the

mortar is green to form an adequate key for finishings.

10 HOLDFASTS

Unless otherwise specified, hardwood frames shall be secured with mild steel holdfasts

25mm wide x 3mm thick x 225mm girth with one end bent and twice drilled and screwed to

back of frame and other end fanged and built into joints of brickwork or blockwork.

11 REINFORCED BRICKWORK AND BLOCKWORK

ARCHITECTURALSPECIFICATIONS

16

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Brick walls of half brick (102.5mm) or on edge (65mm) thickness shall be reinforced with

mesh reinforcement as previously described at every fourth course.

Block walls not exceeding 100mm thick shall be reinforced with mesh reinforcement as

previously described at every course. The mesh reinforcement shall be lapped 150mm at

joints and carried through the full thickness of the end wall at corners and junctions.

12 WALLS BUILT FAIR OR IN FACING BRICKS

Execute sample panels 1000 x 1000mm for each type of facing work for the Architect's

approval and clear away when directed.

Bricks or blocks for faced or fair work shall be specially selected for uniformity of size and

clean, undamaged faces and arrises.

Point faced or fair walls with a neat recessed joint as the work proceeds.

13 LAYING DAMP PROOF COURSES

Lay damp proof courses in continuous strip with 150mm laps at joints and full laps at angles

on an even bed of cement mortar and complete joint to normal thickness.

Keep leading edge of damp proof course flush with face of wall.

14 WATERTIGHTNESS TEST ON EXTERNAL BRICK WALLS

External walls shall be tested for watertightness by spraying with a continuous jet of water

from a water hose reel having a 4.5mm nozzle and a minimum running pressure of 4 bar

held at a distance from the surface under test to be specified by the Architect. The duration

of the test shall not be less than 30 minutes.

The walls shall be examined for dampness or water seepage during the test and within one

hour after completion of the test.

15 ACCURACY

Courses: Level and true to line.

Faces, angles and features: Plumb.

Permissible deviations:

Position in plan of any point in relation to the specified building reference line and/ or point

at the same level 10 mm.

- Straightness in any 5 m length 5 mm.

- Verticality up to 3 m height 10 mm.

- Verticality up to 7 m height 14 mm.

- Overall thickness of walls 10 mm.

- Level of bed joints up to 5 m (brick masonry) 11 mm.

- Level of bed joints up to 5 m (block masonry) 13 mm.

ARCHITECTURALSPECIFICATIONS

17

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

16 LINTELS

Bearing: Ensure full length masonry units occur immediately under lintel ends.

Precast Concrete Lintels:

- Standard: To BS EN 845-2.

- Manufacturer: Contractor's proposal

- Product reference: None

- Sizes: Contractor's proposal

- Additional requirements: Freeze/ thaw: Resistant

- Placement: Bed on mortar used for adjacent

17 JOINTING

Profile: Consistent in appearance.

18 ACCESSIBLE JOINTS NOT EXPOSED TO VIEW

Jointing: Struck flush as work proceeds.

19 APPEARANCE

- Brick/ block selection: Do not use units with damaged faces or arrises.

- Cut masonry units: Where cut faces or edges are exposed cut with table masonry saw.

- Quality control: Lay masonry units to match relevant reference panels.

- Setting out: To produce satisfactory junctions and joints with built-in elements and

components.

- Coursing: Evenly spaced using gauge rods.

- Lifts: Complete in one operation.

- Methods of protecting facework: Submit proposals.

20 CLEANLINESS

- Facework: Keep clean.

-

Mortar on facework: Allow to dry before removing with stiff

21 REINFORCING/ FIXING ACCESSORIES

Angel Supports Generally:

- Manufacturer: Submit proposals .

- Product reference: None .

- Material: Austenitic stainless steel .

- Size: proprietary system .

- Fixings (complete with washers and shims): Manufacturer's instruction .

ARCHITECTURALSPECIFICATIONS

18

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Support Systems Generally:

- Manufacturer: Submit proposals .

- Product reference: None .

- Material: Austenitic stainless steel .

- Components, arrangement and dimensions: As shown on drawings.

22 JOINTS

Unexposed Construction Joints:

- Formation: Close butt as work proceeds.

Pointing in Flashings:

- Joint preparation: Free of debris and lightly wetted.

- Pointing mortar: As for adjacent walling.

- Placement: Fill joint and finish flush.

ARCHITECTURALSPECIFICATIONS

19

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

D

WATERPROOFING

ARCHITECTURALSPECIFICATIONS

20

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

1 GENERAL

All materials including primers, resins, curing agents, and finish coats are to be Green Label

certified or bear a similar internationally recognized certification. Also, the finish coat shall

be environment friendly, containing no solvent

2 LIQUID APPLIED TANKING/ DAMP PROOFING

TYPES OF TANKING/ DAMP PROOFING

Cold Applied Tanking:

- Substrate: As shown on drawings.

- Primer: As coating manufacturer's recommendations.

- Coating: Epoxy resin.

o Manufacturer: submit proposals.

o Product reference: None.

o Application: As coating manufacturer's recommendations.

- Reinforcement: As coating manufacturer's recommendations.

- Blinding: As coating manufacturer's recommendations.

