Professional Documents

Culture Documents

Using Silicone Impression Material and Acrylic Resin To Fabricate Remount Casts For Removable Partial Dentures PDF

Uploaded by

Eddy Mazariegos0 ratings0% found this document useful (0 votes)

35 views5 pagesA technique is described for fabrication of a remount cast for a removable partial denture. It consists of filling the occlusal / incisal thirdwithacrylic resinandinjecting polyvinylsiloxane impression material into the irreversible hydrocolloid impression.

Original Description:

Original Title

Using Silicone Impression Material and Acrylic Resin to Fabricate Remount Casts for Removable Partial Dentures.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA technique is described for fabrication of a remount cast for a removable partial denture. It consists of filling the occlusal / incisal thirdwithacrylic resinandinjecting polyvinylsiloxane impression material into the irreversible hydrocolloid impression.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views5 pagesUsing Silicone Impression Material and Acrylic Resin To Fabricate Remount Casts For Removable Partial Dentures PDF

Uploaded by

Eddy MazariegosA technique is described for fabrication of a remount cast for a removable partial denture. It consists of filling the occlusal / incisal thirdwithacrylic resinandinjecting polyvinylsiloxane impression material into the irreversible hydrocolloid impression.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

TECHNIQUES AND TECHNOLOGIES

Using Silicone Impression Material and Acrylic

Resin to Fabricate Remount Casts

for Removable Partial Dentures

Yung-tsung Hsu, DDS, MS

1

and John B. Farmer, DMD

2

A technique is described for fabrication of a remount cast for a removable partial denture. This

procedure consists of lling the occlusal/incisal thirdwithacrylic resinandinjecting polyvinylsiloxane

impression material into the irreversible hydrocolloid impression. This technique provides a simple

method for making a remount cast and enables the clinician to remove and easily place the partial

denture on the cast during occlusal renement procedures without damage to the removable partial

denture or the remount cast.

J Prosthodont 2005;14:137-140. Copyright C

2005 by The American College of Prosthodontists.

INDEX WORDS: occlusion, adjustment, insertion, articulation, delivery

O

CCLUSAL DISCREPANCIES of removable

prostheses can be easily detected and correc-

ted when the prostheses are accurately mounted

on an articulator.

1

These discrepancies may arise

from treatment procedures, such as errors in oc-

clusal registration and relining of a removable

partial denture, or from material properties, such

as polymerization shrinkage of the acrylic resin.

For a removable partial denture with an acrylic

resin base, the greatest dimensional change oc-

curs when a processed prosthesis is removed from

the master casts.

1

The occlusal relationship after

processing may therefore be different from the

relationship previously developed. It is important

to re-evaluate the occlusion after the dentures

have been processed.

Initial correction of occlusal discrepancies on

the articulator should be performed prior to the

retrieval of the prosthesis from the casts. The

1

Assistant Professor, Department of Prosthodontics and Biomateri-

als, The University of Alabama at Birmingham School of Dentistry,

Birmingham, Alabama.

2

Associate Professor, Department of Prosthodontics and Biomateri-

als, The University of Alabama at Birmingham School of Dentistry,

Birmingham, Alabama.

Accepted July 22, 2004.

Correspondence to: Yung-tsung Hsu, 522A School of Dentistry

Building, 1919, 7th Avenue South, Birmingham, AL 35294-0007.

E-mail: ythsu@uab.edu

Copyright C 2005 by The American College of Prosthodontists

1059-941X/05

doi: 10.1111/j.1532-849X.2005.00013.x

original casts may be broken when retrieving the

prosthesis, especially with removable partial den-

tures. To remount the prosthesis, a remount cast

must be made. For a complete denture, this cast

can be made by blocking out the undercut of the

denture and pouring plaster or stone into the in-

taglio surface, or by using a silicone-type material

to ll the entire intaglio surface.

2

Remount casts

for removable partial dentures must include any

remaining natural teeth or restorations and the

prosthesis. Of the techniques described in the

literature, making an impression of the partial

denture and the remaining teeth simultaneously

is the most frequently reported technique. The

teeth mold in the impression can be lled with

stone,

3-5

metal alloy,

6

or silicone-type impression

material.

