Professional Documents

Culture Documents

CE 470 Lect 1 PDF

Uploaded by

hayder1920Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE 470 Lect 1 PDF

Uploaded by

hayder1920Copyright:

Available Formats

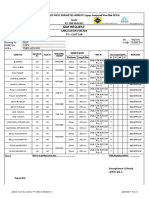

CE 470 STRUCTURAL DESIGN IN METALS Fall 2006

1

Introduction; manufacturing of steel, alloying, and definitions

CE 470 - Lecture #1

Steel

Steel is an alloy made primarily from iron and carbon (the alloy).

Typically, the percent of carbon in steel is relatively low, less than 2% carbon.

Many other elements within common structural steels such as manganese (1%) and small

amounts of silicon, phosphorus, sulfur and oxygen.

Composition controlled by ASTM Standards.

Henry Bessemer, a British inventor is typically credited with the invention of steel in

1856 (Bessemer Steel Company in Sheffield, England). Although steel was produced

before that time, it was his patented Bessemer process which is still used today. In short,

the process involves blowing air through molten pig iron to oxidize the material and

separate impurities.

Steel is different than Wrought Iron and Case Iron.

Wrought Iron - Iron that is almost pure (less than 0.15% carbon). Can be shaped and forge

welded with ease, but is soft and does not harden in the same way as Steel. The properties of

Wrought Iron are partially attributed to the Slag inclusions that result from Puddling and Forge

Welding. Widely used in Bridges, Axles and Ships plates before the development of Bessemer

and Siemens Steel. The last commercial production of Wrought Iron in the U.K. ceased in 1976.

Cast Iron - Iron with a high Carbon content (above 2% to 2.5% but usually less than 6%).

Identical, in most cases, to Pig Iron, it is easily cast to almost any shape and melts at a lower

temperature to other type of iron and steel.

Cast Iron is extremely hard and brittle. Machining is difficult and it is easily shattered, revealing

its crystalline structure. Chilled Cast Iron is even harder and is produced by cooling the castings

to increase the speed at which the iron solidifies. Cast Iron is still is wide use for numerous

casting, from drains covers through to engine blocks and water pipes. Can be Grey, White or

Malleable.

Pig Iron - The name used for the iron directly produced from a blast furnace. Originally cast

into 'pigs' around the base of the furnace, lasted casting machines were developed to produce

pigs but iron is now generally transported while still molten and converted into steel on the same

site. The name is derived from the impression given of piglets feeding from the sow by the iron

being run off the furnace into the original style of sand moulds. Pigs were traditionally sized to

be man handled, but size increase later. Pig Iron changes its name to Cast Iron when re-melted,

although no actual processing takes place. Iron casings can be created directly from the blast

furnace.

CE 470 STRUCTURAL DESIGN IN METALS Fall 2006

2

Back to Steel

Steel is made via two basic routes - from raw materials - iron ore, limestone and coke by the

blast furnace and basic oxygen furnace (BOF) route. If a mill can produce virgin (brand new)

steel as well as roll the steel, it is referred to as an integrated mill or plant.

However, today much steel (about 34% in 2003) is obtained from recycled scrap using the

electric arc furnace (EAF) method. The second technique is much easier and faster since it only

requires scrap steel. Recycled steel is introduced into a furnace and re-melted along with some

other additions to produce the end product.

Iron Ore

Simply rock that happens to contain a high concentration of iron. A few common ores are listed

below.

Common Iron Ores

Hematite - Fe

2

O

3

- 70 percent iron

Magnetite - Fe

3

O

4

- 72 percent iron

Limonite - Fe

2

O

3

+H

2

O - 50 percent to 66 percent iron

Siderite - FeCO

3

- 48 percent iron

Note these all have oxygen attached. To get the iron, we have to get rid of the Oxygen

The more advanced way to smelt iron is in a blast furnace. A blast furnace is charged with

iron ore, coke (coke is charcoal made from coal) and limestone (CaCO

3

). Huge quantities of

air are blasted into the bottom of the furnace. The calcium in the limestone combines with the

silicates to form slag. At the bottom of the blast furnace, liquid iron collects along with a layer

of slag on top. Periodically, you let the liquid iron flow out and cool.

