Professional Documents

Culture Documents

AU Catalogue - Wire Rope, Chain and Chain Fittings

Uploaded by

Robbie van Leeuwen0 ratings0% found this document useful (0 votes)

21 views4 pagesWire rope catalogue applicable for Australian markets.

Original Title

19. AU Catalogue - Wire Rope, Chain and Chain Fittings

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWire rope catalogue applicable for Australian markets.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views4 pagesAU Catalogue - Wire Rope, Chain and Chain Fittings

Uploaded by

Robbie van LeeuwenWire rope catalogue applicable for Australian markets.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

201

Wire Rope, and Chain Fittings

W

i

r

e

R

o

p

e

,

a

n

d

C

h

a

i

n

F

i

t

t

i

n

g

s

202

203

203

204

204

204

Wire Rope

Hamma Pro-Strand

Hamma Mega-Strand

Chain

Quick Link

Connecting Link

High tensile rods systems

Multiple annealing stages during the drawing process to ensure wire

does not work harden, and finished by passing through an ultrasonic

bath to remove any impurities that may have attached during

manufacture. This makes Hamma cable unique in raising ultimat e

corrosion resistance for extreme harsh and severe local conditions as

well as increased work life due to the multiple annealing processes,

ensuring longevity of the wire. Hamma cables are ensured of superior

aesthetic finish due to an excellent surface brightness and smooth

exterior.

Strudyna is proud to offer Hamma cables as part of Strudyna's tensile

cable systems. Hamma cables are developed exclusivel y for high

tensile performances through unique techniques that differentiate from

other manufactures. Hamma cables start with the highest quality of

stainless steel source follow by unique descaling of stainless steel rod

to remove impurities, which may have attached during transport, prior to

commencing production.

HAMMA MEGA-STRAND

Benets - Designed for large structural projects. To date this is the largest

stainless steel strand on the market.

Material : 316 Stainless Steel

Sizes : 20mm- 42mm.

Finish : Bright and smooth for increased corrosion resistance.

Specic features:

- Low stretch.

- Higher comparative breaking strain.

- Wide cable size range.

- Compatible with both splicing and swaging.

- Good corrosion resistance.

HAMMA X-STRAND

Benets - Enhanced corrosion resistance. Produced with a high level

of descaling and ultrasonic removal of impurities.

Resulting in longer lasting shine and ultimate corrosion

resistance, better for NZs harsh corrosive conditions.

Material : 316 Stainless Steel

Sizes : 0.8mm- 19mm

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

Finish : Bright and smooth for increased corrosion resistance.

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

HAMMA PRO-STRAND

Benets - Built with Micro Stretch Technology (MST), the MinimumBreaking

Strength (MBS) is 20-30% higher than conventional 1x19 wire of the

same size. This means that you can downsize the structural cable

and maintain the strength. This results in improved aesthetics, less

weight in the structure, and cost savings on smaller ttings, which

can be signicant on large projects.

Material

:

:

316 Stainless Steel

Sizes :

Types Compact wire strand in constructions 1x7, 1x19, 1x25

1.6mm- 12mm

Finish

:

Bright and smooth for increased corrosion resistance.

Application: Predominantly used for structural cables, e.g glass facades

Specific features:

- Extremely non-exible.

- High breaking strain.

- Smooth clean nish.

- No pre-stress required.

- Extremely low stretch.

1x19 7x7 7x19

1x19

1x37 1x61

with Micro-stretch Technologies.

1x7

with Ultimate Structural cable

Application: Large structural projects, such as bridges.

Application: Balustrades, shade sails, foliage trellises, and

architectural rigging.

Recommended for exterior use in coastal areas.

Types : A conventional 1x37 and 1x61 construction wire stand.

Code: MFW...U

Maintenance: Wire rope must be cleaned & maintained regularly.

See our Maintenance & Cleaning guidelines on p.21.

For wire rigging fittings, see pages: 165-173

Wire Rope 316

with enhanced corrosion resistance

Code: MFW..U

Cleaning &

Maintenance

is required.

See p.230

Highlighted

sizes in stock.

Others available

on request.

Wire Rope Wire Rope

Breaking*

Load (kg)

Breaking*

Load

Size Size

1x19 7x7 7x19

1x19 7x7 7x19

1x19 7x7 7x19

1x19 7x7 7x19

0.8 mm

1.0 mm

1.5 mm

2.0 mm

2.4 mm

3.2 mm

3.5 mm

4.0 mm

4.5 mm

5.0 mm

6.0 mm

7.0 mm

8.0 mm

10.0 mm

12.0 mm

14.0 mm

16.0 mm

19.0 mm

8.0 mm

10.0 mm

12.0 mm

14.0 mm

16.0 mm

18.0 mm

1.0 mm

1.5 mm

2.0 mm

2.4 mm

3.2 mm

3.5 mm

4.0 mm

4.5 mm

5.0 mm

6.0 mm

7.0 mm

8.0 mm

10.0 mm

12.0 mm

14.0 mm

16.0 mm

18.0 mm

20.0 mm

53

84

189

336

525

756

1,030

1,340

1,702

2,100

3,030

4,120

5,380

8,400

12,102

16,473

20,500

30,300

3,670

5,750

8,270

11,200

14,700

21,000

38

59

145

258

374

581

733

1,030

1,312

1,620

2,320

3,160

59

134

239

373

538

731

956

1,206

1,490

2,150

2,930

3,400

5,310

7,650

10,400

13,600

19,300

23,900

Benets Enhanced corrosion resistance. Produced with a high level

of descaling and ultrasonic removal of impurities, resulting

in longer lasting shine and ultimate corrosion resistance.

