Professional Documents

Culture Documents

Log Building News - Issue No. 76

Uploaded by

ursindCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Log Building News - Issue No. 76

Uploaded by

ursindCopyright:

Available Formats

The EP&M is

for sale at the

Winter 2013 Number 76

Agreement Number 40707514

Inside This Issue

Building & Testing Compound

Wooden Beams

page 14,67

Tech Talk: Cross-Tied

Wagon Axles

page 8

40 Years of Log Building

History

page 1122

Tech Talk: Norway

page 2324

Log Building in Switzerland

page 2526

Classifieds

pages 2830

Advertisers in This Issue

page 31

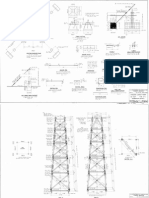

Figure A

www.logassociation.org

ILBA website

Building & Testing Compound

Wooden Beams By Meinrad Rohner & Robert Chambers

MEINRAD MEIRI ROHNER HAD SEEN FANCY OLD

WOODEN BEAMS IN CENTRAL EUROPEON TRAIN

TRESTLES AND BRIDGESWHERE TWO TIMBERS

WERE JOINED TO EACH OTHER TO MAKE ONE

DEEPER, STRONGER, MEMBER: A COMPOUND

WOODEN BEAM.

This September, Meiri and I taught two hands-

on classes in Kuopio, Finland at the Savo Technical

University. Most of the participants were log home

builders in Finland, and some came from Estonia and

Russia.

While Robert was teaching mitered truss

construction to half of the students, Meiri and his

students were building four different compound

wooden beams: three were built with wooden

interlocking joinery, and one used only structural

screws. Halfway through the courses, the students

switched, so they could help both with the

beams, and with the truss.

The beams and mitered truss were all

constructed to be parts of a building for a

customer. All four beams had 7.2m (23 7-1/2)

span, and all were built using Scots pine (Pinus

sylvestris) with 26% to 29% moisture content.

The round logs had about 290mm (11-1/2)

small-end diameter, and the timbers were sawn

from logs of about this same size. The trees

were more than 200 years old when they were

cut downnot surprising, since they had been

growing not that far from the Arctic Circle. It was

very high quality wood.

The four styles of compound wooden beams

that Meiri built during the courses can be seen in

Figure A and Photo 19 (page7).

Log Building News

Download this

current issue at the

ILBA website

www.logassociation.org

40

th

YEAR

I

N

T

E

R

N

A

T

I

O

N

A

L L

O

G

B

U

I

L

D

E

R

S

A

S

S

O

CI A

T

I

O

N

Winter 2013

2

LogBuildingNews

Winter 2013

Issue #76

Published four times a year

2012 International Log Builders Association

P.O. Box 775

Lumby, British Columbia

Canada V0E 2G0

Toll-free: 800-532-2900

Phone: 250-547-8776

Fax: 250-547-8775

www.logassociation.org

Ann Miks, Administrator

ann@logassociation.org

Log Building News Editor

Robert Chambers

robert@logbuilding.org

Contributors to this issue:

Meiri Rohner

info@alppisalvos.fi

Roger Porrenga

postmaster@blockhausbau.ch

Robert Chambers

robert@LogBuilding.org

Association History:

Ingrid Boys

Brian Lloyd

Ed Campbell

Vic Janzen

Gary Pendergrass

Robrt Savignac

David Rogers

Ann Miks

Terry Hall

Ed Shure

Mira Steinbrecher

Tom Hahney

Brian Olynek

Shannon Maris

Robert Chambers

Catharine Hansen

Gunnar Granberg

granberggunnar@hotmail.com

MISSION STATEMENT

This association is a non-profit

organization comprised of log crafters and

affiliated members from many countries.

We are dedicated to the education of

both our members and the public.

Our association has a mandate to

research, develop and share techniques

relevant to the construction of superior

handcrafted log buildings.

Meiri writes:

The sawn-timber lightning bolt is a traditional method, which was used by the central-

European carpenters in early days. The wedged round log beam and the round log

lightning bolt are variations of old techniques, which I fgured out because I wanted to use

great old ideas in round logs.

The development of these beams is not yet fnished. There are things to improve, and

tools / jigs could be fabricated to help. But it is very rare that we are asked to do this

kind of work, and when we make these compound beams for customers (and with their

deadlines) we have little time to build better jigs!

Here are descriptions of how each of the four compound beams was fabricated:

1 Sawn Timbers Connected with Engineered Screws

Sawn timbers, screwed together with a double row of Sihga GoFix XB 8mm x 400mm

screws positioned as seen in the Figure A. Each timber was 170mm wide x 230mm

deep (6-1/2 x 9). The screws were installed using the manufacturers jig to locate

and shoot them in at the correct angle (Photo B).

2 Round Logs with Lightningbolt Cogs

The cogs were 70mm (2-3/4) tall. At completion, seven 16mm (5/8) diameter

throughbolts and small washers at top and bottom were installed (all bolt locations are

shown in Figure A).

Heres the process: set the top log of the beam over the bottom log, and scribe the

long groove using a scriber that puts a scribe line on both logs. Remove the top log.

Mark the top of the log below for the lengths and positions where you want to have

each of the lightningbolt cogs start and end.

Use a block of wood to simulate the cog you will cut into the bottom log. The block

should be nearly as wide as the diameter of the log below, and must be longer than

the length of the longest cog. Set the block onto the lower log and hold it in place at

a slope using wedges.

The sawn timber beams were joined together with

long screws. One man holds the guide that positions

the screw and gives it the correct angle.

t

Photo B

LogBuildingNews

Number 76

3

Now, set a scriber to the distance equal to the height from the

top edge of the block down to the long groove line on the log

below (photo 1). Lock the scriber at that setting. Now, hold the

scriber where you want

this cog to end (where

this cog exits the log

below), and adjust the

wedges so that block

of wood has the slope

that will make the cog

exit the log where you

want this cog to end.

Use the scriber, with

its locked setting, to

match the bottom

surface of the block

of wood to the scribe

line on the log below

(photo 2). In other

words, the bottom of

the block of wood will

meet the scribe lines

where the next cog

will start.

Repeat this process,

with the scriber locked

at the setting, for the

long groove lines on

the other side of this

block / cog position.

Note that the block of

wood might not be

(and probably wont

be) level, side to side.

Scribe from the bottom of the block of wood down to the log

below, all around.

Move the block of wood along the log and repeat the process

for the next cog. Once all the cogs have been marked onto the

log below, cut them out (photo 3).

Position the upper log back in its original position above the

log below. Re-set the scriber so that its scribe distance matches

the long groove scribe line on the upper log with where each

cog ends (well call this distance SC). Scribe everything you can

reach (photo 4), including the part of the endgrain surface that

you can reach (photo 5).

To scribe the parts that you

werent able to reach, put the

block of wood into the cog of

the lower log (photo 6). Mark

a plumb line on the edge of

the block of wood so you

know the plumb thickness

of the blockyou need this

amount to adjust your scribe

setting. Re-set your scriber

distance to the SC scribe

setting minus the plumb

height of the block of wood.

Scribe the parts you could not

reach before (photos 7 and

8). These two photos show

why the block of wood must

be wideabout as wide as

the diameter of the log

because, where the upper

surface of a cog is narrow

the lower surface is wide, and

where the upper surface of a

cog is wide, the lower surface

is narrow.

Cut the lightning bolt in

the upper log, and assemble the compound beam.

3Round Logs with Wedges

This beam was made of two round logs that were linked to each

other with a total of 8 pairs of tipped wedges. This beam also got

seven 16mm (5/8) diameter through bolts and small washers.

When loaded, these two beams want to push away from each

other, and the bolts are necessary (for more on the engineering

of compound beams, see the article listed at the end). The

wedges were oak, 60mm (2-3/8) deep.

Make blocks of wood that are about the width and length

shown in photo 9. On top are the two oak wedges, and

underneath is the block of wood well use for scribing.

Snap a centerline on the top of the log below. Mark the log

below for the positions of all the wedges. Screw blocks to the log

below in these positions. The blocks

are set so they are approximately 90 to the top centerline on

the log below. Little wooden wedges/shims are used to adjust

the slope of each block. Position the upper log, and scribe the

long groove (everything you

can reach). Well call this

scribe setting LG.

