Professional Documents

Culture Documents

1HSM 9543 13-04 DCB - Maximum Availability With Minimum Footprint 2013-03 Edition 2

Uploaded by

Khalid UsmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1HSM 9543 13-04 DCB - Maximum Availability With Minimum Footprint 2013-03 Edition 2

Uploaded by

Khalid UsmanCopyright:

Available Formats

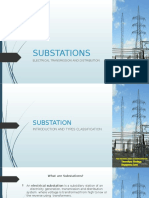

Disconnecting Circuit Breaker

Maximum availability

with minimum footprint

2 Disconnecting Circuit Breaker | ABB Circuit Breakers

Air insulated substations with DCBs give

maximum availability with minimum footprint

HANS-ERIK OLOVSSON, CARL EJNAR SLVER, RICHARD

THOMAS The development of circuit breakers (CBs)

has led to a change of design principle for substations.

Previously the substations design was based on

the fact that CBs needed a lot of maintenance and

were therefore surrounded by disconnectors (DSs) to

enable maintenance without disturbing nearby circuits.

With todays CBs having a maintenance interval of

15 years plus, the design principle is more focused

on the maintenance of overhead lines, transformers,

reactors, etc. The change of design principle has

enabled the integration of the disconnecting function

with the CB, thereby creating a new apparatus called a

disconnecting CB (DCB). Since the primary contacts for

DCBs are in an SF

6

protected environment, free from

pollution, the disconnecting function is highly reliable

and the maintenance interval is increased, providing

greater overall availability of the substation. In addition

the DCB solution reduces the substation footprint by

about 50 percent, see Figure 1a and 1b.

The development of circuit breakers has led to a change of design principle for substations.

ABB Circuit Breakers | Disconnecting Circuit Breakers 3

Development in circuit breaker (CB) technology has led to a

significant decrease in maintenance and an increase in reli-

ability. The maintenance intervals of modern SF

6

CBs requir-

ing the de-energising of the primary circuit is now 15 years or

more. No significant impro vements in maintenance require-

ments and reliability have been made with open air DS, which

during the same period focused on cost reductions by opti-

mising production materials. The maintenance interval for the

open-air DSs main contacts is in the order of two to six years,

depending on user practices and pollution levels (ie, industrial

pollutants and / or natural pollutants, eg, sand and salt).

Reliability of CBs has increased due to evolution of primary

breaking technology, from air blast, oil minimum, SF6 dual

pressure into todays SF6 single pressure type CBs. At the

same time the number of series interrupters has been reduced

and today live tank CBs up to 300 kV are available with one

interrupter per pole. Removal of grading capacitors for live

tank CBs with two interrupters has further simplified the pri-

mary circuit and thus increased the availability. Today CBs up

to 550 kV are available without grading capacitors, enabling

the development of DCBs up to this voltage level. Operating

mechanisms for CBs have also improved going from pneumat-

ic or hydraulic to spring type, leading to more reliable designs

and lower maintenance, see Figure 2.

Figure 2

Development of CBs and corresponding

reduction in failure and maintenance rates

In the past the design principle when building substations was

to surround CBs with DSs to make the frequent mainte-

nance of CBs possible. Due to the large reduction of failure

and maintenance of CBs, the disconnecting function today is

required more for the maintenance of overhead lines, power

transformers, etc. The reduced maintenance on CBs together

with customers reliability problems with open-air DSs, led to

the close co-operative development of the DCB with some

of ABBs major customers [1, 2, 3]. The DCB combines the

switching and disconnecting functions in one device, reducing

the substations footprint and increasing availability [4]. The

first installation of the DCB was in 2000 and today DCBs are

available from 72.5 kV to 550 kV voltage level.

Figure 1a

A traditional substation with circuit breaker and disconnectors

Figure 1b

The disconnecting circuit breaker solution

reduces the substation footprint by about 50 percent

1950 2010

Bulk oil breakers

F

a

i

l

u

r

e

a

n

d

m

a

i

n

t

e

n

a

n

c

e

r

a

t

e

Air blast breakers

Disconnectors with

open contacts

Minimum oil breakers

SF

6

circuit breakers

4 Disconnecting Circuit Breaker | ABB Circuit Breakers

Design of disconnecting circuit-breakers

n a DCB, the normal interrupter contacts also provide the DS

function when in an open position. The contact system is similar

to that of a normal CB with no extra contacts or linkage system,

see Figure 3. The DCB is equipped with silicone rubber insula-

tors. These insulators have hydrophobic properties, ie, any water

on the surface will form droplets. As a result they have excellent

performance in polluted environments and the leakage current

across the poles in the open position is minimized.