Material 316 Stainless Steel

Size 0.8mm 19mm

Types 1x19 (rigid); 7x7 (semi-exible); 7x19 (exible).

Finish Bright and smooth for increased corrosion resistance.

Application Balustrades, shade sails, foliage trellises, and

architectural rigging. Recommended for exterior use in

coastal areas.

202

browse / view your prices / enquire & order online www.anzor.com.au/wire

*Safe Working Load of wire rope, and ttings to determine the safe working load of a wire rope or cable, or ttings, the

nominal strength or Breaking Load (BL) must be reduced by a safety factor. The BL of a wire rope should be considered the

straight line pull which will actually break the wire. The nominal strength or BL of a wire rope should never be used as its

working load.

The safety factor is the ratio of strength of the rope or strand, or tting to the working load required. It is impossible to

establish a uniform safety factor as it will depend upon the type of work performed, government regulations, loads applied,

speed of operation, length of wire rope used, etc. As a guideline, designers/installers commonly use a the Safe Working Load

of 25% of Breaking Load, allowing for a 4:1 safety factor.

It is the customers responsibility to ensure that an appropriate safety factor has been applied to the BL to calculate the safe

working load of the wire rope or tting being specied or ordered. We suggest that you engage a consulting engineer to assist

you. Anzor takes no responsibility for the nal decision, and accepts no liability in the case where loss arises from the safety

factor chosen.

High tensile rods systems

Multiple annealing stages during the drawing process to ensure wire

does not work harden, and finished by passing through an ultrasonic

bath to remove any impurities that may have attached during

manufacture. This makes Hamma cable unique in raising ultimat e

corrosion resistance for extreme harsh and severe local conditions as

well as increased work life due to the multiple annealing processes,

ensuring longevity of the wire. Hamma cables are ensured of superior

aesthetic finish due to an excellent surface brightness and smooth

exterior.

Strudyna is proud to offer Hamma cables as part of Strudyna's tensile

cable systems. Hamma cables are developed exclusivel y for high

tensile performances through unique techniques that differentiate from

other manufactures. Hamma cables start with the highest quality of

stainless steel source follow by unique descaling of stainless steel rod

to remove impurities, which may have attached during transport, prior to

commencing production.

HAMMA MEGA-STRAND

Benets - Designed for large structural projects. To date this is the largest

stainless steel strand on the market.

Material : 316 Stainless Steel

Sizes : 20mm - 42mm.

Finish : Bright and smooth for increased corrosion resistance.

Specic features:

- Low stretch.

- Higher comparative breaking strain.

- Wide cable size range.

- Compatible with both splicing and swaging.

- Good corrosion resistance.

HAMMA X-STRAND

Benets - Enhanced corrosion resistance. Produced with a high level

of descaling and ultrasonic removal of impurities.

Resulting in longer lasting shine and ultimate corrosion

resistance, better for NZs harsh corrosive conditions.

Material : 316 Stainless Steel

Sizes : 0.8mm - 19mm

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

Finish : Bright and smooth for increased corrosion resistance.

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

HAMMA PRO-STRAND

Benets - Built with Micro Stretch Technology (MST), the Minimum Breaking

Strength (MBS) is 20-30% higher than conventional 1x19 wire of the

same size. This means that you can downsize the structural cable

and maintain the strength. This results in improved aesthetics, less

weight in the structure, and cost savings on smaller ttings, which

can be signicant on large projects.

Material

:

:

316 Stainless Steel

Sizes :

Types Compact wire strand in constructions 1x7, 1x19, 1x25

1.6mm - 12mm

Finish

:

Bright and smooth for increased corrosion resistance.

Application: Predominantly used for structural cables, e.g glass facades

Specific features:

- Extremely non-exible.

- High breaking strain.

- Smooth clean nish.

- No pre-stress required.

- Extremely low stretch.

1x19 7x7 7x19

1x19

1x37 1x61

with Micro-stretch Technologies.

1x7

with Ultimate Structural cable

Application: Large structural projects, such as bridges.

Application: Balustrades, shade sails, foliage trellises, and

architectural rigging.

Recommended for exterior use in coastal areas.

Types : A conventional 1x37 and 1x61 construction wire stand.

Code: MFW...U

Maintenance: Wire rope must be cleaned & maintained regularly.

See our Maintenance & Cleaning guidelines on p.21.

0.8 mm

1.0 mm

1.5 mm

2.0 mm

2.4 mm

3.2 mm

3.5 mm

4.0 mm

4.5 mm

5.0 mm

6.0 mm

7.0 mm

W

I

R

E

R

O

P

E

NB: for wire rigging fittings, see pages: 165-173.

203

browse / view your prices / enquire & order online www.anzor.com.au/wire

(Kgf) 450 700 1,025 1,795 2,600 3,700 5,100 6,500 9,000 10,250 13,500 14,400 19,300 25,600 32,000

Hamma Pro-Strand

316

Hamma Mega-Strand

316

Benets Built with Micro Stretch Technology (MST), the Minimum

Breaking Strength (MBS) is 2030% higher than conventional

1x19 wire of the same size. This means that you can downsize

the structural cable and maintain the strength. This results in

improved aesthetics, less weight in the structure, and cost

savings on smaller ttings, which can be signicant on large

projects.

Types Compact wire strand in constructions 1x7, 1x19, 1x25.

Material 316 Stainless Steel

Size 1.6mm 12mm

Finish Bright/smooth for increased corrosion resistance.