- Green Label: SEC Endorsed or similar

Cold Applied Damp Proofing :

- Substrate: As shown on drawings.

- Primer: As coating manufacturer's recommendations.

- Coating: Epoxy resin.

o Manufacturer: submit proposals.

o Product reference: None.

o Application: As coating manufacturer's recommendations.

- Reinforcement: As coating manufacturer's recommendations.

- Blinding: As coating manufacturer's recommendations.

- Green Label: SEC Endorsed or similar

EXECUTION

Suitability of Substrate:

- Substrates generally:

o Smooth, even textured, clean, dry and frost free.

o Within tolerances for level and surface regularity.

o Vertical and horizontal surfaces: Correctly prepared and free from

irregularities.

- Curing period for concrete substrates (minimum): 7 days.

- Moisture content and stability of substrate: Must not impair integrity of finished

tanking/

- damp proofing.

- Preliminary work: Complete including:

o Chases.

o External angles.

o Formation of upstands and kerbs.

o Movement joints.

o Penetrations/ Outlets.

Adhesion Testing:

ARCHITECTURALSPECIFICATIONS

21

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

- Tensile bond strength: Test in accordance with BS EN ISO 4624.

- Test results: Submit.

Primers:

- Application: Uniform, continuous coverage.

Coating Application:

- Adjacent surfaces exposed to view in finished work: Protect.

- Coatings:

o Apply in dry atmospheric conditions when primer is tacky.

o Uniform, continuous coverage. Do not allow to pool in hollows.

o Firmly adhered to substrate and free from imperfections.

o Prevent damage to finished coatings.

- Penetrations: Impervious.

- Final covering: Apply as soon as possible after coating has hardened.

Cold Applied Coatings:

- Thinning: Not permitted unless recommended by manufacturer.

- Successive coats:

Allow to dry before applying next.

Apply at right angles to previous.

Modified Coatings:

- Air and surface temperatures: Do not apply if below minimum recommended by

coating manufacturer.

- Curing: Keep dry until fully cured.

Reinforcement:

- Laying: Laid into second coat with third coating applied locally over fabric .

- Edge overlap (minimum): 75 mm

- Finish: Smooth and free from imperfections.

Junctions with DPCs:

- DPCs: Clean, all edges fully exposed.

- Application: Fully coat dpc and overlap adjacent surfaces by (minimum) 75 mm.

Blinding:

- Coatings: Blind whilst tacky .

- Surplus material: Remove when coatings are completely dry.

COMPLETION

Inspection:

- Interim and final inspections: Submit reports.

Electronic Integrity Test:

ARCHITECTURALSPECIFICATIONS

22

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

- Testing authority: Submit proposals.

- Timing of test: Give notice.

- Condition of coating prior to testing:

o Complete to a stage where integrity can be tested.

o Surface: Clean.

- Test results and waterproof integrity certificate: Submit on completion of testing.

Protection of Coatings:

- Coated surface: Clean and free from contaminants.

- Board manufacturer: submit proposals.

o Product reference: None.

o Thickness: As coating manufacturer's recommendations.

- Placement: Bond protection board to coating with double-sided tape.

o Edges: 75 mm minimum overlap.

o Perimeter treatment: to manufacturer's instruction.

- Contact with coating: Secure and continuous.

3 LIQUID APPLIED ROOF COATINGS

TYPES OF COATING

Cold Deck Roof Coating:

- Substrate: As shown on drawings.

o Preparation: to manufacturer's instruction.

- Waterproof coating: Polyurethane.

o System manufacturer: submit proposals.

- Primer reference: As coating manufacturer's recommendation.

- Coating reference: As coating manufacturer's recommendation.

o Application: As coating manufacturer's recommendation.

o Reinforcement: As coating manufacturer's recommendation.

o Minimum dry film thickness: As coating manufacturer's recommendation.

o Colour: As coating manufacturer's recommendation.

- Surface protection: As coating manufacturer's recommendation.

- Accessories: As shown on drawings.

- Green Label: SEC Endorsed or similar

PERFORMANCE

Roof Performance:

- General: Firmly adhered, free draining and weathertight.

Avoidance of Interstitial Condensation In Warm and Inverted Roofs:

- Interstitial condensation risk of roof construction: Assess as recommended in BS

6229.

- Basic design data:

o Outdoor notional psychrometric conditions, winter:

Temperature: -5C.

Relative humidity: 90%.

Vapour pressure: 0.36 kPa.

Duration: 60 days.

ARCHITECTURALSPECIFICATIONS

23

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

o Outdoor notional psychrometric conditions, summer:

o Temperature: 18C.

o Relative humidity: 65%.

o Vapour pressure: 1.34 kPa.

o Duration: 60 days.

o Indoor notional psychrometric conditions:

Temperature: 20C.

Relative humidity: 40%.

Vapour pressure: 1.17 kPa.

o Winter interstitial condensate (warm roof):

Calculated amount (maximum): 0.35kg/m.

Calculated annual net retention: Nil.

- Vapour control layer: If necessary, provide a suitable membrane so that damage

and nuisance from interstitial condensation do not occur.

- Risk of interstitial condensation in roof construction: Assess in accordance with BS

5250, Annex D.