DCBs will significantly reduce maintenance in air insulated

switchgear (AIS) substations and reduce the risk of failure

due to pollution. By replacing the combination of CBs and

open-air DSs with DCBs in substations, availability will be

significantly improved.

A DCB has to fulll both applicable CB standards and DS

standards. A specic standard for disconnecting circuit break-

ers was issued by IEC in 2005 [5]. An important part of this

standard was the combined function tests. These tests verify

that the disconnecting properties of the DCB are fullled during

its service life, despite contact wear and any decomposition

by-products generated by arc interruption. This is ensured by

making all the breaking and mechanical tests rst and thereaf-

ter conrming the disconnecting dielectric properties.

The DCB is available for rated voltages from 72.5 to

550 kV, see Table 1. Around 900 three phase units have

been installed or ordered.

Safe earthing

When a part of a substation or network is to be maintained or

repaired, one or more DSs are opened to isolate it from the

rest of the system and the isolated equipment is earthed for

personal safety. This can be achieved in different ways:

With conventional air-insulated DSs, the visible open con-

tact gaps verify that the part of the system is de-energised

and then the isolated system is earthed

DCBs are locked in the open position in a failsafe way.

The locking consists of electrical blocking of the operating

mechanism, as well as mechanical locking of the linkage

system to the main contacts. Thereafter the adjacent earth-

ing switch is closed. The visible closed earthing switch

verifies that the part of the system is de-energised and safe

for workers.

Maintenance aspects

In the past the complexity of CBs required high maintenance,

which focused attention on how to isolate them, while keep-

ing the other parts of the substation in service. The main rea-

son for DSs introduction about 100 years ago was to enable

CB maintenance. Single-line configuration was thus built-up

with CBs surrounded by DSs to enable CB maintenance, see

Figure 6 on next page.

A traditional double busbar solution with separate CBs and

DSs versus a sectionalized busbar solution with DCBs, for

a 132 kV substation with four overhead lines, two power

transformers and one bus-coupler or bus-section CB, are

Figure 3

DCB LTB 145 kV. The earthing switch

is integrated on support structure

Type LTB

72,5

LTB

145

HPL

170-300

HPL

362-420

HPL

550

Rated voltage, kV 72.5 145 170-300 362-420 550

Rated current, A 3150 3150 4000 4000 4000

Circuit-breaking

capacity, kA

40 40 50 50 63

Rated frequency, Hz 50/60 50/60 50/60 50/60 50

Table 1

The range of Disconnecting Circuit Breaker

ABB Circuit Breakers | Disconnecting Circuit Breakers 5

A A

A

C

B

B

B

Figure 6

Different types of single-line configurations based on the requirement for the frequent maintenance of CBs, which are no longer required

shown in Figure 9 on page 6. The DCB solution will reduce

the switchyard area by more than 40 percent. Outages for an

incoming / outgoing bay, due to maintenance on the switch-

gear main apparatus are shown in Figure 4 below. Assumed

maintenance intervals are in accordance with manufacturers

recommendations, ie, 5 years for open air DS and 15 years

for CB and DCB. Introduction of the DCB thus reduces the

average maintenance outage from 3.1 to 1.2 hours per year.

Figure 4

Outage duration due to maintenance of 132 kV switchgear apparatus

The reduction of maintenance activities will give the following

advantages:

More satisfied consumers (depending on substation / net-

work topology, the maintenance work can lead to loss of

power supply to some consumers).

Less risk of system disturbances (black-outs) since the

risk for primary faults during a maintenance situation (ie,

when there are people in the substation) is higher than

during normal service and during maintenance a system is

weakerbecause not all equipment is in service

Lower employment costs for maintenance work on site

Higher personnel safety since all work on the substations

high-voltage system has the potential risk of injury due to

electrical shock, or falling from heights, etc.

The disconnecting facility is a point in the switchgear that is pre-

pared for fast opening of the primary connection between the

DCB and the busbar. When the DCB is disconnected in this way

the other parts of the substation may be re-energised while work

continues on the DCB itself.

Fault aspects

Equipment and apparatus are getting more and more reliable,

however faults still happen even though they occur with lon-

ger mean time between failures (MTBF). Faults are a stochas-

tic process, which means that even with very long MTBF, the

fault could happen at anytime and ABBs customers must de-

sign the substations accordingly. When clearing a fault there

is also a slight risk that some CB should fail to open, requiring

back-up CBs to operate.

