Professional Documents

Culture Documents

Chapter 26 - Scaffolding Guideline

Uploaded by

Charlyn Burce MadridCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 26 - Scaffolding Guideline

Uploaded by

Charlyn Burce MadridCopyright:

Available Formats

Effective Date : 18.06.

2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 1 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

ADWEA HSE PROCEDURE MANUAL

SCAFFOLDING GUIDELINES

Prepared

by:

Date:

HSE Specialist

Reviewed

by:

Date:

Technical Advisor

Approved

by:

Date:

Planning & Development

Director

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 2 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

TABLE OF CONTENTS

1. INTRODUCTION:..................................................................................................... 4

2. RELEVANT LEGISLATION, CODES AND STANDARDS: ............................................... 4

3. DEFINITIONS: ......................................................................................................... 4

4. MATERIALS STANDARD, INSPECTION AND RECORDING: ......................................... 6

5. STANDARD SCAFFOLDS: ......................................................................................... 7

6. PORTABLE LADDERS AND STEPLADDERS:................................................................ 10

7. ERECTION, ALTERATION AND DISMANTLING: ......................................................... 13

8. INSPECTION, MAINTENANCE AND REGISTERS......................................................... 14

9. TAGGING SYSTEM.................................................................................................. 14

10. SPECIAL SCAFFOLDS.............................................................................................. 15

11. SAFE USE OF SCAFFOLDS ...................................................................................... 17

ATTACHMENTS

A SCAFFOLD INSPECTION(S) REGISTER....................................................................... 19

B SCAFFOLD FITTINGS................................................................................................ 20

C SCAFFOLD TERMINOLOGY ...................................................................................... 22

D THROUGH TIE FOR INDEPENDENT TIED SCAFFOLD.................................................. 24

E INDEPENDENT TIED SCAFFOLD COLUMN BOX TIE ................................................. 25

F STANDARD SCAFFOLDS TYPICAL INDEPENDENT & PUTLOG SCAFFOLD.................. 26

G LADDER ACCESS TOWER AND MOBILE TOWER SCAFFOLDS..................................... 27

H SCAFFTAG INSERTS ................................................................................................ 31

I SCAFFTAG HOLDER................................................................................................ 32

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 3 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

CHANGES HISTORY SHEET

VERSION

PAGE NUMBER

DESCRIPTION OF CHANGE

APPROVED BY

EFFECTVE

DATE

1 1 HSE Advisor changed to HSE Specialist

1 4

Under section 3 : new definitions added as per

OHSAS18001:2007

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 4 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

1. INTRODUCTION:

The following guidelines are developed to ensure that scaffolds are properly designed,

erected and maintained to provide both a means of access and a working place which

shall be as safe as those found in existing structures and on permanent structures.

2. RELEVANT LEGISLATION, CODES AND STANDARDS:

The following legislation, codes and standards or acceptable equivalents which the

CONTRACTOR shall apply in conjunction with this document:

Ministry of Labour and Social Affairs Ministerial Order No. (32) of the year 1982.

BRITISH STANDARD, BS 1139: 1990 - Specification for Metal scaffolding.

BRITISH STANDARD, BS 2482: 1981 - Specification for Timber scaffold boards.

BRITISH STANDARD, BS 5973: 1993 - Code of practice for Access and working

scaffolds and special scaffold structures in steel.

BRITISH STANDARD, BS 5974: 1990 - Code of practice for temporarily installed

suspend scaffolds and access equipment.

3. DEFINITIONS:

For the purposes of this Guideline, the following definitions apply, as appropriate.

Document: Information and its supporting medium (paper, magnetic, electronic or

optical computer disc, photograph or master sample, or combination thereof).

Record: Document stating results achieved or providing evidence of activity performed

Base Plate: A metal plate with a spigot for distributing the load from a standard or

raker or other load-bearing tube.

Bay: The space between the centre lines of two adjacent standards along the face of a

scaffold.

Brace: A tube placed diagonally with respect to the vertical or horizontal members of a

scaffold and fixed to them to afford stability.

Brace Coupler: A coupler used for fixing braces, which may be a right angle coupler or

any other coupler capable of sustaining a safe working load of 5kN.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 5 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Brick Guard: A metal or other fender filling the gap between the guardrail and

toe-board, and sometimes incorporating one or both of these components.

Check Coupler or Safety Coupler: A coupler added to a joint under load to give

additional security to the coupler(s) carrying the load.

Competent Scaffolder: An operative assigned duties in the erection, alteration,

maintenance or dismantling of a scaffold or staging, who has undergone and passed a

scaffolding training course.

Coupler: A component used to fix scaffold tubes together.

Foreman Scaffolder: Foreman assigned as in-charge in the erection, alteration,

maintenance or dismantling of a scaffold or staging who has undergone and passed an

advanced scaffold training course and has at least five years experience as a scaffolder.

Guardrail: A member incorporated in a structure to prevent the fall of a person from a

platform or access way.

Joint Pin: An expanding fitting placed in the bore of a tube to connect one tube to

another coaxially.

Ledger: A longitudinal tube normally fixed parallel to the face of a structure (building)

in the direction of the larger dimensions of the scaffold. It acts as a support for the

putlogs and transoms and frequently for the tie tubes and ledger braces and is usually

joined to the adjacent standards.

Lift: The assembly of ledgers and transoms forming each horizontal level of a scaffold.

Parallel Coupler: A coupler used to join two tubes in parallel.