Now, one at a time, adjust

the slope and side-to-side tip

of each block of wood. The

blocks often have to be tipped

off to the side because, of

course, the long groove scribe

Photo 6

Photo 9

Photo 7

Photo 4

Photo 8

Photo 5

Photo 1

Photo 2

Photo 3

Winter 2013

4

lines are not level side-

to-side across a log

(photo 10).

Set a scriber so that

it has a scribe distance

equal to 1/2 of the

long groove scribe

setting you just used.

At the high end of the

block of wood, hold

the scriber as shown

in photo 11, and have

a helper adjust the

wedges so that at the

bottom edge of the

block of wood the

scriber just touches the

scribe line below. Now

test it for the upper

edge of the block and

the long-groove scribe

line on the upper

log. Adjust and tweak

the blocks position

and slope, and re-check how well the block edges meet the

scribe lines. When you are as happy as you can get, scribe the

underside of the block (photos 12 and 13). Well call this setting

L for lower scribe setting.

Photo 11

Photo 12 Photo 13

Wood Moisture Meters

LIGNOMAT USA

PO Box 30145

Portland OR 97294

800-227-2105

sales@lignomat.com Tel: 503-257-8957

www.lignomat.com FAX: 503 255-1430

Worry about

MOISTURE? MOISTURE? MOISTURE? MOISTURE? MOISTURE?

The enemy is mold

and dry rot, which

florishes in high

moisture environ-

ments.

---------------------------

To protect new or

existing log homes

avoid high wood

moisture and high

relative humidity.

Use Lignomats

wood meters and

relative humidity

gauges to measure.

Check out the new

BL2 - Moisture

Tracker with

memory and alarm.

Photo 10

continued on page 6

LogBuildingNews

Number 76

5

THE NEW GENERATION OF LOG HOME CENTER

LPR-80P Log Lathe Milling Machine

The Reliable and Flexible solution

to log rounding and profling

Super dimensional accuracy of finished logs, guaranteeing the top

class straightness and perpendicularity without efforts. No more aligning

works. No more gaps left between logs.

Incomparably smooth surface quality, no dents or cutting marks left

on the log, even under heavy load cutting.

Maximum reliability and flexibility to tackle the pressure of demanding

workload and the ever-changing customer preference.

SHING MATIC CO., LTD.

Tel: +86-28-8768 6921

Fax: +86-28-8768 6920

Email: info@shingmatic.com

For more information, visit us at

www.shingmatic.com /ILBA.aspx

Log length up to 11.5 m (38ft)

Log diameter up to 600 mm (23)

Maximum flexibility

Finish all profiles by one machine

Maximum productivity

Finish all works by one-time loading

Winter 2013

6

lightningbolt pattern with a plumb line along the faces of the

timbers (red lines in Figure 16).

Each cog is traditionally about as long as the total height of

the compound beam. Each tooth in the cog is about 1/10th the

length of each cog. The end

of every cog is a plumb cut.

(The engineer would usually

prefer that the end cuts

be at a sloping angle, not

plumb.)

Use a dressed piece

of wood (a lath) or a

straightedge to draw the

sloping planes. The width of

the lath, or the straightedge,

must be 5mm to 10mm

(1/4 to 1/2) wider than

the maximum depth of the

teeth. If there is no gap at

all between the two beams,

then the lath or straightedge

can be exactly as wide as the

depth of the teeth.

Lay the lath on the faces of the timbers and line up the bottom

edge of one end, and the top edge of the other end, where the

plumb lines you drew meet the space between the timbers (blue

lines, fgure 16).

Now scribe the upper

surface of the block to the

log above using a scribe

setting that is equal to the

LG setting minus L (photo

14). The scribe setting you

use for the below the block

(L) plus the scribe setting

for the above the block

surface (A) must be equal

to the long groove setting.

L + A = LG. Scribe settings

L and A may be slightly

different amounts, but

when added together they

must equal the long groove

scribe setting (LG).

This positioning of a block, and scribing the lower and upper

surfaces of the block is critical for success. This is because the end

of the wedges must not touch both logs, anywhere. In photo 15

the block is in place, where the oak wedges will be. Note that the

top surface of the block comes exactly even with the long groove

scribe lines on both sides. If the wedges touch both logs at one,

or at both, ends, then you can not tighten them.

Once everything is scribed, remove the upper log and cut the

cogs on both logs. Instead of a coped or coved long groove, we

cut fat across from scribeline to scribeline (photo 15) because

we are going to bolt these logs together, and the friction of fat

on fat improves the strength of the connection, and fat-on-fat

removes as little total wood from the logs as possible (less total

wood is removed than would be removed with a coved groove).

4 Sawn timbers with Lightningbolt Cogs

The interlocking portions were 50mm (about 2) tall, and

spaced lengthwise by 515mm (20). Again, we connected the

two component beams to each other with seven 16mm (5/8)

diameter throughbolts with small washers top and bottom.

The timbers need to be sawn and dressed on at least three,

or on four, sides. The two sides that will mate do not have to be

planed frst, but it is okay if they are. Set the timbers on top of

one another. Do not worry about the small gap between the two

timbers. Mark the midspan of the beam, and work the layout to

the left and right from there. Mark the end of each cog of the

Figure 16

Photo 14

Photo 15

Learn about timber framing

Experience the joy of building

community through craft

Timber Framers Guild

education inspiration

888-453-0879

www.TFGUILD.ORG

Photo 17

LogBuildingNews

Number 76

7

Testing Defection

After all four beams were built, they were loaded to

test for defection. As mentioned earlier, all beams had

the same span, and about the same width and depth

(or were sawn timbers made from logs of the same

diameter). The beams were loaded at their midspan

using concrete counterweights (borrowed from a tower

crane)up to a total of 9590 Kg (21,140 pounds) for

three of the beams.

The wedged round log beam can be seen in photo 18

at the start of the defection test. Photo 17 shows more

than 21,000 pounds of concrete on that beam, and a

very happy (and relieved) Meiri Rohner.

When Meiri loaded the screwed beam, the structural

engineer who was supervising all the tests, stopped the

test at 5480 Kg (12,080 pounds) because adding one more counterweight would have sent the defection over the maximum he

allowed. After all, the goal here was to test defection of four compound beams, not break them.

Figure B shows the defection results for all four beams. The steeper the line, the larger the defectionas can be seen, the compound

beam made of two sawn timbers that were screwed together

according to the manufacturers specifcations had the greatest

defection. The test on this beam was stopped at 5480 Kg.

The round log lightening bolt was the stiffest of the four

beams. At a midspan load of more than 21,000 pounds it

had less defection than the screwed beam had at 9,000

pounds. A very impressive result, and gratifying that traditional

joinery methods adapted for round log construction could

outperform the defection of a beam built with modern

engineered screws.

For more information:

Watch video of the testing at this website:

www.kantti.net/artikkeli/2012/09/hirsiliitosten-kuormitustesti

For more on the design of Mechanically Laminated Beams,

see the article by Ben Brungraber and Joe Miller, in Timber

Framing #93, September 2009, pages 14-21.

Figure B

Each of the 4 beams was tested by loading

concrete at midpsan and measuring defection

with a stretched string. This beam was made of

round logs with wedges.

Nearest to us is the sawn timber lightningbolt

beam; then a mitered truss; round log

lightningbolt; and, farthest back, round log beam

with wedges.

Photo 18

Photo 19

t

t

Winter 2013

8

TechTalk

TI PS AND TOOL S

This old wagon was used for hauling

logs out of West Australia forests in the

1880s, and is now in a logging museum.

Heavy wooden wheels with full-wrap

steel. Both the front and the rear axles

turn. Wire rope cross-ties connect the

front axle and the rear axle, so they

always turn opposite directions. Very

useful for making super- tight corners

with heavy loads. As I remember, Lloyd

Beckedorf had modifed a semi trailer

fatbed to do this to deliver log home

packages on narrow, winding driveways.

t

Cross-tied wagon axlesPhoto credit: Robert Chambers

Elevating the Design & Engineering

of Timber Structures

Joe Miller and friends raising a porch bent for his new home.

Licensed in:

USA: CA, CO, CT, DE, FL,

GA, IA, ID, IN, KS, KY, LA, MD,

MA, ME, MI, MN, MO, MT,

NC, NH, NJ, NY, OH, OR,

PA, RI, SC, TX, UT, VT, WA,

WI, WY

Canada: AB, BC and ON

Ben Brungraber, Ph.D., P.E.

Mack Magee, M.S.

Duncan McElroy, P.E.