Application Predominantly used for structural cables,

e.g glass facades.

Specic Extremely nonfexible Smooth, clean fnish

Features High breaking strain No prestress required

Extremely low stretch

Metric 2.0 2.5 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 14.0 16.0 19.0

Construction 1x37 1x37 1x37 1x37 1x61 1x61 1x61 1x61

(Kgf) 31,713 38,647 46,499 63,630 78,824 96,261 98,606 114,208

(kN) 311 379 456 624 773 944 967 1,120

Closest Inch 5/64 1/8 5/32 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4

Construction 1x7 1x7 1x7 1x7 1x19 1x19 1x19 1x19 1x19 1x19 1x19 1x19 1x25 1x25 1x25

min.

Breaking

Load*

min.

Breaking

Load*

(kN) 4.41 6.86 10.05 17.60 25.50 36.28 50.01 63.74 88.26 100.52 132.39 141.22 189.27 251.05 313.81

Metric 20 22 24.3 28 30 34 36 42

*Z

R,D

DIN 18800 *Refer to p.228 for guidelines on Safe Working Loads

*Refer to p.228 for guidelines on Safe Working Loads

Benets Designed for large structural projects. To date, this is the

largest stainless steel strand on the market.

Types A conventional 1x37 and 1x61 construction wire strand

Material 316 Stainless Steel

Size 20mm 42mm

Finish Bright and smooth for increased corrosion resistance

Application Large structural projects, such as bridges

Specic Low stretch

Features Higher comparative breaking strain

Wide cable size range

Compatible with both splicing and swaging

Good corrosion resistance

High tensile rods systems

Multiple annealing stages during the drawing process to ensure wire

does not work harden, and finished by passing through an ultrasonic

bath to remove any impurities that may have attached during

manufacture. This makes Hamma cable unique in raising ultimat e

corrosion resistance for extreme harsh and severe local conditions as

well as increased work life due to the multiple annealing processes,

ensuring longevity of the wire. Hamma cables are ensured of superior

aesthetic finish due to an excellent surface brightness and smooth

exterior.

Strudyna is proud to offer Hamma cables as part of Strudyna's tensile

cable systems. Hamma cables are developed exclusivel y for high

tensile performances through unique techniques that differentiate from

other manufactures. Hamma cables start with the highest quality of

stainless steel source follow by unique descaling of stainless steel rod

to remove impurities, which may have attached during transport, prior to

commencing production.

HAMMA MEGA-STRAND

Benets - Designed for large structural projects. To date this is the largest

stainless steel strand on the market.

Material : 316 Stainless Steel

Sizes : 20mm - 42mm.

Finish : Bright and smooth for increased corrosion resistance.

Specic features:

- Low stretch.

- Higher comparative breaking strain.

- Wide cable size range.

- Compatible with both splicing and swaging.

- Good corrosion resistance.

HAMMA X-STRAND

Benets - Enhanced corrosion resistance. Produced with a high level

of descaling and ultrasonic removal of impurities.

Resulting in longer lasting shine and ultimate corrosion

resistance, better for NZs harsh corrosive conditions.

Material : 316 Stainless Steel

Sizes : 0.8mm - 19mm

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

Finish : Bright and smooth for increased corrosion resistance.

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

HAMMA PRO-STRAND

Benets - Built with Micro Stretch Technology (MST), the Minimum Breaking

Strength (MBS) is 20-30% higher than conventional 1x19 wire of the

same size. This means that you can downsize the structural cable

and maintain the strength. This results in improved aesthetics, less

weight in the structure, and cost savings on smaller ttings, which

can be signicant on large projects.

Material

:

:

316 Stainless Steel

Sizes :

Types Compact wire strand in constructions 1x7, 1x19, 1x25

1.6mm - 12mm

Finish

:

Bright and smooth for increased corrosion resistance.

Application: Predominantly used for structural cables, e.g glass facades

Specific features:

- Extremely non-exible.

- High breaking strain.

- Smooth clean nish.

- No pre-stress required.

- Extremely low stretch.

1x19 7x7 7x19

1x19

1x37 1x61

with Micro-stretch Technologies.

1x7

with Ultimate Structural cable

Application: Large structural projects, such as bridges.

Application: Balustrades, shade sails, foliage trellises, and

architectural rigging.

Recommended for exterior use in coastal areas.

Types : A conventional 1x37 and 1x61 construction wire stand.

Code: MFW...U

Maintenance: Wire rope must be cleaned & maintained regularly.

See our Maintenance & Cleaning guidelines on p.21.

High tensile rods systems

Multiple annealing stages during the drawing process to ensure wire

does not work harden, and finished by passing through an ultrasonic

bath to remove any impurities that may have attached during

manufacture. This makes Hamma cable unique in raising ultimat e

corrosion resistance for extreme harsh and severe local conditions as

well as increased work life due to the multiple annealing processes,

ensuring longevity of the wire. Hamma cables are ensured of superior

aesthetic finish due to an excellent surface brightness and smooth

exterior.

Strudyna is proud to offer Hamma cables as part of Strudyna's tensile

cable systems. Hamma cables are developed exclusivel y for high

tensile performances through unique techniques that differentiate from

other manufactures. Hamma cables start with the highest quality of

stainless steel source follow by unique descaling of stainless steel rod

to remove impurities, which may have attached during transport, prior to

commencing production.

HAMMA MEGA-STRAND

Benets - Designed for large structural projects. To date this is the largest

stainless steel strand on the market.

Material : 316 Stainless Steel

Sizes : 20mm - 42mm.

Finish : Bright and smooth for increased corrosion resistance.