To create a ton of pig iron, you roughly start with 2 tons of ore, 1 ton of coke and half-ton of

limestone. The fire consumes 5 tons of air. The temperature reaches almost 3000 degrees F

(about 1600 degrees C) at the core of the blast furnace! The pig iron produced is tapped from

the furnace. Recall Pig iron is high in carbon and is very brittle, so the carbon must be removed.

Bessemer Furnace (Process)

The process method of producing steel from a charge consisting mostly of pig iron,

however limestone and iron ore are also added.

The process is carried on in a large container called the egg-shaped Bessemer converter,

which is made of steel and has a lining of silica and clay or of dolomite.

The capacity is from 8 to 30 tons of molten iron; the usual charge is 15 or 18 tons.

The wide end, or bottom, has a number of perforations through which the air is forced

upward into the converter during operation and is set on pivots (trunnions) so that it can

be tilted at an angle to receive the charge, turned upright during the "blow," and inclined

for pouring the molten steel after the operation is complete.

CE 470 STRUCTURAL DESIGN IN METALS Fall 2006

3

As the air passes upward through the molten pig iron, impurities such as silicon,

manganese, and carbon unite with the oxygen in the air to form oxides; the carbon

monoxide burns off with a blue flame and the other impurities form slag.

Open Hearth Furnace

The pig iron, limestone and iron ore go into an open hearth furnace.

Heated to about 1600 F (871 C).

The limestone and ore forms a slag that floats on the surface. Impurities, including

carbon, are oxidized and float out of the iron into the slag.

When the carbon content is right, you have carbon steel.

Basic Oxygen Furnace

The process method of producing steel from a charge consisting mostly of pig iron.

The charge is placed in a furnace similar to the one used in the Bessemer process of

steelmaking except that pure oxygen instead of air is blown into the charge to oxidize the

impurities present.

One desirable feature of this process is that it takes less than an hour, and is thus much

faster than the open-hearth process, another important method of steelmaking.

A second advantage is that a major byproduct is carbon monoxide, which can be used as

a fuel or in producing various chemicals, such as acetic acid. The basic oxygen process

also produces less air pollution than methods using air.

Electric Arc Furnace (EAF)

Scrap is melted in an electric arc furnace (100%).

The raw material fed into the furnace may be selected but untreated scrap (old machine

parts, for example), or may be delivered as sorted, crushed and calibrated scrap with a

minimum iron content of 92 percent.

The produces the molten steel, which then undergoes the same refining and grading

processes as pig iron.

The raw materials must be carefully selected for each different steel grade. Selection

depends on the type of "impurities" that any metal or ore in the scrap might contain.

About 40% of all steel in the US is from EAF

CE 470 STRUCTURAL DESIGN IN METALS Fall 2006

4

CE 470 STRUCTURAL DESIGN IN METALS Fall 2006

5

Coke

Combustible substance obtained by the dry distillation (gasification of undesirable

components) of coal in a coke oven.

Coke is virtually pure carbon, with a porous structure and highly resistant to crushing.

Burned in the blast furnace, it provides the heat and gases needed to melt reduce iron ore.

Sintering Plant

The sinter plant is where the iron ore is prepared

The iron ore is crushed and calibrated into grains which are "sintered", or bonded

together.

The sintered iron ore is then crushed and fed, in alternating layers with coke, into the

blast furnace.

Continuous Caster

Molten steel is poured continuously into a bottomless mold. As it is drawn, the steel

comes into contact with the water-cooled interior surface of the mold, and begins to

solidify.

The cast metal is then drawn downwards, guided by a series of rollers, while it continues

to cool.

The cross-section can be controlled and several basic shapes exist.

By the time it reaches the end, the steel is completely solidified, and is immediately cut

into the required lengths

Alloying of Steel

Steels are easily the most common alloy in civil engineering structures and there are many

alloying elements added to the basic steel alloy in order to achieve the desired properties.

An iron-based mixture is considered to be an alloy steel when manganese is greater than 1.65%,

silicon over 0.5%, copper above 0.6%, or other minimum quantities of alloying elements such as

chromium, nickel, molybdenum, or tungsten are present. An enormous variety of distinct

properties can be created for the steel by substituting these elements in the recipe. Some

common alloying elements are listed below, but there are many more.