- Vapour control layer: If necessary, provide a suitable membrane so that damage

and nuisance from interstitial condensation do not occur.

Insulation:

- Requirement: Determine type and thickness of insulation and integral or separate

overlay to satisfy the following criteria:

o Thermal transmittance of roof (maximum): 0.25 W/mK.

o Compressive strength of insulation (minimum) at 10% compression: 220

kPa.

o Substrate surface: Suitably even, stable and robust to receive roof coatings.

o Insulation compliance: To a relevant British Standard, or Agrment certified.

PRODUCTS

Timber Trims:

- Quality: Planed, free from wane, pitch pockets, decay and insect attack (except

ambrosia

- beetle damage).

- Moisture content at time of covering (maximum): 22%.

- Preservative treatment: As recommended for purpose by waterproof coating

manufacturer.

Vapour Control Layer:

- Type: Reinforced polyethylene sheet.

- Manufacturer: Submit proposals.

o Product reference: None.

- Thickness: 500 micrometres.

- Vapour resistance: 1000 MNs/g.

Extruded Polystyrene (XPS) Warm Deck Roof Insulation:

- Standard: To BS EN 13164.

- Manufacturer: submit proposals.

o Product reference: None.

- Grade: E2.

- Thickness: 50mm.

- Facing: Factory bonded foil upper face.

ARCHITECTURALSPECIFICATIONS

24

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Precast Concrete Paving Slabs:

- Standard: To BS EN 1339, hydraulically pressed.

- Manufacturer: Submit proposals.

o Product reference: None.

- Colour/ Finish: Natural with smooth surface.

- Recycled content: Submit proposals.

- Size: 600 x 600 x 50 mm.

- Support system: Not required.

EXECUTION GENERALLY

Adverse Weather:

- Do not apply coatings:

o In wet conditions or at temperatures below 5C, unless otherwise permitted

by coating manufacturer.

o In high winds (speeds > 7 m/s), unless adequate temporary windbreaks are

erected

o adjacent to working area.

- Unfinished areas of roof: Keep dry.

Suitability of Substrate:

- Substrates generally:

o Secure, clean, dry, smooth, free from frost, contaminants, loose material,

voids, protrusions and organic growths.

o Compatible with coating system.

- Preliminary work: Complete, including:

o Formation of upstands, kerbs, box gutters, sumps, grooves, chases and

expansion joints.

o Fixing of battens, fillets and anchoring plugs/ strips.

- Moisture content and stability: Must not impair integrity of roof.

NEW SUBSTRATES/ VAPOUR CONTROL LAYERS/ WARM DECK ROOF INSULATION

Fixing Timber Trims:

- Fasteners: Sherardized steel screws.

- Fixing centres (maximum): 600 mm.

Laying Vapour Control Layer:

- Membrane: As shown on drawings.

- Laps: Sealed using materials and method recommended by membrane

manufacturer.

- Upstands, kerbs and other penetrations: Enclose edges of insulation. Lap with

coatings to form a complete seal.

Laying Warm Deck Roof Insulation:

- Setting out:

o Long edges: Fully supported and run at right angles to direction of span.

o Joints: Butted together.

ARCHITECTURALSPECIFICATIONS

25

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

o Ends: Adequately supported.

o Joints: Staggered.

- Bedding: Full bed of bonding compound.

- Mechanical fixing: Determined by contractor.

- Completion: Boards must be in good condition, well fitting and stable.

ROOF COATING SYSTEM

Adhesion Tests:

- Requirement: Carry out a trial coating to determine priming requirements and/ or

system

- suitability.

- Nature of test: 5 x 5 m application of coating system to concrete roof .

- Test results: Submit and arrange for inspection.

Applying Primers/ Conditioners:

- Coverage per coat (minimum): 0.2 L/m.

- Surface coverage: Brushed well in to ensure local or full area coverage according

to type.

- Coats: Allow to dry before overcoating.

Laying Carrier Membrane:

- Bond: Full to provide a continuous surface for application of coatings.

- Mechanical fixing: In accordance with manufacturer's recommendations.

Movement Joints in Substrate:

- Debonding tape: Apply over movement joints.

- Reinforcement strip: Apply over debonding tape.

o Bedding: Preliminary coating application.

o Joints: Lap in length.

o Bond: Continuous over whole surface, with no air pockets.

o Condition at completion: Smooth.

Preliminary Local Reinforcement:

- Reinforcement strip: Apply to junctions at upstands, penetrations and outlets, joints

and fixings in discontinuous unit substrates.

o Bedding: Preliminary coating application.

o Joints: Lap in length.

o Bond: Continuous over whole surface, with no air pockets.

o Condition at completion: Smooth.

Application of Roof Coatings:

- Thickness: Monitor by taking wet/ dry film thickness readings.

- Continuity: Maintain full thickness of coatings around angles, junctions and features.

- Rainwater outlets: Form with watertight joints.

- Drainage systems: Do not allow liquid coatings to enter piped rainwater or foul

systems.

- Edge trims: Apply coatings over horizontal leg of trim and into recess.

ARCHITECTURALSPECIFICATIONS

26

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Skirtings and Upstands:

- Top edges of coatings: Where not protected by flashings, apply into chases cut to a

- minimum depth of 10 mm.