Specic features:

- Low stretch.

- Higher comparative breaking strain.

- Wide cable size range.

- Compatible with both splicing and swaging.

- Good corrosion resistance.

HAMMA X-STRAND

Benets - Enhanced corrosion resistance. Produced with a high level

of descaling and ultrasonic removal of impurities.

Resulting in longer lasting shine and ultimate corrosion

resistance, better for NZs harsh corrosive conditions.

Material : 316 Stainless Steel

Sizes : 0.8mm - 19mm

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

Finish : Bright and smooth for increased corrosion resistance.

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

HAMMA PRO-STRAND

Benets - Built with Micro Stretch Technology (MST), the Minimum Breaking

Strength (MBS) is 20-30% higher than conventional 1x19 wire of the

same size. This means that you can downsize the structural cable

and maintain the strength. This results in improved aesthetics, less

weight in the structure, and cost savings on smaller ttings, which

can be signicant on large projects.

Material

:

:

316 Stainless Steel

Sizes :

Types Compact wire strand in constructions 1x7, 1x19, 1x25

1.6mm - 12mm

Finish

:

Bright and smooth for increased corrosion resistance.

Application: Predominantly used for structural cables, e.g glass facades

Specific features:

- Extremely non-exible.

- High breaking strain.

- Smooth clean nish.

- No pre-stress required.

- Extremely low stretch.

1x19 7x7 7x19

1x19

1x37 1x61

with Micro-stretch Technologies.

1x7

with Ultimate Structural cable

Application: Large structural projects, such as bridges.

Application: Balustrades, shade sails, foliage trellises, and

architectural rigging.

Recommended for exterior use in coastal areas.

Types : A conventional 1x37 and 1x61 construction wire stand.

Code: MFW...U

Maintenance: Wire rope must be cleaned & maintained regularly.

See our Maintenance & Cleaning guidelines on p.21.

AVAILABLE

TO ORDER

Delivery approx.

23 days

High tensile rods systems

Multiple annealing stages during the drawing process to ensure wire

does not work harden, and finished by passing through an ultrasonic

bath to remove any impurities that may have attached during

manufacture. This makes Hamma cable unique in raising ultimat e

corrosion resistance for extreme harsh and severe local conditions as

well as increased work life due to the multiple annealing processes,

ensuring longevity of the wire. Hamma cables are ensured of superior

aesthetic finish due to an excellent surface brightness and smooth

exterior.

Strudyna is proud to offer Hamma cables as part of Strudyna's tensile

cable systems. Hamma cables are developed exclusivel y for high

tensile performances through unique techniques that differentiate from

other manufactures. Hamma cables start with the highest quality of

stainless steel source follow by unique descaling of stainless steel rod

to remove impurities, which may have attached during transport, prior to

commencing production.

HAMMA MEGA-STRAND

Benets - Designed for large structural projects. To date this is the largest

stainless steel strand on the market.

Material : 316 Stainless Steel

Sizes : 20mm - 42mm.

Finish : Bright and smooth for increased corrosion resistance.

Specic features:

- Low stretch.

- Higher comparative breaking strain.

- Wide cable size range.

- Compatible with both splicing and swaging.

- Good corrosion resistance.

HAMMA X-STRAND

Benets - Enhanced corrosion resistance. Produced with a high level

of descaling and ultrasonic removal of impurities.

Resulting in longer lasting shine and ultimate corrosion

resistance, better for NZs harsh corrosive conditions.

Material : 316 Stainless Steel

Sizes : 0.8mm - 19mm

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

Finish : Bright and smooth for increased corrosion resistance.

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

HAMMA PRO-STRAND

Benets - Built with Micro Stretch Technology (MST), the Minimum Breaking

Strength (MBS) is 20-30% higher than conventional 1x19 wire of the

same size. This means that you can downsize the structural cable

and maintain the strength. This results in improved aesthetics, less

weight in the structure, and cost savings on smaller ttings, which

can be signicant on large projects.

Material

:

:

316 Stainless Steel

Sizes :

Types Compact wire strand in constructions 1x7, 1x19, 1x25

1.6mm - 12mm

Finish

:

Bright and smooth for increased corrosion resistance.

Application: Predominantly used for structural cables, e.g glass facades

Specific features:

- Extremely non-exible.

- High breaking strain.

- Smooth clean nish.

- No pre-stress required.

- Extremely low stretch.

1x19 7x7 7x19

1x19

1x37 1x61

with Micro-stretch Technologies.

1x7

with Ultimate Structural cable

Application: Large structural projects, such as bridges.

Application: Balustrades, shade sails, foliage trellises, and

architectural rigging.

Recommended for exterior use in coastal areas.

Types : A conventional 1x37 and 1x61 construction wire stand.

Code: MFW...U

Maintenance: Wire rope must be cleaned & maintained regularly.

See our Maintenance & Cleaning guidelines on p.21.

AVAILABLE

TO ORDER

Delivery approx.