Carbon has a major effect on steel properties. Carbon is the primary hardening element in steel.

Hardness and tensile strength increases as carbon content increases up to about 0.85% C as shown in the

figure above. Ductility and weldability decrease with increasing carbon.

Manganese is generally beneficial to surface quality especially in resulfurized steels. Manganese

contributes to strength and hardness, but less than carbon. The increase in strength is dependent upon the

carbon content. Increasing the manganese content decreases ductility and weldability, but less than

carbon. Manganese has a significant effect on the hardenability of steel.

CE 470 STRUCTURAL DESIGN IN METALS Fall 2006

6

Phosphorus increases strength and hardness and decreases ductility and notch impact toughness of steel.

The adverse effects on ductility and toughness are greater in quenched and tempered higher-carbon steels.

Phosphorous levels are normally controlled to low levels. Higher phosphorus is specified in low-carbon

free-machining steels to improve machinability.

Sulfur decreases ductility and notch impact toughness especially in the transverse direction. Weldability

decreases with increasing sulfur content. Sulfur is found primarily in the form of sulfide inclusions.

Sulfur levels are normally controlled to low levels. The only exception is free-machining steels, where

sulfur is added to improve machinability.

Silicon is one of the principal deoxidizers used in steelmaking. Silicon is less effective than manganese

in increasing as-rolled strength and hardness. In low-carbon steels, silicon is generally detrimental to

surface quality.

Copper in significant amounts is detrimental to hot-working steels. Copper negatively affects forge

welding, but does not seriously affect arc or oxyacetylene welding. Copper can be detrimental to surface

quality. Copper is beneficial to atmospheric corrosion resistance when present in amounts exceeding

0.20%. Weathering steels are sold having greater than 0.20% Copper.

Chromium is commonly added to steel to increase corrosion resistance and oxidation resistance, to

increase hardenability, or to improve high-temperature strength. As a hardening element, Chromium is

frequently used with a toughening element such as nickel to produce superior mechanical properties. At

higher temperatures, chromium contributes increased strength. Chromium is a strong carbide former.

Complex chromium-iron carbides go into solution in austenite slowly; therefore, sufficient heating time

must be allowed for prior to quenching.

Nickel is a ferrite strengthener. Nickel does not form carbides in steel. It remains in solution in ferrite,

strengthening and toughening the ferrite phase. Nickel increases the hardenability and impact strength of

steels.

Molybdenum increases the hardenability of steel. Molybdenum may produce secondary hardening during

the tempering of quenched steels. It enhances the creep strength of low-alloy steels at elevated

temperatures.

Titanium is used to retard grain growth and thus improve toughness. Titanium is also used to achieve

improvements in inclusion characteristics. Titanium causes sulfide inclusions to be globular rather than

elongated thus improving toughness and ductility in transverse bending.

Vanadium increases the yield strength and the tensile strength of carbon steel. The addition of small

amounts of Niobium can significantly increase the strength of steels. Vanadium is one of the primary

contributors to precipitation strengthening in micro-alloyed steels. When thermo-mechanical processing

is properly controlled the ferrite grain size is refined and there is a corresponding increase in toughness.

The impact transition temperature also increases when vanadium is added.

CE 470 STRUCTURAL DESIGN IN METALS Fall 2006

7

Some Useful ASTM Specifications

A36/A 36M Specification for Carbon Structural Steel

A514/A 514M Specification for High-Yield-Strength, Quenched and Tempered Alloy Steel

Plate, Suitable for Welding

A588/A 588M Specification for High-Strength Low-Alloy Structural Steel with 50 ksi [345

MPa] Minimum Yield Point to 4 in. [100 mm] Thick

A572/A 572M Specification for High-Strength Low-Alloy Columbium-Vanadium Structural

Steel

A709/A709M Specification for bridge steels

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A307 Specification for Carbon Steel Bolts and Studs, 60000 psi Tensile Strength

A502 Specification for Rivets, Steel, Structural

A668/A668M Specification for Steel Forgings, Carbon and Alloy, for General Industrial Use

You might also like

- 7 - Presentation - NanoDocument7 pages7 - Presentation - Nanohayder1920No ratings yet

