Professional Documents

Culture Documents

Variable Refrigerant Flow

Uploaded by

Rohitash NitharwalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Variable Refrigerant Flow

Uploaded by

Rohitash NitharwalCopyright:

Available Formats

Variable Refrigerant Flow

Variable refrigerant flow (VRF) is an HVAC technology invented in Japan by Daikin company

in 1982. Like ductless minisplits VRFs use refrigerant as the cooling and heating medium. This

refrigerant is conditioned by a single outdoor condensing unit, and is circulated within the

building to multiple fan-coil units (FCUs).

VRFs are typically installed with an Air conditioner inverter which adds a DC inverter to the

compressor in order to support variable motor speed and thus variable refrigerant flow rather

than simply on/off operation. By operating at varying speeds, VRF units work only at the needed

rate allowing for substantial energy savings at partial-load conditions. Heat recovery VRF

technology allows individual indoor units to heat or cool as required, while the compressor load

benefits from the internal heat recovery. Energy savings of up to 55% are predicted over

comparable unitary equipment.This also results in greater control of the building's interior

temperature by the building's occupants.

VRFs come in two system formats, two pipe and three pipe systems. In a 2 pipe system all of the

zones must either be all in cooling or all in heating. A three pipe Heat Recovery (HR) systems

has the ability to simultaneously heat certain zones while cooling others. In this case the heat

extracted from zones requiring cooling is put to use in the zones requiring heating. This is made

possible because the heating unit is functioning as a condenser, providing sub-cooled liquid back

into the line that is being used for cooling. While the 3 pipe system has a greater initial cost, it

allows for better zoned thermal control of a building and overall greater efficiencies.

Benefits of VRF

Installation Advantages. Chillers often require cranes for installation, but VRF systems

are lightweight and modular. Each module can be transported easily and fits into a

standard elevator. Multiples of these modules can be used to achieve cooling capacities of

hundreds of tons. Each module (or set of two) is an independent refrigerant loop, but they

are controlled by a common control system. The modularity also enables staged, floor-

by-floor installations, for example, if a building is only partly occupied, which is similar

to currently available self-contained VAV systems. The relatively light weight of the

system also may reduce requirements for structural reinforcement of roofs. Because

ductwork is required only for the ventilation system, it can be smaller than the ducting in

standard ducted systems, reducing building height and costs.

Design Flexibility. A single condensing unit can be connected to many indoor units of

varying capacity (e.g., 0.5 to 4 tons [1.75 to 14 kW]) and configurations (e.g., ceiling

recessed, wall-mounted, floor console). Current products enable up to 20 indoor units to

be supplied by a single condensing unit. Modularity also makes it easy to adapt the

HVAC system to expansion or reconfiguration of the space, which may require additional

capacity or different terminal units.

Maintenance and Commissioning. VRF systems with their standardized configurations

and sophisticated electronic controls are aiming toward near plug-and-play

commissioning. Because they are DX systems, maintenance costs for a VRF should be

lower than for water-cooled chillers, so water treatment issues are avoided. Normal

maintenance for a VRF, similar to that of any DX system, consists mainly of changing

filters and cleaning coils. However, chillers, which often operate for 20 to 30 years,

normally would be anticipated to have a longer life expectancy than a DX system such as

a VRF.2 The large number of compressors in a VRF may create a higher probability of

compressor failure, although the redundancy also leads, in many cases, to a greater ability

to continue to occupy the space while repairs are made.

Comfort. Many zones are possible, each with individual setpoint control. Because VRF

systems use variable speed compressors with wide capacity modulation capabilities, they

can maintain precise temperature control, generally within 1F (0.6C), according to

manufacturers literature.

Energy Efficiency. The energy efficiency of VRF systems derives from several factors.

The VRF essentially eliminates duct losses, which are often estimated to be between 10%

to 20% of total airflow in a ducted system.3VRF systems typically include two to three

compressors, one of which is variable speed, in each condensing unit, enabling wide

capacity modulation. This approach yields high part-load efficiency, which translates into

high seasonal energy efficiency, because HVAC systems typically spend most of their

operating hours in the range of 40% to 80% of maximum capacity.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm A319.370238-1Document2 pagesAstm A319.370238-1Fabio Augusto Hincapie Henao100% (1)

- FAG Rolling Bearing LubricationDocument69 pagesFAG Rolling Bearing LubricationSam ChengNo ratings yet

- Cti-Std 154 - FRP PipesDocument12 pagesCti-Std 154 - FRP PipesNilesh Kitey100% (2)

- ASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteDocument5 pagesASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteOmid DeldarNo ratings yet

- Variable Frequency Drive Basics and Benefits for HVAC ApplicationsDocument3 pagesVariable Frequency Drive Basics and Benefits for HVAC ApplicationsRohitash NitharwalNo ratings yet

- Variable Frequency Drive Basics and Benefits for HVAC ApplicationsDocument3 pagesVariable Frequency Drive Basics and Benefits for HVAC ApplicationsRohitash NitharwalNo ratings yet

- Noise in Ventilation Ducts Sound in DuctsDocument8 pagesNoise in Ventilation Ducts Sound in DuctsRohitash NitharwalNo ratings yet

- Simulated AnnealingDocument7 pagesSimulated AnnealingRohitash NitharwalNo ratings yet

- Eer, Cop, Seer & Energy StarDocument11 pagesEer, Cop, Seer & Energy StarRohitash NitharwalNo ratings yet

- Jurnal ItayoDocument5 pagesJurnal ItayoFlorence Brenda PoppyNo ratings yet

- 491-80044934 A4-P 1.0 enDocument49 pages491-80044934 A4-P 1.0 enAtiq Ur RehmanNo ratings yet

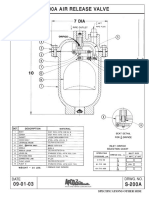

- APCO. S-200a Air Release ValveDocument2 pagesAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- Condenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToDocument37 pagesCondenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToAliceNo ratings yet

- Practice problems-STEELDocument14 pagesPractice problems-STEELreanNo ratings yet

- 5 6138727946501751075Document3 pages5 6138727946501751075Xkarr RastaNo ratings yet

- Wood ArmerDocument14 pagesWood ArmerMarek100% (1)

- Materi Teknologi PolimerDocument56 pagesMateri Teknologi PolimerMeysa DwiNo ratings yet

- 9.9 Diaphragms-With-Interior-Shearwalls PDFDocument4 pages9.9 Diaphragms-With-Interior-Shearwalls PDFnickNo ratings yet

- Rupture DiscDocument2 pagesRupture Discbigs1303No ratings yet

- SS621 TUV Testing Report (Full Permission)Document5 pagesSS621 TUV Testing Report (Full Permission)Christiano RodriguezNo ratings yet

- Material PTFE PT009807: Technical Data Sheet in Accordance With ASTMDocument2 pagesMaterial PTFE PT009807: Technical Data Sheet in Accordance With ASTMCAT CYLINDERNo ratings yet

- Catalogue Fan Coil Unit Fudfwcfwwfwefwk PDFDocument17 pagesCatalogue Fan Coil Unit Fudfwcfwwfwefwk PDFMinh Nhut LuuNo ratings yet

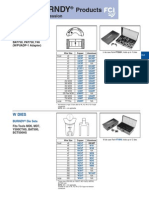

- U DiesDocument1 pageU DiesadrianNo ratings yet

- Flux Skimming PDFDocument6 pagesFlux Skimming PDFpbp2956No ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- KK 225 PDFDocument1 pageKK 225 PDFVladimir Illich PinzonNo ratings yet

- Enau Polyla (FDM Filament) : Problem StatementDocument1 pageEnau Polyla (FDM Filament) : Problem Statementhakim nasirNo ratings yet

- MEN 321 Chapter 9 Flow Over Immersed BodiesDocument81 pagesMEN 321 Chapter 9 Flow Over Immersed BodiesGeo AyoubNo ratings yet

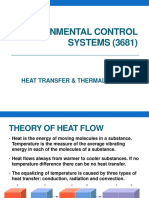

- ENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3Document73 pagesENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3shariq talatNo ratings yet

- DESIGN OF PRESSURE VESSEL Full Report DEDocument48 pagesDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- Project Report Group 4Document28 pagesProject Report Group 4Akame TakashitaNo ratings yet

- RFP-EAH-2016-008 - Section V - Annex C - Technical SpecificationsDocument147 pagesRFP-EAH-2016-008 - Section V - Annex C - Technical SpecificationsKhlif NadaNo ratings yet

- Architextures - Barrisol Stretch Ceilings SpecDocument4 pagesArchitextures - Barrisol Stretch Ceilings SpecMohammed Abdul BaseerNo ratings yet

- Beep 2 CdevDocument1,241 pagesBeep 2 CdevIzio SilvaNo ratings yet

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaNo ratings yet