23 days

0.8

1x19

0.31

53

0.52

1.0

1x19

0.49

84

0.82

1.2

3/64

1x19

0.71

121

1.19

1.5

1x19

1. 11

189

1.85

1.6

1/16

1x19

1.27

215

2.11

2

5/64

1x19

1.98

336

3.3

2.4

3/32

1x19

2.84

483

4.74

2.5

1x19

3.09

525

5.15

3

1x19

4.45

756

7.41

3.2

1/8

1x19

5.06

861

8.44

3.5

1x19

6.06

1,030

10.1

4

5/32

1x19

7.88

1,340

13.14

4.5

1x19

10.01

1,702

16.69

4.8

3/16

1x19

11.39

1,935

18.98

5

1x19

12.39

2,100

20.59

6

1x19

3,030

29.71

5.5

7/32

1x19

2,639

25.88

6.4

1/4

1x19

3,442

33.75

7

1x19

4,120

40.4

7.2

9/32

1x19

4,357

42.73

8

5/16

1x19

5,380

52.76

9.6

3/8

1x19

7,746

75.96

10

1x19

8,400

82.38

11.1

7/16

1x19

10,574

103.7

12

1x19

12,102

118.68

12.7

1/2

1x19

13,555

132.93

14

1x19

16,473

161.54

14.3

9/16

1x19

17,186

168.54

16

5/8

1x19

20,500

201.04

19

1x19

30,300

297.14

with Micro-stretch Technologies.

20

1x37

197.40

31,713

311

22

1x37

240.60

38,647

379

24.3

1x37

274.32

46,499

456

28

1x37

375.72

63,630

624

30

1x61

465.78

78,824

773

34

1x61

568.56

96,261

944

36

1x61

601.98

98,606

967

42

1x61

672.00

114,208

1,120

Extreme Condition Gear

Ultimate Structural cable

METRIC

INCH

Construction

Limit Tension* (kN)

min.

Breaking

Load*

(Kgf)

(kN)

METRIC

INCH

Construction

Limit Tension* (kN)

min.

Breaking

Load

(Kgf)

(kN)

METRIC

INCH

Construction

min.

Breaking

Load

(Kgf)

(kN)

METRIC

INCH

Construction

Limit Tension (kN)

min.

Breaking

Load*

(Kgf)

(kN)

*Z

R,D

DIN 18800

Micro-stretch Technologies

14.0

1x25

113.586

19,300

189.27

12.0

1x19

84.73

14,400

141.22

2.0

5/64

1x7

2.60

450

4.41

2.5

1x7

4.06

700

6.86

3.0

1x7

5.88

1,025

10.05

4.0

5/32

1x7

10.47

1,795

17.60

5.0

1x19

14.36

2,600

25.50

6.0

1x19

20.89

3,700

36.28

7.0

1x19

28.89

5,100

50.01

8.0

5/16

1x19

36.19

6,500

63.74

9.0

3/8

1x19

46.48

9,000

88.26

10.0

7/16

1x19

57.49

10,250

100.52

11.0

1x19

71.20

13,500

132.39

16.0

1x25

150.63

25,600

251.05

19.0

1x25

188.29

32,000

313.81

1x7

0.8

1x19

0.31

53

0.52

1.0

1x19

0.49

84

0.82

1.2

3/64

1x19

0.71

121

1.19

1.5

1x19

1. 11

189

1.85

1.6

1/16

1x19

1.27

215

2.11

2

5/64

1x19

1.98

336

3.3

2.4

3/32

1x19

2.84

483

4.74

2.5

1x19

3.09

525

5.15

3

1x19

4.45

756

7.41

3.2

1/8

1x19

5.06

861

8.44

3.5

1x19

6.06

1,030

10.1

4

5/32

1x19

7.88

1,340

13.14

4.5

1x19

10.01

1,702

16.69

4.8

3/16

1x19

11.39

1,935

18.98

5

1x19

12.39

2,100

20.59

6

1x19

3,030

29.71

5.5

7/32

1x19

2,639

25.88

6.4

1/4

1x19

3,442

33.75

7

1x19

4,120

40.4

7.2

9/32

1x19

4,357

42.73

8

5/16

1x19

5,380

52.76

9.6

3/8

1x19

7,746

75.96

10

1x19

8,400

82.38

11.1

7/16

1x19

10,574

103.7

12

1x19

12,102

118.68

12.7

1/2

1x19

13,555

132.93

14

1x19

16,473

161.54

14.3

9/16

1x19

17,186

168.54

16

5/8

1x19

20,500

201.04

19

1x19

30,300

297.14

with Micro-stretch Technologies.

20

1x37

197.40

31,713

311

22

1x37

240.60

38,647

379

24.3

1x37

274.32

46,499

456

28

1x37

375.72

63,630

624

30

1x61

465.78

78,824

773

34

1x61

568.56

96,261

944

36

1x61

601.98

98,606

967

42

1x61

672.00

114,208

1,120

Extreme Condition Gear

Ultimate Structural cable

METRIC

INCH

Construction

Limit Tension* (kN)

min.

Breaking

Load*

(Kgf)

(kN)

METRIC

INCH

Construction

Limit Tension* (kN)

min.

Breaking

Load

(Kgf)

(kN)

METRIC

INCH

Construction

min.

Breaking

Load

(Kgf)

(kN)

METRIC

INCH

Construction

Limit Tension (kN)

min.