7

When the teeth mold is lled with

stone, the stone teeth may be broken upon the

removal of the prosthesis, or the prosthesis may

be locked in by the stone. To prevent the possible

lock inof the prosthesis, certaincomponents of the

partial denture, such as clasps or undercuts of the

denture base, must be blocked out before pouring

the stone. The blockout can be done with wax,

5

but

the disadvantages of using wax include weakening

of the abutment teeth on the cast due to decreased

stone thickness and distortion of the morphology

of the teeth by the wax. Using metal alloy requires

special materials and devices, and the prosthesis

may still be locked in the cast if there is not ade-

quate block out. Another technique is the use of

polyvinylsiloxane registration material to ll the

Journal of Prosthodontics, Vol 14, No 2 ( June), 2005: pp 137-140 137

138 Fabricating Remount Casts for Removable Partial Dentures

r

Hsu and Farmer

teeth mold in the alginate impression.

7

The main

concern of this technique is that the resiliency of

silicone teeth on the cast may not be stiff enough

for evaluation of occlusal contact or stops during

the occlusal adjustment on the articulator. This

article presents a simplied technique for making

a remount cast for the removable partial denture

using dental stone, acrylic resin, and silicone im-

pression material.

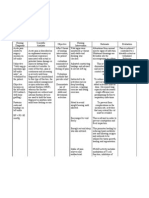

Procedure

1. Place the removable partial denture in the

mouth, and ensure that it is fully seated. Make

a facebow transfer if no mounted maxillary

cast or remount index is available.

2. Load irreversible hydrocolloid (alginate) in

an appropriate size stock tray and make an

impression of the removable partial denture

and remaining teeth.

3. After the alginate has set, remove the im-

pression. If the prosthesis does not remain in

the impression upon removal, trim the algi-

nate and carefully reinsert it into the impres-

sion. Ensure the prosthesis is passively seated

(Fig 1).

4. Mix the autopolymerizing acrylic resin

(Duralay, Reliance Dental, Worth, IL) and

ll in the occlusal or incisal 1/3 of the teeth

mold. Keep the acrylic resin away from any

partial denture components. Insert dowel pins

(Knurled dowel pin, Sterngold, Attleboro,

Figure 1. Alginate impression with inserted removable

partial denture.

Figure 2. Fill the incisal 1/3 of the alginate teeth mold

with acrylic resin. Insert dowel pins before the acrylic

polymerizes.

MA) into the acrylic resin before the resin

polymerizes (Fig 2).

5. Inject low-viscosity polyvinylsiloxane (PVS)

impression material (Aquasil LV, Dentsply

International, Inc., Milford, DE) into the rest

seat area of the teeth mold in the alginate

impression up to the gingival level (Fig 3).

6. If there are any undercuts on the intaglio

surface of the denture base, block them

out with the PVS impression material. Cre-

ate irregularities on the poured silicone ma-

terials prior to set, for mechanical reten-

tion between the stone and PVS impression

material.

Figure 3. Inject PVS impression material into the rest

part of the teeth mold.

June 2005, Volume 14, Number 2 139

Figure 4. Fill the gap betweenthe denture and alginate

impression material with PVS impression material.

Figure 5. Remount cast, occlusal view.

7. If the alginate does not cover the entire par-

tial denture while making the impression, ll

any gaps or deciencies with PVS impression

material (Fig 4).

8. After the PVS has set, pour the remainder of

the alginate impression with fast-set plaster

or type III dental stone.

9. Retrievethecast fromthealginateimpression

after the stone has set (Figs 5 and 6).

10. Articulate the remount cast to the opposing

cast using an interocclusal record.

Discussion

Remounting the fabricated removable prosthesis

onthe articulator not only allows accurate occlusal

adjustment, but also offers the clinician an un-

obstructed view of the articulation. Occlusal dis-

Figure 6. Remount cast, front view.

crepancies can be more accurately detected on the

articulator rather thaninthe mouth, especially for

tissue borne removable partial dentures.

