Professional Documents

Culture Documents

Concrete Formwork Work Method Statement (SWMS) V8

Uploaded by

pparreraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Formwork Work Method Statement (SWMS) V8

Uploaded by

pparreraCopyright:

Available Formats

Ful l Document Avail able Here

CONCRETE FORMWORK

WORK METHOD STATEMENT

Ful l Document Avail able Here: CONCRETE FORMWORK WORK METHOD STATEMENT

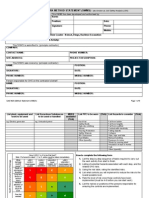

DOCUMENT NO: S812.0057 ACTIVITY : Concrete Formwork REVIEW NO: DATE:

Authorised by: SafetyCulture All rights reserved Page 1 of 14- Version 8.0

Signature: Date:

CONCRETE FORMWORK SAFE WORK METHOD STATEMENT Part 1

Company Details

Company Name: ABN:

Contact Name, Position and Phone number:

Address:

Project details

Project: Area:

J ob Address:

J ob Description:

Activity: Concrete Formwork

Rel evant workers must be consulted i n the devel opment, approval and communi cati on of thi s SWMS SWMS Approved by: Page 1 of 14

Name: (Include names of workers who

were consulted in relation to this SWMS)

Signature: J ob Title: Date:

Name:

Signature:

Date:

Personnel responsible for monitoring and managing activity:

Overall Risk Rating After

Controls

4 Acute 3 High

2 Moderate 1 Low

ALL PERSONS INVOLVED IN TASK MUST HAVE THIS SWMS COMMUNICATED TO THEM PRIOR TO WORK COMMENCING

Regular inspections and observations will be conducted by ______________to ensure SWMS is being complied with.

Daily Tool Box Talks will be undertaken to identify, control and communicate additional site hazards.

Work must cease immediately if incident or near miss occurs. SWMS must be amended in consultation with relevant persons.

Amendments must be approved by ______________ and communicated to all affected workers before work resumes.

SWMS must be made available for inspection or review as required by WHS legislation.

Record of SWMS must be kept as required by WHS legislation (until job is complete or for 2 years if involved in a notifiable incident).

S

A

M

P

L

E

Ful l Document Avail able Here

CONCRETE FORMWORK

WORK METHOD STATEMENT

Ful l Document Avail able Here: CONCRETE FORMWORK WORK METHOD STATEMENT

DOCUMENT NO: S812.0057 ACTIVITY : Concrete Formwork REVIEW NO: DATE:

Authorised by: SafetyCulture All rights reserved Page 2 of 14- Version 8.0

Signature: Date:

Personal Protective Equipment

General:

Safety footwear (rubber boots), gloves, protective clothing (long sleeve shirts and long trousers or overalls). Ensure all PPE meets relevant Australian

Standards. Inspect, and replace PPE as needed.

Provide UV sun protection where required, (broad brimmed hat, UV rated clothing, SPF 30+sunscreen, tinted safety glasses with adequate UV protection).

Where required:

Hearing protection, high visibility shirt or vest, hard hat.

Foot

Protection

Hearing

Protection

High

Visibility

Head

Protection

Eye

Protection

Hand

Protection

Protective

Clothing

Safety Notes

Formwork is the surface, supports and framing used to define the shape of concrete until the concrete is self-supporting. It includes the forms on which the concrete

is poured, the supports to withstand the loads imposed by the forms and the concrete and any bracing added to ensure stability.

Main hazards include:

- formwork collapse (before, during and after placement of concrete)

- falls from heights and slips/trips

- falling objects

- noise/dust

- manual handling

S

A

M

P

L

E

Ful l Document Avail able Here

CONCRETE FORMWORK

WORK METHOD STATEMENT

Ful l Document Avail able Here: CONCRETE FORMWORK WORK METHOD STATEMENT

DOCUMENT NO: S812.0057 ACTIVITY : Concrete Formwork REVIEW NO: DATE:

Authorised by: SafetyCulture All rights reserved Page 3 of 14- Version 8.0

Signature: Date:

Task Breakdown

Possible Safety or

Environmental Hazards

RB Control Measures to Reduce risk RA

Responsible

Officer

NOTE: RB =Risk Rating before controls implemented - RA =Risk Rating after controls are implemented.