Breaking

Load*

(Kgf)

(kN)

*Z

R,D

DIN 18800

Micro-stretch Technologies

14.0

1x25

113.586

19,300

189.27

12.0

1x19

84.73

14,400

141.22

2.0

5/64

1x7

2.60

450

4.41

2.5

1x7

4.06

700

6.86

3.0

1x7

5.88

1,025

10.05

4.0

5/32

1x7

10.47

1,795

17.60

5.0

1x19

14.36

2,600

25.50

6.0

1x19

20.89

3,700

36.28

7.0

1x19

28.89

5,100

50.01

8.0

5/16

1x19

36.19

6,500

63.74

9.0

3/8

1x19

46.48

9,000

88.26

10.0

7/16

1x19

57.49

10,250

100.52

11.0

1x19

71.20

13,500

132.39

16.0

1x25

150.63

25,600

251.05

19.0

1x25

188.29

32,000

313.81

1x19 1x25

0.8

1x19

0.31

53

0.52

1.0

1x19

0.49

84

0.82

1.2

3/64

1x19

0.71

121

1.19

1.5

1x19

1. 11

189

1.85

1.6

1/16

1x19

1.27

215

2.11

2

5/64

1x19

1.98

336

3.3

2.4

3/32

1x19

2.84

483

4.74

2.5

1x19

3.09

525

5.15

3

1x19

4.45

756

7.41

3.2

1/8

1x19

5.06

861

8.44

3.5

1x19

6.06

1,030

10.1

4

5/32

1x19

7.88

1,340

13.14

4.5

1x19

10.01

1,702

16.69

4.8

3/16

1x19

11.39

1,935

18.98

5

1x19

12.39

2,100

20.59

6

1x19

3,030

29.71

5.5

7/32

1x19

2,639

25.88

6.4

1/4

1x19

3,442

33.75

7

1x19

4,120

40.4

7.2

9/32

1x19

4,357

42.73

8

5/16

1x19

5,380

52.76

9.6

3/8

1x19

7,746

75.96

10

1x19

8,400

82.38

11.1

7/16

1x19

10,574

103.7

12

1x19

12,102

118.68

12.7

1/2

1x19

13,555

132.93

14

1x19

16,473

161.54

14.3

9/16

1x19

17,186

168.54

16

5/8

1x19

20,500

201.04

19

1x19

30,300

297.14

with Micro-stretch Technologies.

20

1x37

197.40

31,713

311

22

1x37

240.60

38,647

379

24.3

1x37

274.32

46,499

456

28

1x37

375.72

63,630

624

30

1x61

465.78

78,824

773

34

1x61

568.56

96,261

944

36

1x61

601.98

98,606

967

42

1x61

672.00

114,208

1,120

Extreme Condition Gear

Ultimate Structural cable

METRIC

INCH

Construction

Limit Tension* (kN)

min.

Breaking

Load*

(Kgf)

(kN)

METRIC

INCH

Construction

Limit Tension* (kN)

min.

Breaking

Load

(Kgf)

(kN)

METRIC

INCH

Construction

min.

Breaking

Load

(Kgf)

(kN)

METRIC

INCH

Construction

Limit Tension (kN)

min.

Breaking

Load*

(Kgf)

(kN)

*Z

R,D

DIN 18800

Micro-stretch Technologies

14.0

1x25

113.586

19,300

189.27

12.0

1x19

84.73

14,400

141.22

2.0

5/64

1x7

2.60

450

4.41

2.5

1x7

4.06

700

6.86

3.0

1x7

5.88

1,025

10.05

4.0

5/32

1x7

10.47

1,795

17.60

5.0

1x19

14.36

2,600

25.50

6.0

1x19

20.89

3,700

36.28

7.0

1x19

28.89

5,100

50.01

8.0

5/16

1x19

36.19

6,500

63.74

9.0

3/8

1x19

46.48

9,000

88.26

10.0

7/16

1x19

57.49

10,250

100.52

11.0

1x19

71.20

13,500

132.39

16.0

1x25

150.63

25,600

251.05

19.0

1x25

188.29

32,000

313.81

W

I

R

E

R

O

P

E

Available to order on request.

Available to order on request.

For wire rigging fittings (swage turnbuckles, crimps etc) see pages 165-173.

High tensile rods systems

Multiple annealing stages during the drawing process to ensure wire

does not work harden, and finished by passing through an ultrasonic

bath to remove any impurities that may have attached during

manufacture. This makes Hamma cable unique in raising ultimat e

corrosion resistance for extreme harsh and severe local conditions as

well as increased work life due to the multiple annealing processes,

ensuring longevity of the wire. Hamma cables are ensured of superior

aesthetic finish due to an excellent surface brightness and smooth

exterior.

Strudyna is proud to offer Hamma cables as part of Strudyna's tensile

cable systems. Hamma cables are developed exclusivel y for high

tensile performances through unique techniques that differentiate from

other manufactures. Hamma cables start with the highest quality of

stainless steel source follow by unique descaling of stainless steel rod

to remove impurities, which may have attached during transport, prior to

commencing production.

HAMMA MEGA-STRAND

Benets - Designed for large structural projects. To date this is the largest

stainless steel strand on the market.

Material : 316 Stainless Steel

Sizes : 20mm - 42mm.

Finish : Bright and smooth for increased corrosion resistance.

Specic features:

- Low stretch.

- Higher comparative breaking strain.

- Wide cable size range.

- Compatible with both splicing and swaging.

- Good corrosion resistance.

HAMMA X-STRAND

Benets - Enhanced corrosion resistance. Produced with a high level

of descaling and ultrasonic removal of impurities.

Resulting in longer lasting shine and ultimate corrosion

resistance, better for NZs harsh corrosive conditions.

Material : 316 Stainless Steel

Sizes : 0.8mm - 19mm

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

Finish : Bright and smooth for increased corrosion resistance.

Types : 1x19 (rigid), 7x7 (semi-exible), 7x19 (exible)

HAMMA PRO-STRAND

Benets - Built with Micro Stretch Technology (MST), the Minimum Breaking

Strength (MBS) is 20-30% higher than conventional 1x19 wire of the

same size. This means that you can downsize the structural cable

and maintain the strength. This results in improved aesthetics, less

weight in the structure, and cost savings on smaller ttings, which

can be signicant on large projects.