- Completion of chases: When coatings are fully cured, prepare chase and apply

sealant:

o Sealant: To BS EN ISO 11600.

- Colour: As coating.

COMPLETION

Inspection:

- Coating surfaces: Check when cured for discontinuities.

o Defective areas: Apply another coating.

Electronic Roof Integrity Test:

- Testing authority: Submit proposals .

- Timing of test: Give notice .

- Condition of roof prior to testing:

o Coating: Complete to a stage where integrity can be tested.

o Surface: Clean.

- Test results: Submit.

- Waterproof integrity certificate: On completion of testing, submit.

Flood Test:

- Condition of roof prior to testing:

o Coating: Complete to a stage where integrity can be tested.

o Surface: Clean.

- Outlets: Externally cover and seal. Protect against damage from water pressure

using

- temporary kerbs. Do not use plugs to seal outlets.

- Flood levels: Submit proposals. In no case higher than existing kerbs.

- Flood duration: 24 hours .

- Inspection: Regular to detect leaks.

- Completion of test: Slowly drain roof. Do not overload or flood outlets.

- Test results: Submit.

Completion:

- Roof areas: Clean.

o Outlets: Clear.

o Flashings: Dressed into place.

- Work necessary to provide a weathertight finish: Complete.

- Storage of materials on finished surface: Not permitted.

- Completed coatings: Protect against damage.

4 WATERPROOFING MEMBRANE

TYPES OF MEMBRANE

ARCHITECTURALSPECIFICATIONS

27

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Pre-Applied High Density Polyethylene (HDPE) Film

- Manufacturer:

o Contractor to submit proposals to the Architect for approval

o Product Reference: Preorufe 160R by Grace Construction

- Description:

o Composite HDPE film

- Preparation:

o Substrate Preparation: to manufacturer's instruction.

- Coating reference: As manufacturer's recommendation.

o Application: As manufacturer's recommendation.

o Reinforcement: As manufacturer's recommendation.

o Minimum dry film thickness: As manufacturer's recommendation.

o Colour: As manufacturer's recommendation.

- Surface protection: As manufacturer's recommendation.

- Accessories: As manufacturer's recommendation.

- Green Label: SEC Endorsed or similar

INSTALLATION GENERALLY

Membrane rolls with tapes are to be supplied with a selvedge on one side to provide self-

adhered laps for continuity between rolls. Disposable plastic release liners, if any, are to be

removed before placing reinforcement and concrete.

Membrane Installation:

- During Damp conditions, selvedge and tape adhesive to be warmed using hot air

gun or similar to remove moisture and condensation.

- Refer to Manufacturers instruction on the laying and positioning of each membrane

roll

Penetrations:

- Grouting of penetration and any additional steps to Manufacturers instruction.

Hydrostatic Head Test:

- Testing authority: Submit proposals .

- Timing of test: Give notice .

- Condition of ground prior to testing:

o Surface: Clean.

- Test results: Submit.

- Waterproof integrity certificate: On completion of testing, submit.

Completion:

- Ensure plastic release liner is removed from all areas before pouring of concrete.

- Concrete to be poured within 42 days of the application of the membrane/or as

specified by the Manufacturer.

- Concrete to be poured must be placed and compacted carefully to avoid damage to

the membrane

ARCHITECTURALSPECIFICATIONS

28

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

E

FLOOR/SURFACEFINISH

ARCHITECTURALSPECIFICATIONS

29

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

1 CEMENT BASED LEVELLING / WEARING SCREEDS

TYPES OF SCREED

Cement: Sand Levelling Screed to Floors:

- Substrate: In situ concrete slab.

- Screed construction: Partially bonded, as clause 270.

o Reinforcement for crack control: Not required.

- Thickness .

o Nominal: 70 mm.

o Minimum: 50 mm.

- Mix:

o Proportions (cement:sand): 1:3-4.5.

- In situ crushing resistance (ISCR) category: 1:3-4.5.

o Mass of test weight: 4 kg.

- Flatness/ Surface regularity: Maximum permissible deviation: 5 mm or 2 mm under

a 1 m straightedge .

- Finish: Smooth floated, as clause 530.

o To receive: Varies, as shown on drawings.

- Other requirements: None.

Fine Concrete Levelling Screed to Ramps:

- Substrate: Precast concrete planks.

- Screed construction: Partially bonded, as clause 270.

o Reinforcement for crack control: Not required.

- Thickness:

o Nominal: 70 mm.

o Minimum: 50 mm.

- Mix:

o Proportions (cement: total aggregate): 1:4-5.

o Sand to coarse aggregate: Between 75:25 and 60:40, adjusted to facilitate

trowelling.

- In situ crushing resistance (ISCR) category: B (4 mm maximum indentation).

o Mass of test weight: 4 kg.

- Flatness/ Surface regularity: Maximum permissible deviation: 5 mm and also 2 mm

under a

- 1 m straightedge .

- Finish: Trowelled, as clause 540.

o To receive: Polyurathane paint.

- Other requirements: Movement joints .

Concrete Wearing Screeds (Pebblewash) to Floors:

- Substrate: In situ concrete slab.