For the single line configuration shown inFigure 9 on next

page, a primary fault on one of the outgoing objects, plus CB

failure for that bay, would

lead to de-energisation

of one busbar section. A

failure in the bus-section

or bus-coupler breaker will

lead to loss of the whole

substation. For important

substations it might not be

acceptable from a sys-

tem security perspective

to have a risk of loosing

the whole substation at

a primary fault. To make

the substation immune

to busbar faults and to

minimize the disturbance

if a CB fails to open at a

primary fault, 1 -breaker

or 2-breaker configurations

can be used, see Figure 5.

InFigure 10 on page 7 single line diagram and correspond-

ing space requirement is compared, for a traditional type of

solution with CBs and DSs versus a solution with DCBs, for

a typical 420 kV substation with three OH-lines, two power

transformers and one shunt reactor. By using DCB the out-

door switchyard area is reduced by almost 50 percent.

O

u

t

a

g

e

d

u

r

a

t

i

o

n

(

h

o

u

r

s

/

y

e

a

r

)

4

2

0

3.1

CBs + DSs DCBs

1.2

A

B

A

B

Figure 5

Single-line configurations

immune to busbar faults

6 Disconnecting Circuit Breaker | ABB Circuit Breakers

77 m

50 m

49 m

54 m

Disconnecting facility, to be used in

case of maintenance or failure of DCB

Disconnecting Circuit Breaker

Figure 9

Single-line and layout for 132 kV traditional CBs and DSs vs the DCBs solution

O

u

t

a

g

e

d

u

r

a

t

i

o

n

(

h

o

u

r

s

/

y

e

a

r

)

0.3

0.2

0.1

0.0

0.19

CBs + DSs DCBs

0.09

50%

}

Figure 7

Outage duration due to primary faults in the 400 kV switchgear.

8a Solution with traditional apparatus

8b Modified version by removing busbar DS

8c DCB solution

a. Before 1979 b. 1979-2000 c. 2001 onwards

DF = Disconnecting facility

O

u

t

g

o

i

n

g

b

a

y

O

u

t

g

o

i

n

g

b

a

y

O

u

t

g

o

i

n

g

b

a

y

DS

CB

DS

DF

CB

DS

DF

CB

DF

DS

CB

DS

DS

CB

DF

DF

CB

DF

ABB Circuit Breakers | Disconnecting Circuit Breakers 7

Figure 10

Single-line and layout for 420 kV traditional CBs and DSs vs the DCB solution

Outages for an incoming / outgoing bay, due to faults in the

switchgear, are shown in Figure 7 on page 6. Failure frequen-

cy input are taken from international statistics sources, such

as CIGRE and CEA, which gather information from apparatus

in service. Since the DCB is very similar to a traditional CB,

failure statistics are assumed to be the same for CB and DCB.

The introduction of the DCB thus reduces outages by 50 per-

cent. Unplanned outages may be very problematic and lead to

loss of power supply to consumers, which is not acceptable

no black-outs please.

Application of DCB

DCBs can be applied in most traditional substation configura-

tions, and directly replace traditional CB / DS arrangements.

This reduces the substations footprint substantially, reduces

maintenance activities and reduces outages due to main-

tenance and faults, ie, increases availability. The increased

availability could be used to simplify the single-line configura-

tion and still keep the availability to the level it was before.

The total investment cost for the substation could be de-

creased using DCBs (depending on the cost of preparing land,

piling, blasting, land ll, etc., which would differ from case to

case). Operation costs will be reduced thanks to lower costs

for outages (this is usually the highest cost) and maintenance.

DS DS CT

VT

CB

DCB CT

VT VT

VT

DS DS CT CB DS DS CT CB

DS DS CT CB DS DS CT CB DS DS CT CB

DS DS CT CB DS DS CT CB DS DS CT CB

DCB CT DCB CT

DCB CT DCB CT DCB CT

DCB CT DCB CT DCB CT

160 m

72 m

103 m

60 m

8 Disconnecting Circuit Breaker | ABB Circuit Breakers

Svenska Kraftnt (SvK), the transmission system operator

(TSO) in Sweden, is responsible for the 420 kV and 245 kV

systems in Sweden. The Swedish 420 kV system started in

the 1950s, and was real pioneering work since it was the

first system in the world at that voltage level. Today the

Swedish 420 kV system consists of about 70 substations,

most of which are coming to the end of their life, so

SvK now makes a complete renewal (retrofit) of about 3

substations per year.

Basic principle for renewal of the substations is to make a

complete exchange of all primary and secondary equipment.

By doing a complete renewal, a number of technical and

commercial advantages can be obtained such as:

Future work will be minimized since all equipment has the

same vintage.

Single-line configuration can be adapted to developments

of high-voltage apparatus and to possible changes in the

importance of the substation to the network since it was

originally built.

Outage times can be kept to a minimum by using the exist-

ing equipment to keep the substation in service during the

renewal.