Putlog: A horizontal tube with a flattened end, to rest in or on part of the brickwork or

structure.

Putlog Coupler: A coupler used for fixing a putlog or transom to a ledger, or to

connect a tube used only as a guardrail to a standard.

Reveal Pin: A fitting used for tightening a reveal tube between two opposite surfaces.

Right Angle Coupler: A load-bearing coupler used to join tubes at right angles.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 6 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Scaffold: A temporary structure on or from which persons work or which provides

support for the materials used in construction, maintenance, inspection, repair, or

demolition work or access to certain areas or equipment.

Sleeve Coupler: An external coupler used to join one tube to another coaxially.

Sole Plate: A timber, concrete or metal spreader used to distribute the load from a

standard or base plate to the ground.

Standard: A vertical or near vertical tube, which carries the scaffold's weight and loads

imposed to the supporting structure.

Swivel Coupler: A coupler used for joining tubes at an angle other than a right angle.

Tie or Tie Assembly: The components attached to an anchorage or the structure

(building) or framed around a part of it or wedged or screwed into it with a tie tube.

Used to secure the scaffold to the structure.

Toe-board: An up-stand at the edge of a platform, intended to prevent materials or

operatives' feet from slipping off the platform.

Transom: A tube spanning across ledgers to form the support for boards or units

forming the working platform or to connect the outer standards to the inner

standards.

Universal Coupler: A load-bearing coupler used for connecting two tubes together at

right angles or in parallel

Working Platform: The deck from which (building/structural) operations are carried

out.

4. MATERIALS STANDARD, INSPECTION AND RECORDING:

Steel Tubes and Fittings:

All steel tubing, couplers and fittings used for scaffolding shall conform to British

Standard Specification No. BS 1139 or acceptable equivalent.

Tubes shall be free from cracks, splits, surface flaws and other defects. The ends

of the tubes shall be cut clean and square.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 7 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

All couplers and fittings shall be properly oiled and maintained. Nuts shall have a

free running fit on their bolts. Bolts with worn or damaged threads shall be

replaced.

Aluminium Tubing:

1. Aluminium tube shall not be mixed with steel tube or steel fittings due

to different loadings and the fact that steel fittings could crush

aluminium tube.

2. Aluminium tube shall not be used if bent.

3. Aluminium tube shall not be straightened; the straight parts of the tube

may be cut out and re-used, but the remainder shall be disposed of.

4. Aluminium tube shall not be heated by welding or flame cutting, etc.

Scaffold Boards:

All scaffold boards shall comply with British Standard Specification No. BS 2482 or

acceptable equivalent.

Boards shall not be painted or treated in any way which shall conceal defects in

them.

The ends of all scaffold boards shall be bound and protected by metal hoops.

Boards shall not be split up more than 300mm from the end with the metal hoop

fixed and shall not be decayed or warped by more than 12mm. The parts affected

may be cut out to obtain shorter boards that shall also comply with BS 2482 or

acceptable equivalent.

5. STANDARD SCAFFOLDS (Attachment F)

Un-sheeted scaffolds up to 50m high may be constructed without being specifically

designed, provided they comply with the requirements outlined below and do not carry

greater loads, or have greater bay lengths than those specified in BS 5973 or acceptable

equivalent.

Where sheets are to be added to a scaffold to afford protection to operatives or the work,

the scaffold shall be specifically designed with consideration given to the wind forces to

which it will be subjected.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 8 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

When a temporary roof is to be fixed to the top of an access scaffold, the scaffold and its

attachment shall be specifically designed.

Firm Foundation:

All scaffolds shall be erected on a firm level and consolidated base.

Base plates shall be used below each standard on surfaces where there is the

possibility of standards deforming the surface.

On surfaces which shall be penetrated by base plates which support standards,

sole plates of timber shall be used beneath the base plates in order to achieve a

greater distribution of the load.

Sole plates shall be at least 35mm thick and 219mm wide. The sole plate area

beneath any one standard shall be at least 1,000cm

2

but, if the ground is soft or

has been disturbed, this area shall be increased to 1,700cm

2

.

Jointed Standards and Ledgers:

A mixture of longer and shorter tubes shall be used when constructing long

ledgers or tall standards.

Joints in completed scaffolds shall not occur in adjacent standards in the same lift

and joints in adjacent ledgers shall not occur in the same bay.

Joints in standards shall be made either with joint pins or with sleeve couplers,

and shall be positioned near ledgers.

Joints in ledgers shall be made with sleeve couplers and shall be positioned at a

distance not more than one third of the span between adjacent standards.

Fixing of Ledgers to Standards and Transoms, or Putlogs to Ledgers:

Ledgers shall be fixed to standards with right angle couplers.

A transom shall be fixed adjacent to every standard in every lift of a scaffold by

means of right angle couplers.

Intermediate board-bearing tubes may be fixed to ledgers by putlog couplers.

Bracing:

Bracing shall be in the form of ledger or cross bracing and longitudinal or facade

bracing.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 9 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Ledger bracing shall be positioned at alternative standards in a scaffold and each brace

shall run from a ledger in one lift to the diagonally opposite ledger the lift above.

Longitudinal bracing shall be in the form of a zig-zag arrangement of tubes running from

the bottom to the top of the scaffold between a pair of adjacent standards.

Or

A continuous tube running from the bottom to the top of the scaffold at an angle of

between 35

o

and 55

o

to the horizontal.