- Screed construction: Fully bonded.

- Thickness:

o Nominal: 50 mm.

o Minimum: 30 mm.

o Maximum: 40mm.

- Mix:

o Proportions (cement:sand:pebble stone): 1:1:5 .

ARCHITECTURALSPECIFICATIONS

30

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

- Flatness/ Surface regularity: Maximum permissible deviation: 5 mm and also 2 mm

under a 1 m straightedge.

- Abrasion resistance:

o Standard: To BS 8204-2, Table 4.

o Classification: AR3/ WS Moderate Duty.

- Finish: Trowelled, as clause 550.

o Slip resistance value (minimum SRV): SRV 40.

- Other requirements: Movement joints .

GENERALLY/PREPARATION

Suitability of Substrates:

- General:

o Suitable for specified levels and flatness/ regularity of finished surfaces.

Consider permissible minimum and maximum thicknesses of screeds.

o Sound and free from significant cracks and gaps.

- Concrete strength: To BS 8204-1, Table 2.

- Cleanliness: Remove plaster, debris and dirt.

- Moisture content: To suit screed type. New concrete slabs to receive fully or

partially

- bonded construction must be dried out by exposure to the air for minimum six

weeks.

Control Samples:

- General: Complete areas of finished work and obtain approval of appearance

before

- proceeding.

- Screed type: As clauses 115, 120, 180A.

o Location/ Size: To be selected / 1 m x 1 m.

Conduits Case Into Or Under Screeds:

- Reinforcement: Overlay with reinforcement selected from:

o 500 mm wide strip of steel fabric to BS 4483, reference D49, or

o Welded mesh manufactured in rolls from mild steel wire minimum 1.5 mm

diameter to BS 1052, mesh size 50 x 50 mm.

- Placing reinforcement: Mid depth between top of conduit and the screed surface.

o Screed cover over conduit (minimum): 25 mm.

Pipe Ducts / Trunking:

- Preformed access ducts: Before laying screed, fix securely to substrates and level

- accurately in relation to finished floor surface.

Partially Bonded Construction:

- Preparation: Generally in accordance with BS 8204-1.

- Substrate surface: Brushed finish with no surface laitance.

o Texture of surface: Suitable to accept screed and achieve a bond over

complete area.

Cement Slurry Bonding:

- Slurry type: Neat cement.

ARCHITECTURALSPECIFICATIONS

31

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

- Application: Shortly before laying screed, thoroughly wash clean the surface and

keep well

- wetted for several hours. Remove free water then brush in cement slurry bonding

coat of

- creamy consistency.

- Screeding: While slurry is still wet.

BATCHING/MIXING

Cements:

- Cement types: In accordance with BS 8204-1, clause 5.1.3.

Aggregates:

- Sand: To BS EN 13139.

o Grading limits: In accordance with BS 8204-1, Table B.1.

- Coarse aggregates for fine concrete levelling screeds:

o Standard: To BS EN 12620.

o Designation: 4/10.

- Lightweight aggregates: To BS 8204-1, Annex A.

Mixing:

- Water content: Minimum necessary to achieve full compaction, low enough to

prevent

- excessive water being brought to surface during compaction.

- Mixing: Mix materials thoroughly to uniform consistency. Mixes other than no-fines

must be

- mixed in a suitable forced action mechanical mixer. Do not use a free fall drum type

mixer.

- Consistency: Use while sufficiently plastic for full compaction.

- Ready-mixed retarded screed mortar: Use within working time and site

temperatures

- recommended by manufacturer. Do not retemper.

In-Situ Crushing Resistance (ISCR):

- Standards and category: To BS 8204-1, table 4.

o Testing of bonded and unbonded screeds: To Annex D.

o Testing of floating levelling screeds: To Annex E.

Adverse Weather:

- Screeds surface temperature: Maintain above 5C for a minimum of four days after

laying.

- Hot weather: Prevent premature setting or drying out.

LAYING

Laying of Screed Surfaces:

- Permissible deviation: (allowing for thickness of coverings) 5 mm from datum.

ARCHITECTURALSPECIFICATIONS

32

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Screeding to Falls:

- Minimum screed cover: Maintain at the lowest point.

- Falls: Gradual and consistent.

o Gradient (minimum): As shown on drawings .

Screeding to Ramps:

- Screed cover: Maintain consistent screed depth to graduated substrate.

- Falls: Gradual and consistent.

Flatness / Surface Regularity of Floor Screeds:

- Standard: To BS 8204-1, Table 5.

- Test: To BS 8204-1, Annex C.

- Sudden irregularities: Not permitted.

Flatness / Surface Regularity of Roof Screeds:

- Sudden irregularities: Not permitted.

- Deviation of surface: Measure from underside of a 2 m straightedge (between

points of

- contact), placed anywhere on surface.

o Permissible deviation (maximum): 6 mm.

Compaction of Screeds:

- General: Compact thoroughly over entire area.

- Screeds over 50 mm thick: Lay in two layers of approximately equal thickness.

Roughen

- surface of compacted lower layer then immediately lay upper layer.

Joints in Levelling Screeds Generally:

- Laying screeds: Lay continuously using 'wet screeds' between strips or bays.

Minimize

- defined joints.