SvK personnel can concentrate on a few larger projects

and the renewed substations will not need any attention

for many years after the renewal.

Example 420 kV substation in Sweden

Already by the end of the 1970s the open-air DSs were identi-

ed as apparatus that required high levels of maintenance

compared to CB, so SvK started to reduce the number of DS in

their substations, see Figure 8b. When DCBs were introduced

in 2000, SvK made the rst installation in a 245 kV station to

obtain operational experience of this concept. In 2001 the rst

420 kV substation renewals using the DCB started and since

then the DCB solution has been used exclusively for large and

important substations in the 2-CB scheme in Figure 8c. For the

smaller 245 kV substations, the single busbar scheme is also

applied. SvKs operating experience with DCB is good.

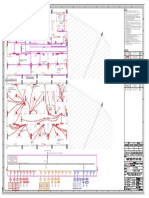

The footprint of the substation is reduced by almost 50 percent

when going from the traditional CB / DS to the DCB solution.

This reduction of the footprint can be advantages, not only for

new substation, but also when making substation renewals,

see Figure 11. During these renewal works the old apparatus

(pink) together with old busbar (red) is kept in service, while

the new equipment, including a second busbar are erected in

the area labelled in green on opposite side of the old busbar.

Thanks to the small footprint of the new primary equipment

the three existing line towers marked in blue can be kept in the

original position saving cost, outage time and reduce risks.

After installing and testing, the service is changed to the new

equipment. The complete renewal of this substation was done

with less than one week of outage.

9 Disconnecting Circuit Breaker | ABB Circuit Breakers

Existing line towers can remain due to

low space requirement of DCB.

New equipment located beside old

substation equipment

Old main busbar reused and extended.

Location of old equipment.

Outage less than one week for whole

renewal of S/S.

Relay and

control house

400/132 kV

Power transformer connection

OH-lines OH-lines OH-lines

OH-lines

Figure 11

Example of renewal of a Swedish 420 kV transmission substation

Contact us

P

u

b

l

i

c

a

t

i

o

n

1

H

S

M

9

5

4

3

1

3

-

0

4

e

n

,

E

d

i

t

i

o

n

2

,

2

0

1

3

-

0

3

D

C

B

-

M

a

x

i

m

u

m

a

v

a

i

l

a

b

i

l

i

t

y

w

i

t

h

m

i

n

i

m

u

m

f

o

o

t

p

r

i

n

f

P

h

o

t

o

:

H

a

s

s

e

E

r

i

k

s

s

o

n

,

M

a

t

s

F

i

n

d

e

l

l

ABB AB

High Voltage Products

SE-771 80 LUDVIKA, SWEDEN

Phone: +46 (0)240 78 20 00

Fax: +46 (0)240 78 36 50

E-Mail: circuit.breaker@se.abb.com

www.abb.com

www.abb.com/highvoltage

Copyright 2013 ABB. All rights reserved

NOTE! ABB is working continuously to improve the

products. We therefore reserve the right to change

designs, dimensions and data without prior notice.

Authors

Hans-Erik Olovsson

ABB Substations

Vsters, Sweden

hans-erik.olovsson@se.abb.com

Carl Ejnar Slver

ABB Power Products

Ludvika, Sweden

carl-ejnar.solver@se.abb.com

Richard Thomas

ABB Power Products

Ludvika, Sweden

richard.thomas@se.abb.com

References

[1] B Wahlstrm, Y Aoshima, Y Mino, C Lajoie-

Mazenc, D R Torgerson, A N Zomers, The Future

Substation: a reflective approach, Report 23-207,

Cigr Session, Paris, 1996.

[2] P Norberg, M Tapper, W Lord, A Engqvist,

The Future Substation Reflection About Design,

Report 23-105, Cigr Session, Paris, 1998.

[3] C-E Slver, H-E Olovsson, W Lord, P Norberg, J

Lundquist, Innovative Substations with High Avail-

ability using Switching Modules and Disconnecting

Circuit-breakers, Report 23-102, Cigr Session,

Paris, 2000.

[4] Jing, L., Olovsson, H-E., Fan, J., Thomas, R.

(2008) Small footprint, high performance.

ABB Review Special Report Dancing with the

Dragon.