Or

Individual tubes running from the bottom to the top of the scaffold between a pair of

adjacent standards, all sloping the same way.

Bracing assemblies shall be fixed along the face of the scaffold at intervals not exceeding

30m.

Stability:

The prevention of inward and outward movement of a scaffold shall be achieved by the

use of ties being in place every 4 m (rise) 6 m horizontal.

Only one tie shall be temporally removed and this shall be replaced before removing

another.

Ties shall be staggered in location wherever the building surface permits.

Tie working Loads

Box, Lip or through ties : 6.25kN

Reveal ties : 3.50kN

Drilled in anchor ties : 6.25kN or as recommended by

manufacturer

Each tie assembly for sheeted scaffolds shall have at least a 12.5kN capacity.

Safe Working Platforms General:

All boards which make up the platform shall rest squarely and evenly on correctly spaced

transoms, and be secured to prevent accidental displacement.

All boards shall be of the same thickness.

Each board shall have at least three supports unless its thickness or span is enough to

prevent sagging under load.

No board shall overhang its end support by more than four times its thickness unless

secured to prevent tipping; the minimum overhang shall be at least 50mm.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 10 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Where boards overlap, bevels or other precautions shall be used to prevent a tipping

hazard.

Toe-boards shall be fixed on the inside of standards and shall be at least 150mm high.

Where men have to sit at the edge of the platform between the structures, the gap

between the platform and the structure shall not exceed 300mm.

Guardrails and toe-boards shall be positioned at every edge from which a person is liable

to fall more than 2m.

Guardrails shall be fixed on the inside of standards at a height of between 910mm and

1.15m above the level of the platform.

The distance between guardrails and toe-boards shall not exceed 765mm.

Maximum span of scaffold boards

Normal

thickness of

board

Maximum Span

between transoms

Minimum

overhang

Maximum

overhang

mm M mm mm

38 1.50 50 150

50 2.60 50 200

63 3.25 50 250

Widths of access and working platforms

Purpose Minimum Width Practical width using

225mm boards

Work on spherical or cylindrical metal

structures; work from ladder, folding

trestle, slung or suspended scaffolds

600mm - Onshore 650mm

- Offshore

3 boards

Working platform for persons and for

deposit of material

850mm

(there must be 430mm

passage for persons, clear

of materials)

4 boards

For support of a trestle or other higher

platform

1.05m 5 boards

Use by masons for dressing or shaping

stone

1.30m 6 boards

Use by masons to support trestles or

other higher platform

1.50m 7 boards

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 11 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

6. PORTABLE LADDERS AND STEPLADDERS

This section contains requirements for portable ladders and stepladders, including job-made

ladders.

Condition

All portable ladders and stepladders shall be maintained in good condition at all

times. Joints shall be tight. All rungs, hardware and fittings shall be securely

attached, and movable parts shall operate freely without binding or undue play.

Each portable ladder shall be examined before use. Any ladder that is damaged or

weakened shall be immediately removed.

Position

Straight ladders and extension ladders shall be placed at a slope of 4:1 (for every 4

meters of vertical rise, the base set 1 meter out) (Attachment G). Or, straight

ladders and extension ladders may be placed vertically if both side rails are rigidly

attached to a supporting structure (i.e. scaffold) at the top, middle, and bottom of

the ladder.

All ladders shall extend at least 900 mm (3 feet) above the landing, platform,

eave, or roofline (Attachment-G).

The base supports of all ladders shall be equally supported on a firm level surface.

Boxes, blocks, barrels, etc., shall not be used as a means of support.

The bottom rung of ladders shall not be more than 600 mm (2 feet) above the

lower level used to mount the ladder.

The area at the base of a ladder shall be kept clear.

Ladders shall not be used in a horizontal position as platforms, walkways, or

scaffolds.

Ladders shall not be supported on their rungs. Rungs shall not be used to support

scaffold planks.

Both side rails of a ladder shall be evenly supported at the upper resting-place.

Side rails should be securely tied off to prevent movement. Where secure fixing is

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 12 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

impractical, other measures shall be taken to prevent movement by securing at

the base, using side guys, or stationing a man at the base.

When a ladder could be struck by moving vehicles or equipment, a flagman shall

be stationed to warn of f drivers, or a substantial barricade with flashers erected

around the ladder base.

If a ladder is erected near a doorway, the door shall either be locked shut, or

secured in the open position with a man on guard to prevent anyone from using

the door .

Clearances

Safe clearances shall be maintained to prevent workers from bumping into, or

snagging onto, projecting objects while ascending or descending the ladder.

Ladders shall have a minimum clear perpendicular distance of 760 mm (30 inches)

from the rungs to the nearest projecting object on the climbing side. When

unavoidable obstructions are encountered, the minimum clearance distance may be

reduced to

610 mm (24 inches) if deflector plates are provided.

The perpendicular distance from the face of the rung on the climbing side to the

nearest fixed object on the back side of the ladder shall not be less than 250 mm

(10 inches).

When unavoidable, horizontal obstructions (e.g. beams, pipes, etc.) are

encountered, the vertical toe clearances specified below shall apply.

The minimum clearance to the nearest fixed object shall be 330 mm (13 inches)

on each side of the centerline of single-rung ladders.

The minimum vertical toe clearance shall be 100 mm (4 inches) above the top

edge of the rung.

The minimum clear distance between the sides of adjacent single-rung ladders or

stepladders shall be 410 millimeters (16 inches).