Design Specifications Personal injury

- crushing

- falls

- being struck by falling

object

Collapse of structure

Legislation breach

4A Designers must:

- Fully describe all features of design

- Provide SWMS for installation and stripping

- Define load areas

- define acceptance criteria

- Provide for field adjustment

- Describe location of weep, vibrator and clean-out

holes and inspection openings

- Detail sequence of concrete placement, including any

slopes, direction of pour and time between pours

- Describe strength, stability and stiffness of system

- Detail foundation materials

- Detail surface type (filling, compaction, drainage)

- Allow for loads during construction (such as workers,

materials, wind, false decks, rain, water runoff) reduce

fall risks where practicable

Certification of design must be provided by a competent

person (such as a structural engineer)

All formwork materials (timber/plywood, prefab modules

aluminum, steel or plastic) must meet quality testing criteria as

defined in AS 3610.

All exposed rebar ends must contain end-caps.

Ensure:

- Correct size for bar

- Fitted correctly

- Regular inspections are undertaken to check condition of

end caps and to ensure no caps are missing

Note: End-caps to NOT provide adequate protection against

impalement. Safe systems of work must be in place to prevent

persons falling onto rebar ends (capped or not). Examples include

guardrails, screens, edge protection of scaffolds, barriers and

exclusion zones.

1L

S

A

M

P

L

E

Ful l Document Avail able Here

CONCRETE FORMWORK

WORK METHOD STATEMENT

Ful l Document Avail able Here: CONCRETE FORMWORK WORK METHOD STATEMENT

DOCUMENT NO: S812.0057 ACTIVITY : Concrete Formwork REVIEW NO: DATE:

Authorised by: SafetyCulture All rights reserved Page 4 of 14- Version 8.0

Signature: Date:

Task Breakdown

Possible Safety or

Environmental Hazards

RB Control Measures to Reduce risk RA

Responsible

Officer

NOTE: RB =Risk Rating before controls implemented - RA =Risk Rating after controls are implemented.

Preparation Personal injury

- crushing

- falls

- being struck by falling

object

Collapse of structure

Legislation breach

4A Project documentation must be available on site and include

(at least):

- designs specifications

- drawings

- loading calculations

- plans/elevations

- general arrangements

- maximum point loadings

- component types and spacings

- methods of securing structure and components

- formply size

- minimum stripping times

- effects of post-tensioning

- edge protection

- back propping where required

- any variations from design and subsequent

certification of variations

- safe load bearings

- timeframes between pours and pour rates

1L

Personnel requirements Personal injury

- crushing

- falls

- being struck by falling

object

Collapse of structure

Legislation breach

4A Competency Based Training:

Should include:

- site induction

- nature of hazards and emergency plans

- requirements of AS3610

- Operation of plant/equipment as required

- PPE (use, maintenance, storage)

- Specific SWMS

Persons required to erect formwork must have formal

scaffolding certification where required, and be competent in

specific modular system

1L

S

A

M

P

L

E

Ful l Document Avail able Here

CONCRETE FORMWORK

WORK METHOD STATEMENT

Ful l Document Avail able Here: CONCRETE FORMWORK WORK METHOD STATEMENT

DOCUMENT NO: S812.0057 ACTIVITY : Concrete Formwork REVIEW NO: DATE:

Authorised by: SafetyCulture All rights reserved Page 5 of 14- Version 8.0

Signature: Date:

Task Breakdown

Possible Safety or

Environmental Hazards

RB Control Measures to Reduce risk RA

Responsible

Officer

NOTE: RB =Risk Rating before controls implemented - RA =Risk Rating after controls are implemented.

Risk assessment. Personal injury

- crushing

- falls

- being struck by falling

object

Collapse of structure

Legislation breach

4A Consider:

- size/weight of building and type of formwork

- plant/equipment required for construction and

dismantling

- environment (slopes, wind, rain)

- level of relevant worker experience

- height

Note: A risk assessment should be revised at least 3 yearly, or

where major changes or an incident/near miss occurs.