- Daywork joints: Form with vertical edge.

Crack Inducing Grooves in Levelling Screeds:

- Groove depth: At least half the depth of screed.

- Cutting grooves: Straight, vertical and accurately positioned. Select from the

following:

o Trowel cut as screed is laid.

o Saw cut sufficiently early after laying to prevent random cracking.

FINISHING/CURING

Finishing Generally:

- Timing: Carry out all finishing operations at optimum times in relation to setting and

- hardening of screed material.

- Prohibited treatments to screed surfaces:

o Wetting to assist surface working.

o Sprinkling cement.

ARCHITECTURALSPECIFICATIONS

33

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Wood Floated Finish:

- Finish: Slightly coarse, even texture with no ridges or steps.

Smooth Floated Finish:

- Finish: Even texture with no ridges or steps.

Trowelled Finish To Levelling Screeds:

- Floating: To an even texture with no ridges or steps.

- Trowelling: To a uniform, smooth but not polished surface, free from trowel marks

and other blemishes, and suitable to receive specified flooring material.

Trowelled Finish to Wearing Screeds:

- Floating: To an even texture with no ridges or steps.

- Trowelling: Successively trowel at intervals, applying sufficient pressure to close

surface and give a uniform smooth finish free from trowel marks and other blemishes.

Curing:

- General: Prevent premature drying. Immediately after laying, protect surface from

wind,

- draughts and strong sunlight. As soon as screed has set sufficiently, closely cover

with

- polyethylene sheeting.

- Curing period (minimum): Keep polyethylene sheeting in position for: period

recommended

- by screed manufacturer.

- Drying after curing: Allow screeds to dry gradually. Do not subject screeds to

artificial

- drying conditions that will cause cracking or other shrinkage related problems.

Roof Screeds:

- Protection: Cover screeds during wet weather. When weathertight coverings are

laid, screeds must be as dry as practicable.

2 IN-SITU FINISHINGS

PLASTERING

Plastering sand shall be clean, natural, uncrushed or partially crushed sand of a light colour,

free from organic matter, suitable for use in plastering and approved by the Architect. The

clay-plus-fine silt content shall not exceed 5% by weight and 15% by volume as specified in

BS 1199.

The field test for determining the volume of silt shall be carried out in accordance with the

methods as hereinafter described. All sand found to contain silt in excess of 15% by

volume shall not be used for plastering or in mortars but shall be removed from the Site at

the Contractor's expense.

Sand shall be sieved fine and of as light a colour as possible.

ARCHITECTURALSPECIFICATIONS

34

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

GYPSUM PLASTER SKIM COAT ON PLASTERBOARD

- Plasterboard: 12.5 mm .

o Preparation: Bonding agent recommended by plaster manufacturer .

- Plaster: Board finish/ finish plaster to BS EN 13279-1.

o Manufacturer: Submit proposals .

- Product reference: None .

o Thickness: 3-5 mm .

o Finish: Smooth.

- Accessories: Beads and stops .

WATERPROOFING ADDITIVE

- Manufacturer: Submit Proposals

- Product Reference: None

HARDENER AND DUSTPROOFING TREATMENT

To submit proposals for Manufacturer. No Product Reference.

The treatment shall consist of three coats applied to surfaces which are clean, dry and free

of all loose dirt, oil, wax, sealers and other foreign matter. New concrete must be

thoroughly cured for a minimum of 14 days.

DUSTPROOFING TREATMENT

To submit proposals for Manufacturer. No Product Reference

The treatment shall consist of two coats applied to surfaces which are clean, dry and have

been adequately cured for a minimum of 14 days.

After the second coating, the surface shall be thoroughly washed and scrubbed with a stiff

broom to remove excess efflorescence.

THIN SET MORTAR : MATERIALS

Portland cement shall be grey or standard colour. Use white colour where specified for

grout.

Sand shall be 30 - 60 mesh silica, clean and graded natural sand. For grout, white sand

passing a 16-mesh screen shall be used.

To submit proposals for all motar additive and grouting Manufacturer. No Product reference.

FIELD TEST TO DETERMINE LEVEL OF CONTAMINANTS IN PLASTERING SAND

Carry out field tests as and when required by the Architect for determining the volume of silt

and clay in plastering sand.

Prepare a salt solution using one teaspoonful of table salt to half litre of cold tap water. Fill

a clean jam jar to about one third of its volume with a sample of the plastering sand. Pour

ARCHITECTURALSPECIFICATIONS

35

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

the prepared salt solution into the jam jar to about 90% full. Close lid of the jar, shake its

contents vigorously and leave to stand for half an hour. A layer of silt will settle over the top

of the sand. Should the layer of silt exceeds one-tenth of the depth of the sand in the jar,

the sand is too contaminated to be used and shall be rejected.

The Architect may also carry out a physical inspection of a batch of sand. If it stains

excessively or balls up in the fingers when rubbed, the sand shall be removed from the Site

at the Contractor's expense.

MIXING MATERIALS

Materials shall be batched by volume in properly sized gauge boxes, one for each material.

The materials shall be mechanically mixed or hand mixed on watertight boarded platforms.