This technique describes a simplied proce-

dure to prevent the denture from locking in the

stone remount cast. It also prevents the breaking

of the cast abutment teethwhenremoving the par-

tial denture. Additionally, this technique creates

appropriately rigidocclusal andincisal surfaces for

evaluation of occlusal contacts as the equilibra-

tion proceeds on the remounted prosthesis. Use

of the low viscosity polyvinylsiloxane impression

material will result in a better t while injecting

the material into the teeth mold. If the acrylic

resin or PVS impression material ows over the

metal components, such as the indirect retainer

or occlusal rest, it can be trimmed by a sharp

instrument after the remount cast is made. This

technique can also be used for partial denture

repairs or prosthetic tooth replacement. By using

the resilient silicone impression material around

the precision components of the removable partial

denture, the denture can be easily removed from

the cast without any distortion. The cast will not

deform during the occlusal adjustment on the

articulator because of the acrylic resin on the oc-

cluding surfaces and the dental stone supporting

the majority of the prosthesis.

Summary

A procedure for the fabrication of a removable

partial denture remount cast has been described.

This simple technique achieves a cast for the

accurate placement and removal of the partial

140 Fabricating Remount Casts for Removable Partial Dentures

r

Hsu and Farmer

denture without breaking the cast or distorting

the prosthesis. This is achieved through the use

of acrylic resin, resilient silicone impression ma-

terial, and conventional dental stone.

References

1. ZarbGA, Bolender CL, Eckert SE: Prosthodontic Treatment

for Edentulous Patients: Complete Dentures and Implant-

Supported Prostheses (ed 12). St. Louis, MO, Mosby, 2004,

pp 404-405

2. Ansari IH: A procedure for making remount casts without

blocking out undercuts. J Prosthet Dent 1993;70:482

3. Ulmer FC, Ward JE: Simplied technique for production

of a distal-extension removable partial denture remounting

cast. J Prosthet Dent 1979;41:473-474

4. Lauciello FR: Technique for remounting removable partial

dentures opposing maxillary complete dentures. J Prosthet

Dent 1981;45:336-340

5. McGivney GP, Carr AB: McCrackens Removable Partial

Prosthodontics (ed 10). St. Louis, MO, CV Mosby, 2000, pp

422-424

6. Kratochvil FJ: Partial Removable Prosthodontics. Philadel-

phia, PA, Saunders, 1988, pp 157-163

7. Billy EJ, Shotwell J: Combination stone and resilient mate-

rial for removable partial denture remount cast described

and compared with two other remount cast procedures.

J Prosthet Dent 1994;71:417-419

You might also like

- Use of Contact Testing in The Characterization and Design of All-Ceramic Crownlike Layer Structures - A ReviewDocument16 pagesUse of Contact Testing in The Characterization and Design of All-Ceramic Crownlike Layer Structures - A ReviewEddy MazariegosNo ratings yet

- Cosmetic Klaff PDFDocument11 pagesCosmetic Klaff PDFEddy MazariegosNo ratings yet

- Tecnica Sandiwch PDFDocument10 pagesTecnica Sandiwch PDFEddy MazariegosNo ratings yet

- Photographs TipsDocument1 pagePhotographs TipsEddy MazariegosNo ratings yet

- The Independent Funciont of The Two Heads of The Lateral Pterygoid Muscle PDFDocument9 pagesThe Independent Funciont of The Two Heads of The Lateral Pterygoid Muscle PDFEddy MazariegosNo ratings yet

- The Importance of Width and Length Ratios in Anterior Pemanent Dentition PDFDocument11 pagesThe Importance of Width and Length Ratios in Anterior Pemanent Dentition PDFEddy Mazariegos100% (1)

- Smile With Balance PDFDocument9 pagesSmile With Balance PDFEddy MazariegosNo ratings yet

- Natural Head Position in Standing Subjects PDFDocument17 pagesNatural Head Position in Standing Subjects PDFEddy MazariegosNo ratings yet

- Load Fatigue of Teeth Restored With Cast Posts and Crowns Affected by Ferrule LengthDocument8 pagesLoad Fatigue of Teeth Restored With Cast Posts and Crowns Affected by Ferrule LengthEddy Mazariegos100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Complete VaccinationDocument2 pagesComplete VaccinationNgoo NwosuNo ratings yet

- 1866 PSC Iasc Ref Guidance t2 DigitalDocument11 pages1866 PSC Iasc Ref Guidance t2 DigitalDama BothNo ratings yet