1L

Risk Control Personal injury

- crushing

- falls

- being struck by falling

object

Collapse of structure

Legislation breach

4A Consider:

- edge protection and netting to prevent falling objects

- fit for purpose work platforms/scaffolding

- traffic management

- mechanical lifting

- adequate lighting

- certificate of competencies where required

- PPE and housekeeping

A SWMS should be developed for the specific task and select

controls as required.

1L

Formwork Erection Personal injury

- crushing

- falls

- being struck by falling

object

Collapse of structure

Legislation breach

4A All framing must be carried out so that it complies with on site

design documentation and any manufacturers' requirements.

Inspect all formwork components to ensure acceptable

condition as per AS3610.

Traditional

Foundation:

- ensure stable base

- ensure suspended slabs can safely support loads (e.g.

persons and crane lifted loads)

- ensure base plates are provided under props and

standards

- ensure suitable sole boards are provided

1L

S

A

M

P

L

E

You might also like

- Environmental, Health and Safety Risk AssessmentDocument2 pagesEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- Estimation Man HourDocument241 pagesEstimation Man HourAnonymous ynJByUs52% (42)

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Concrete Works Risk AssessmentDocument14 pagesConcrete Works Risk AssessmentUMUT100% (1)

- Concrete Formwork Suspended SlabDocument5 pagesConcrete Formwork Suspended SlabKate HopleyNo ratings yet

- Safe Work Procedure, Gem MaintenanceDocument46 pagesSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- OHS SWMS Form 005 ExcavationDocument8 pagesOHS SWMS Form 005 Excavationazlinaz100% (2)

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- Steel FixingDocument5 pagesSteel Fixingrishanmulky88% (8)

- Cleaning Risks AssessedDocument6 pagesCleaning Risks Assessedjulius0% (1)

- Steel Structure Installation Risk AssessmentDocument8 pagesSteel Structure Installation Risk Assessmentjameel100% (3)

- JSA for safe fence installationDocument5 pagesJSA for safe fence installationMoaatazz Nouisri50% (2)

- 45 - Method Statements For Erection of Steel PDFDocument1 page45 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocument17 pagesThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaNo ratings yet

- Safe Working at HeightsDocument27 pagesSafe Working at Heightscosty_mcv100% (7)

- SWMSElevated Work PlatformsDocument4 pagesSWMSElevated Work PlatformsRay LeeNo ratings yet

- General Instruction Manual: Crane Suspended Personnel Platform (Manbasket) OperationsDocument9 pagesGeneral Instruction Manual: Crane Suspended Personnel Platform (Manbasket) OperationsJoseph Magbanua100% (2)

- QS ContractualClaimsDocument7 pagesQS ContractualClaimspparrera100% (2)

- Safe Work Method Statement - PlumbingDocument4 pagesSafe Work Method Statement - PlumbingJohn KurongNo ratings yet

- Master Builders SA - Safe Work Method Statement - Roof Metal InstallationDocument7 pagesMaster Builders SA - Safe Work Method Statement - Roof Metal InstallationvictorNo ratings yet

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementianllagasNo ratings yet

- MS & JSA Piling Work PDFDocument11 pagesMS & JSA Piling Work PDFmesmerize59100% (2)

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhNo ratings yet

- Safe Work Method Statement ScaffoldingDocument4 pagesSafe Work Method Statement Scaffoldingdox4useNo ratings yet

- Safe Work Method StatementDocument11 pagesSafe Work Method StatementJNo ratings yet

- Rebar Job Hazard AnalysisDocument1 pageRebar Job Hazard Analysisjoker batmanNo ratings yet

- Safe Work Method Statement - Formwork and ConcretingDocument8 pagesSafe Work Method Statement - Formwork and ConcretingAnonymous gmNTrHsNo ratings yet

- Risk Assesment For CompactionDocument12 pagesRisk Assesment For CompactionAzhar MushtaqNo ratings yet