Mixes containing cement shall be used within two hours of the first contact of the cement

with water. All materials remaining after this period shall be discarded and not re-tempered.

Submit to the Architect certification from the supplier of the plasticiser incorporated in the

plaster mix that the quantity used and the dosage is in accordance with the manufacturer's

recommendations.

PREPARATION OF SURFACES

Rake out joints of brickwork and blockwork for a depth of 10mm. Hack off projecting fins on

concrete work and remove all traces of mould oil, paint, grease, dirt and other incompatible

materials by scrubbing with water containing detergent and washing off with clean water.

Thoroughly hack surfaces to form a key.

Rake out joints between concrete work and brickwork of external walls and point with a

waterproof cement grout.

Brush surfaces to remove all loose particles, dust, laitance and efflorescence, etc and well

wet and re-wet as required to receive coating and to equalise suction.

MOVEMENT JOINTS

Movement joints in the base shall be carried through applied coatings and finishings. Form

joints against properly braced timber formwork.

CURING

Work shall be kept damp and adequately cured to prevent shrinkage and cracking. No

traffic shall be permitted on insitu pavings or beds until 7 days after laying.

ANGLES IN PAVING, PLASTERING AND RENDERING

Internal angles shall be slightly coved, external angles and arrises slightly rounded true to

line and with neatly formed mitres.

BEDS AND BACKINGS TO RECEIVE OTHER FINISHINGS

ARCHITECTURALSPECIFICATIONS

36

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Beds shall be laid in bays not exceeding 15m2 as near square shaped as is practicable.

Bays shall be laid to break joint to avoid four corners coinciding and with at least 24 hours

allowed between placing adjacent bays.

Finish beds and backings with a screeded finish to receive insitu finishings or finishings

bedded in mortar; with a wood floated finish left plain to receive inflexible finishings fixed

with an adhesive; and with a smooth steel trowelled finish free from protuberances and

hollows to receive flexible finishings. Where the finishing will be executed by a specialist

sub-contractor, the bed or backing shall be finished to the sub-contractor's approval. In

such cases, the Contractor shall obtain the sub-contractor's written confirmation that the

bed or backing is satisfactory in all respects and forward a copy of such confirmation to the

Architect.

PLACEMENT OF SCREEDS AND PAVINGS

Ensure proper adhesion between pavings and the structure and replace any loose or

defective work.

Place and finish the screeds and pavings in the following successive operations:-

Spread, rake, screed and thoroughly compact by hand, tamping or rolling with a 100

kg roller. If a roller is used, three transverses shall be made in each direction.

Compact by hand at corners and at any joints as they are being formed.

Power float in two operations. Power floating shall be taken over joints in order to

obtain a compact flush surface finish.

Power trowel in one operation to produce a smooth surface relatively free from

defects but which may still contain some trowel marks.

After the surface has hardened, hand trowel to produce a surface free from trowel

marks, uniform in texture and appearance.

Screeds which are to receive surface application of materials such as waterproofing

or roofing membranes shall be smoothly finished in strict accordance with the base

conditions required for such applications.

Immediately after trowelling, cure the surface as hereinbefore described.

All finished surfaces shall be finished to a true and even surface over the whole area.

Screeds and pavings finished to falls shall be laid to the levels shown on the drawings and

shall be free from all irregularities and depressions so that water drains off the floor, leaving

none standing.

PROTECTION TO SCREEDS AND PAVINGS

Protect surfaces which are to receive subsequent finishes against mechanical damage, etc

immediately after laying. If, when the finish is to be laid, the surface shows irregularities

likely to affect the finish, grind back within limits to 2.5mm below the intended finished level

and bring up to a finished level by the application of an approved levelling compound

applied strictly in accordance with the manufacturer's recommendations.

ARCHITECTURALSPECIFICATIONS

37

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Protect paved surfaces after laying and limit traffic over the floor. Remove immediately

prior to completion.

Take up and lay protective coverings as required for cleaning, sealing and polishing.

Protection shall include a periodical cleaning where required to prevent dirt, grit, etc from

becoming engrained. No protective finish shall be laid or applied which will in any way

inhibit fixing of later floor finishes.

PLASTERWORK

Unless otherwise specified, plaster shall be applied in two coats to the total nominal

thickness indicated. The first coat shall be cross scored to provide a key for the second

coat which shall be 6mm thick trowelled or floated to produce a tight, matt, smooth surface

in a true plane to correct line and level with walls and reveals plumb and square.

Carry plaster into grooves and rebates of frames and finish with a slightly coved internal

angle against metal window frames.

CEMENT PAVING

Immediately before laying, the surface shall be well dampened with a slurry of neat cement

and water brushed on. The new paving shall be laid while the slurry is wet.

Paving shall be laid in bays not exceeding 15m2 as near square shaped as is practicable.

Bays shall be laid to break joint to avoid four corners coinciding and with at least 24 hours

allowed between placing adjacent bays.

Finish surface true to plane with a smooth steel trowelled finish free from protuberances

and hollows.

POLYURETHANE FLOOR COATING

Manufacturer : Flowcrete Pte Ltd

Product Reference : DECKSHIELD ID

Location on Drawings : As shown on drawings.