[5] IEC 62271-108, High-voltage alternating current

disconnecting circuit-breakers for rated voltages of

72.5 kV and above, 2005

[6] P-O Andersson, H-E Olovsson, B Franzn,

U Lager, J Lundquist, Applications of disconnect-

ing circuit-breakers, Report A3-201, Cigr Session,

Paris, 2004

You might also like

- Produse ABBDocument12 pagesProduse ABBTomuta StefanNo ratings yet

- Applications of Disconnecting Circuit-Breakers P-O Andersson H-E Olovsson B Franzén U Lager J Lundquist ABB Power Technologies Svenska Kraftnät Sydkraft Nät StriDocument8 pagesApplications of Disconnecting Circuit-Breakers P-O Andersson H-E Olovsson B Franzén U Lager J Lundquist ABB Power Technologies Svenska Kraftnät Sydkraft Nät StriryueyiteuiNo ratings yet

- Costsaving and Reliability Improvement by Using Innovative Technique For Refurbishment of A SubstationDocument4 pagesCostsaving and Reliability Improvement by Using Innovative Technique For Refurbishment of A SubstationGiuseppe FerrariNo ratings yet

- DCB Buyers and Application GuideDocument40 pagesDCB Buyers and Application GuideModisa TsamaaseNo ratings yet

- ABB 2340enDocument6 pagesABB 2340enThangco HutNo ratings yet

- DCB Buyers and Application Guide Ed2.1Document48 pagesDCB Buyers and Application Guide Ed2.1Nelson LozanoNo ratings yet

- Disconnecting Circuit Breakers: Buyer's and Application GuideDocument44 pagesDisconnecting Circuit Breakers: Buyer's and Application GuideModisa TsamaaseNo ratings yet

- Vacuum Circuit Breakers For A.C. Traction VehiclesDocument5 pagesVacuum Circuit Breakers For A.C. Traction VehiclesIlan AtamanNo ratings yet

- CH - 1Document62 pagesCH - 1ISHAN MEHROTRANo ratings yet

- ABBs Disconnecting Circuit BreakersDocument8 pagesABBs Disconnecting Circuit BreakersAndrea AtzeniNo ratings yet

- DCB Disconnecting Circuit Breakers ABB Buyers and Application GuideDocument48 pagesDCB Disconnecting Circuit Breakers ABB Buyers and Application GuideAnu Sun100% (1)

- Maintaining Industrial Sector Electricity SupplyDocument36 pagesMaintaining Industrial Sector Electricity SupplyAvi OjhaNo ratings yet

- DCB Buyers and Application Guide PDFDocument40 pagesDCB Buyers and Application Guide PDFkaraganda38No ratings yet

- Selection of 400kV Circuit Breakers and IsolatorsDocument5 pagesSelection of 400kV Circuit Breakers and Isolatorsgagandeeppruthi21No ratings yet

- Diary Report SirDocument14 pagesDiary Report SirNeeraj PurohitNo ratings yet

- Ehv EquipmentsDocument5 pagesEhv EquipmentskjfensNo ratings yet

- ABB Review NR 2 2013Document80 pagesABB Review NR 2 2013sorin1gunnerNo ratings yet

- Bus Bar ProtectionDocument9 pagesBus Bar ProtectionparameshvkrNo ratings yet

- B3 - 206 - 2006-Substation Design Using Phase To Phase InsulationDocument9 pagesB3 - 206 - 2006-Substation Design Using Phase To Phase Insulationarmien edwardsNo ratings yet

- Circuit Breakers: Presented by Ajay.S 11EE02Document28 pagesCircuit Breakers: Presented by Ajay.S 11EE02Ahmad Kalbounah0% (1)

- Catalogo CBGS-2 PDFDocument24 pagesCatalogo CBGS-2 PDFJuan E Torres M100% (1)

- Bus Riser - CouplerDocument3 pagesBus Riser - CouplerMarey MorsyNo ratings yet

- Electrical Power TransmissionDocument40 pagesElectrical Power TransmissionSonu Lovesforu100% (1)

- GisDocument31 pagesGisMahmoud MoezNo ratings yet

- Abb GCB Chapter 9Document9 pagesAbb GCB Chapter 9RagsNo ratings yet

- An Innovative Design of Indoor Medium Voltage Vacuum: SwitchgearDocument6 pagesAn Innovative Design of Indoor Medium Voltage Vacuum: SwitchgearkhkamalNo ratings yet

- Electrical SwitchgearsDocument63 pagesElectrical Switchgearsmuaz_aminu142292% (12)

- 1HSM 9543 22-12en Series Capacitor By-Pass SwitchDocument8 pages1HSM 9543 22-12en Series Capacitor By-Pass SwitchOscar BräuerNo ratings yet

- Coordination of LV Protection DevicesDocument44 pagesCoordination of LV Protection Deviceslsanchezorjuela100% (1)

- Different Types of Bus Bar ArrangementDocument18 pagesDifferent Types of Bus Bar ArrangementRajeshRaman67% (3)

