Professional Documents

Culture Documents

Earth Leakage Relays ELRM44V30-2-A

Uploaded by

Brian BurchOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earth Leakage Relays ELRM44V30-2-A

Uploaded by

Brian BurchCopyright:

Available Formats

Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN.

England

Telephone: +44 (0) 1902 773746 Facsimile: +44 (0) 1902 420639 Email: sales@broycecontrol.com Web: http://www.broycecontrol.com

The information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the users own risk.

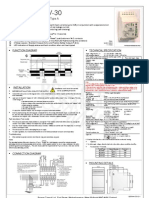

ELRM44V30-2-A

CONNECTION DIAGRAM

14

t

e

s

t

1

8

2 3 4 5 6 7

9 10 11 12 13

5

0

m

*

m

a

x

.

The Earth MUST NOT pass through

the C.T. For single phase applications,

only the live and neutral need to be

passed through the C.T.

*Cabling:

For distances >1m, use twisted pair

cable between the unit and C.T.

Both relays are

shown in the

de-energised state

(i.e. where power is

not present on the

supply terminals)

0

115V* AC Only

12 - 125V DC

24V AC

400V AC

230V* AC

*Dual voltage only available

as 115V/230V AC.

For 115V, connect across

terminals 6 and 7

For all other voltages,

connect across

terminals 5 and 7.

C.T.

50m* max.

E

L1

L2

L3

N

E

r

e

s

e

t

standard

output

positive

safety

output

A1 (+ve)

A3

A2 (-ve)

.

Type: ELRM44V-30

Earth Leakage Relay (Variable) - Type A

q 44mm (2.5 modules) wide DIN rail housing

q Designed to monitor and detect true RMS earth fault currents (up to 30A) in conjunction with a separate toroid

q LED bargraph provides constant indication of any leakage current

q Microprocessor controlled with internal monitoring (self-checking)

q Adjustable Sensitivity (In) - 30mA to 30A

q Adjustable Time Delay (t) - 0 (instantaneous)* to 10 seconds

q Separate Test and Reset push buttons

q Connection facility for remote Test and Reset push buttons or N.O. contacts

q Toroid open circuit detection forces unit to trip (Red LED flashes during this condition)

q 2 Relay outputs - Standard Output (S.O.) and Positive Safety Output (P.S.O.)

q LED indication of Supply status and fault condition after unit has tripped

TECHNICAL SPECIFICATION

Supply voltage Un (5, 6, 7): 12 - 125V DC (85 - 110% of U)

(see connection diagram) 24, 115/230, 400V AC (85 - 115% of Un)

All AC supplies are galvanically isolated between the supply and the

toroid and remote test/reset connections.

Frequency range: 50/60/400Hz (AC supplies)

Isolation: Over voltage cat. III

Rated impulse withstand voltage: 800V (24V AC supplies ), 2.5kV (115V AC supplies)

(1.2 / 50S) IEC 60664 4kV (230V, 400V AC supplies)

Power consumption (max.): 6VA (AC supplies) 5W (DC supplies)

Monitored leakage current: 0 to 30A (15 - 400Hz) (through external toroid with 1000:1 ratio

and connected to terminals 8 and 9)

Sensitivity In (see Accessories) 30, 100, 300, 500mA, 1, 3, 5, 10, 20, 30A (user selectable)

Trip level limits: 80 - 90% of In

Reset Value: 85% of tripped level

Time delay t: 0*, 60, 150, 250, 500, 800mS, 1, 2.5, 5, 10 sec. (user selectable)

*Actual delay for 0 or Instantaneous is <25mS when fault current @ 5 x In.

Reset time: 2S (from supply interruption)

LED indication:

Power supply present: Green

Bargraph: Green x 3 (25, 50 and 75% of actual trip level)

Tripped: Red (see INSTALLATION to the left)

Memory: storage of the leakage fault and reset with the Reset push button

Ambient temp: -20 to +55C (-5 to +40C in accordance with IEC 60755)

Relative humidity: +95%

Output : 1 x SPNO, 1 x SPDT relays

Output rating: S.O. (12, 13, 14) P.S.O. (10, 11)

AC1 (250V) 8A (2000VA) 6A (1500VA)

AC15 (250V) 2.5A 4A

DC1 (25V) 8A (200W) 6A (150W)

Electrical life: 150,000 ops at rated load

Dielectric voltage: 2kV AC (rms) IEC 60947-1

Rated impulse withstand voltage: 4kV (1.2 / 50S) IEC 60664

Remote Test / Reset (1, 2, 3) Requires N.O. contacts. (i.e. push buttons)

Minimum trigger time: >80mS (Actual trigger time = 80mS + t setting for remote test)

Housing: Grey flame retardant Lexan UL94 VO

Weight: 190g (AC power supplies) 110g (DC power supply)

Mounting option: On to 35mm symmetric DIN rail to BS5584:1978

(EN50 002, DIN 46277-3)

Terminal conductor size: 2.5mm

2

stranded, 4mm

2

solid

Approvals: Conforms to: IEC60755, 60947, 62020, 61543.