- 6 - Presentation - NanoDocument6 pages6 - Presentation - Nanohayder1920No ratings yet

- 7 - Presentation - NanoDocument7 pages7 - Presentation - Nanohayder1920No ratings yet

- Powder Metallurgy: Powder Metallurgy Is Production Technology, Vastly Used in TheDocument2 pagesPowder Metallurgy: Powder Metallurgy Is Production Technology, Vastly Used in Thehayder1920No ratings yet

- 10 - Presentation - NanoDocument10 pages10 - Presentation - Nanohayder1920No ratings yet

- Hall-Petch strengthening mechanismsDocument2 pagesHall-Petch strengthening mechanismsJatin DarveNo ratings yet

- 1 - Presentation NanoDocument9 pages1 - Presentation Nanohayder1920No ratings yet

- 2 - Presentation - NanoDocument9 pages2 - Presentation - Nanohayder1920No ratings yet

- Processing of PM PartsDocument7 pagesProcessing of PM Partshayder1920No ratings yet

- 8 - Presentation - NanoDocument7 pages8 - Presentation - Nanohayder1920No ratings yet

- NDT Methods for Weld Inspection - Radiography and UltrasonicsDocument2 pagesNDT Methods for Weld Inspection - Radiography and Ultrasonicshayder1920No ratings yet

- NDT Methods for Weld Inspection - Radiography and UltrasonicsDocument2 pagesNDT Methods for Weld Inspection - Radiography and Ultrasonicshayder1920No ratings yet

- Characterization of PM PartsDocument3 pagesCharacterization of PM Partshayder1920No ratings yet

- Results of Solidification PatternsDocument17 pagesResults of Solidification Patternshayder1920No ratings yet

- Characterization of PM PartsDocument3 pagesCharacterization of PM Partshayder1920No ratings yet

- Experimenting, Numerical Modeling, and Programming: Table (3.1) - Chemical Composition (Mass %)Document3 pagesExperimenting, Numerical Modeling, and Programming: Table (3.1) - Chemical Composition (Mass %)hayder1920No ratings yet

- Numerical Modelling Simulation of Casting SolidificationDocument7 pagesNumerical Modelling Simulation of Casting Solidificationhayder1920No ratings yet

- Processing of PM PartsDocument7 pagesProcessing of PM Partshayder1920No ratings yet

- Experimenting, Numerical Modeling, and ProgrammingDocument3 pagesExperimenting, Numerical Modeling, and Programminghayder1920No ratings yet

- Results of Solidification PatternsDocument17 pagesResults of Solidification Patternshayder1920No ratings yet

- Simulation of Aluminum SolidificationDocument11 pagesSimulation of Aluminum Solidificationhayder1920No ratings yet

- Heat Transfer Simulation of Casting SolidificationDocument5 pagesHeat Transfer Simulation of Casting Solidificationhayder1920No ratings yet

- Numerical Modelling Simulation of Casting SolidificationDocument7 pagesNumerical Modelling Simulation of Casting Solidificationhayder1920No ratings yet

- Numerical Modelling of SolidificationDocument6 pagesNumerical Modelling of Solidificationhayder1920No ratings yet

- Experimenting, Numerical Modeling, and ProgrammingDocument3 pagesExperimenting, Numerical Modeling, and Programminghayder1920No ratings yet

- Experimenting, Numerical Modeling, and Programming: Table (3.1) - Chemical Composition (Mass %)Document3 pagesExperimenting, Numerical Modeling, and Programming: Table (3.1) - Chemical Composition (Mass %)hayder1920No ratings yet

- Numerical Modelling of SolidificationDocument6 pagesNumerical Modelling of Solidificationhayder1920No ratings yet

- Heat Transfer Simulation of Casting SolidificationDocument5 pagesHeat Transfer Simulation of Casting Solidificationhayder1920No ratings yet

- General Shrinkage BehaviourDocument5 pagesGeneral Shrinkage Behaviourhayder1920No ratings yet

- Heat Transfer Simulation of Casting SolidificationDocument5 pagesHeat Transfer Simulation of Casting Solidificationhayder1920No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- UYU Cat Apr 2023 - 230323 - 222505Document40 pagesUYU Cat Apr 2023 - 230323 - 222505gabzhaddadNo ratings yet