- 18 11KV VCBs PDFDocument37 pages18 11KV VCBs PDFSharafat AliNo ratings yet

- Eee 7Document1 pageEee 7api-3761679No ratings yet

- Guide To Decoupling of Electrical Equipment On Cathodically Protected StructuresDocument10 pagesGuide To Decoupling of Electrical Equipment On Cathodically Protected StructuresMohamed HassanNo ratings yet

- Metal-Oxide Surge Arrester Protection OF Distribution SystemsDocument24 pagesMetal-Oxide Surge Arrester Protection OF Distribution SystemsSukant Kumar MohantyNo ratings yet

- SHORT CIRCUIT CURRENT LIMITATION TECHNIQUESDocument13 pagesSHORT CIRCUIT CURRENT LIMITATION TECHNIQUESariefNo ratings yet

- Guidelines of Electricity ConstructionDocument26 pagesGuidelines of Electricity ConstructionPhool Mohammad Rayeen100% (1)

- Mid EXAMD DepBSC - Elect Tech - CourseEPDUName Mhammad Suliman Reg SU-18-01-146-029Document6 pagesMid EXAMD DepBSC - Elect Tech - CourseEPDUName Mhammad Suliman Reg SU-18-01-146-029sardar aliNo ratings yet

- Introduction To Power Systems: 1.1: A.C Transmission SystemDocument23 pagesIntroduction To Power Systems: 1.1: A.C Transmission Systemkar1740No ratings yet

- Grounding, Backfeed Breakers & PV Disconnect 2002Document3 pagesGrounding, Backfeed Breakers & PV Disconnect 2002ronniedakingpouNo ratings yet

- Disconnectors Reliability On The French Grid and Means To Reduce The Consequences of Their FailuresDocument7 pagesDisconnectors Reliability On The French Grid and Means To Reduce The Consequences of Their Failureskushwah9kpriyaNo ratings yet

- Comparison Between Ais Compact and Hybrid Switch GearDocument1 pageComparison Between Ais Compact and Hybrid Switch GearMansoor100% (1)

- Protection OverviewDocument6 pagesProtection Overviewwriteonpoint4youNo ratings yet

- Designing of HV Power Substation and Layout - EEPDocument12 pagesDesigning of HV Power Substation and Layout - EEPAshrafReyad100% (1)

- Catalogo CB41Document22 pagesCatalogo CB41MJ100% (1)

- Power Evacuation Main Single Line Diagram Grid Interconnection and Switchyard LayoutDocument24 pagesPower Evacuation Main Single Line Diagram Grid Interconnection and Switchyard Layoutkanav.davesarNo ratings yet

- Raychem Terminations For GIS and TransformerDocument1 pageRaychem Terminations For GIS and Transformerrasheed313No ratings yet

- Advantages of NGLA For Transmission SystemDocument15 pagesAdvantages of NGLA For Transmission SystemipraoNo ratings yet

- Rangkaian Kelistrikan IIDocument31 pagesRangkaian Kelistrikan IIariNo ratings yet

- Design and Installation of EHV - EHV and EHV - HV SubstationsDocument22 pagesDesign and Installation of EHV - EHV and EHV - HV SubstationsBalmNo ratings yet

- Layout and SLDDocument30 pagesLayout and SLDmeraatNo ratings yet

- InTech-Bidirectional DC DC Converters For Energy Storage SystemsDocument19 pagesInTech-Bidirectional DC DC Converters For Energy Storage SystemsSandy RonaldoNo ratings yet

- 2 2C8Document4 pages2 2C8Luis MurilloNo ratings yet

- Schneider - ETC 5-Coordination of LV Protection Devices PDFDocument48 pagesSchneider - ETC 5-Coordination of LV Protection Devices PDFmanfredm6435No ratings yet

- Low Voltage Switchgear or LV SwitchgearDocument20 pagesLow Voltage Switchgear or LV SwitchgearIrfan AhmedNo ratings yet

- CIGRE 2016: 21, Rue D'artois, F-75008 PARISDocument7 pagesCIGRE 2016: 21, Rue D'artois, F-75008 PARISMarko KojicNo ratings yet

- Options For Ground Fault Clearance in HVDC Offshore NetworksDocument8 pagesOptions For Ground Fault Clearance in HVDC Offshore NetworksFelix GamarraNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- Monarch Lite PsDocument2 pagesMonarch Lite PsHung Cuong PhamNo ratings yet

- RET670 Transformer Testing GuideDocument7 pagesRET670 Transformer Testing Guidefrodo frodoNo ratings yet

- Acti 9 iC60N 4A miniature circuit breaker datasheetDocument3 pagesActi 9 iC60N 4A miniature circuit breaker datasheetHung Cuong PhamNo ratings yet