IEC 61000-4-2, -3, -4, -5 , -6, -12 and -16. CISPR 22.

CEand Compliant.

( ) Numbers in brackets shown above refer to terminal numbers on the relay housing.

Options

1. For other supply voltages, alternative trip levels or time delays, please consult the sales office.

Accessories Toroids

Toroid Type: Internal diameter: In (min.) A

BZCT035 35mm 0.03

BZCT070 70mm 0.03

BZCT120 120mm 0.1

BZCT210 210mm 0.3

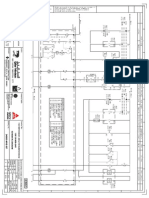

FUNCTION DIAGRAM

Standard

output

fault

current

failure of connection

to toroid

"Reset"

button

pressed

"Test"

button

pressed

supply

interrupted

Trip level (I n)

Positive safety

output

t

Reset level

INSTALLATION

BEFORE INSTALLATION, ISOLATE THE SUPPLY.

Connect the unit as shown in the diagram below (N.B. certain features may not be required and therefore do not need

to be connected).

Apply power, the green supply on LED will illuminate and the positive safety output relay will energise. The relay

will de-energise if:

a, the fault current level exceeds the set trip level (In) **

b, there is a failure of the connection between the relay and the toroid ** (Note the red tripped LED

will flash during this condition)

c, the supply to the unit is removed

d, the relay fails internally

** causes the standard output relay to energise in response to the fault condition.

Prior to a fault occurring, the LED bargraph will indicate the % of In being detected (the display is scaled between 25,

50, and 75% of the actual trip level). After all 3 LED's have illuminated and the unit trips due to an excessive fault

current, the red tripped LED will illuminate. The unit will now remain in a latched condition.

Fault simulation (Test mode)

The unit can be placed into a fault condition by pressing the Test button on the front of the unit (or by pressing the

remote Test button - if fitted). The output relays operate accordingly.

Press the Reset button on the front of the unit (or remotely - if fitted) to reset the unit. The output relays revert back

to their non-tripped state.

The unit can also be reset by interrupting the power supply.

To satisfy regulations, it is recommended that the device be tested periodically to ensure correct operation.

Troubleshooting

If the unit fails to operate correctly check that all wiring and connections are good.

Note:

The operating function of this unit is classed as a Type A for which tripping is ensured for residual sinusoidal

alternating currents and residual pulsating direct currents, whether applied suddenly or slowly rising. Additionally, this unit is

protected against nuisance tripping . This unit will also satisfy the requirements for Type AC devices which only need to

detect residual alternating currents.

This unit should be installed in conjunction with the latest wiring regulations and practices (IEE, etc).

MOUNTING DETAILS

63.5mm

4

5

m

m

6

1

m

m

8

5

m

m

49.5mm

30mm

44mm

Installation work must be carried

out by qualified personnel.

Please state Supply voltage

when ordering.

Note:

1. For In setting of 30mA, the time delay is fixed to 0 (instantaneous) and is not adjustable (i.e. any

other time delay cannot be selected when 30mA is set).

2. The unit is factory set to 30mA trip and instantaneous delay. Adjustment of these settings can be

made if necessary to suit the requirements of the installation. A seal is supplied allowing the user to

secure the clear window and hence prevent any unnecessary adjustment of the settings.

Dims:

to DIN 43880

W. 44mm

Terminal Protection to IP20

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 250T Frequency TransmitterDocument13 pages250T Frequency Transmitterreality88No ratings yet

- DevOps training resources and tutorialsDocument6 pagesDevOps training resources and tutorialsKiran Wadeyar100% (3)

- Essbase OptimizationDocument17 pagesEssbase Optimizationaloo sharmaNo ratings yet

- Relay TestingDocument39 pagesRelay Testingmuchinda67% (6)

- LG 60PN6500Document34 pagesLG 60PN6500Luis SantosNo ratings yet

- ALSTOM Instntneous Voltage Relay VAGM HighResDocument4 pagesALSTOM Instntneous Voltage Relay VAGM HighResMorgan Brooks0% (1)