- JSA For Crawler Crane Installation FormDocument3 pagesJSA For Crawler Crane Installation FormHu Man88% (8)

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- Activity Hazard Analysis (AHA) ScaffoldingDocument6 pagesActivity Hazard Analysis (AHA) Scaffoldingkashif ManzoorNo ratings yet

- Plasma Cutter Work Method Statement (SWMS) V8Document4 pagesPlasma Cutter Work Method Statement (SWMS) V8afonsobuenoNo ratings yet

- SWMS Scaffold FixedDocument11 pagesSWMS Scaffold FixedEdha AliNo ratings yet

- TBT-Driving in FogDocument2 pagesTBT-Driving in FogImran KhanNo ratings yet

- Piling Safety PlanDocument8 pagesPiling Safety PlanBalogun Isaac100% (1)

- Chapter 4 Tool and Die DesignDocument70 pagesChapter 4 Tool and Die Designdawit solomonNo ratings yet

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Plumber - Drainer SWMSDocument12 pagesPlumber - Drainer SWMSallen2912100% (1)

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementShahed Facebook100% (1)

- Dimensional Control Procedure for Offshore and Onshore FacilitiesDocument57 pagesDimensional Control Procedure for Offshore and Onshore Facilitiesmayur7789No ratings yet

- Excavation Trenching and HorizontalDocument5 pagesExcavation Trenching and HorizontalRaed Naim Khammash100% (1)

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfNo ratings yet

- SWMS DemolitionDocument18 pagesSWMS Demolitionalee0007100% (1)

- Components of Railway Track 1Document21 pagesComponents of Railway Track 1Mudasar HussainNo ratings yet

- Safe Work ProcedureDocument2 pagesSafe Work ProcedureSuco IdeunkNo ratings yet

- Safe Unloading of Cut and BentDocument16 pagesSafe Unloading of Cut and BentAbhinav SinhaNo ratings yet

- Safe Work Method Statement TemplateDocument3 pagesSafe Work Method Statement TemplateJonasNo ratings yet

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Risk assessment for waterproofing worksDocument4 pagesRisk assessment for waterproofing worksfaisal nadeem75% (4)

- GRP Installation GuideDocument13 pagesGRP Installation GuidepparreraNo ratings yet

- Structural Masangkay Quiz 3Document6 pagesStructural Masangkay Quiz 3Sharmaine FalcisNo ratings yet

- SWP 5 Excavations Shoring and Trenches PDFDocument4 pagesSWP 5 Excavations Shoring and Trenches PDFThanesh ManogaranNo ratings yet

- Safety Method StatementDocument14 pagesSafety Method StatementnayakyaNo ratings yet

- JSA-009a Drilling and Mon Well Construction-SonicDocument4 pagesJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi83% (6)

- Progress Payment Certificate for SubcontractorsDocument1 pageProgress Payment Certificate for Subcontractorspparrera50% (2)

- Ra & Jsa FormatDocument19 pagesRa & Jsa Formatspecpro50% (2)

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- Coordinate and supervise progress claimsDocument43 pagesCoordinate and supervise progress claimsupamyNo ratings yet

- Coordinate and supervise progress claimsDocument43 pagesCoordinate and supervise progress claimsupamyNo ratings yet

- Concrete Safety AnalysisDocument14 pagesConcrete Safety AnalysisTahar Berrachedi100% (1)

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- Astm c33-99 Standard Specification For Concrete AggregatesDocument8 pagesAstm c33-99 Standard Specification For Concrete AggregatespparreraNo ratings yet

- Tool Box Talk - MK - Emergency Response ProceduresDocument2 pagesTool Box Talk - MK - Emergency Response ProceduresPaul McGahanNo ratings yet

- HSF-PR-0063 Work at HeightDocument32 pagesHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- Concrete Formwork SafetyLSite SupervisorDocument10 pagesConcrete Formwork SafetyLSite SupervisoradiNo ratings yet

- Excavation, Backfill & Compaction Method StatementDocument16 pagesExcavation, Backfill & Compaction Method StatementpparreraNo ratings yet