Joe Miller, Ph.D., P.E., P. Eng.

27 Sims Avenue, unit 2r

Providence, RI 02909

401.654.4600 www.FTET.com

Bringing a Modern Perspective

to an ancient craft, Fire Tower

specializes in timber structures

and related systems.

Talk to us about your next project, large or small.

Yes, Its Possible

Contact us today.

(401) 441-5217

www.fraserwoodindustries.com

Timber Products

Green & Dry Timbers

Standard Glulams*

GrainMatched

Glulams*

Pressure-Washed Logs

Timber Services

Drying

CNC Fabrication

3D Modeling

Steel Fabrication

*CSA and APA Certied

Courtesy of Kettle River Timberworks

LogBuildingNews

Number 76

9

Winter 2013

10

TimberTools.com

Your source for quality tools and service

Timber Tool Forge Hand forged: chisels, scarf slicks,

spuds, draw knives, Lassiter tools and more

Belgian garnet sharpening stones

SwissPro/HEMA Mortisers, slotters, guide tracks, drill

guides, circular saws, skew notchers & tenon cutters,

portable planers, chain beam saws, portable band saws

Serra Saw Mills wide blade technology, electric drive,

perfect production saw for logs up to 3' - 5'-4

REX / Mida 4-sided planers, moulders for reliable

continuous operation

CNC joinery and log milling machines Essetre/Krusi

Land Ark All natural wood finish, also exterior, soft wax

for end grain or polish. Reduces checking.

Double-cut auger bits Cleanest cut, easily powered:

18 or 24 long. 3/8 to 1-1/2 wide

Zentra Drilling system with centering points, from 5/16

to 8, most materials: man-made or timber

Tel: 1-800-350-8176

hats right. The average 2,200 sq. ft. home has over

5280 feet of log joint exposed to the elements. Dont

take a chance keeping out the invasive power of Mother

Naturejoin the thousands of homeowners who have sealed

their home with Log Jam chinking.

When other chinking pulls away Log Jam holds its seal.

Since its introduction in 1985, Log Jam chinking

has been the recognized industry standard

in elasticity, adhesion, and durability. It is

also the only chinking to hold a UL fire

resistance rating. Log Jam doesnt just

fill the gaps, it provides ultimate

protection against the elements.

T

10300 E. 107th Place Brighton, CO 80601

1-800-767-5656 www. sashco.com

Over 1 mile of

Gaps this Wide?

Over 1 mile of

Gaps this Wide?

1974 1st AGM, at Mackies home, BC

6 founding members: Al Mackie, Art Long, Ed Campbell,

Vic Janzen, Bernie Legault, & Fergus OConnor. Allan

Mackie is President; there is serious discussion on

methods of cost estimating.

1975 2nd AGM, at Mackies home, BC

Ed Campbell is President; 24 builders attend (32

members total); All agreed that a single afternoon

was not enough time to take full advantage of the rare

opportunity to exchange information. membership is

limited to those who have built at least one log home

of sizeable construction approved by the Association, or

have taken an approved log building course.

1976 3rd AGM, at Vic Janzens home,

South Langley, BC

85 members, Vic Janzen elected President; work begins

on Log Building Standards, discussion of Ethics within

teaching log construction; about 50 at the AGM

(on the agenda: bullshit sessions); the rst display

advertisement ever in our newsletter is for Pat Wolfe

Scribers ($16, including postage); I hope to see the day

when the initials C.L.B.A. are synonymous with good log

building anywhere in Canada. Dues are $125 per year.

Allan Mackie and Ed Campbell plan to direct the CLBA

manpower in erecting a building in one day.

1977 4th AGM, at Banff, Alberta

Log cabin built in 8 hours and 2 minutes; AGM held

during the Conference on the Log Structures of

Canada. Janzen re-elected President; 46 members

attended; dues are $50 per year; the Society is ofcially

registered in BC; CLBA regalia sashes are available for

$20; membership is ofcially closed to Americans. Ethics

document adopted. Brian Olynek is Secty-Treasurer.

Victor Nymark (Montebello builder) voted to be an

honourary member.

Vic Janzen remembers:

These men were all interesting gures. One left medicine to become

a log builder. Another an American diplomat to Japan. Orchardists.

Accountants. High school shop teachers. Regular teachers. Social workers.

-- so many of us left respectable secure jobs to follow this dream. The

times were exactly right for such divergence.

The objective of the project was to naysay the manufacturer builders who

claimed we were too slow and expensive compared to them

Brian Olynek remembers:

I was standing on top of that building wondering, now what am i going

to do with this building? when a man named Carl Chulakal offered to

buy it. We shipped it to his home outside Nakusp!

40

OF LOG

BUILDING

H I S T O R Y Y

E

A

R

S

LogBuildingNews

Number 76

11

40

th

YEAR

I

N

T

E

R

N

A

T

I

O

N

A

L L

O

G

B

U

I

L

D

E

R

S

A

S

S

O

CI A

T

I

O

N

1978 5th AGM, at Columbia Valley

Community Centre near Cultus Lake,

British Columbia; Tech Talk at Janzen farm

Art Lloyd is President; John Brown speaks on lifting

with a skyline and on log acquisition; Jack Haden from

CMHC on mortgages; the Association is now publishing

Log Builders News; log builders games; John Brown

is editing the newsletter; discussion if there are now too

many log builders; $50 membership fee; plan to lease

30 acres of crown near Mackie School for a permanent

CLBA home; One building was liberally pinned with

rebar which has hung up the logs. Dont use rebar,

Turkey!; Doris Muir wants to organize an international

log conference.

1979 6th AGM, at Nakusp, British

Columbia. We are now called Western

Canadian Log Builders Association

James Durham, President; held at Nakusp Senior

Citizens Hall (a log building built by CLBA members in

1978); CLBA T-shirts for sale $7; Art Lloyd is editor of

newsletter; $15 conference fee (includes dinner).

1980 7th AGM, at Golden,

BC at Brian Olyneks house

Bill Peyton elected President; Brian

Lloyd (VP), Lloyd Beckedorf, Walt

Murray, John Brown, and more

24 members attended; now

called Canadian Log Builders

Association, BC Chapter; there

are CLBA chapters in the Maritimes,

Quebec, Ontario, Alberta, and BC.

CLBA-BC has a display booth at the

Vancouver Sportsman Show.

1981 8th AGM, at Golden, British Columbia

1982 No 9th AGM?

But there was a builders get together at the Mackie

School reunion during Canadian Thanksgiving.

Lloyd Beckedorf

John Brown on saw; Jim Durham with foot on log. 1980 AGM.

Early ideas for the CLBA logo

Winter 2013

12

1983 10th AGM, at Mackie School

John Brown is President; membership $10 per year;

AGM costs $25; Beckedorf: I really believe that log

building . . . is such a young industry. Things which

were standard a few years ago are

quickly becoming outdated;

Larry Parker attends; pot-luck

supper; slide show.

1984 11th AGM, at Mackie School

Lloyd Beckedorf is president; 143 members; bus tour

of log homes west of Prince George; Lois Isabelle and

Freda Greenlees are the caterers; Ralph Salm asks the

School to archive CLBA les; CMHC is working on a log

home code, and is using the CLBA Standards.

David Rogers remembers:

Standing on the porch of the

old classroom, observing the

gathering at the new classroom,

I asked Robert Chambers What

is the CLBA? Thinking to

myself, How is it different

than the School?

The Gatehouse at the 1983 AGM.

1983: Allan Mackie

and Larry Parker

Dave Gardner demos a slabbing

jig with Kolve chain (1984).

1984 group photo at the new tool building.

1985 AGM

Gary Pendergrass, David Rogers, Val Rasmussen, Steve Schwartz &

Vicki Strobe, and others . . . Tom Hahney teaches Design &

Engineering pre-conference session.

1985 12th AGM, at Mackie School

Lloyd Beckedorf is president; Design & Engineering pre-

conference course by Hahney; Tom Hahney article about

the need for gaskets and inltration seals in grooves and

notches; 57 attend conference; founder Art Long passes

away; $25 registration fee; Kyra Guest (Mary Mackies PA)

performs belly dancing; Technical Talk; Chambers talks

on kerng logs to locate checking.

David Rogers remembers:

I had to make a hole in the ice in order to get to the lake water to cool off

after being in the sauna.