- Strain Hardening in Aerospace AlloysDocument14 pagesStrain Hardening in Aerospace AlloysAbdelwahab ElaichiNo ratings yet

- Ultrasonic Testing On Duplex SsDocument9 pagesUltrasonic Testing On Duplex Sskukuriku13No ratings yet

- 0824743083Document5,071 pages0824743083Shiv Kumar RathoreNo ratings yet

- US 0925A Laminated Elastomeric Bearings AaefDocument78 pagesUS 0925A Laminated Elastomeric Bearings AaefspattiwarNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- Cimolai Welding Book for LBNF Test Pieces ProjectDocument12 pagesCimolai Welding Book for LBNF Test Pieces ProjectSuryana MamanNo ratings yet

- Tips To Succeed at Descaling - Chemical ProcessingDocument3 pagesTips To Succeed at Descaling - Chemical ProcessingPrince MathewNo ratings yet

- Positive Material Identification ProcedureDocument6 pagesPositive Material Identification Procedureomar100% (1)

- ASTM A179 2005 LTCS Tubes Seamless Cold-Drawn For Heat-Exchanger and CondenserDocument2 pagesASTM A179 2005 LTCS Tubes Seamless Cold-Drawn For Heat-Exchanger and Condensernse mcxNo ratings yet

- Gad Tungsten Arc WeldingDocument7 pagesGad Tungsten Arc WeldingRizwan MrnNo ratings yet

- Naffco Diesel Tank For Fire Protection DetailsDocument2 pagesNaffco Diesel Tank For Fire Protection DetailsRdb Haxor100% (1)

- Forging and Extrusion Defects Causes and TypesDocument8 pagesForging and Extrusion Defects Causes and TypesVenkat KrishnaNo ratings yet

- POSCO Brochure (플랜트소개용)Document27 pagesPOSCO Brochure (플랜트소개용)German Jaramillo VillarNo ratings yet

- Nde-Wqt-011 - Structure (08-05-23)Document2 pagesNde-Wqt-011 - Structure (08-05-23)cindy anggrilitaNo ratings yet

- Boiler Pressure Parts - Straight TubesDocument2 pagesBoiler Pressure Parts - Straight TubesLTE002No ratings yet

- Chinese Standards On Steel Materials-1Document3 pagesChinese Standards On Steel Materials-1mesmerize59100% (2)

- G 123 - 00 (2015)Document10 pagesG 123 - 00 (2015)ruben carcamo100% (1)

- PX Pumps FolletoDocument4 pagesPX Pumps FolletoBenicio Joaquín Ferrero BrebesNo ratings yet

- Saes A 007Document29 pagesSaes A 007NagarjunNo ratings yet

- Basic Welding GMAW Lab SheetDocument2 pagesBasic Welding GMAW Lab SheetMUHAMMAD AFIQ IQWAN KAMARUL BADRINNo ratings yet

- Cost of Structural SteelworkDocument16 pagesCost of Structural Steelworkdvs99No ratings yet

- Astm E1025 PDFDocument6 pagesAstm E1025 PDFmga_4566472No ratings yet

- 4.1 Weldwell ElectrodesDocument10 pages4.1 Weldwell Electrodesg_sanchetiNo ratings yet

- STELEX PrO (E) FinalDocument4 pagesSTELEX PrO (E) FinalGhita-Mehedintu GheorgheNo ratings yet

- How To Carry Out Tack WeldingDocument2 pagesHow To Carry Out Tack WeldingwentropremNo ratings yet

- Induction PWHTDocument6 pagesInduction PWHTMallinatha PNNo ratings yet

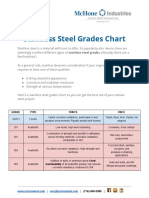

- MCHONE Stainless Grades Chart DownloadableDocument3 pagesMCHONE Stainless Grades Chart DownloadableSagar TikoneNo ratings yet

- Cleaning of Stainless SteelDocument7 pagesCleaning of Stainless SteelSaut Maruli Tua SamosirNo ratings yet

- Nitriding SteelDocument40 pagesNitriding SteelkaoblekstenaNo ratings yet