- SR-50S - W (Cont. Climare) Manual de Peças TK 51281-0.0Document57 pagesSR-50S - W (Cont. Climare) Manual de Peças TK 51281-0.0Электроника Eletroeletrônica100% (1)

- TM Functional Safety 07 2011 enDocument229 pagesTM Functional Safety 07 2011 enWaldemarNo ratings yet

- Cubase 6 Manual Español e Inglés PDFDocument117 pagesCubase 6 Manual Español e Inglés PDFJorge William Rueda CanoNo ratings yet

- JTAG Explained (Finally!) - Why - IoT - Makers, Software Security Folks, and Device Manufacturers Should Care - SenrioDocument42 pagesJTAG Explained (Finally!) - Why - IoT - Makers, Software Security Folks, and Device Manufacturers Should Care - SenrioRonaldMartinez100% (1)

- Crompton Protector 250Document33 pagesCrompton Protector 250jishyNo ratings yet

- A Isometer IR475LYDocument3 pagesA Isometer IR475LYUrsula JohnsonNo ratings yet

- Earth Leakage Relays Elrm44v-1-ADocument1 pageEarth Leakage Relays Elrm44v-1-Aapi-230026640No ratings yet

- Earth Leakage Relays ELRM44V30-2-ADocument1 pageEarth Leakage Relays ELRM44V30-2-Akalesh005No ratings yet

- Earth Leakage Relays ELRV30-2-A RMS PDFDocument2 pagesEarth Leakage Relays ELRV30-2-A RMS PDFDEADMANNo ratings yet

- ZEN-PA03024: Model Number StructureDocument8 pagesZEN-PA03024: Model Number Structuregustaf parlindunganNo ratings yet

- Model Ut51-55: Operating ManualDocument20 pagesModel Ut51-55: Operating ManualAdv Faizan GorayaNo ratings yet

- Control RelaysDocument21 pagesControl RelaysarifzakirNo ratings yet

- LA 76931S 7N DatasheetDocument20 pagesLA 76931S 7N DatasheetjulioescandonNo ratings yet

- Service Manual: Model: - SZ2 MONO SeriesDocument20 pagesService Manual: Model: - SZ2 MONO SeriesHamza AbbasiNo ratings yet

- Power Meter E51C2Document29 pagesPower Meter E51C2atereñoneNo ratings yet

- PT-76 Series Temperature Controller Operation Manual - B0Document2 pagesPT-76 Series Temperature Controller Operation Manual - B0jowegNo ratings yet

- CA3059, CA3079: Description FeaturesDocument12 pagesCA3059, CA3079: Description FeaturesMiltongrimi GrimilNo ratings yet

- DAEWOO (T011-21") : Colour Television Service ManualDocument19 pagesDAEWOO (T011-21") : Colour Television Service ManualFidel ArroyoNo ratings yet

- Primary Current InjectorDocument2 pagesPrimary Current Injector021804No ratings yet

- Hanyoung Ax Serie Instruction Manual Eng PDFDocument4 pagesHanyoung Ax Serie Instruction Manual Eng PDFMorita HdzNo ratings yet

- Inst Ext GB Asm-01 UDocument2 pagesInst Ext GB Asm-01 UabdiNo ratings yet

- Em306a User ManualDocument2 pagesEm306a User ManualNguyễnĐìnhDầnNo ratings yet

- Compaq Monitor CPQ Fs7550-V7550Document32 pagesCompaq Monitor CPQ Fs7550-V7550KathafiNo ratings yet

- Dvpes2 ManualDocument10 pagesDvpes2 Manualmarie1320No ratings yet

- 4003 ManualDocument24 pages4003 ManualBanduka MiladinNo ratings yet

- Installation Manual for Model 440 & 450 Electronic Vibration SwitchesDocument18 pagesInstallation Manual for Model 440 & 450 Electronic Vibration SwitchesMichael JordanNo ratings yet

- 700W1000W User ManualDocument19 pages700W1000W User Manualvanhuong87No ratings yet

- Iu.e5.116.0 XCSW240Document2 pagesIu.e5.116.0 XCSW240FolpoNo ratings yet

- KLC 1508us1521usDocument17 pagesKLC 1508us1521usalbertec51No ratings yet

- Panasonic TC 15lt1 SMDocument127 pagesPanasonic TC 15lt1 SMDaniboy1994No ratings yet

- .J N I - .J N - P U1 0 S : 0Document15 pages.J N I - .J N - P U1 0 S : 0Montse TovarNo ratings yet