Usage

Metal ladders, ladders with metal reinforced side rails, and ladders that are wet

shall not be used near electrical equipment or while using electrical tools. Only

wooden or fiberglass ladders shall be used for electrical applications. Portable

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 13 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

met al ladders shall have a warning notice attached to guard against use near

electrical equipment.

Do not splice, lash, or tie ladders or ladder sections together.

Before climbing a ladder, workers shall check that their shoes and the ladder are

free from grease, oil, and mud.

Only one person shall be on a single-rung ladder at a time.

Workers shall not carry tools and materials in their hands when climbing a ladder.

Tools may be carried in secure pockets or on special tool belts. Material or heavy

tools shall be raised and lowered by rope.

If work is done while standing on a ladder and the worker is higher than 1.8 meters

(6

feet) above the ground, either one hand shall remain on the ladder or a personal fall

arrest system shall be used.

Ladders shall not be moved, shifted, or extended while occupied.

While climbing or descending, workers shall face the ladder and keep both hands on

the ladder.

Stepladders

In addition to requirements stated above, the following apply to stepladders:

Stepladders shall have folding cross-braces that are hinged. Both sections shall be

fully opened with hinged braces flat and taut before use to ensure stability.

Stepladders shall be faced with the steps facing the work location.

Do not stand on stepladder top platform, top step, pail shelf, braces, or back

section.

Only one man shall be on a stepladder at a time.

Do not use the top platform or top step to store tools and materials.

Never leave a ladder unattended with tools or materials stored on it.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 14 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Do not use a stepladder to gain access to roofs or other elevated surfaces.

Never use a stepladder that is leaned against a wall or other support. Stepladders

shall only be used when equally supported by all four legs.

The length of portable stepladders shall not exceed 6 meters (20 feet).

7. ERECTION, ALTERATION AND DISMANTLING:

Erection, alteration and dismantling of a scaffold shall only take place by Competent

Scaffolders under the supervision of the Contractor's Foreman Scaffolder.

Erection:

The erection sequence of a scaffold shall ensure that at no time will the scaffold

reach an unstable condition.

Ties shall be fixed in place as erection proceeds, not when the scaffold is

complete.

Warnings notices stating "Danger Scaffold Incomplete - Do not Use" (See Tagging

System Section) shall be fixed to those parts of a scaffold which are incomplete and not

for use.

Alteration:

All modifications to existing scaffolding shall be carried out in such a way that the

stability of the scaffolding is not impaired.

Supplementary components shall be added before those which have to be removed are

taken away.

If standards are to be removed in order to provide access, additional standards shall first

be fixed to both sides of the proposed opening so that the total number of standards in

the scaffold is never reduced.

Dismantling:

Prior to dismantling a scaffold, the scaffold shall be inspected and a safe procedure for

dismantling be established by the Contractor's Foreman Scaffolder.

During dismantling, no component, the removal of which would endanger the scaffold,

shall be removed until steps have been taken to compensate for its removal.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 15 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

If dismantling has reached the stage at which a critical number has to be removed, the

stability of the scaffold shall be ensured by fixing a similar component in place lower

down the scaffold.

8. INSPECTION, MAINTENANCE AND REGISTERS

Prior to erection, the Contractors Foreman Scaffolder, in charge of the works, shall inspect the

ground area upon which the scaffold is to be positioned, and shall inspect all equipment which

shall form any part of the scaffold staging, means of access, work platform and lifting gear.

The Contractor's Foreman Scaffolder shall appoint a competent Scaffolder(s) to be solely

responsible for maintenance works on scaffolds and staging.

Prior to persons being allowed to use, the scaffolds or staging shall be checked by the

Contractors Forman Scaffolder before each work period or where they are altered, adjusted or

subjected to rain or heavy winds. Thereafter the scaffolding shall be examined/inspected at

least once in every seven days. The Contractors Forman Scaffolder shall examine/inspect the

scaffold inclusive of peripheral equipment and shall record his findings in the Scaffold

Inspection Register' (Attachment A).

9. TAGGING SYSTEM

The Contractors Forman Scaffolder shall place a weather proof plasticated or equivalent colour

coded label at each access point and at the boundary of each scaffold section from the initial

erection stage until final dismantling, which shall clearly state if the scaffold is "ready for use" or

"not to be used" (Attachment H). In addition the label shall state:

Date Erected, with name and initials of Scaffolder

Maximum Loading kN/m

2

Date Inspected, with Foreman name and Signature

Date Modified, with name and initials of Scaffolder

Date Re-inspected, with name and signature of Forman Scaffolder.

Expire Date of label

Dismantling Date

All entries onto the tag shall be made with a permanent ink pen.

The Contractor shall ensure that all personnel under his control, who come into contact

with scaffolding, are trained in the use of the scaffold tagging system.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 16 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

10. SPECIAL SCAFFOLDS

All scaffolds over 50m high and all sheeted scaffolds over 25m high, together with Hanging,

Bridging, Birdcage, Truss-out, Slung, Cantilever Scaffolds, Hoist Towers, Loading Bays and

Protection Fans, shall be designed by the Contractor's Senior Civil Engineer in accordance with

the requirements of British Standard Specification No. BS 5973 or acceptable equivalent.

The Engineer shall provide a written erection and dismantling procedure together with the

scaffold drawing and his design calculations, for the approval of the Consultant.