- M6 8ST PDFDocument1 pageM6 8ST PDFHung Cuong PhamNo ratings yet

- Abb Ref615-2Document186 pagesAbb Ref615-2frajaprNo ratings yet

- P132 EN M R-11-B 310 650 Volume 2Document412 pagesP132 EN M R-11-B 310 650 Volume 2Hung Cuong PhamNo ratings yet

- P132 TechnicalDataSheet en 12 BDocument42 pagesP132 TechnicalDataSheet en 12 BAlexandre Moreno100% (1)

- Smart Relay - Zelio Logic SR2 - SR3 - SR2B121FU PDFDocument5 pagesSmart Relay - Zelio Logic SR2 - SR3 - SR2B121FU PDFHung Cuong PhamNo ratings yet

- M6 8ST PDFDocument1 pageM6 8ST PDFHung Cuong PhamNo ratings yet

- M4 6Document1 pageM4 6Hung Cuong PhamNo ratings yet

- Catalog SIPROTEC 5 Protection PDFDocument330 pagesCatalog SIPROTEC 5 Protection PDFcarlosNo ratings yet

- Protect Transformer Assets: Serveron Tm8Document6 pagesProtect Transformer Assets: Serveron Tm8Hung Cuong PhamNo ratings yet

- Cam Switches Electric Diagrams Telergon PDFDocument198 pagesCam Switches Electric Diagrams Telergon PDFHung Cuong PhamNo ratings yet

- Micom P132: Feeder Management and Bay ControlDocument796 pagesMicom P132: Feeder Management and Bay ControlHung Cuong PhamNo ratings yet

- P132 EN M R-11-B 310 650 Volume 1 PDFDocument1,062 pagesP132 EN M R-11-B 310 650 Volume 1 PDFHung Cuong PhamNo ratings yet

- ALSTOM Relay CatalogueDocument20 pagesALSTOM Relay CatalogueINZAMAM MUSHTAQNo ratings yet

- 1SNC169045C0201 Main Catalogue Essailec 2018 enDocument68 pages1SNC169045C0201 Main Catalogue Essailec 2018 enHung Cuong PhamNo ratings yet

- ALSTOM Relay CatalogueDocument8 pagesALSTOM Relay CatalogueHung Cuong PhamNo ratings yet

- P3 - EN - AN - A004 Parallel Redundancy Protocol For Easergy P3Document10 pagesP3 - EN - AN - A004 Parallel Redundancy Protocol For Easergy P3Hung Cuong PhamNo ratings yet

- Micom P54X Series: Current Differential Protection With Optional Subcycle DistanceDocument8 pagesMicom P54X Series: Current Differential Protection With Optional Subcycle DistanceHung Cuong PhamNo ratings yet

- Arteche CT Trfmvi enDocument40 pagesArteche CT Trfmvi enAshutosh SharmaNo ratings yet

- ISKRA MI 456 Measuring Transducer DatasheetDocument5 pagesISKRA MI 456 Measuring Transducer DatasheetHung Cuong PhamNo ratings yet

- Arteche CT MV IndoorDocument12 pagesArteche CT MV IndoorChandra Hamidi KautsarNo ratings yet

- Arteche CT Trfmvi enDocument40 pagesArteche CT Trfmvi enAshutosh SharmaNo ratings yet

- Micom P14X: Feeder Management RelaysDocument8 pagesMicom P14X: Feeder Management RelaysAlejandra E. HernandezNo ratings yet

- 1HSB535256 C Shock Absorber For Blk222 Operating MechanismDocument1 page1HSB535256 C Shock Absorber For Blk222 Operating MechanismHung Cuong Pham100% (1)

- P543 P545 EN MC Lb4 V57Document52 pagesP543 P545 EN MC Lb4 V57Hung Cuong PhamNo ratings yet

- Micom P54X Series: Current Differential Protection With Optional Subcycle DistanceDocument8 pagesMicom P54X Series: Current Differential Protection With Optional Subcycle DistanceHung Cuong PhamNo ratings yet

- 7 Daniel Cáceres - Live Tank Circuit Breakers PDFDocument44 pages7 Daniel Cáceres - Live Tank Circuit Breakers PDFElmer UNINo ratings yet

- Micom P54X Series: Current Differential Protection With Optional Subcycle DistanceDocument8 pagesMicom P54X Series: Current Differential Protection With Optional Subcycle DistanceHung Cuong PhamNo ratings yet

- Series Test BlocksDocument3 pagesSeries Test BlocksCorey PorterNo ratings yet

- Contactoare Si Relee Protectie SIRIUS SiemensDocument148 pagesContactoare Si Relee Protectie SIRIUS Siemensemilakis100% (1)

- National Electrical Code®Document3 pagesNational Electrical Code®icaroNo ratings yet