- Excavation, Backfill & Compaction Method StatementDocument16 pagesExcavation, Backfill & Compaction Method StatementpparreraNo ratings yet

- Joints in Concrete SlabsDocument2 pagesJoints in Concrete SlabsmutyokaNo ratings yet

- WP1052 Time EstimatingDocument7 pagesWP1052 Time EstimatingMact Manit Cse AlumniAssociationNo ratings yet

- Aashto T 277-07Document12 pagesAashto T 277-07pparreraNo ratings yet

- Cementitious Grout for Construction RepairDocument2 pagesCementitious Grout for Construction RepairMosaad KeshkNo ratings yet

- K 450 Plus PDFDocument8 pagesK 450 Plus PDFrkssNo ratings yet

- Mock Test 276Document4 pagesMock Test 276Ngan Nguyen PhuongNo ratings yet

- MED BV Certificate For FDL 1Document4 pagesMED BV Certificate For FDL 1ov.ei.clerk1No ratings yet

- Inform Practice Note #16: ContentDocument6 pagesInform Practice Note #16: ContentTSHEPO DIKOTLANo ratings yet

- Shop Drawings: LegendDocument1 pageShop Drawings: LegendSadev Mini VlogsNo ratings yet

- Operating Manual: Cutter KU 130 ACDocument189 pagesOperating Manual: Cutter KU 130 AClemuelNo ratings yet

- Ebook 4 PrintingDocument91 pagesEbook 4 PrintingManuel AsitimbayNo ratings yet

- CSH Program-Philsci KoronadalDocument16 pagesCSH Program-Philsci KoronadalAlmher RemolloNo ratings yet

- 2019-10-15 Daily Observation Report CilamayaDocument1 page2019-10-15 Daily Observation Report CilamayaghifariaghniaNo ratings yet

- Primer for Denso HB80 High Strength Epoxy MortarDocument2 pagesPrimer for Denso HB80 High Strength Epoxy Mortarmehdi_hoseineeNo ratings yet

- The Perfect SandcastleDocument3 pagesThe Perfect Sandcastleapi-248724176No ratings yet

- Midland Brick Coursing ChartDocument2 pagesMidland Brick Coursing ChartAmit LakhaniNo ratings yet

- Hydro-Lift Core Catcher Technical Data SheetDocument2 pagesHydro-Lift Core Catcher Technical Data Sheethaoues23No ratings yet

- Pyroswiss Sbs (Smoke Barrier System) Int enDocument4 pagesPyroswiss Sbs (Smoke Barrier System) Int enptoriceNo ratings yet

- Ceiling ReportDocument23 pagesCeiling Reportdolar buhaNo ratings yet

- Wall Footing Detail: Fin. Grnd. Flr. Lvl. NGLDocument1 pageWall Footing Detail: Fin. Grnd. Flr. Lvl. NGLDarwin TanNo ratings yet

- CompactGrid - Mounting Instructions V2 I400176GB PDFDocument8 pagesCompactGrid - Mounting Instructions V2 I400176GB PDFCamilo Andres Bayona AguileraNo ratings yet

- ITR-B (Piping) Witness Joint1Document1 pageITR-B (Piping) Witness Joint1Momo ItachiNo ratings yet

- Civil Engineering: Works, Infrastructure, and Sub-DisciplinesDocument1 pageCivil Engineering: Works, Infrastructure, and Sub-DisciplinesRahmad EfendiNo ratings yet

- QCR W 2036Document1 pageQCR W 2036Madhan KannanNo ratings yet

- Subsea Engineer Resume 2023 JulyDocument3 pagesSubsea Engineer Resume 2023 JulyAchanta MounicaNo ratings yet

- Wiring DevicesDocument6 pagesWiring DevicesMohammed Hussain OMNo ratings yet

- Hazard Communication and Hazardous ES-RQ-191Document3 pagesHazard Communication and Hazardous ES-RQ-191remember100% (1)

- Change Order - Blank TemplateDocument1 pageChange Order - Blank Templategordym93No ratings yet