After erection and prior to work commencing upon the scaffold, the Contractor's Engineer shall

inspect the scaffold with the Consultant who shall approve the scaffold and record his

inspection in the "Scaffold Inspection Register". The Consultant shall "tag" the scaffold.

Tower Scaffolds (Attachment G):

Scaffold towers shall only be erected and used on firm level ground.

Static towers shall have metal base plates under the standards, and unless the

foundation is concrete, the load shall be spread by timber sole plates.

Wheels, or castors, on mobile towers shall not less than 150mm in diameter. Castors

shall be fixed into the base of the standards and be fitted with brakes which cannot

accidentally be released.

All free standing towers shall be guyed or tied every 6m.

Where joints in standards are necessary, they shall be made with sleeve or parallel

couplers.

Ledgers and transoms, at right angles to the standards, shall commence not more than

150mm from the bottom to provide a firm base clear of the castors.

Except at working platform level, ledgers and transoms shall be fixed to the standards

with right angle couplers.

Lifts shall not exceed 2.7m on static or mobile towers.

Bracing shall be fixed to ledgers and transoms with right angle couplers in the form of:

Plan bracing, i.e. diagonally at the base and working platform, and also at alternative

lifts;

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 17 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Diagonal bracing in zig-zag fashion to the full height of the tower on all four sides.

The maximum height to which a static or mobile tower shall be erected is calculated

below. The second figure in each ratio represents the smaller of the two base

dimensions of the tower.

Maximum height of tower scaffolds

Type of Tower Height / base ratio

Static Tower used indoors 4 : 1

Static Tower used outdoors 3.5 : 1

Mobile Tower used indoors 3.5 : 1

Mobile Tower used outdoors 3 : 1

The maximum height established shall be the height to the working platform, not to the

guardrail.

The maximum free-standing height for mobile towers shall be 9.6m and, for static

towers, 12m which may be extended to 16m with the use of tie in (consult

manufacturers guide).

In any case the height to base ratio shall apply unless outriggers are provided for

additional height.

Where the maximum free-standing height or the maximum recommended height to the

base ratio requires to be exceeded or the tower is likely to be exposed to appreciable

wind loading, the scaffold shall be tied to the structure it is serving, or designed to

ensure stability by means of ground anchors, guys or kentledge.

A ladder for access purposes shall be lashed vertically to one of the narrow sides inside

the base area, with the foot resting on an additional transom.

The ladder shall extend at least 1.00m above platform level to provide a handhold at the

stepping off point.

A ladder or trestle shall not be placed on the top platform to extend the height of the

tower.

Mobile towers shall have their castors turned outwards to provide maximum base

dimensions and the brakes locked "ON" when the scaffold is in use.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 18 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Mobile towers shall be moved only by pulling or pushing at the base.

Whenever they are moved consideration must be given to reduce the height by 1/3,

before pulling or pushing, particularly in those systems where outriggers are provided.

Working platforms shall be cleared of persons and materials before towers are moved.

11. SAFE USE OF SCAFFOLDS

General

The Contractor shall ensure that scaffolding is only for its intended purpose. It shall never be

overloaded or extended by the use of ladders or other makeshift devices.

If handrails are removed for any reason, the Contractor shall ensure that temporary rope or

wire replacements are in place, capable of preventing persons from falling, or a full body safety

harness be worn by persons working on the scaffolding during the period for which the

scaffolding is without handrails.

The Contractor shall ensure small tools, equipment, bolts and other loose material are kept in

containers to prevent them falling off the scaffolding. Parts of staging, tools or other

equipment shall be carefully lowered and not thrown down from a height.

Scaffolding shall be kept free of rubbish and any other obstruction.

The Contractor shall ensure that his personnel wear the required personal protective

equipment at all times.

Earth leads for welding shall never be attached to scaffolding.

Personnel shall not work underneath scaffolding unless absolutely necessary and only if

overhead protection is provided.

Drums or barrels shall not be used as a means of scaffolding.

Welding of scaffold joints is not permitted.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 19 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

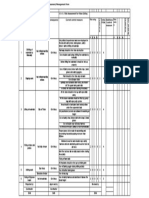

Attachment A Scaffold Inspection(s) Register

Name of Contractor

Address of Site

Work Commenced Date

Location and description of scaffold etc. Date of Result of inspection Name and signature of person

and other plant or equipment inspected Inspection State whether in good order who made the inception

Short check list - at each inspection check that your scaffolding does not have these faults:

WEEK WEEK WEEK

1 2 3 4 1 2 3 4 1 2 3 4

FOOTINGS Soft and uneven BRACING Some missing TIES Some missing

No base plates Facade and Loose Loose

No side boards Ledger Wrong Fittings

Undermined BOARDING Bad boards

PUTLOGS Wrongly spaced Trap boards

AND Loose Incomplete

STANDARDS Not plumb TRANSOMS Wrongly supported Insufficient

Joined at same height Wrong fittings Supports

Wrong spacing Loose

Damaged GUARD Wrong heigh

COUPLINGS Damaged RAIL & Loose

No check Couplers TOE BOARD Some missing

LEDGERS Not level

Joint in same bays BRIDLES Wrong Space LADDERS Damaged

Loose Wrong Coupling Insufficient length

Damaged Weak Support Not tied

SCAFFOLD INSPECTIONS SCAFFOLD INSPECTIONS SCAFFOLD INSPECTIONS SCAFFOLD INSPECTIONS

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 20 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Attachment B Scaffold Fittings

BASE PLATE

ADJUSTA!3LE BASE PLATE

RJGHT -ANGLE COULPER

PUTLOG COUPLER

UNIVERSAL COUPLER

BRACE COUPLER

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 21 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Swivel Coupler

Joint Pin

Reveal Pin

Sleeve Coupler

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 22 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Attachment C Scaffold Terminology

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 23 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 24 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Attachment D Through Tie for Independent Tied Scaffold

Tie fixed with right angle couplers

and placed close to the window

reveal.