Gary Pendergrass adds:

Somehow Dave and I convinced the others that going from Sauna to hole

in the ice was a Rite of passage. ..and somehow we talked all the others

into giving it a try. Dont think Ive laughed that hard since.

Gary Pendergrass remembers:

During a treasurers (?) report, a listed expense

was $900 for dishes and silverware. I looked

down at the paper plate I was eating off, with

a plastic spoon...and interrupted with a query

If we have $900 worth of dishes, why are we

eating on paper plates?. . . It went downhill

from there, with Larry Parker, who was sitting

beside me, egging me on with a go get em

LogBuildingNews

Number 76

13

1986 13th AGM, at Mackie School

Allan unveils his new Mackie scribers; David Rogers

and Tom Hahney speak on stair railings; Robert

Chambers elected president; $5,550 in the bank; 21

attendees; Hahney gave rave reviews of his new

Macintosh computer; Mary Mackie will no longer

publish the CLBA newsletter.

Tom Hahney remembers:

When elected to the CLBA board of directors, with the position of

secretary-treasurer, in 1986 it was my rst time as a board member,

and the rst time I had met Robert Chambers, who was chosen as our

president. The Board gathered in a circle. Robert said that we were

going to have a newsletter that was focused on the technical skills and

knowledge of log building, and that he was asking each member of the

board to submit two articles for the coming year. I remember feeling a

sense of excitement as I took this in. And indeed, I still feel delight when

I get a new edition of Log Building News the glue that through

communication has held us together.

David Rogers remembers:

Lloyd Beckedorf introduced the buttery notch, and Allan Mackie

showed us his power scriber concepta grinder with attachments to

score the groove on both logs.

1987 14th AGM, at Mackie School

Now is called Canadian Log Builders

Association, International.

Jack Sobon, architect and timber framer, is guest

speaker; Randy Campbell on business; Tom Hahney

brought his Macintosh computer; Albie Barden on

thermally massive replaces; dues $10 per year; 130

members; our newsletter is Joiners Quarterly.

1988 15th AGM, at Mackie School

$35 conference fee; rst issue of Log Building News

published; a full page ad costs $100; Allan Mackie

reects on sharing knowledge between builders, and

how that improves quality; Tech Talk: Timbor (borate)

rods, Ken Guest and hoof shapers; Duane Sellman

showed the scribers he is making; Ed Campbell speaks

on accessing logs; Tom Hahney on stress and strain;

Beckedorf gets Technical Excellence Award--a painted

antique slick.

1989 16th AGM, at

Mackie School

Mary Mackie ofcially honored

as the founding mother of

the CLBA; Tech Talk: sheep

wool as insulation; Garth

Farquhar is President; CLBA

has a certicate of deposit that

is paying 10.4% interest.

Mary Mackie, Founding

Mother, 1989

Winter 2013

14

1992 AGM at Sorrento, BC.

1990 17th AGM, at Sorrento,

British Columbia

Doyle Burke, engineer; Murray Hardie on exporting;

Ralph Salm on roof panels; Tech Talk: braided line for

chalklines; $3000 laser level; Wayne Sparshu peeling

machine; Shannon Maris is hired (our rst paid staff

person); Association ofces will be in Tom Hahneys

design ofce; $60 conference fee; singing around the

campre; Maritimes log builders; Beckedorfs shoes end

up in the auction, but beer commands a higher price;

life memberships removed by the members at AGM;

a few members report they now have mobile phones;

Beckedorf reports his double scribe groove has been

patented.

1991 18th AGM, at Sorrento,

British Columbia

Terry Hall is President; Membership numbers have

doubled since last year, and we now have 283; Jeff Arvin

gives keynote on timber framing; Skip Ackermann built

a 55,000 sf house for Saudi prince in Aspen; Company

Membership is now offered; exports of log shells from

Canada are down 20% from 1989; Tech Talk: plate log

roll; random-orbital sanders demonstrated; Radomske

explains underscribing; Chambers on log selection;

planning starts for 1993 Yellowstone conference--Brian

Lloyd is in charge; Standards Committee works on big

revision (meets twice at Radomske School).

Catharine Hansen Remembers:

The display of international ags in Yellowstone, the people who travelled

from around the world to attend the wide variety of workshops, and the

buffalo and hot pools we had to dodge on our way back to our cabins late

at night ~ it was an amazing time.

1992 19th AGM, at Sorrento,

British Columbia

Radomske on log selection; Chambers on Kizhi, Russia;

Latvian builders available for US companies; Terry Hall

on roof systems; major revision of Log Building Standards

will be ready in 1993; the Association now accepts

credit cards; Mackie School is closed and buildings are

auctioned; Chambers is President and Radomske Vice

President; Commentary column to be added to Log

Building Standards.

Shannon Maris remembers:

A BIG bonre, a clear night, and a full moon. A group of fellows

from Nova Scotia who were on their way, or just back from Maritime

Music Festival burst out rip roaring a cappella sea shantys late into

the night while those of musical talent used found object such as

an empty guitar case to sticks and driftwood on empty beer cans to

accompany the singers with percussion. The annual auction with

wacky and wonderful donations, sometime bottles of beer being the

most protable auction item.

Standards Committee meets at Radomske School in 1991.

LogBuildingNews

Number 76

15

R Chambers, S Greer, T Hahney, E Shure, S Ackerman, K Mogenson, 1995

Shannon Maris Remembers:

20th Anniversary Conference at Yellowstone

National Park took every Board person, staff

and volunteer hour that could be mustered

to pull that one off. We had delegates, log

historians, authors, craftsman, and legends

ying in from Japan, Finland, Germany.

Switzerland, and all corners of Canada

and the United States. A cornucopia

of information exchange, talent, new

friendships, business connections, mentoring

and camaraderie. We all needed a two week

vacation after packing up that phenomenal

event.... but WOW! what an event.

Gunnar Granberg Remembers:

Im thinking back of those wonderful and

exciting days at Yellowstone, it was a

great statement of the skill and vision in

craftmanship -- it brought people and ideas

together on an international arena. I have

warm memories of an enthusiastic crowd

who gave, and received, inspiration. The

knowledge must be nourished to stay alive!

Robert Chambers Remembers:

Giving my speech at the banquet in

Yellowstones Glacier Hall in front of

the largest gathering of log builders

the world has ever known. Even

now, it gives me goosebumps.

Some of the 500 people at the Yellowstone 20th International Conference

Ole-Karl

Ed Shure Mitered

Banff Truss, 1994

Some of the 500 people at the Yellowstone 20th International Conference

Ed Shure remembers:

Since the statute of limitations has passed- I can now share one of my

fondest memories. The local logs we had sourced didnt meet Ole-Karls

specs, so we cajoled a logger in Northern Montana into felling a load of

peeler poles and running em down to us at the eleventh hour. He must

of been up for two or three days straight cause he showed up (with

remnants of a deer carcass on his grill), parked his rig, and disappeared.

The show had to go on so I committed one felony (and at least a couple

of misdemeanors) by hot wiring his rig and taking my rst drive in an

honest to god 18-wheeler. Roy, wherever you are, Thanks!

1993 20th AGM, at Yellowstone National

ParkNow we are called CLBA and ALBA.

Ole-Karl Prois from Norway; Brian Lloyd is Conference

Chair; Brungraber and Hahney on engineering; dues

are now $35; Henrik Andersen from Denmark; Merle

Adams; Ed Levin on roof kernals; Jean Steinbrecher on

design; Hahney and Brian Lloyd on Building Details;

bison trafc jams between Old Faithul and West

Yellowstone venues; Doris Muir, Log Home Guide; big

trade show in Glacier Hall; Duane Sellman wins World

Notching title; perhaps 450 to 550 people at the

conference. Cathy McIntyre (Hanson) assists; Ed Shure

elected President. Log Span Tables now published by

CLBA.

1994 21st AGM, at Banff, Alberta

John Brown on kiln-dry logs; Ed Shure - Tom Hahney

with mitered truss demo; new Constitution, Bylaws

and Code of Ethics adopted; Tom Stonecipher and

Brian Lloyd on construction contracts; Log Span

Tables now published by the Association; Shure

re-elected President.

1995 22nd AGM, at Banff, Alberta

Steve Loken on resourceful building; Hahney retires

as Treasurer (14 years), and CLBAI has $50,000 in the

bank (from Yellowstone); 202 members.

Winter 2013

16

Stephen Kemper, Barry Houseal, Jerry Wait in 1999

On the Whistler log home tour.