- Kew Snap: Instruction ManualDocument24 pagesKew Snap: Instruction ManualClaudio CostaNo ratings yet

- Plasma TV: Service ManualDocument48 pagesPlasma TV: Service ManualSuperlano JoséNo ratings yet

- DVP Slim Digital I/O Extension Instruction SheetDocument2 pagesDVP Slim Digital I/O Extension Instruction SheetBustamante PerroneNo ratings yet

- Data Sheet STK672Document21 pagesData Sheet STK672Mario Karma LeivaNo ratings yet

- Measuring Multimeter's Features and SpecificationsDocument20 pagesMeasuring Multimeter's Features and SpecificationsNicoara Stoica Paul FlorinNo ratings yet

- DRC-24V30W1A Technical DatasheetDocument11 pagesDRC-24V30W1A Technical Datasheetzivko13No ratings yet

- La 42102Document8 pagesLa 42102buyadiNo ratings yet

- EARTH LEAKAGE RELAYS & CORE BALANCE CTsDocument2 pagesEARTH LEAKAGE RELAYS & CORE BALANCE CTsDEADMANNo ratings yet

- Plasma TV: Service ManualDocument35 pagesPlasma TV: Service ManualjohnnysNo ratings yet

- Selectable AC Power and Reactive Power TransducerDocument4 pagesSelectable AC Power and Reactive Power TransducerRicardo NunesNo ratings yet

- AC/DC CLAMP ADAPTOR INSTRUCTION MANUALDocument16 pagesAC/DC CLAMP ADAPTOR INSTRUCTION MANUALchockanan suwanprasertNo ratings yet

- Panasonic Sa-Ak570pl GCPDocument134 pagesPanasonic Sa-Ak570pl GCPCrist MartinezNo ratings yet

- TTi Model QPX1200 DC Power Supply Service ManualDocument49 pagesTTi Model QPX1200 DC Power Supply Service ManualT3brzNo ratings yet

- Op MFM384 MFM384-C Op347-V05Document4 pagesOp MFM384 MFM384-C Op347-V05Lyle ThompsonNo ratings yet

- Ta 8050 PDocument9 pagesTa 8050 PJuan Alamada Reynoso100% (1)

- S8VK-C DataSheet en 201303 T058-E1-01Document16 pagesS8VK-C DataSheet en 201303 T058-E1-01Raphael Paulino BertiNo ratings yet

- Service Manual Fastmig Pulse Power Sources: Released 30.12.2009 Updated 13.01.2010Document39 pagesService Manual Fastmig Pulse Power Sources: Released 30.12.2009 Updated 13.01.2010Solange Bacian San MartinNo ratings yet

- Data Sheet: Overload Relays, RMP-111D ANSI Code 32Document7 pagesData Sheet: Overload Relays, RMP-111D ANSI Code 32LUATNo ratings yet

- SERVICE MANUAL FOR COLOR TVDocument9 pagesSERVICE MANUAL FOR COLOR TValopezcuervoNo ratings yet

- DC POWER SUPPLY SPECIFICATIONSDocument23 pagesDC POWER SUPPLY SPECIFICATIONSMe MeNo ratings yet

- Service Manual: MT1191V 19" Color TelevisionDocument23 pagesService Manual: MT1191V 19" Color TelevisionAntonio Jose Rodriguez AlvaradoNo ratings yet

- LG 50PB560B Chassis PU41A PDFDocument47 pagesLG 50PB560B Chassis PU41A PDFCesar Guzman100% (1)

- JVC AV-21CS24 AV-21CX14 Service ManualDocument86 pagesJVC AV-21CS24 AV-21CX14 Service ManualLara Atos100% (4)

- Fuente Goldstar PDFDocument11 pagesFuente Goldstar PDFdirectNo ratings yet

- E284Document4 pagesE284aimonmdNo ratings yet

- TripDocument1 pageTripBrian BurchNo ratings yet

- SIPROTEC Catalog SIP3.01Document210 pagesSIPROTEC Catalog SIP3.01Brian BurchNo ratings yet

- Mba 2015 TimetableDocument3 pagesMba 2015 TimetableBrian BurchNo ratings yet

- Alpha AS1440: Electronic Polyphase MeterDocument2 pagesAlpha AS1440: Electronic Polyphase MeterBrian BurchNo ratings yet

- How Solar Inverters Work With Solar PanelsDocument13 pagesHow Solar Inverters Work With Solar Panelsglobalrevolution100% (2)