GENERAL

Scope of Specification

This specification includes materials and installation methods (execution) required to install

polyurethane floor coating for a complete, operational system, including not limited to, the

following:

1. Heavy duty, wearing surface, solvent free polyurethane floor coating.

2. Other items and accessories as indicated on the drawings and as specified herein.

All materials including, primers, sealents, resins, curing agents and finish coats are to be

Green Label certified or bear a similar international certification.

ARCHITECTURALSPECIFICATIONS

38

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

References

Referenced publication within this specification shall be the latest revision, unless otherwise

specified, and applicable parts of the referenced publication shall become a part of this

specification as is fully included.

Submittals

A. General: Submit the following items to the Architect/ Engineer for review in

accordance with the Contract requirements.

B. Product Data: For each type of product specified, include manufacturers technical

data, installation instructions, and recommendations for each flooring component

required.

C. Sample for Initial Selection: Manufacturers colour charts showing the full range of

colours, textures, and patterns available for each flooring system indicated.

D. Material Certificates: Material test reports, signed by manufacturers certifying that

materials furnished comply with requirements, in addition to the internationally

recognized green certificates.

E. Installation Instructions: Submit Manufacturers standard installation instructions for

each type of flooring system specified.

Quality Assurance

A. Installer Qualifications: Engage an experienced installer (licensed applicator) who

has specialized in installing the flooring similar in material, design, and extent to

that indicated for this Project and who is acceptable to the flooring manufacturer.

1. Engage an installer who employs only persons trained and approved by

the flooring manufacturer for installing polyurethane flooring specified.

B. Source Limitations: Obtain primary flooring materials, including primers, resins,

hardening agents, aggregates and sealing or finish coats, through one source from

a single manufacturer. Provide secondary materials including patching and fill

material, joint sealant, and repair materials of type and from source recommended

by manufacturer of primary materials.

Delivery, Storage, and Handling

A. Deliver materials in original packages and containers, with seals unbroken,

bearing manufacturers labels indicating brand name and directions for

storage and mixing with other components.

B. Store materials to comply with manufacturers written instructions to

prevent deterioration from moisture, heat, cold, direct sunlight, or other

detrimental effects.

C. Store materials in unopened containers at a temperature of 10C

(minimum) to 30C (maximum).

ARCHITECTURALSPECIFICATIONS

39

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

Project Conditions

A. Environmental Limitations: Comply with the flooring manufacturers written

instructions for substrate temperature, ambient temperature, moisture, ventilation,

and other conditions affecting the floor installation.

1. Work shall not proceed without proper results from moisture testing for

each flooring system and area of Work.

B. Lighting: Provide permanent lighting or, if permanent lighting is not in place,

simulate permanent lighting conditions during the flooring installation.

C. Close spaces to traffic during the flooring application and for not less than 24 hours

after application, unless manufacturer recommends a longer period.

Warranty

The Owner shall receive a written warranty against defects due to improper material

performance and installation for a period of 5 years following the completion of installation.

PRODUCTS

Manufacturers and Products

A. Manufacturers: subject to compliance with requirements, products that may

be incorporated into work include

1. Flowcrete

2. Approved equivalent (Green Label certified or similar)

B. Available Products: Subject to compliance with requirements, products that

may be incorporated into work include those indicated in the flooring

schedule at the end of Part 3.

Materials

A. Polyurethane Flooring: The floor surfacing system consisting of solvent free

polyurethane primer, quartz aggregates, solvent free polyurethane top coat and UV

resistant wearing surface polyurethane finish coat. Comply with requirements

indicated in the flooring Schedule.

B. Patching and Fill Materials: The patching and repair material for repairing the floor

substrate should be recommended by the flooring manufacturer.

C. Joint Sealant: Type recommended or produced by the flooring manufacturer for

type of service and joint condition indicated.

1. Provide flooring manufacturers recommended high strength trafficable PU

joint sealant

D. Equipment: Mixing, cleaning, and application equipment shall be as

recommended in Manufacturers printed installation procedures.

ARCHITECTURALSPECIFICATIONS

40

KAY NGEE TAN ARCHITECTS

02 MAY 2012

KNT 11001 - PROPOSED DEVELOPMENT OF

FUNTASY ISLAND RESORT AT PULAU MANIS,

BATAM, PROVINSI KEPULAUAN RIAU, INDONESIA

EXECUTION

Inspection

A. Inspect surfaces to be covered before starting work to ensure satisfactory

conditions. Report to Construction Manager in writing on surface and

ambient conditions not conforming to the manufacturers instructions, and

not within the scope of this specification. Starting work shall construct

acceptance of surfaces and the responsibility for performance of finished

floor.

B. The strength of the concrete substrate must be minimum 25N/mm

2

in

compressive strength.

C. All new concrete substrate must be a minimum 28 days old or the RH of

the concrete must be below 5% prior to the application of the flooring.

D. The lowest basement floor must be waterproofed with a proper

waterproofing material to ensure no rising moisture causing problem to the

polyurethane floor.

Preparation

A. General: Prepare and clean substrate according to the flooring manufacturers

written instruction for substrate indicated. Provide clean, dry, and neutral substrate

for the flooring application.

B. Concrete Substrates: Provide sound concrete surfaces free of laitance, glaze,