24th AGM at Herrison Hot Springs, BC.

1996 23rd AGM, at Duluth, Minnesota

North Shore tour of homes; Thierry Houdart from

France; Latvians: Egils, Gintis, & Karlis Apinis; David

Salmela on design; Ed Miller dovetail jig and Mike

Heintzman tenon and drill jigs; 233 members; Ed Shure

is President; our Association gets its rst email account.

1997 24th AGM, at Harrison Hot Springs,

British Columbia

Steve Badanes of Jersey Devil is keynote; CLBA contract

for building is for sale; CLBAI gives $2000 to start the

BC-LTBI; hydraulic peeling spud; Mafell hand-held

bandsaw; Makita curved base planers make their rst

appearance at Tech Talk. Robrt Savignac and John Boys,

and others create Log Home: From Land to LockUp,

our rst publication for customers.

1998 25th AGM, at Whistler,

British Columbia

Tour of local homes; Ric & Matheo Dureld; Steve

Kemper with hydraulic chainsaw and drill; Jay Wan Yu

attends from Korea; Tracy Wakeeld from Australia;

Wayne Sparshu on jobsite efciency; James Mitchell on

using short logs for construction.

1999 26th AGM, at Glenwood, Colorado

Tour of Aspen and Snowmass log homes, many by

Ackermans; Barry Houseal with a non-settling building;

gasket demo; Osborne bufng brushes demonstrated;

Lateral Loads research - Hahney presentation; Tenonizer;

Shannon Maris retires from Association after 9 years;

BC apprenticeship program being established; Cathy

Hansen hired and Association ofces move to Lumby,

BC; Builder Certication initiative is underway; 400

members: CLBAI now has a website.

Shannon Maris

retires after 9 years

as Association

administrator.

Number 76

LogBuildingNews 17

Left to Right: Rouleau, Savignac, John & Ingrid, Ann Miks

2000 27th AGM, at Montebello, Quebec

Now we are the International Log

Builders Association

Two-day pre-conference design workshop

with Jean Steinbrecher; Round Meets

Square gazebo workshop with Shure,

Chambers, & McCarty goes into extra in-

nings; 250 members; Standards are now in

French; Gary Espe demonstrates lasers on

scribers; Jim Grieb scribers unveiled; John

Boys is President. ILBA buys ofce building.

2001 28th AGM, at Kananaskis, Alberta

John Boys is president; Ann Miks is hired; Robert Savi-

gnac hired as Executive Director; draft of the Chinking

Standards; Chambers leads two Accelerated hands-on

workshops; Jerry Rouleau workshop on marketing;

ArchiCAD workshop; Dalibor Houdek speaks about his

research on re and log walls.

2002 29th AGM, at Park City, Utah

Tom Hahney on settling jacks; Compound Log Joinery

pre-conference; French Scribing; Jerry Wait is Presi-

dent; scientic testing of lateral stability of log walls;

Savignac co-chairs ICC committee for log home code.

1st Fall Rendezvous

in Cherryville, BC

Mary Mackie speaks;

Frederick Brilliant

French-scribe work-

shop; saddle notch

workshop. Robrt

Savignac organizes

and spearheads a

European log build-

ing summit, held in

Sweden. Board de-

velopment retreats

at Sugar Lake and

Canmore.

Robrt Savignac remembers:

The French-translation group got

stuck on the title of the document:

Log Building Standards... there

was no consensus on how Log

Building should be translated.

Maisons en billots, maisons en

rondin, maisons de bois brut,

maisons en bois rond, construction

en fustes. We had trouble getting

past the rst TWO WORDS!

Cutting an Accelerated shell.

Duane Sellman explains

something technical.

Gary Espe shows laser

scriber.

Wayne Sparshu with his

scaffold.

Joel and Robrt atop gazebo.

Ann Miks Remembers:

My favorite memory and one

that I treasure, is the rst

slide show that I attended in

2000. It showcased the most

incredible work that I had ever

seen. It truly took my breath

away. I was so proud of all

of the builders that made up

the ILBA and to think that

they allowed me, Ann Miks

(who knew nothing about log

building) to be a part of this

special group.

Winter 2013

18

2003 30th AGM, at Alymer, Quebec

Dave Gardner is President; Jean Rodrigue stair workshop;

367 members; $480,000 in revenue this year; $484,000

in expenses; Les Jozsa speaks on wood technology;

Simon Auger and Ron Hann win notching competition;

Jig Book is published; Builder Certication Program is

tabled.

2nd Fall Rendezvous, in Cherryville, BC John

Boys and Mark Fritch instruct chinked dovetail course

(cabin sold for $29,000); Russell Joseph tool system is

demonstrated.

2004 31st AGM, at Parksville, BC

Gazebo project with Egils Artmanis, Duane

Sellman, & Dai Ona; raw oysters off the rocks

with Tim Bullock; Cyril Courtois on animation

in design; Dietrichs 3-day workshop on

CAD design; Design expo; Russell Joseph

with jig for cutting arc windows; the auction

raises $45,000; 500 members; Mark Deagle

champion of competition; 3rd annual

rendezvous cancelled; Del Radomske receives

the 1st - ILBA Grand Achievement Award.

Robrt Savignac Remembers:

Cathy & I worked hard to develop greater Board

responsibilities and participation, organizing special board

retreats & planning/vision sessions.

Ron Hann, Frederick

Brilliant, and Simon Auger

Del Radomske receives

Grand Achievement

Award from John. Parksville gazebo project.

Number 76

LogBuildingNews 19

Cathy and Mira.

2005 32nd AGM,

at Coeur dAlene, Idaho

Jeff Patterson is president; 8-week 17,000 km

Road Trip is announced; Tom Hahney gets Grand

Achievement Award; Simon Auger is notching champ;

Jeff Pedersen conducts hands-on dovetail course at

AGM; Wil Dancey conducts timber frame course;

$40,000 raised in auction, Tom Terry auctioneer;

Canada GST levy on US members hit us; Savignac let

go; Cathy on sick leave; nancial strife for Association;

attacks posted on LHOTI are baseless; conference

workshop for kids.

Tom Hahney remembers:

One of the great honors of my life was to

be given the Achievement Award in 2005.

As I remember that moment now, it was so

unexpected, I can still be knocked over with

a feather!

2006 33rd AGM, at Montebello, Quebec

ICC log building code development is underway; auc-

tion brings in $59,000; Higgy Jigger; Robert Chambers

gets ILBA Grand Achievement Award; Ed Campbell

addresses the members; Ingrid Boys provides histori-

cal and scriber displays; compound roof course. Patty

LaFrancois organizes conference; Ed Shure is president;

members now must apply annually to join.

Ed Campbell remembers:

Giving that speech was one of the prouder

moments of my life . . . .

I am always interested to the progress of

the organization that I helped to form and I

have deep respect for those individuals who

work so hard to further the interests of this

industry. My hat is off to all the log builders

who keep this industry alive and thriving.

2007 34th AGM,

at Abbotsford, BC

Log Grading by ALS nixed; major

revision to Constitution and

Ethics; ICC-400 Code is adopted;

Chainsaw carving with Mike

McVay; Litller brothers win. Ann

Miks hired as ofce Administrator.

Ann & Andree at Montebello 2006

Higgs Murhpy with his Jigger.

Team Littler competing.

Brian Lloyd Remembers:

One evening at Montebello I

walked into the bar where I

found Allan Mackie sitting alone,

surprising enough... I picked up a

beer and sat down with Allan. He

looked up slowly and told me that

we were among the very few Old

Log Builders at the conference.

I aged considerably at that

moment!

Rob with ChambersScribers at Tech Talk 2009.

2008 35th AGM, at Whitesh, Montana

Logworks Helper pricing

program available (created

by Dai Ona & John Boys);

Log Building News now in

color; SketchUp workshop

with Egils Artmanis and

Clark Bremer; Toshio Odate

wood sculpture; Mira

Steinbrecher awarded by

ILBA; Katrina Koebel

receives design award.

2009 36th AGM, at Cable, Wisconsin

Our rst joint conference

with Great Lakes

LogCrafters Association;

work starts on what

will become Effective

Practices & Methods;

Dusko Ballmer on scanning

logs and cutting with

CNC machine; Ed Burke

log grading workshop;

Finns and Estonians

at conference; crane

certication workshop;

sill log layout; David Rogers

on log repair.