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 25 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Attachment E Independent Tied Scaffold Column Box Tie

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 26 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Attachment F Standard Scaffolds Typical Independent & Putlog

Scaffold

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 27 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Attachment G Ladder Access Tower and Mobile Tower Scaffolds

Mobile Scaffold

(Internal Ladder)

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 28 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Fabricated Tabular Frame Mobile Scaffold

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 29 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Tower Scaffold

Portable Ladder

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 30 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Mobile Tower Scaffolds

Height Too Short

Height to least base

ration

Steel Tube and fitting towers

Indoors more than 3.5 to 1 Outdoor more than 3 to 1

Other types (e.g. aluminium alloy)

Maximum height to least base ratio not in accordance with manufacturers

instructions, including outriggers.

Tie Guys or Base

Weights if Needed

Some missing

Surface Soft Uneven Sloping

Access Ladder, stairway or ladder

frame not provided

Ladder of insufficient

length

Ladder not

tied

Bracing Some missing Wrong direction

Brakes or Chocks Not provided Not secured

Wheels Liable to fall out

Guard Rails Wrong height Loose Missing

Toe Boards Wrong height Loose Missing

Connections (Aluminium

Alloy &Other Proprietory

Towers)

Damaged Latching hooks not secured Socket & spigot connections

not fully engaged

Temporary Roof and Beamed Scaffolds

Design Drawings Not provided Not sufficiently detailed

Scaffold Not in accordance with

drawings

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 31 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

Attachment H Scafftag Inserts

Note:-The front of the Scafftag is to have a green background with white lettering.

The back of the Scafftag is to have a yellow background with black lettering

SCAFFTAG

ERRECTION AND

INSPECTION RECORD

Location ________________________

Date Erected ___________________

Built By ______________________

Date Inspected __________________

Forman Scaffolder Signature ___________

Date Modified ___________________

Modified By _____________________

Date Re-inspected ______________

Forman Scaffolder Signature___________

Expiry Date of Label __________

Dismantling Date _______________

STRUCTURE TO BE

USED FOR

Very Light Duty

0.75 kN/m

2

Light Duty

1.50 kN/m

2

General Purpose

2.00 kN/m

2

Heavy Duty

2.5 kN/m

2

Special Purposes

.kN/m

2

WARNING

UNLAWFUL REMOVAL OR

INTERFERENCE WITH THIS SIGN

COULD MAKE YOU LIABLE FOR

DISCIPLINARY ACTION

Contractors Forman Scaffolder

(every 7 days)

DATE SIGNED

LADDER No RUNGS: _______________

No OF STANDARDS: _______________

No OF LIFT: _______________________

M

2

BOARDING _____________________

STRUCTURE DECOMMISIONED

DATE: ____________________________

SIGNATURE: _____________________

Effective Date : 18.06.2009

Volume Chapter Version

19 26 1

ABU DHABI WATER AND ELECTRICITY

AUTHORITY (ADWEA)

Page 32 of 32

Approved by:

SCAFFOLDING GUIDELINES

Director of Planning & Development

This document is the property of ADWEA, and can not be used nor given to outside party without prior authorisation

The Scafftag is to be placed in the Scafftag Holder (See attachment -I)

Attachment I Scafftag Holder

You might also like

- Wyckoff e BookDocument43 pagesWyckoff e BookIan Moncrieffe95% (22)

- WMS Electrical Working On or Near Exposed Energised Electrical EquipmentDocument7 pagesWMS Electrical Working On or Near Exposed Energised Electrical EquipmentFresly PatriaNo ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Civil Work SpecificationDocument143 pagesCivil Work Specificationgea alifa amorynaNo ratings yet

- Safe Lifting Operations in The WorkplaceDocument14 pagesSafe Lifting Operations in The WorkplacetlalovićNo ratings yet

- Environment ProtectionDocument7 pagesEnvironment ProtectionPhilip YapNo ratings yet

- Flood Mitigation PlanningDocument14 pagesFlood Mitigation PlanningJingNo ratings yet

- OHS PROC 113 BarricadesDocument9 pagesOHS PROC 113 BarricadesPhillip L100% (1)

- ETP48300-C6D2 Embedded Power User Manual PDFDocument94 pagesETP48300-C6D2 Embedded Power User Manual PDFjose benedito f. pereira100% (1)

- Proposed Mixed Use Building SECSF-14 ChecklistDocument1 pageProposed Mixed Use Building SECSF-14 ChecklistFrancis Enriquez TanNo ratings yet

- Barricading and Signage ProcedureDocument10 pagesBarricading and Signage ProcedureAristotel C. Cabais, RN50% (2)

- Summary of Quantities: Item D E S C R I P T I O N Unit Quantity As Plan Quantity Remarks As TakeDocument1 pageSummary of Quantities: Item D E S C R I P T I O N Unit Quantity As Plan Quantity Remarks As TakeLuigi MontederamosNo ratings yet