- Confidence Intervals For Ratio of Two Poisson Rates Using The Method of Variance Estimates RecoveryDocument23 pagesConfidence Intervals For Ratio of Two Poisson Rates Using The Method of Variance Estimates RecoveryJaneNo ratings yet

- Lester Desjarlais Inquest Parts I and IIDocument108 pagesLester Desjarlais Inquest Parts I and IIJames Turner100% (1)

- 100-Bed General Hospital LayoutDocument1 page100-Bed General Hospital LayoutAshish chauhanNo ratings yet

- Storage Tanks Selection and Sizing: Richardhaw@sympatico - CaDocument50 pagesStorage Tanks Selection and Sizing: Richardhaw@sympatico - CamanojjuvaliNo ratings yet

- Reiki Tummo Brochure 2013Document2 pagesReiki Tummo Brochure 2013Alicia TerryNo ratings yet

- Pricelist Aleena Skin Clinic KendariDocument2 pagesPricelist Aleena Skin Clinic Kendariwildan acalipha wilkensiaNo ratings yet

- Oferta Hexis - Multisign: Preturile Sunt in EURO Si Nu Includ TVADocument9 pagesOferta Hexis - Multisign: Preturile Sunt in EURO Si Nu Includ TVAPoschina CiprianNo ratings yet

- Process Design For 1.70 IFAS STPDocument18 pagesProcess Design For 1.70 IFAS STPGenesis International0% (1)

- The Precious Little Black Book DownloadDocument226 pagesThe Precious Little Black Book DownloadAsanda YekiNo ratings yet

- hdf492 Portfolio PresentationDocument14 pageshdf492 Portfolio Presentationapi-403412647No ratings yet

- 3D Printing Technology in Drug Delivery: Recent Progress and ApplicationDocument10 pages3D Printing Technology in Drug Delivery: Recent Progress and ApplicationAngela DelarmenteNo ratings yet

- Complaints Handling: BDA AdviceDocument8 pagesComplaints Handling: BDA Advicedruzair007No ratings yet

- NCP - Acute Pain - FractureDocument1 pageNCP - Acute Pain - Fracturemawel73% (22)

- Function: What Is The Skeletal System?Document6 pagesFunction: What Is The Skeletal System?Mr. Christian ParabuacNo ratings yet

- 4020 Assessment 4 Instructions - Improvement Plan Tool Kit - ..Document4 pages4020 Assessment 4 Instructions - Improvement Plan Tool Kit - ..Sabahat BashirNo ratings yet

- VetcareDocument18 pagesVetcareMy binNo ratings yet

- Idiopathic Thrombocytopenic PurpuraDocument3 pagesIdiopathic Thrombocytopenic Purpuraproxytia64No ratings yet

- 11 - Comfort, Rest and Sleep Copy 6Document28 pages11 - Comfort, Rest and Sleep Copy 6Abdallah AlasalNo ratings yet

- Incident Reports 2017-2019Document8 pagesIncident Reports 2017-2019Buddzilla FranciscoNo ratings yet

- K55 MSDSDocument7 pagesK55 MSDSalocNo ratings yet

- Debat ProDocument3 pagesDebat ProVony CantikaNo ratings yet

- Heart Failure Lily ModifiedDocument57 pagesHeart Failure Lily ModifiedSabila FatimahNo ratings yet

- Hse in Drilling OperationsDocument13 pagesHse in Drilling OperationsSamad Ali Siddiqui100% (2)

- Per. Dev. (Bin-Bin)Document21 pagesPer. Dev. (Bin-Bin)Jayric BanagyoNo ratings yet

- Letter of Intent Paternity LeaveDocument2 pagesLetter of Intent Paternity LeaveFloryen Daprosa100% (1)

- Behavorial Methods IIDocument18 pagesBehavorial Methods IImehak727No ratings yet

- Insert - Elecsys Anti-HAV IgM.07026773500.V5.EnDocument4 pagesInsert - Elecsys Anti-HAV IgM.07026773500.V5.EnVegha NedyaNo ratings yet

- TULUA Lipoabdominoplasty Transversal Aponeurotic.12Document14 pagesTULUA Lipoabdominoplasty Transversal Aponeurotic.12Carolina Ormaza Giraldo100% (1)