2010 37th AGM, at Prescott, Arizona

Manitowoc crane demo; Effective Practices adopted;

new Incremental Accelerated video shown by Chambers;

Arcosanti tour; Earl Laverty explores ILBA vision.

Catharine Hansen Remembers:

I miss: the annual conferences, hugs from Uli Walther, a glass of wine with

Robert Chambers, Kat Koebels infectious smile, watching John Boys and

Lloyd Beckedorf out bid each other at auctions. . . the list goes on!

The Finns: Raimo, Hannu, Henrik

John Boys & Jim Grieb

Ed Burke teaches log grading.

LogBuildingNews

Number 76

21

2011 38th AGM, at Niagara, Ontario

Centerline dovetail workshop with Higgs Murphy;

Peter Gott keynote; John Boys brings Buster; Wayne

Sparshu buys Mackie axe for $2100 in auction; LBN

goes 100% digital; Chambers on new underscribe

method; Dalibor Houdek on Canada energy codes;

Dan Wait on low-tech kiln; Chinese businesswoman

attends and wants to buy hundreds of log shells.

2012 39th AGM, at Asilomar, California

First joint conference with TFGNA; Dietrichs

10-year anniversary; EP&M published in paper

and digital; Chambers speaks on Dreams & Creativity;

Brungraber and others break joints; Higgs, Preston,

and Whitehouse hands-on lofting and more; Uli Walter

on marketing.

Peter Gott and John Nininger

Matt Davidson frst in notching.

Ben Brungraber shows how easy it is for

him to break things that timber framers

have carefully built.

Winter 2013

22

40

th

YEAR

I

N

T

E

R

N

A

T

I

O

N

A

L L

O

G

B

U

I

L

D

E

R

S

A

S

S

O

CI A

T

I

O

N

LogBuildingNews

Number 76

23

TechTalk

TI PS AND TOOL S

Photo credit: Robert Chambers

Detail of a drain hole carved

about 900 years ago, in the

sill log of the Borgund Stave

Church. The hole drains water

so it wont collect in the groove

that accepts the thick vertical

log siding above the sill log.

Many of the large logs in this

1600 AD farmhouse were free

of heart center (FOHC) -- the

builders must have produced

two oval house logs from each

tree.

t

t

Norway Provides Historical Gems

Winter 2013

24

TechTalk

TI PS AND TOOL S

Photo credit: Robert Chambers

Probably the oldest log building I saw

in Norway, the Bjolstad Chapel. The stave

churches are older (as old as 1050 AD), but

are log post and beam, not horizontal scribe-

ft log. This church was round log, not oval,

had full long grooves, and diamond notches

in the cornerssaddle scarfs top and bottom.

The fts were superb.

This large barn (obviously still being used by

the farmer) was built on sloping land. The

low corners were held on log corners (piers).

It looked very tippy to me, but had been in

place for many hundreds of years. The secret

is that the log pier is a triangle in plan. A

solid log-wall triangle very stable. The logs

of the back wall (under the barn) are tipped,

of course, because they have to cross down

to the round below. I have drawn yellow lines

that indicate half of the logs of the back wall.

t

t

Summer Beam Books

w

w

w

.

s

u

m

m

e

r

b

e

a

m

b

o

o

k

s

.

c

o

m

specializing in timber framing

and related topics

2299 Rte 488

Clifton Springs, NY 14432

toll free 877-272-1987

315-462-3444

Charlotte Cooper, owner

LogBuildingNews

Number 76

25

Log Building

in Switzerland

By Roger Porrenga

Blockbau is the Swiss word for buildings with crossed corners,

that includes also boards from 1 inch thickness, and up to Log

Buildings. In the region around Zurich and the Lake Greifensee,

in 1975 was found a log building (actually Pfahlbautena

building on stilts) that dates from 1050 BC. The frst round was

in the mud, under water, anchored down with pins, the log walls

were then erected on that round, so that it not was sinking in to

the mud. This is the oldest found in Switzerland, so far.

In the Alps is where most new log buildings are being built

now in different styles, most with hewn logs for homes and

round log for farm buildingsfor example, hay sheds with wide

roofs.

In the mid-1990s North American style log construction

started to come to Switzerland. In the beginning, there were

just a few log builders and they used the saddle notch and the

techniques we were taught mostly in North America.

We started also to use old carpenters knowledge and mixed

that together. with our new North American log building

training. We made buildings with modern interiors, mixed with

steel, concrete and colors. Swiss peoples taste is mostly modern,

and not very rustic.

Everything went fne, until the Swiss Heimatschutz (protecting

architectural heritage) in 2007 wrote to all the building

regulation departments, in almost every town, that they should

not accept log buildings (made with round trees) anymore,

because the overhang at the corners were too rough, the

building style was too simple and it is a step backwards in

craftsmanship. They also questioned the aesthetics of log

buildings.

The log builders were shocked, all the work we had done in

10 years, was it for nothing? A handful of log builders came

together and we founded the IG Blockbau Schweiz (Swiss

Photo credit: Roger Porrenga

Log home in Mllheim, Switzerland.

Saddle notch, character logs, modern

kitchen, stainless steel details.

t

Logbuilders Association) and we tried to contact Heimatschutz

to discuss the situation, but there has not been one discussion or

meeting until recently.

We wrote to all the building regulation departments a paper

that tells our views. We try to build every house better and

better, and at the end the market will regulate everything

(mostly).

Winter 2013

26

A few years ago, it was not easy to fulfll the energy effciency

requirements as they got harder and harder. Now we usually are

able to fulfll those standards, because there are different ways to

calculate.

I wont go into the complicated details here, but the log

diameter should be 44 cm+ (17+) in the middle; the tip should

not be less than 38 cm (15). Grooves and kerfs and corners

have to be carefully and proper insulated. We use mostly sheep

wool, because its organic and last a long time.

This is not new technique. I have helped to renovate a

350-year-old house, and the wool we took out of the wall,

looked just as it did when it came off the sheep. Sheep wool

is able to take 1/3 of its weight in moisture and still insulate.

Mineral wool or glass wool, fberglass is not able to do this.

Sheep wool is able to take building toxics such as formaldehyde,

absorb it, and keep it locked inside. At times we also use gaskets.

The windows must have 3 sealed panes of glass. The roof has

to be insulated very well to 24 cm+ (9-1/2) I usually prefer

the insulation made of wood (cellulose insulation).

All connections and joinery have to be airtight. If you have a

controlled air ventilation with heat recovery, the required energy

effciency number is easier to reach. The regulations are going

to be more and more specifc as time goes on. The idea is to

produce less and less CO2.

So, you may get a bonus for heating with a new clean-

burning woodstove, geothermal, passive solar etc. If you have

photovoltaic you get a bonus and so on.

What kind of sense does it make to insulate a house with

styrofoam etc. that is made out of oil and a lot of energy? Some

articles report that with the energy that is used to make foam

insulations you could heat a house for 20 years.

Historic grain storage building built of log.

t

Photo credit: Roger Porrenga

canada@sherpa-connector.com

SHERPA TIMBER CONNECTIONS

THE CLEVER SOLUTION FOR YOUR STRUCTURES

Time is running -

SHERPA optimizes

Short-term orders and short construction times require an

increase in efficiency and optimized operational processes.

The SHERPA-timber connecting concept provides consistent

improvement for all production steps from planning on.

1. Measurement 2. Pre-Assembly 3. Assembly

The efficient planning, simple pre-fabrication and fast

assembly on the constuction site with maximum security crea-

te a competitive advantage for timber structures to

alternative building material.

The only direction we can go is to minimize the grey energy.

That is where the log buildings and other wooden buildings have

their strength. Wooden houses store a lot of CO2. An example: a

house with 250 cubic meters of wood-volume stores 62,000 kg

(135,000 pounds) of carbon. There are wooden houses in Russia

that are more the 1000 years old. The oldest wooden House in

Switzerland is 750 years. We are talking about a lot of life cycle

storage of carbon.

LogBuildingNews

Number 76

27

BRODA nishes were developed by a loghome builder

from Whistler, to deliver mountain- tough durability with

easy maintenance. Visit our web site. Download

our free spec guide for loghome builders and nd

out more about our water- borne natural oil nish,

water- based acrylic clear- coats and urethanes.

While youre there, check our gallery to see how

other builders have used BRODA. Because

longer- lasting nishes are

more fun for everyone.

cbrproducts. com/rather be playing

FREE Spec Guide: www.cbrproducts.com/ratherbeclimbing For samples, call toll- free: 1 888311 5339

Support the advertisers who support Log Building News. Its a win-win situation!