- Steel Erection Method StatementDocument16 pagesSteel Erection Method StatementPangky AbasoloNo ratings yet

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocument12 pagesIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpNo ratings yet

- Emergency Response and Contingency PlanDocument21 pagesEmergency Response and Contingency PlanKarimo KilaniNo ratings yet

- Opti Tower Health and Safety File Oct 12Document387 pagesOpti Tower Health and Safety File Oct 12Pieter HerbstNo ratings yet

- Metod of Staitment CDP (Pasha Construction)Document7 pagesMetod of Staitment CDP (Pasha Construction)GurbanNo ratings yet

- Scaffolding Work Method Statement for RDMP ProjectDocument31 pagesScaffolding Work Method Statement for RDMP Projectogyrisky100% (1)

- Work Procedure For CCB Scaffolding - FinalDocument80 pagesWork Procedure For CCB Scaffolding - FinalLeo PascualNo ratings yet

- SMN-OHS-MONTHLY REPORTS-Safety-StatisticsDocument3 pagesSMN-OHS-MONTHLY REPORTS-Safety-Statisticsalmamunmolla96No ratings yet

- Qcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working ADocument9 pagesQcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working Abryanpastor106No ratings yet

- Concrete Pipe & Box Culvert InstallationDocument91 pagesConcrete Pipe & Box Culvert Installationya9a_ya9m_ya9q2595No ratings yet

- Test UploadDocument79 pagesTest UploadFeri Rahman100% (1)

- 15T DG EOT Crane Installation Method StatementDocument17 pages15T DG EOT Crane Installation Method StatementJohn Rey PerlasNo ratings yet

- Guide Crane-Lifted Work PlatformsDocument13 pagesGuide Crane-Lifted Work PlatformssheqarayzanNo ratings yet

- CEMEX Global Strategy CaseDocument4 pagesCEMEX Global Strategy CaseSaif Ul Islam100% (1)

- MJEC HSE Req For Contractors Second Issue V2 2017 ApprovedDocument27 pagesMJEC HSE Req For Contractors Second Issue V2 2017 Approvedadnanakhtarhrp100% (1)

- China Harbour Engineering Company Safety PlanDocument126 pagesChina Harbour Engineering Company Safety Plandi2p2th22s2nNo ratings yet

- Staircase Tower CuplockDocument1 pageStaircase Tower CuplockManu MohanNo ratings yet

- Soil Nailing and Rock Anchors ExplainedDocument21 pagesSoil Nailing and Rock Anchors ExplainedMark Anthony Agnes AmoresNo ratings yet

- SFPSG-Reducing Unintended Movement of PlantDocument60 pagesSFPSG-Reducing Unintended Movement of PlantLyle KorytarNo ratings yet

- Checklist Site and Security Fencing SchoolsDocument2 pagesChecklist Site and Security Fencing Schoolsakshay aryaNo ratings yet

- RT Working at Heights StandardDocument4 pagesRT Working at Heights StandardJohn Kalvin100% (1)

- X Ay TFF XMST 3 N Avx YDocument8 pagesX Ay TFF XMST 3 N Avx YRV SATYANARAYANANo ratings yet

- LOCG-GEN-Guideline-007 Rev 0 - Offshore PipelinesDocument50 pagesLOCG-GEN-Guideline-007 Rev 0 - Offshore PipelinesTomkel Voon100% (1)

- Health, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)Document4 pagesHealth, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)rizal azizanNo ratings yet

- SA Form 9613 - Suspended (Dancing Platform)Document6 pagesSA Form 9613 - Suspended (Dancing Platform)Ramil LazaroNo ratings yet

- 14.lifting Operations & Lifting EquipmentDocument28 pages14.lifting Operations & Lifting EquipmentbabadapbadapNo ratings yet

- Method StatementDocument14 pagesMethod StatementArulkumar SR CHETTINo ratings yet

- Silica Gel Blue MSDSDocument5 pagesSilica Gel Blue MSDSRajesh GalgalikarNo ratings yet

- 37 Material StorageDocument5 pages37 Material StorageCaron KarlosNo ratings yet

- A Study of Factors Influencing The Consumer Behavior Towards Direct Selling Companies With Special Reference To RCM Products1Document79 pagesA Study of Factors Influencing The Consumer Behavior Towards Direct Selling Companies With Special Reference To RCM Products1Chandan SrivastavaNo ratings yet

- 8-Pipe Fitting Risk Assessment ReportDocument8 pages8-Pipe Fitting Risk Assessment ReportSyed Ali HassanNo ratings yet

- Scaffold Plan Completeness ChecklistDocument6 pagesScaffold Plan Completeness ChecklistRamil LazaroNo ratings yet

- JSA Erection & Dismantling of ScaffoldingDocument3 pagesJSA Erection & Dismantling of ScaffoldingMc Evans MagallanesNo ratings yet

- Steel CstructionDocument18 pagesSteel CstructionChen QingNo ratings yet

- Crane Safety Tool Box TalkDocument2 pagesCrane Safety Tool Box Talksathees4329No ratings yet

- SGB CUPLOK - Approvals and Accreditations PDFDocument1 pageSGB CUPLOK - Approvals and Accreditations PDFAnupam GhoshNo ratings yet

- Final Handover Certificate ElecricalDocument1 pageFinal Handover Certificate ElecricalDeonNo ratings yet

- Specification - Topographic and Plant Surveys SpecificationDocument4 pagesSpecification - Topographic and Plant Surveys SpecificationAzhar AliNo ratings yet