- IEC Type 1 Type 2 CoordinationDocument8 pagesIEC Type 1 Type 2 CoordinationArun BalasubramaniamNo ratings yet

- SubstationsDocument39 pagesSubstationspNo ratings yet

- 300 MW Variable Speed Drives For Pump-Storage Plant Application GoldisthalDocument24 pages300 MW Variable Speed Drives For Pump-Storage Plant Application GoldisthalMiguel Esteban MartinezNo ratings yet

- Datasheet 15Kw-110KW 3PH - 2021Document1 pageDatasheet 15Kw-110KW 3PH - 2021Eureka SolarNo ratings yet

- Sulphur Recovery Unit Transformer Test ReportDocument11 pagesSulphur Recovery Unit Transformer Test ReportNaveed Bin QasimNo ratings yet

- Service Manual: AmplifierDocument8 pagesService Manual: AmplifierbeytullahNo ratings yet

- BS 7671 Tables 41.2, 41.3, & 41.4Document2 pagesBS 7671 Tables 41.2, 41.3, & 41.4Edward Challoy60% (10)

- ELECTRICAL CONDUIT AND FITTING LAYOUT PLANDocument1 pageELECTRICAL CONDUIT AND FITTING LAYOUT PLANSatya Vamsi DorapalliNo ratings yet

- Relay MvajDocument12 pagesRelay MvajCarlos MontoyaNo ratings yet

- RME PEC EXAMDocument11 pagesRME PEC EXAMglenn100% (1)

- 1SDA068058R1 xt3n 250 TMD 200 2000 3p F FDocument3 pages1SDA068058R1 xt3n 250 TMD 200 2000 3p F FLorena OrtizNo ratings yet

- PTS-20WM319 04 Design CriteriaDocument42 pagesPTS-20WM319 04 Design CriteriaDurgaprasad RyaliNo ratings yet

- 7MBR100SD060: PIM/Built-in Converter With Thyristor and Brake (S Series) 600V / 100A / PIMDocument7 pages7MBR100SD060: PIM/Built-in Converter With Thyristor and Brake (S Series) 600V / 100A / PIMPhong PhongNo ratings yet

- ABB High Voltage Fuses CatalogueDocument64 pagesABB High Voltage Fuses CataloguerocketvtNo ratings yet

- Anthem Generator Installation, Operation, & Service ManualDocument3 pagesAnthem Generator Installation, Operation, & Service ManualSeanNo ratings yet

- LS501 Data Sheet PDFDocument2 pagesLS501 Data Sheet PDFtp_fasilNo ratings yet

- Grid Stds AlkaDocument54 pagesGrid Stds AlkaTshering PeljorNo ratings yet

- Modern Electrical Designand Installationof Equipmentof High Rise Building Using Proposed Busbar Trunkingand Fault Analysis Systemforthe Perspectiveof BangladeshDocument14 pagesModern Electrical Designand Installationof Equipmentof High Rise Building Using Proposed Busbar Trunkingand Fault Analysis Systemforthe Perspectiveof Bangladeshyonas belayNo ratings yet

- S-AAA-SWG-MV-GIS (Rev.0-2015)Document28 pagesS-AAA-SWG-MV-GIS (Rev.0-2015)Muhammad hussainNo ratings yet

- CT Installation and Commissioning TestsDocument7 pagesCT Installation and Commissioning Testsmad_sam282729No ratings yet

- Overcurrent Protection / 7SJ63Document38 pagesOvercurrent Protection / 7SJ63KnjigescribdNo ratings yet

- ICEA-S 96-659 5kVDocument2 pagesICEA-S 96-659 5kVAnamulKabirNo ratings yet

- Load Schdule Boiler Surin 150 TPH Rev.0 14.06.2564Document6 pagesLoad Schdule Boiler Surin 150 TPH Rev.0 14.06.2564Ekanit ChuaykoedNo ratings yet

- Ground Fault Protection Ungrounded Systems To High Resistance Grounding Conversion GuideDocument12 pagesGround Fault Protection Ungrounded Systems To High Resistance Grounding Conversion GuideFelipe Prado100% (1)

- 400kV Protection Panel Schematic DiagramDocument64 pages400kV Protection Panel Schematic Diagrammahesh100% (1)

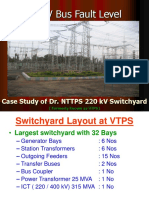

- 220 KV Bus Fault Level: Case Study of Dr. NTTPS 220 KV SwitchyardDocument7 pages220 KV Bus Fault Level: Case Study of Dr. NTTPS 220 KV SwitchyardRukma Goud ShakkariNo ratings yet