Winter 2013

28

C L A S S I F I E D A D S

FOR S ALE

Building logs for sale - regular and oversize. Fir Cut to peeler lengths

mainly 43 and 52 ft. Trees were harvested in fall 2010 and some in

winter 2011. Good straight logs for building - approx 200 cu m. Also

oversize logs for Timberframe stock. Woodlot 454 Golden BC.

250-344-4646.

1999 Heartwood Band Sawmill Model 310 Electric Never been

used; 6 Double-Cut (cutting travel speed up to 3 feet per second

forward or reverse). Will require 600 Volt 3 Phase Power or motor

exchange. The only noticeable noise this mill makes is the actual blade

cutting through wood. Eighty-eight feet of track; operator travels

with mill head along track. Numerous track-mounted hydraulic log

handing systems and full programmable computer controlled set

works. (We purchased 2 and only set one up for use.) Purchased in

1999, replacement value of this unit today is over $130,000 Canadian.

Asking $65,000.00 Canadian, will require some site preparation

and assembly. To compare this to any of the small bandsaws is like

comparing a hi-way tractor/ trailer to a go-cart, this is a serious

production mill. We often can go three weeks between bandsaw

blade sharpenings! Please arrange for an appointment to see the twin

unit in operation. Link to this model at Heartwood Saw: http://www.

heartwoodsaw.com/Model_310.html. Email to info@moosemountain.

com or phone toll free 1-877-932-3992 Lloyd Beckedorf, Moose

Mountain Log Homes Inc.

Logworks Helper Pricing program specially written for fast and

accurate takeoffs and quotes of log home shells. You can customize

it for the pricing methods and preferences you currently use. Note:

you must own a copy of Microsoft Excel to run Logworks Helper.

Developed by Dai Ona with help from John Boys. Contact Ann at

the ILBA offices for sales and enquiries. CDN $500.

Hand scribed Log Home Projects CD called Drawing Dreams - a

selection of 24 log home projects. A CD of 24 log homes $19.99 tax

and shipping included. Call 1-877-832-0165 RSM Drafting Services Ltd.

House logs for sale We are selling dry and semi dry Lodge Pole Pine

and Engelmann White Spruce house logs. We ship Worldwide.

Please phone 780-674-6325 or email karma.log.homes@live.com

Northern White Pine Building Logs available in most sizes and

lengths. Winter Cut from Quebec. Please contact: Select Log,

Fred Temperton, 2899 Stella, Rawdon J0K 1S0

Phone: 514-867-5430 Email: fred@temperton.ca

HELP WANTED

Experienced full-scribe log builder wanted for year round, full-time

work. Big White Pine logs. Good working conditions, minimal travel,

good pay and benefits. Rural and beautiful Northern Vermont near

Connecticut River and White Mountains of New Hampshire. 3 hours

from Boston, Montreal and coast of Maine. Outdoors oriented person

with good woodworking and math skills. To apply send or email

resume and references. The Wooden House Co., Ltd., 3714 North

Road, S. Ryegate, Vermont to Newbury, Vermont 05051. Phone: 802-

429-2490, email: john@woodenhousecompany.com

Need 2 experienced log builders immediately until the fall for sure.

prefer builders with dovetail experience. This is in the Smithers area,

a full four season adventure. contact Bryan at

info@harrisonloghomes.com

LOG BUILDING TOOLS

STARRETT & MACKIE scribers; heavy duty drawknives up to 30; peeling spuds;

chopping & fnishing axes; broadaxes; adzes; GRANSFORS axes; ENGLISH slicks;

ROBERT SORBY, HENRY TAYLOR, FOOT PRINT & PHEIL chisels and gouges;

JAPANESE slicks, chisels, saws, ink lines & fex squares; hand-forged Flarens,

shovel gouges, fat & scarf slicks, drawknives & draw-gouges; BARR Specialty

Tools; peavies; cant hooks; lifting tongs; log dogs & cleats; log horses; water

stones; Diamond whetstones; NORTHWEST calipers, tenon cutters & long auger

bits; ship augers; chainsaw mills & attachments; MAKITA & MAFELL planers, saws

& chain mortisers; MACKIE log building books & videos.

MAGARD VENTURES LTD. Attn: Maurice Gardy

8365 Domagala Road, Prince George, BC, Canada V2K 5R1

Tel: 250-962-9057 Fax: 250-962-9157

magardlogtools@telus.net www.logbuildingtools.ca

FREE

32-page

catalogue

A Boys Big Book of Jigs

A Log Builders Reference to Jigs, Tools and Techniques

An informative book on jigs and work methods specifc

to our trade. Sections include: Scribing and Layout,

Stairs and Railings, Cutting and Drilling, Stairs and Railings,

Holding, Mills and Machines, Lifting, Work Methods,

Accessing Heights, Resources, Cool Tools and New Stuff.

Available to ILBA members only

Convenient binder format allows additional

information to be inserted

Price $95.00 CAN plus shipping

To order, contact the ILBA offce at 1-800-532-2900 or

250-547-8776 or email info@logassociation.org

JIG BOOK

- - - -

ON SALE

NOW!

LogBuildingNews

Number 76

29

C L A S S I F I E D A D S

HELP WANTED

Log Builder/Timber Framer We are seeking

to fill a position requiring the following skills:

Timber Framer; must have 4 year journey-

man certificate in the European Tradition

(Zimmerman), or equivalent in experience. Lo g

Building: mastery of scribed, post and beam and

dovetail log construction.

Other Assets: working knowledge of CLT (Cross

Laminated Timber) Technology, roof math and

roof layout for the purpose of massive log to log

and timber to timber connections and joinery.

Experience with hand and power tools; including

chainsaw, planers, routers. Valid drivers license.

Must be able to read plans, work independently

as well as integrate with our existing team.

Computer drafting skills are an asset but not

required. Hourly pay: $20.00 $24.00 hr

commensurate with skills.

Our company is located in Merritt BC. To apply:

logworks@logworks.ca

Experienced quality orientated log builders

needed. Moose Mountain Log Builders is

looking for experienced log builders who would

enjoy interesting projects to work on in the

Calgary area, in Cochrane Alberta. Earnings

based on experience. Please call Kevin at

1-587-433-6719 or Lloyd if Kevin is unavailable

at: 403-932-3992.

Legendary Logcrafters Limited is a hand crafted

log home producer in Collingwood Ontario. Due

to a consistent annual growth, our company is

adding multiple positions from apprenticeships

to experienced log home builders. Legendary

offers highly competitive wages and a very

structured work environment. Please email

resume to Legendary@legendarylog.com or fax

705-444-6675 or call 705-444-0400.

Full time log chinker. Full time log hand

crafter and timber framer. For both of these

positions we require years of experience and

references. Contact - Southwest Log Homes, Inc

Email: david@southwestloghomes.com

Log Builder Required in Scotland

We seek to employ a log builder to assist with

building fully scribed and Post and Beam Log

Homes in the Scottish Borders.

Applicants should have a minimum of three years

experience in building Full Scribe Log Homes

using the over scribe technique, and Post and

Beam Log Homes. The applicant should also be

able to work from plans, work unsupervised,

and holds either a British or EU passport or a UK

working Visa. Wages to be discussed depending

on experience. Please contact John via e-mail:

info@caledonialoghomes.co.uk

HELP WANTED

Log Builder Wanted Log Home Builder career

opportunity available with a progressive, quality

oriented, full service log home company.

Edmonton area, permanent full time, year round.

1-2 years experience, must have own tools and

transportation, wages are $18.00-$30.00/hr on

piece work. Fax resume to 780-460-2584.

The Log Connection is currently seeking

three to four highly motivated, enthusiastic

individuals to become part of our design

team. Two positions are available for drafters

with a minimum of two years architectural

CADD drafting. Two positions are available for

accomplished drafters/designers with ability to

complete highly detailed log home construction

drawings within a specified time period is a

definite asset. Duties will include the creation

of working drawings for custom log homes

based on preliminary designs, production

design and detailing, shop drawings as well as

modifications to existing designs. Scope of work

may range from medium sized residential to

large commercial projects. Preferred experience

would include log home design/drafting.

Provide resume and samples of past CADD

work, attention to: Mr. Dave Sutton, The Log

Connection, 129 Nanaimo Ave. West, Pentict on,

BC Canada V2A 1N2.