- Cable Installation For - SWMSDocument6 pagesCable Installation For - SWMSthanitoNo ratings yet

- Scaffolding For LifeDocument27 pagesScaffolding For LifeSameer KulkarniNo ratings yet

- Silo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment FormDocument9 pagesSilo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment Form891629100% (1)

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranNo ratings yet

- Health, Safety AND Environmental PlanDocument63 pagesHealth, Safety AND Environmental Planm.umarNo ratings yet

- HSS Hire - Scaffold TowersDocument2 pagesHSS Hire - Scaffold TowersKevin MorrisNo ratings yet

- Risk Assessment Tables GuidanceDocument6 pagesRisk Assessment Tables GuidanceBhargav BbvsNo ratings yet

- Erection MethodologyDocument30 pagesErection MethodologyravindraNo ratings yet

- ScaffoldingDocument16 pagesScaffoldingHSENo ratings yet

- Working On, Over, in or Near Water ProcedureDocument6 pagesWorking On, Over, in or Near Water ProcedureAly ShahNo ratings yet

- Work Method Statement For Sub Structure Works: (Pile Cap)Document9 pagesWork Method Statement For Sub Structure Works: (Pile Cap)AlbawaviNo ratings yet

- Scaffolding standards and rolesDocument20 pagesScaffolding standards and rolesMounir Boutaghane100% (1)

- Traffic Safety Management Plan (TSMP) : Karnataka Road Development Corporation LimitedDocument81 pagesTraffic Safety Management Plan (TSMP) : Karnataka Road Development Corporation LimitedShaileshRastogiNo ratings yet

- Painting, Taping, Texturing or Epoxy CoatingsDocument1 pagePainting, Taping, Texturing or Epoxy CoatingsHenryOdohNo ratings yet

- Roof 3Document24 pagesRoof 3Ahmad ZuwairisyazwanNo ratings yet

- AAFA Webinar Intertek Jan 2012 V5Document29 pagesAAFA Webinar Intertek Jan 2012 V5rabiulfNo ratings yet

- Tutorial 2 EOPDocument3 pagesTutorial 2 EOPammarNo ratings yet

- SAPGLDocument130 pagesSAPGL2414566No ratings yet

- 028 Ptrs Modul Matematik t4 Sel-96-99Document4 pages028 Ptrs Modul Matematik t4 Sel-96-99mardhiah88No ratings yet

- Midterm Exam SolutionsDocument11 pagesMidterm Exam SolutionsPatrick Browne100% (1)

- All India Corporate Photography Contest Promotes Workplace ArtDocument3 pagesAll India Corporate Photography Contest Promotes Workplace Artharish haridasNo ratings yet

- 1Z0-062 Exam Dumps With PDF and VCE Download (1-30)Document6 pages1Z0-062 Exam Dumps With PDF and VCE Download (1-30)Humberto Cordova GallegosNo ratings yet

- Feedback Mechanism InstrumentDocument2 pagesFeedback Mechanism InstrumentKing RickNo ratings yet

- ITC Report and Accounts 2016Document276 pagesITC Report and Accounts 2016Rohan SatijaNo ratings yet

- Journal of Petroleum Science and Engineering: Bin Yuan, David A. WoodDocument13 pagesJournal of Petroleum Science and Engineering: Bin Yuan, David A. Woodarash7495No ratings yet

- RAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefDocument26 pagesRAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefMardiana MardianaNo ratings yet

- Cis285 Unit 7Document62 pagesCis285 Unit 7kirat5690No ratings yet

- Questions For ReviewDocument2 pagesQuestions For ReviewJoemar JavierNo ratings yet

- F20-W21 - LP1 LP2 Instructions and Grading Rubric-STUDENT VersionDocument9 pagesF20-W21 - LP1 LP2 Instructions and Grading Rubric-STUDENT VersionjohnamenNo ratings yet

- Analysis of Financial Ratios of Manufacturing CompaniesDocument61 pagesAnalysis of Financial Ratios of Manufacturing CompaniesNine ZetNo ratings yet

- Basic Concept of Process Validation in Solid Dosage Form (Tablet) : A ReviewDocument10 pagesBasic Concept of Process Validation in Solid Dosage Form (Tablet) : A Reviewqc jawaNo ratings yet

- Applied Econometrics ModuleDocument142 pagesApplied Econometrics ModuleNeway Alem100% (1)

- RIE 2013 Dumping and AD DutiesDocument21 pagesRIE 2013 Dumping and AD Dutiessm jahedNo ratings yet

- Manual Mue Home RGBDocument8 pagesManual Mue Home RGBJason OrtizNo ratings yet

- Rubrics For Lab Report For PC1 Lab, PC2 Lab, CIC LabDocument4 pagesRubrics For Lab Report For PC1 Lab, PC2 Lab, CIC LabHunie PopNo ratings yet

- Memo in Motion For ContemptDocument118 pagesMemo in Motion For ContemptMark SternNo ratings yet

- Gustilo Vs Gustilo IIIDocument1 pageGustilo Vs Gustilo IIIMoon BeamsNo ratings yet

- CV of Prof. D.C. PanigrahiDocument21 pagesCV of Prof. D.C. PanigrahiAbhishek MauryaNo ratings yet

- BR18 Mechanical Engineering Robotics Semester VIDocument2 pagesBR18 Mechanical Engineering Robotics Semester VIPRAVEeNo ratings yet