- Mathematics ModelDocument31 pagesMathematics ModelBrian BurchNo ratings yet

- Magic of ThinkingDocument159 pagesMagic of ThinkingBrian BurchNo ratings yet

- Operations Research ModelDocument24 pagesOperations Research ModelBrian BurchNo ratings yet

- Business ComunicationDocument3 pagesBusiness ComunicationBrian BurchNo ratings yet

- Eee 5-8Document72 pagesEee 5-8pandiaraj.u7251No ratings yet

- Earth Leakage Relays V12Document9 pagesEarth Leakage Relays V12Brian BurchNo ratings yet

- III May PMBC Pmb1cDocument4 pagesIII May PMBC Pmb1cShanmugam AnnamalaiNo ratings yet

- P/id 77801/PMBSBDocument21 pagesP/id 77801/PMBSBBrian BurchNo ratings yet

- Current Transformer DesignDocument8 pagesCurrent Transformer DesignfernandozilloNo ratings yet

- Legal Systems in Business PDFDocument3 pagesLegal Systems in Business PDFBrian BurchNo ratings yet

- Quantitative and Research Methods in BusinessDocument3 pagesQuantitative and Research Methods in BusinessBrian BurchNo ratings yet

- Management PrinciplesDocument3 pagesManagement PrinciplesBrian BurchNo ratings yet

- 31 PDFDocument4,999 pages31 PDFSmruti Ranjan Behera100% (1)

- SA Industrial Washer Brochure PDFDocument4 pagesSA Industrial Washer Brochure PDFAl AdcockNo ratings yet

- LaTeX Reader (Version Atlee)Document97 pagesLaTeX Reader (Version Atlee)itsthomsonNo ratings yet

- Mutillidae Installation On Xampp Win7Document12 pagesMutillidae Installation On Xampp Win7Álvaro Riobóo de Larriva100% (1)

- Stocktacking Barat AprilDocument2 pagesStocktacking Barat AprilBaginda P Siregar NamoraNo ratings yet

- Vodafone 246 UserguideDocument2 pagesVodafone 246 UserguideKngt S. KnightNo ratings yet

- How To Add A Shockwave Flash Control To A Slide in PowerPointDocument4 pagesHow To Add A Shockwave Flash Control To A Slide in PowerPointBestarieNo ratings yet

- Um10430 1 PDFDocument1,278 pagesUm10430 1 PDFKavyashreeMNo ratings yet

- CCNA QuestionsDocument29 pagesCCNA QuestionsfelipemunozmoraNo ratings yet

- Haitian Jupiter SeriesDocument6 pagesHaitian Jupiter SeriesClaudio Rafael Deola SadaNo ratings yet

- Tutorials For STM32F103RB: Nicolas BarbotDocument13 pagesTutorials For STM32F103RB: Nicolas BarbotcarNo ratings yet

- SoftwareDocument89 pagesSoftwarezydusNo ratings yet

- Textron G1 7120 en ManualDocument24 pagesTextron G1 7120 en Manualdesportista_luisNo ratings yet

- HP Compaq 620 621 CQ320 CQ321 Inventec 6050A2364401-MB-A01 DDR3 SchematicDocument70 pagesHP Compaq 620 621 CQ320 CQ321 Inventec 6050A2364401-MB-A01 DDR3 SchematicRamon Alexander PradaNo ratings yet

- Cameleon 5000 ManualDocument64 pagesCameleon 5000 ManualstreakerstreetNo ratings yet

- Bridgeless PFCDocument18 pagesBridgeless PFCsolid690No ratings yet

- SLING Series: FeaturesDocument8 pagesSLING Series: FeaturesCharlesNo ratings yet

- Serial Port Control Through A Shell Script - Stack OverflowDocument2 pagesSerial Port Control Through A Shell Script - Stack OverflowAntonio DxNo ratings yet

- IMS Information Gateway - Issue 1Document9 pagesIMS Information Gateway - Issue 1Avianto MarindaNo ratings yet

- Pro I I 93 Silent Install GuideDocument5 pagesPro I I 93 Silent Install Guidemfruge7No ratings yet

- Linear Actuator La23 Data Sheet EngDocument8 pagesLinear Actuator La23 Data Sheet EngAlfonso MedinaNo ratings yet

- Factors Affected To 3D Image in Digital WatermarkingDocument3 pagesFactors Affected To 3D Image in Digital WatermarkingInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- MSI Motherboard & Video Card PricelistDocument1 pageMSI Motherboard & Video Card PricelistMarvin Mark AbamongaNo ratings yet

- Linux QsDocument7 pagesLinux QsSayantan DasNo ratings yet