Material

:

:

316 Stainless Steel

Sizes :

Types Compact wire strand in constructions 1x7, 1x19, 1x25

1.6mm - 12mm

Finish

:

Bright and smooth for increased corrosion resistance.

Application: Predominantly used for structural cables, e.g glass facades

Specific features:

- Extremely non-exible.

- High breaking strain.

- Smooth clean nish.

- No pre-stress required.

- Extremely low stretch.

1x19 7x7 7x19

1x19

1x37 1x61

with Micro-stretch Technologies.

1x7

with Ultimate Structural cable

Application: Large structural projects, such as bridges.

Application: Balustrades, shade sails, foliage trellises, and

architectural rigging.

Recommended for exterior use in coastal areas.

Types : A conventional 1x37 and 1x61 construction wire stand.

Code: MFW...U

Maintenance: Wire rope must be cleaned & maintained regularly.

See our Maintenance & Cleaning guidelines on p.21.

Cleaning &

Maintenance

is required.

See p.230

Cleaning &

Maintenance

is required.

See p.230

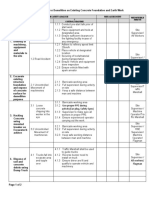

Internal

Link Size

Breaking

Load

(kgs)

Link

Thickness

Size

X

MEASUREMENTS MAY VARY SLIGHTLY. IF THEY ARE CRITICAL, PLEASE CHECK THEM.

Chain 316

Code: CHM..

Safe Working Load (SWL) guide 25% of Breaking Load.

It is the users responsibility to determine the SWL see p.202.

Internal

Link Size

Breaking

Load

(kgs)

2.0 X 12mm 127

2.0 X 22mm 127

3.0 X 16mm 428

4.0 X 16mm 816

5.0 X 18mm 1407

Quick Link 316

Type: S7350

L1

(mm)

B

(mm)

S

(mm)

Breaking

Load

(kgs)

Size

(A)

4.0mm 32 12 5.5 1400

5.0mm 39 13 6.5 2250

6.0mm 45 14 7.5 3200

8.0mm 58 18 9.5 5100

10.0mm 69 22 12.0 8500

12.0mm 81 24 14.5 11000

Safe Working Load (SWL) guide 25% of Breaking Load.

It is the users responsibility to determine the SWL see p.202.

204

browse / view your prices / enquire & order online www.anzor.com.au/chain

6.0 X 18mm 1836

6.0 X 25mm 1274

8.0 X 24mm 3265

10.0 X 28mm 5314

Connecting Link 316

Type: S661

Safe Working Load (SWL) guide 25% of Breaking Load.

It is the users responsibility to determine the SWL see p.202.

Breaking

Load

(kgs)

A1

(mm)

D

(mm)

L

(mm)

L1

(mm)

Size

(A)

6mm 11.0 25.0 35.0 21.0 800

8mm 11.8 29.0 42.0 24.0 1450

10mm 14.5 35.0 53.0 30.5 1900

12mm 19 42.0 61.0 37 3200

C

H

A

I

N

Link

Thickness

Size

X

You might also like

- AS XP User Guide PDFDocument72 pagesAS XP User Guide PDFRobbie van LeeuwenNo ratings yet

- 4051 1Document13 pages4051 1Ani SarojiniNo ratings yet

- Phraseology From AIP v2 PDFDocument38 pagesPhraseology From AIP v2 PDFRobbie van LeeuwenNo ratings yet

- AnconDocument40 pagesAnconRobbie van LeeuwenNo ratings yet

- Workedproblems PDFDocument14 pagesWorkedproblems PDFRobbie van LeeuwenNo ratings yet

- Rotate MD-80 Simplified Procedural Steps 1.31.0.3 PDFDocument9 pagesRotate MD-80 Simplified Procedural Steps 1.31.0.3 PDFgochilindaNo ratings yet

- ASI Limit State Steel Connections Design Series - Part 1 - SC - 42 - 1 - J PDFDocument36 pagesASI Limit State Steel Connections Design Series - Part 1 - SC - 42 - 1 - J PDFDenise251280% (5)

- SAP2000v16 Analysis Reference ManualDocument518 pagesSAP2000v16 Analysis Reference ManualAlonso Aguilar SalasNo ratings yet

- Steel Onesteel HandbookDocument34 pagesSteel Onesteel HandbookjlolhnpNo ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - SpaTec Plus Mechanical AnchoringDocument8 pagesRamset Specifiers Anchoring Resource Book ANZ - SpaTec Plus Mechanical AnchoringRobbie van LeeuwenNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Hints On Writing Technical PapersDocument4 pagesHints On Writing Technical PapersBoda KishanNo ratings yet

- 1a - IntroDocument5 pages1a - IntroRobbie van LeeuwenNo ratings yet

- Welcome To ETABSDocument57 pagesWelcome To ETABSmizanaNo ratings yet

- Matlab For Advanced Users, WI4141TU: K.dekker@tudelft - NL P.wilders@tudelft - NLDocument7 pagesMatlab For Advanced Users, WI4141TU: K.dekker@tudelft - NL P.wilders@tudelft - NLRobbie van LeeuwenNo ratings yet

- Neoprene Bridge Bearings Dupont 1984 PDFDocument16 pagesNeoprene Bridge Bearings Dupont 1984 PDFPauloAndresSepulvedaNo ratings yet

- Dissertationguide PDFDocument33 pagesDissertationguide PDFAlvin John Benavidez SalvadorNo ratings yet

- Natspec EarthworkDocument12 pagesNatspec EarthworkRobbie van LeeuwenNo ratings yet