Daizen Joinery Ltd. is looking for full time, HSB

CAD operator and K2 machine operator, timber

frame production assistant. Please contact

Dai, 250-679-2750 or email dai@daizen.com

Big Foot Manufacturing Inc. in Tappen British

Columbia is looking to hire a qualified Timber

Framer with CNC experience. We are currently

expanding our product lines now that we are

entering the North American market. The ideal

candidate will be a journeyman Timber Framer

who has experience operating a Hundegger k2.

This person will be responsible for processing

and fitting final pieces and may be required to

do some on-site erection. Please email resums

in confidence to: wayne@bigfoot-mfg.com

or deliver them in person to: Big Foot

Manufacturing, 3380 Ford Road, Tappen B.C.

Confort Nature is looking for an experienced

log builder who will be in charge of production.

As a hands-on team leader, he will be responsible

of log shell construction from blueprint reading

to quality management. As a small company

looking to develop and always get better, we will

give a lot of place to your ideas and techniques.

We are located in Quebec, 100km north of

Montreal, in the beautiful region of Lanaudire,

next to Saint-Donat and Mont-Tremblant

Park, nearby lakes and mountains. Lets build

something together! Please contact us via email

at info@confortnature.com or phone

1-877-424-3525.

HELP WANTED

Draftsman with Dietrichs CAD experience.

Must have full working knowledge of the

Dietrichs Program, and hands on experience

in wood engineering and/or massive log and

timber joinery. Wages - 21.00 to 24.00 per hour

- please e-mail applications to: Nicola LogWorks,

attention: John Boys. john@logworks.ca

John Devries Log Homes, a small upscale

company operating in Rural Eastern Ontario

since 1976 seeks an experienced log crafter

preferably with hands on supervisory experience

that can read plans and manage projects. We

foster a dynamic, creative, solution oriented

work environment that emphasizes quality while

attempting not to sacrifice productivity (that

elusive log builders Holy Grail) in a structured

but fun atmosphere. (At least we think its fun) It

would be helpful (but not required) if applicant

has timber framing experience as well. Salary

dependent on experience. Plenty of lakes, great

fishing, hunting and other outdoor recreation.

2 hours to Toronto or Ottawa (for some

serious city fun) Call to Martin or Martin to

discuss at 613-478-6830 or e-mail

info@jdvloghomes.com.

WANTED

A set of Gearhead Scribers Please contact:

Leo Scales - monicanleo@roadrunner.com.

603-846-5703.

Looking for work in the northwest. I have

23 years of professional full-scribe log building

experience. I am only available for short term

temporary work, labor fine also. Patrick Dalton

(907) 803-0092 daltonlogshells@gmail.com

and website www.daltonlogshells.com

Traveling Timberwright Professional Finish

Carpenter for Scribe Fit and Post & Beam

structures. 30 years accomplished tradesman in

this field. Mobile, with extensive selection of

tools. Honest and Reliable. Contact:

RALPH CLEGG 604-740-2404 BC Canada.

ANNOUNCEMENTS

Island School of Building Arts 3199 Coast

Road, Gabriola, BC Tel: 250.247.8922

www.isba.ca

Fall 2012 courses:

*Building with Logs - Sept 3 - 28, 2012

*Timber Frame Post & Beam - Oct 1 - 26, 2012

*Timber Frame Bents - Oct 29 - Nov 23, 2012

New Short Courses:

*Custom Door Making - July 23 - July 27, 2012

Concrete Counter tops and Sketchup - Stay

tuned to our website for additional information

on these new short courses.

Winter 2013

30

FOR MORE INFORMATION

Ann Miks, Administrator

ann@logassociation.org

International Log Builders Association

P.O. Box 775

Lumby, British Columbia Canada V0E 2G0

800-532-2900 toll-free

250-547-8776 phone

250-547-8775 fax

www.logassociation.org

2012 ILBA Board of Directors

President

Higgs Murphy

Email: logdoggies@yahoo.com

Vice-President

Earl Laverty

Email: earl@lavertyloghomes.com

Clerk

Liberty Lewis

Email: llewis@callSBSA.com

Treasurer

Martin Slager

Email: info@jdvloghomes.com

Directors

Ron Brodigan

Email: courses@schoolofogbuilding.com

Robert W. Chambers

Email: robert@logbuilding.org

Konrad Gallei

Email: konrad@gallei.de

Noah Hedges

Email: nandadevi@hotmail.com

Dan Wait

Email: dan@fbiloghomes.com

C L A S S I F I E D A D S

ANNOUNCEMENTS

As a seasoned professional

or student, journey through

the fundamentals and varied

complexities of timber

framing in James Mitchells

new guidebook on Timber

Frame construction.

For more information visit

www.MastersGuideBook.com

West Coast Restoration LLC is pleased to

announce that they offer complete restoration

services, insurance litigation support and

consulting. Call Bill Finley at 360-961-3220 or

email: billfinley@westcoastrestoration.com

S ERVI CES

Brian Lloyd Construction Consulting

Industry Consulting

Building Inspection

Expert Witness

Conflict Resolution

Vernon, BC Tel/Fax 250-549-3821

email: bg_Lloyd@hotmail.com

Drafting and Design Services - RSM Drafting

Services Ltd. is a freelance drafting and design

service that specializes in log and timber frame

buildings. We have been Drawing Dreams

since 1977. We have a CD of 24 log homes

available for $19.99 all taxes and shipping

included. Contact Bob at www.rsmdrafting.com.

Email bob.rsmdrafting@telus.net or call

1-877-832-0165 toll free Ask me first

Building design consultants.

Fire Tower, bringing a modern perspective

to time-honored craft, specializes in the

engineering and design of new and existing

log and timber structures. Licensed in BC, AB

& ON and 31 States.

Fire Tower Engineered Timber, Inc.

Mack Magee

m@ftet.com

27 Sims Avenue

Unit 2R, Providence, RI 02909

Phone: 401-489-4567

Fax: 401-441-5218

www.ftet.com

FraserWood Industries Mack Magee

FraserWood is a pioneering, full-service

provider of innovative timber products and

services committed to extending the reach

of natural timbers in built environments.

Mack Magee

27 Sims Avenue

Unit 2R, Providence, RI 02909

Phone: 401-489-4567

Fax: 401-441-5218

email: mmagee@fraserwoodindustries.com

www.fraserwoodindustries.com.

TRAI NI NG

FREE Log Selection Calculator Go to www.

LogBuilding.org and then click on Free

Information. From that page choose the log

selection calculator and download it to your

computer. Requires Excel software to open and

use this file. It gives you T-1, T-2, B-1 and B-2

for any set of logs.

Space Available

Advertise TODAY!

40

th

YEAR

I

N

T

E

R

N

A

T

I

O

N

AL LO

G

B

U

I

L

D

E

R

S

A

S

S

O

CI AT

I O

N

The ILBA 40th

Anniversary conference

will be held in sunny

Arizona, April 4 to 7.

G

et R

ea

d

y

!!

G

et R

ea

d

y

!!

Effective Practices

& Methods

The ILBAs new

publication EP&M

is available for

sale online at

the ILBA website

www.LogAssociation.org.

You can buy and download a

PDF file, or the paper book.

LogBuildingNews

Number 76

31

Advertisers in This Issue

A Boys Big Book of Jigs . . . . . . . . . . . . . . . 28

BC Log & Timber Industry. . . . . . . . . . . . . 10

CBR Products. . . . . . . . . . . . . . . . . . . . . . . 27

Dietrichs . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fire Tower Engineered Timber Inc. . . . . . . . 9

Fraser Wood Industries . . . . . . . . . . . . . . . . 9

GRK Fasteners . . . . . . . . . . . . . . . . . . . . . . . 8

Lignomat USA. . . . . . . . . . . . . . . . . . . . . . . 4

Log Home Store . . . . . . . . . . . . . . . . . . . . . 6

Magard Ventures Ltd. . . . . . . . . . . . . . . . . 28

Nicola Log Works . . . . . . . . . . . . . . . . . . . 32

Pat Wolfe Log Building . . . . . . . . . . . . . . . . 4

Perma-Chink Systems Inc. . . . . . . . . . . 4, 28

Precision Structural Engineering . . . . . . . . 24

RSM Drafting. . . . . . . . . . . . . . . . . . . . . . . 24

Sashco. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Schroeder Log Home Supply. . . . . . . . . . . . 9