- Layout and MeasuringDocument10 pagesLayout and MeasuringRobbie van Leeuwen100% (3)

- Conc HolesDocument17 pagesConc HolesRobbie van LeeuwenNo ratings yet

- Engineering Competency StandardsDocument11 pagesEngineering Competency StandardsRobbie van LeeuwenNo ratings yet

- SydneyCityBikeMap Nov 20121Document1 pageSydneyCityBikeMap Nov 20121Robbie van LeeuwenNo ratings yet

- Material Properties For DesignersDocument124 pagesMaterial Properties For Designersৰিতুপর্ণ HazarikaNo ratings yet

- Pole Building DesignDocument50 pagesPole Building DesignAuner ArthurNo ratings yet

- Design Barns Wind LoadDocument73 pagesDesign Barns Wind LoadRobbie van LeeuwenNo ratings yet

- Danley PD3 Dowel Cradle BrochureDocument8 pagesDanley PD3 Dowel Cradle BrochureRobbie van LeeuwenNo ratings yet

- Guide To Adopting Paint Systems For Galvanized Steel - Edition 2 May 201...Document16 pagesGuide To Adopting Paint Systems For Galvanized Steel - Edition 2 May 201...Robbie van LeeuwenNo ratings yet

- Burj Dubai - An Architectural Technical Design Case StudyDocument26 pagesBurj Dubai - An Architectural Technical Design Case StudyRobbie van LeeuwenNo ratings yet

- Bwa 201408Document62 pagesBwa 201408Robbie van LeeuwenNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Industrial Hose Products - DAYCODocument200 pagesIndustrial Hose Products - DAYCOHebert CcahuanaNo ratings yet

- Singly Linked Lists AlgorithmDocument18 pagesSingly Linked Lists AlgorithmGSX-R 1100No ratings yet

- Transmission Line Surveyors Face Challenges in Projecting Data onto MapsDocument3 pagesTransmission Line Surveyors Face Challenges in Projecting Data onto MapsTATAVARTHYCH HANUMANRAONo ratings yet

- Weather Wonders PDFDocument5 pagesWeather Wonders PDFLalNo ratings yet

- Banyule Standard DrawingsDocument103 pagesBanyule Standard DrawingsTarek AbulailNo ratings yet

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- Barco RLM g5 PDFDocument114 pagesBarco RLM g5 PDFRainer AdelsbergerNo ratings yet

- SemaphoreDocument29 pagesSemaphoreSaranya ThangarajNo ratings yet

- Ktu Laca Solved Question PaperDocument22 pagesKtu Laca Solved Question PaperSofiyaNo ratings yet

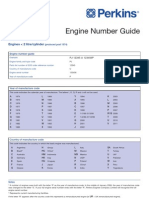

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Everyday Vocabulary Telephone TestDocument3 pagesEveryday Vocabulary Telephone TestzdravkamajkicNo ratings yet

- Sae j419 1983 Methods of Measuring Decarburization PDFDocument8 pagesSae j419 1983 Methods of Measuring Decarburization PDFSumeet SainiNo ratings yet

- RCP-15 Drilling Fluid Agitator Parts ListDocument5 pagesRCP-15 Drilling Fluid Agitator Parts ListwaleedNo ratings yet

- PNG382 FT en 11Document2 pagesPNG382 FT en 11Misu1983No ratings yet

- Romanian Power Grid Substation Refitting StrategyDocument16 pagesRomanian Power Grid Substation Refitting StrategyParmeshwar MbNo ratings yet

- Sol 2Document21 pagesSol 2Candice Xie100% (3)

- Ip Qos Principles: Theory and PracticeDocument108 pagesIp Qos Principles: Theory and Practicetest2012No ratings yet

- Westinghouse Manuals PDFDocument38 pagesWestinghouse Manuals PDFCarl HensonNo ratings yet

- Technical Guidance Notes: Level 2, No. 13Document4 pagesTechnical Guidance Notes: Level 2, No. 13Τε ΧνηNo ratings yet

- Electrical Machine DesignDocument2 pagesElectrical Machine DesignAnonymous 1abQZINo ratings yet

- GEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEDocument1 pageGEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEManas Kumar SamalNo ratings yet

- Install bladder tanks under homesDocument4 pagesInstall bladder tanks under homessauro100% (1)

- (Reprint From Handbuch Der Physik - Encyclopedia of Physics) R. N. Bracewell (Auth.) - Radio Astronomy Techniques-Springer-Verlag Berlin Heidelberg (1962)Document91 pages(Reprint From Handbuch Der Physik - Encyclopedia of Physics) R. N. Bracewell (Auth.) - Radio Astronomy Techniques-Springer-Verlag Berlin Heidelberg (1962)garfacio30No ratings yet

- High Precision Ball Bearings SolutionsDocument71 pagesHigh Precision Ball Bearings SolutionsTravis DavisNo ratings yet

- Home water pressure booster pumpDocument3 pagesHome water pressure booster pumpbadaasaabNo ratings yet

- XT316 Air SockerDocument4 pagesXT316 Air Sockeryudiar djamaldilliahNo ratings yet

- Acer Ferrari 3400 Laptop ManualDocument113 pagesAcer Ferrari 3400 Laptop Manualmoming1No ratings yet

- Scie 5 q1 Week 1 FinalDocument74 pagesScie 5 q1 Week 1 FinalPrecilla HalagoNo ratings yet

- Foundation DesignDocument7 pagesFoundation DesignPrasad GNNo ratings yet

- Frame RelayDocument33 pagesFrame RelayDilsha AshrafNo ratings yet